Expertise, Customer Driven, Service - in Good Hands with NIEHOFF - Trends in automotive wiring 02/2015

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Expertise, Customer Driven, Service – in Good Hands with NIEHOFF 02/2015

Trends in automotive wiring

Alternative conductor materials require different

manufacturing methods – NIEHOFF offers solutionsNIEHOFF Double Twist

D 632 with double benefit:

High energy efficiency

and intuitive control.

In our latest double twist bunching machine model we the same time! On top of that you profit from a trouble-free

incorporated more than 60 years of NIEHOFF experience. paying-off in the subsequent operation – even at high speed.

Your double benefit: During the development of the D 632 Our solution is the NBAT system – our patented optoelectronic

we focused on energy efficiency and user-friendliness. NIEHOFF Bunching Automatic Traverse System. You get

perfectly filled spools for fast and easy downstream processing.

You can save more energy with the new D 632 since we use

the energy-class IE3 “premium efficiency” energy-saving rotor NIEHOFF combines outstanding expertise along your entire

drive combined with the NIEHOFF ECO-Bow. And our new NMI value chain with customer proximity and reliable service, for

(NIEHOFF Machine Interface) enables a simplified and intuitive the entire lifecycle of your investment. It is just this combina-

handling – machine operation made easy. More benefits: this tion that will make the difference, so you can concentrate on

machine allows stepless adjustment of the winding tension as what is most important to you: Your decisive competitive

well as its control along the entire spool filling. Thus, you can advantage.

meet the highest quality requirements while saving copper at

Expertise, Customer Driven, Service –

in Good Hands with NIEHOFF24-45

Editorial Contents 46

47

Major changes underway 4-9

Trends in automotive

Dear Readers,

wiring and automotive wire

production

Today a couple of NIEHOFF’s key powerful driving forces of the global

personalities join me with great economic condition. You can read

pleasure in welcoming you. The a lot about automotive cables and Springboard your business to greater 10

quotation we chose reflects one our products for this industry in this success – NIEHOFF is the right partner

for you

crucial maxim of how NIEHOFF issue. What we also know is that

NIEHOFF at wire Southeast ASIA 2015

works: companies – NIEHOFF as well as trade fair

others – today have to face up to

”No one can whistle a symphony. visibly increasing dynamics. Cycles Competent partner for the Southeast 11

Asian wire and cable industry

It takes an orchestra to play it.” of innovation are getting shorter NIEHOFF Singapore Pte. Ltd.

Halford E. Luccock and globalization is moving forward

rapidly. Ready to jump 12-13

Many people committed to work- We rise to this challenge. For you, The “new Tiger States“ in Southeast Asia

ing for you stand behind the name our customers we want to meet it, are on the way to an economic power

NIEHOFF. Today I’d like to show you and we have to meet it.

Efficiency and cost reduction 14-15

the faces of the management team ual requirements drive us, and our To accommodate multidimensional South American cable manufacturers

spearheading the NIEHOFF group. products and innovations have one requirements to provide you with face massive challenges

I would like to introduce the people goal: Satisfied customers. benefits – this symphony orches-

who form the operative and strate- To achieve this we continuously trated by the NIEHOFF team is our Your partner in Latin America 16

NIEHOFF at wire South America 2015

gic center, and who control all the examine market developments vocation. We play it with passion, trade fair

activities of the NIEHOFF group, with eagle eyes and simultaneously with expertise and with a keen eye

including its subsidiaries and branch always watch mega trends, which on strategic priorities! NIEHOFF in Latin America =

17

offices worldwide from our head- are important for your business 40 years of excellent service

quarters at Schwabach. future and consequently ours. This Let us take you along – Introduction of NIEHOFF-Herborn

Máquinas Ltda.

Next to me are Executive Man- is why we know that the automo- you are welcome!

ager (CFO) Elena Graf and Execu- tive industry is one of the most Pursuing opportunities that come out 18-19

tive VP / CMO Bernd Lohmueller. in crisis-ridden times

Acome do Brasil, Irati, Paraná/Brazil

Both have enormous know-how

and many years of experience that Manufacturing and braiding of 20-21

contribute essentially to the devel- automotive cables

opment of our company in an envi- Arnd Kulaczewski Elena Graf Bernd Lohmüller Stranding and braiding technology from

ronment with multidimensional (Dipl.-Ing.), President / CEO (Diplom-Betriebswirtin FH, (Dipl.-Ing. FH, Graduate Engineer), NIEHOFF

Graduate in Business Executive Vice President / CMO

requirements, which always focuses Administration, and NIEHOFF in Japan 22

on you: Our customers. Your individ- Diplom-Economist (Moskau), Schwabach, April 2015 Nippon NIEHOFF Co., Ltd.

CFO

News / Events 23

In the future, the NIEHOFF Magazine will be delivered also by email.

We assume that you don’t object to this mode of dispatch. If you don’t wish to

receive the NIEHOFF Magazine by email, please inform us explicitly by phone

(+49 9122 9770), by mail or by email (info@niehoff.de). In case we don’t receive

your refusal, we will act on the assumption that you agree to receive the NIEHOFF

Magazine electronically (by email).Major changes underway

Trends in automotive wiring and automotive wire production

“The automotive market is changing rapidly,” summarizes a study on trends in automotive wiring.

The study provided by CRU was recently published by the International Cablemakers Federation ICF

in the ICF News – Issue 76 (1). According to the study three trends which have a bearing on automotive

wire and harness manufacturers can be noticed: There will be more cars on the road mainly in

the emerging markets, there are tougher goals for weight and efficiency forced by

environmental regulations, and there are more on-board

electronic features. More cables and more functions are leading

to a lack of space in vehicles. As a consequence, cables need to get

smaller, which is leading to miniaturization of the cables, and hence

the need for alternative conductor materials.

Furthermore, price pressure and the necessary cost reductions

are driving new developments (2). In consideration of the

above mentioned study, the present article offers an

overview of the current state of technology,

different conductor materials and different

production methods for these

alternative materials.

4 NIEHOFF Magazine 15/02Reinforced small

Reducing copper to reduce using aluminum wires instead of

wires

e.g. Cu alloys

Remain Cu, but potential for Al Aluminium

wire weight copper wires amounts to several

The power systems in large cars kilograms per vehicle (1). A graphic

0,5 mm² 16 mm² can have up to 3 km of cable and which was presented by Dr. Klaus

4.000

weight (g)

Number of cables cable systems that weigh up to Probst, Leoni AG, at the CabWire

3.500 538 1

3.000

324 114 60 kg. In order to reduce weight, Conference 2011, gives an over-

2.500 there is a shift away from all-copper view of number and weight of the

2.000 conductors towards the develop- wires in relation to the cross section

1.500

75

ment of aluminum cables as well in a typical harness for car (3). The

75 36

1.000 1 as aluminum alloys, copper alloys, signal wires with 0.35 mm² and 0.5

500

18 2

and composite materials alterna- mm² are contributing 3.8 and 3.5

2

0

8 1 tives. Work on alternative conduc- kg respectively to the total harness

0.35 0.50 0.75 1.00 1.50 2.50 4 6 10 16 25 35 80

tors goes back at least 45 years. weight (Fig. 1). There is only one

Stand 2011 Cross section (mm²)

From 1969 to 1985, e.g., the auto- or a maximum of two wires with a

Fig. 1. Number and weigth of the conductors in relation to the cross section in a typical harness motive wire manufacturer Delphi large cross section of 16 to 80 mm².

for car shipped 35,000 km of battery cable In the year 2011 the substitution

with copper clad aluminum con- of 0.35 mm² and 0.5 mm² signal

ductors, and from 1974 to 1989, wires with wires made from copper

Reinforced

small wires Remain Cu, but Aluminum wire the company shipped 900,000 km alloys was already ongoing, while

e.g. Cu alloys potential for Al

of solid-core aluminum battery the larger cross sections of 16 mm²

0,5 mm² 2,5 mm² cable. Currently, aluminum battery to 80 mm² is being substituted with

4.000 cables are in use by several carmak- aluminum. The middle segment

3.500 ers throughout the world. In 2010, from 0.75 mm² to 10 mm² will con-

3.000

Toyota began using stranded alu- tinue to be copper conductors.

weight (g)

2.500

minum conductors in the door har- At the Advanced Automotive

2.000

1.500

nesses of some its vehicles models. Cabling Conference 2014 a similar

1.000 Depending on the vehicle manu- graphic was presented by Volker

500 facturer, the aluminum cables used Seipel, Tyco Electronics (Fig. 2).

0 have cross sections as small as to The change, which can be seen, is

0,35 0,5 0,75 1 1,5 2,5 4 6 10 16 25 35 50

2.5 mm² and in some cases they that since 2011 automotive (cop-

Stand 2014 Cross section (mm²) are even used for signal cables. per) wires with bigger cross sections

The weight reduction achieved by and as small as 2.5 mm² were being

Fig. 2. Weight of harnesses of a mid size car

NIEHOFF Magazine 15/02 5replaced by aluminum. The rea- ing process. Another disadvantage Manufacturing aluminum The production process progresses

son for this change is that in recent of aluminum is cold creeping under conductors as follows:

years, harness makers and connec- the influence of pressure. This phe- A typical aluminum wire strand • Rod breakdown drawing

tor companies have developed new nomenon is also very negative for construction for a battery cable for without annealing 9.52 mm

crimping methods for aluminum crimping as it causes losening of the German mid-size cars to the LV112 to 2.5 mm diameter;

strands for cross sections as small crimp connection and results in an specification (dated Nov. 2012) is • Multiwire drawing with inline

as 2.5 mm². One area of innovation electrical connection failure. Finally, shown in Fig. 3. The cable consists annealing 2.5 mm to 0.52 mm;

has been new shapes, contours, there is the risk of electro galvanic of 280 individual wires with 0.52 • Pre-stranding of 7 conductors,

and surface finishes in the crimp contact corrosion when aluminum mm diameter each (280 x 0.52 mm each 40 times 0.52 mm

hardware. Other developments comes into contact with other met- corresponding to 60 mm², com- (40 x 0.52 mm);

include sealants and other surface als such as copper or copper alloys. pared to 35 mm² Cu). • Main stranding 7 x (40 x 0.52 mm).

treatments in addition to work on

different aluminum alloys.

Disadvantages of aluminum in

comparison to copper

Aluminum is characterized by a

lower specific weight, lower prices,

and less price volatility than copper.

Due to the lower specific weight,

40% weight reduction can be

achieved. However, aluminum has

also a lower electrical conductiv-

ity – therefore aluminum conduc-

tors must be 30% bigger in diam-

eter than copper wires for the same

power transmission capacity. The

lower tensile strength of aluminum

(100 MPa for Al vs. 250 MPa for

Cu) is limiting the minimum cross

sections. It is important to note

that when aluminum, as soon as it

is exposed to oxygen (air), quickly

develops a hard layer of non-con-

ductive aluminum oxide. The alu-

minum oxide layer causes contact

problems during manufacturing in

the annealer and also in the crimp- Fig. 4. MMH 104 + RMA 201 type multiwire drawing line for the production of wires made from aluminum and aluminum alloys

6 NIEHOFF Magazine 15/02NIEHOFF played a guiding role in aluminum and aluminum alloys, The drawing machine is equipped tective gas. Annealing is achieved by

the development of rod breakdown NIEHOFF already built several MMH with special die holders and built-in the two-zone annealing principle. To

and multiwire drawing technologies 104 and RMA 201 type multiwire drawing die sprayers tailor-made for reduce slip and avoid wire damage

as well as bunching and stranding drawing lines, which are in opera- the specific requirements of alumi- and wear of the contact tubes, each

technologies. In close cooperation tion around the world (Fig. 4). The num wire drawing. The MMH 104 is contact pulley is driven by its own

with wire manufacturers, NIEHOFF MMH 104 + RMA 201 drawing line operated using emulsion as drawing AC motor. With the RMA 201 type

has developed proven solutions for is capable of drawing up to sixteen lubricant. continuous resistance annealer an

wires made from copper, copper aluminum or aluminum alloy wires The MMH 104 is plugged with an elongation of 30% can be reached

alloys, aluminum, aluminum alloys simultaneously to finish diameters RMA 201 type continuous resistance and a tensile strength below 80

and other non-ferrous metals. For of 0.20 – 0.71 mm (Al 99.7) at a annealer with individually driven N/mm² (80 MPa) for Al 99.7 (Fig.

the production of wires made from maximum line speed of 36 m/s. contact pulleys working under pro- 5). With inline annealing a very

fine and uniform grain size can be

reached. After cooling, wires leave

the annealer with a lubrication layer.

Because of the residual lubrication

the wires can be processed at high

speeds in the downstream pro-

cesses: Bunching and extrusion.

The pre-stranding of the alumi-

num wires can be accomplished in

a line which consists of three single

ARH 800 type pay-offs for 800 mm

flange diameter spools (two with

16 wires and one with 8 wires) plus

a D 801 type double twist bunch-

ing machine (Fig. 6). The bunch-

ing machine has to be specially

adapted for the manufacturing of

aluminum wires with roller bow

and special surface material for

guide pulleys.

The main-stranding of the finished

battery strand can be carried out in

a line which consists of seven single

ARH 800 pay-offs and one D 1001

or D 1251 double twist bunching

Fig. 3. Aluminum wire strand construction for a battery cable machine.

NIEHOFF Magazine 15/02 7The winding tension is infinitely at a production speed of 4,500 tpm.

adjustable and is regulated from The lay length is 30 mm. The wires

empty to full spool within close tol- were inline annealed and had an

erances of ± 1%. inlet tensile strength of 110 MPa.

A special feature is also the pat-

ented opto-electronic NBAT sys- Manufacturing conductors made

tem (NIEHOFF Bunching Automatic from copper alloys

Traverse), which allows spools to Future signal cables will be made

be perfectly spooled. Spooled wire out of copper alloys for weight and

can then be payed-off tangle-free space savings. Copper signal cables

at extremely high speeds with no with the cross sections 0.35 mm²

damage. The micro-section (Fig. 7) and 0.50 mm² used up to now will

shows the cross section of a typical be replaced by signal cables made

aluminum alloy strand with 19 wires of copper alloys (e.g. CuMG0.2)

made from AlFeMg (19 x 0.365 mm, with cross sections of 0.13 mm²

without compaction) manufactured (Fig. 1 and 2). Criteria for the selec-

Al 99,7 diameter 0,52 mm

35 160

30 140

25 120

Rm / Rp (N/mm²)

100

20

80

15

60

10 40

A (%)

5 20

0 0

5 6 7 8 9 10 11

factor

Rp 0,2 (N/mm²) Rm (N/mm²) Rp 0,2 (N/mm²)

Fig. 5 Physical properties of Al 99.7 wire drawn on an MMH 104 + RMA 201 line

Fig. 6. Aluminium wire double twist bunching (pre-stranding)

on a ARH 800 + D 801 bunching line

8 NIEHOFF Magazine 15/02tion of copper alloys are a good ger than the surrounding wires. It ing) and with NIEHOFF “Stretch Outlook

relation between electrical con- is obvious that this effect must be Forming and Straightening” technol- To keep up with today’s manufac-

ductivity and tensile strength and eliminated. Moreover, the bunched ogy. The NIEHOFF solution results in turing standards and the above

a good drawability to fine wires. strand must beas straight as possible three advantages: There is no con- mentioned trends, automotive wire

Using copper alloy wires weight with no remaining internal stress. tortion of single wires and thus the manufacturing equipment needs

reduction to 40% and cross section NIEHOFF has developed an inno- outer diameter is smaller and there- to be innovative, efficient, reliable

reduction to 65% compared to pure vative solution which meets these fore also the circumference which and flexible to withstand cost and

copper wires are possible. Such requirements. Fig. 8 shows strands must be insulated, and the Crown- price pressures and fulfill the high

wires can be drawn on MMH type compacted with conventional tech- ing effect is avoided. technical and environmental stan-

multiwire drawing lines. nology (compacting before bunch- dards. Important at the same time is

the service that the manufacturers

When bunching wires of copper of such facilities offer their custom-

alloys such as CuMg0.2, the crown- ers. Along with reliable customer

ing effect must be considered: This NIEHOFF is the strong partner service and a dependable supply of

means that e.g. in a 6+1 strand spare parts and wear parts, it is also

after cutting the central wire is lon- for the wire and cable industry. essential to provide expert technical

consulting which includes the com-

munication of know-how and train-

ing courses for process engineers

and machine operators.

(1) Trends in automotive wiring. ICF News

– Issue 76, April 2015.

http://www.icf.at/news/icf-newsletter/

trends-in-automotive-wiring/

(2) Light, high-performance and complex.

Trends in wires for automobiles NIEHOFF

Magazine 1/2013, 6-9

(3) Klaus Probst: Trends and developments in

Fig. 7. Cross section of a strand with 19 wires Fig. 8 Comparison of strands compacted with conventional technology (compacting before automotive wires. Wire Journal

made from AlFeMg (19 x 0.365 mm, not bunching) and with NIEHOFF “stretch forming and straightening” technology. International, August 2012, pp 68 – 71

compacted) made with NIEHOFF technology

NIEHOFF Magazine 15/02 9Springboard your business to greater success

– NIEHOFF is the right partner for you*

NIEHOFF at the wire Southeast ASIA 2015 trade fair

Bangkok, Thailand, 16–18 September 2015, booth H 33

At the wire Southeast ASIA 2015 trade fair, Maschinenfabrik NIEHOFF Energy efficiency and ers anneal the wire homogeneously

and its subsidiary NIEHOFF Singapore Pte. Ltd. are showing an MSM 85 high quality wire from zero to full speed operation.

rod breakdown machine (booth H 33). The drive principle enables a mini-

mized slip operation resulting in Easy and efficient operation

high wire quality, low wear, a long Like all other new machines built by

service life of the drawing tools and NIEHOFF, the MSM 85 is operated

maximum energy savings. You can by the newly designed and stan-

achieve energy savings of more than dardized NMI (NIEHOFF Machine

20% with MSM machines in com- Interface), a network-compatible

parison with conventional rod break- color touchscreen which features a

down machines. The adjustable clear task and user-oriented naviga-

drives allow working with different tion structure and enables an easy

wire elongations for each draft. This intuitive operation.

The MSM rod breakdown Successful since its launch capability is especially useful when

technology The MSM rod breakdown technol- processing different materials. Partner companies at the

The electronically controlled MSM ogy developed by NIEHOFF has Additional features include an opti- NIEHOFF booth

machines, such as the MSM 85 been successfully operating in the mized wire path, innovative pressure At the NIEHOFF booth will also be

on display, are designed to pro- international wire industry since die holders and the reliable fully present with their products and

duce wires made of copper, copper its market launch in 1998. Since submerged drawing process – all services the cold rolling mill manu-

alloys, aluminum, aluminum alloys, then the MSM machines have seen of them contribute to the high wire facturer Bühler Würz Kaltwalztech-

and other non-ferrous materials. continuous development. They are surface quality. nik and the lead extruder and cable

The MSM 85 is capable of drawing equipped with the latest controls You can combine the MSM repair and recovery system manu-

copper wires with a maximum inlet and drive technology offering you machines with the newly devel- facturer HFSAB.

diameter of 10 mm (or 12.5 mm a vast range of benefits in terms of oped R 502 continuous resistance * In keeping with the slogan for the wire Southeast

aluminum wires) to a minimum final process technology. annealer is designed for an anneal- ASIA 2015 trade fair, “Springboard your business

to greater success”, NIEHOFF helps cable and wire

diameter of 1.0 mm. The maximum ing power of 600 kW. You benefit manufacturers in Southeast Asia to strengthen and

line speed is 40 m/s. from the fact that NIEHOFF anneal- further enhance their competitiveness.

10 NIEHOFF Magazine 15/02Competent partner for the

Southeast Asian wire and cable industry

NIEHOFF Singapore Pte. Ltd.

Maschinenfabrik NIEHOFF can look back Experienced team facturers. And to build production Asia have to work reliably in climate

on 20 years of experience with custom- NIEHOFF’s Singapore team is lines specially designed to meet conditions which are widely varying.

ers in Southeast Asia and their techno- headed by Beng Kok Kee who has your individual requirements and We at NIEHOFF therefore regularly

logical requirements. Today our sub- been in charge of the business since specifications. In case of any tech- face technical challenges. Our solu-

sidiary NIEHOFF S ingapore Pte. Ltd. 2007. He is a mechanical engineer- nical problems, NIEHOFF custom- tions provide benefit to all NIEHOFF

– is the direct and important contact ing graduate with a master’s degree ers are of course provided with fast customers, and this is how we have

present for all NIEHOFF customers in in business administration (MBA) online solutions. If exisiting NIEHOFF gained our reputation to be a tech-

Southeast Asian countries. and had many years of experience in machines are to be modernized – nology specialist.

the cable and wire industry before you can rely on our support. The NIEHOFF Singapore team also

joining the NIEHOFF Group. In collaboration with our head office have to deal with cultural chal-

Supported by service engineer in Germany and other business- lenges, since the countries they

Leszek Szczepanowski since 1999 related partners, the NIEHOFF look after differ in the extent of

and his assistant Jennifer Fong, he Singapore team arranges also tech- industrialization, in tradition and in

is familiar with all NIEHOFF machin- nical seminars for the cable and wire culture. NIEHOFF has established a

ery and has extensive experience in industry in various Southeast Asian lot of good partnerships with cable

NIEHOFF process technology. countries. All attendants get impor- and wire manufacturers in South-

tant information on market trends, east Asia as a whole. We think this

Process knowledge, service and technological tendencies and future- is a proof that we are able to meet

seminars oriented production solutions . a wide range of different require-

Our Singapore team coordinates ments for you – our customers.

on-site support for customers when Challenges

machines and accessories are sup- Southeast Asia is a very important

plied directly from NIEHOFF in Ger- region for NIEHOFF and its custom- NIEHOFF Singapore Pte. Ltd.

many. Moreover, they train machine ers worldwide in terms of technol- 175A Bencoolen Street

operators on-site and provide the ogy. Why? Because the demands #05-12 Burlingtion Square

Singapore 189650

after-sales service. Wire drawing on machines for the cable and wire

Phone +65 6336 9936

knowledge acquired over decades production are extremely high since Fax +65 6336 4070

enables us to offer competent the products made by cable and E-mail: niehoff@niehoff.com.sg

advice to wire and cable manu- wire manufacturers in Southeast

NIEHOFF Magazine 15/02 11Ready to jump

The “new Tiger States“ in Southeast Asia are on the way to an economic power

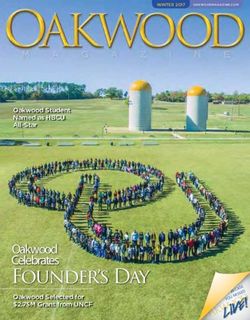

The ten member countries* of the Association of Southeast Asian Nations several raw materials. The region for the ASEAN customs-free trade

(ASEAN) with a total population of approximately 625 million inhabitants benefits also from the oil price zone. Until 2017, the Indonesian car

and a common Gross National Product (GDP) of more than 2,300 billion USD decline and consequently the more production should increase by 70 %

form the third largest economic area in Asia behind the PR of China and India favourable energy costs. Extensive to 2.2 million units, reports the for-

(Fig. 1). If considered as one country, this community of states would be the construction projects in connection eign trade agency Germany Trade &

world’s seventh largest economy with a an economic growth of 5.7 % in the with the generation and supply of Invest (gtai) [4].

year 2014. If the neighbour states are added with which the ASEAN com- energy, transport infrastructure and

munity maintains free trade agreements, Southeast Asia will be an economic industrial plants are planned or are Malaysia received the second-best

area with 3.2 billion inhabitants [1]. already realized [3]. Since wires and ranking in Southeast Asia behind

cables are required in all industrial Singapore in the US economic free-

For experts, the ASEAN region with Raw materials areas, cable manufacturers expect dom index which considers corrup-

an expected growth rate of 5 % and industrialisation also in future extensive orders. tion, regulation and trade barriers,

to 6 % on average per annum will The “Neue Zürcher Zeitung“ (NZZ) reported the German “Rheinische

be one of the world’s most quickly newspaper published in February A look at the Post“ newspaper in January 2015 [5].

sprouting economic regions. With 2015 an analysis of “ASEAN as an individual countries Myanmar is in the view of the US

a view to the economic momen- economic area“ [2]. The author of Indonesia, with about 250 mil- Chamber of Commerce one of the

tum of the ASEAN countries, there this contribution pointed out that lion inhabitants the largest national four most attractive countries in

is already talk of the “new Tiger the ASEAN states benefit from their economy in Southeast Asia, has Southeast Asia for new business,

States“. The original term came up proximity to China. In the course of abundant resources of raw materials behind Indonesia, Thailand and Viet-

in the 1980s and was related to the the year 2015, however, it should such as petroleum, bauxite, copper nam [5]. The Asian Development

economically fast-growing countries become more and more apparent ores, wood and palm oil. Instead of Bank (ADB) considers the favourable

South Korea, Taiwan and Singapore that China’s economic growth is only exporting raw materials, how- geographic position of the country

and the Chinese special administra- decelerating. Since labor costs have ever, the country wants to change between China and India, the young

tive zone of Hong Kong. A reason strongly increased in China, the into a production site. The sales of population and mineral resources as

for the dynamic development of second-largest national economy motor vehicles declined slightly in some of the country’s strengths [3].

the different ASEAN states could be of the world, labor-intensive manu- 2014 and should stagnate in 2015. Regarding the Philippines, the ADB

that these countries form a very het- facturing processes are increasingly Nevertheless, Japanese car manu- expects an economic growth of

erogeneous group regarding pros- relocated to the ASEAN states. The facturers are investing into the pro- 6,4 % for the year 2015 [5]. A fast

perity, politics, culture and economic Southeast Asian states are the glob- duction in the country and develop extension of the energy-sector is

structure (Fig. 1). ally most important suppliers for the archipelago into an export hub prerequisite for this since the power

12 NIEHOFF Magazine 15/02supply doesn’t keep up with the the criteria for investments in the be boosted, whereby solar and wind

economic-development. country are a cost-effective produc- energy will gain in importance [9].

[1] Lanza, G. (Hrsg.), Peters, S., Weis, T.: Stand der

Numerous power plants projects of tion site, a well-functioning infra- Automobilwirtschaft in der ASEAN-Region –

domestic and foreign investors are structure, an extensive supplier net- Vietnam should become the third 2015. Institute of Production Science (wbk),

Karlsruhe Institute of Technology (KIT), Global

in the planning phase. This entails work and a liberal economic system. EU partner for a free trade agree- Advanced Manufacturing Institute (GAMI) - Lea-

large import requirements [6]. The The Thai government considers the ment in 2015 following Singapore ding Edge Cluster Electric Mobility South-

West(https://www.wbk.kit.edu/downloads/

sale of motor vehicles should grow massive expansion of infrastructure and Malaysia. Vietnam as a factory ASEAN_Studie_2015.pdf)

in 2015 at doubledigit rates. The as one of the state cornerstones to location has profited from the wage [2] Werner Grundlehner: Wenn der Tiger erwacht.

professional associations are expect- stimulate economic growth. For the growth in China [5]. Among the Asean als Wirtschaftsraum. Neue Zürcher

Zeitung, Februar 2015 (http://www.nzz.ch/

ing the sale of 310,000 units in the development of transport infra- many major infrastructure projects finanzen/aktien/wenn-der-tiger-er-

current year. structure until 2022 investments of there is the construction of subway wacht-1.18478727)

[3] Ideal timing for wire & Tube Southeast Asia 2015

The local production mainly based approximately 50 billion Euros are and express bus systems in Hanoi staging. Messe Düsseldorf North America

on assembly plants of Japanese planned. The focus is on intercity and Ho Chi Minh City. (mdna), Mai 2015 (http://www.mdna.com/

wireseap2)

brands is considerably growing. A train connections and the urban [4] Roland Rohde: Branche kompakt - Kfz-Industrie

new government program should transport system in the greater und Kfz-Teile - Indonesien, gtai, Juni 2015.

encourage to investments [7]. Bangkok area. Two long-distance * The ASEAN economic comunitiy regroups (http://www.gtai.de/GTAI/Navigation/DE/Trade/

the following countries: Brunei Darussalam, Maerkte/Branchen/Branche-kompakt/

railway connections from Bangkok Indonesia, Cambodia, Laos, Malaysia, branche-kompakt-kfz-industrie-und-kfz-

Thailand is the world’s ninth-larg- to Japan and China are in prepara- Myanmar, Philippines, Singapore, Thailand

teile,t=branche-kompakt--kfzindustrie-und-

kfzteile--indonesien-2015,did=1254702.html)

est automobile producer. Among tion [8]. Also the energy supply will and Vietnam. [5] Südostasien bekommt sechs neue Tigerstaaten.

Die Staatengemeinschaft Asean schafft einen

gemeinsamen Markt. Es deuten sich Milliarden-

geschäfte an. Rheinische Post, Januar 2015.

(http://www.rp-online.de/wirtschaft/

Country Population GDP Export Import suedostasien-bekommt-sechs-neue-tigerstaa-

(m) (bn $) (bn $) (bn $) ten-aid-1.4778049)

Brunei 0,4 16,1 11,4 3,6 [6] Jürgen Maurer: Philippinen streben ausgegliche-

nen Energiemix an, gtai, August 2015.

Indonesia 248,8 860,8 182,6 186,6 (http://www.gtai.de/GTAI/Navigation/DE/Trade/

Cambodia 15,0 15,5 9,1 9,2 Maerkte/suche,t=philippinen-streben-ausgegli-

Laos 6,6 10,3 2,6 3,3 chenen-energiemix-an,did=1293394.html)

[7] Jürgen Maurer: Automobilmarkt der Philippinen

Malaysia 29,9 312,1 228,3 205,9 bleibt im Expansionsmodus, gtai, August 2015

Myanmar 61,6 54,7 11,4 12,0 (http://www.gtai.de/GTAI/Navigation/DE/Trade/

Phillipines 99,4 269,0 54,0 65,1 Maerkte/suche,t=automobilmarkt-der-philippi-

nen-bleibt-im-expansionsmodus,did=1291560.

Singapore 5,4 297,9 410,2 373,0 html)

Thailand 68,3 387,6 228,7 249,5 [8] Waldemar Duscha: Thailand baut seine

Vietnam 89,7 171,2 132,7 132,1 Verkehrsinfrastruktur aus, gtai, Juni 2015.

(http://www.gtai.de/GTAI/Navigation/DE/Trade/

Source: ASEAN Secretariat Maerkte/suche,t=thailand-baut-seine-verkehrs-

infrastruktur-aus,did=1263800.html)

[9] Waldemar Duscha: Thailand legt neuen

Energieplan auf, gtai, Juni 2015.

http://www.gtai.de/GTAI/Navigation/DE/Trade/

Fig 1. Important economic data of the ASEAN states (as at 2013)

Maerkte/suche,t=thailand-legt-neuen-energie-

plan-auf,did=1263798.html

NIEHOFF Magazine 15/02 13Efficiency and cost reduction

South American cable manufacturers face massive challenges

The economic situation of South America is marked by Brazil, the largest Brazilian economic-newspaper DCI dency of the Brazilian Real [4]. It is

national economy of the subcontinent (Fig. 1) and the seventh-largest world- Diário Comércio Indústria & Ser- expected that the Olympic Games,

wirde. The country with more than 200 million inhabitants had been con- viços published in February 2015 which will take place in the coun-

sidered for many years as a coming economic power. Since the year 2012, a contribution, in which the man- try next year, will help to boost the

however, the growth has weakened considerably, in the first half of 2015 agers of the cable manufacturers economy by infrastructure projects

the country even dropped into recession. In this period of time, the industrial Furukawa América Latina, Prysmian which are related to this event.

output plunged by about 6.3 % told the Brazilian institute for statistics at the América do Sul and Nexans do Brasil

beginning of August. This is the sharpest decline since 2009. The electron- described the situation of the indus- Infrastructure projects

ics sector (-27.8 %) and the car manufacturing (-20.7 %) were particularly try and its outlooks for this year [3]. At present in the metropolis of

affected. The article finishes with the state- São Paulo for example construc-

ment of Marcello Del Brenna, Prys- tion works are under way on several

Automotive sector was about 18.5 % below the previ- mian América do Sul: “This will be monorail and underground railway

The weaker momentum of the ous year´s level, the number of new a year with special attention to effi- lines, and both airports should be

whole economy puts down the registrations decreased by about ciency and cost reduction” [3a]. accessible by rail in future. Heav-

motor vehicle markets in virtually all 20.7 %. For this year, Anfavea, the ily used routes to and from work

of Latin America. In 2015, accord- Brazilian sector association, assumes Consumers are reluctant to the eastern and western neigh-

ing to forecasts the sales of cars are that the production will gener- The weak economic situation, ris- bouring towns will be enlarged by

expected to decrease by approxi- ally drop by about 17.8 % and the ing inflation and high interest rates, express bus corridors. Rio de Janeiro

mately 5.2 %. Mainly Brazilians and sales by 20.6 % [1]. The association the threat of unemployment and is building the underground line 4

Argentinians demand less vehi- expects for the Brazilian automotive not least uncertainty about gov- to the Olympic village, the bus cor-

cles. On the other hand, Mexico is sector, one of the most important ernment austerity measures forces ridors Transbrasil and Transolym-

going to establish itself increasingly customers of the Brazilian wire and down the consumers’ propensity to pica as well as a network of street-

strongly as one of the worldwide cable industry, a new upturn only in buy. Growth impulses, according to cars in the center. Additionally, the

leading car manufacturing nations. the year 2016 at the soonest. Since a report of the foreign trade agency mega-city wants to better integrate

In the year 2014, there were manu- cables and wires are needed not Germany Trade & Invest (gtai), its suburbs into the public transport

factured more vehicles than in only there but in all industrial areas, should be pushed by investments system. Also some other metro

Brazil, the largest vehicle market in the cable industry is fully affected which, however, are postponed for polises are planning underground

Latin America. In the first six months by the economic decline [2], but the moment, or by the export which railways, streetcars and bus corri-

of 2015, the Brazilian car production had expected this development. The is promoted by the devaluation ten- dors.

14 NIEHOFF Magazine 15/02Power transmission Forecast & Opportunities, 2019” Alternative energy sources tion technologies the wire and

The most important source for elec- in Mays 2014 [5]. According to the Approximately 65 % of the electric- cable industry has also the possi-

tric power generation in Brazil as in study, the ANEEL national agency ity generated in Latin America (more bility to take an active part in the

all Latin America is hydropower. The for electric energy is planning to than 725 TWh) comes from large strenghtening of the whole

Brazilian government is confronted install overhead power transmission hydropower plants [6]. The depen- economy.

with the enormous task to connect lines with a total length of more dence on hydraulic power, however,

the renewable energy sources, for than 15,000 km in some regions in should be reduced because, inter

example the utilization of hydro- the north, northeast and in the mid- alia, water is becoming an ever- [1] Florian Steinmeyer: Kfz-Branche in

power in the Amazon region, to dle west until 2017. In order to con- scarcer resource in most countries Lateinamerika mit Licht und Schatten,

gtai, August 2015. (http://www.gtai.de/

those regions where there is a lack nect the energy sources with those and the risk of blackouts is increas- GTAI/Navigation/DE/Trade/Maerkte/

of electricity. To achieve these aims areas having a lack of electricity, ing because of varying precipitation suche,t=kfzbranche-in-lateinamerika-

mit-licht-und-schatten,did=1294306.

big quantities of transmission lines an estimated 25,000 km of further quantities. Up to now, only 6 % of html)

are necessary, among other things. lines should be installed. The report, the electricity consumption is cov- [2] CRU market survey: Wire & Cable Market

Outlook. January 2015. (http://

The management consulting com- however, also reveals that already in ered by other renewable energy wireandcablenews.crugroup.com/

pany TechSci Research has analyzed 2013 several projects were behind in sources. Solar energy plants are wireandcablenews)

the potential of the Brazilian market schedule due to not answered legal coming into vogue in Latin America [3] Estagnação econômica impede setor de

fios e cabos de crescer em 2015 DCI

for this and published the results in questions concerning environmental and are regarded very promising - (03/02/2015). (https://www.costdrivers.

the market survey“ Brazil Overhead matters and the acquisition of land, as a growth market. Furthermore, com/costdrivers/en/news/2015/2/

estagnacao-economica-impede-setor-

Power Transmission Cables Market and due to bureaucratic barriers. Brazil is among the four countries de-fios-e-cabos-de-crescer-

with the highest number of new em-2015-169338/)

[3a] “Este será um ano de foco em eficiência

wind parks worldwide. The produc- e redução de custos.”

Brazil is by far the largest consumer & producer in South America tion capacity in the country doubled [4] Oliver Döhne: Wirtschaftstrends

alone in 2014 on 4,888 MW, and Jahresmitte 2015 – Brasilien, gtai, May

$ million $ million 2015. (https://www.gtai.de/GTAI/

3500 3500 until the end of 2015, further wind Navigation/DE/Trade/Maerkte/

2014 Production 2014 Consumption parks are foreseen with a perfor- Wirtschaftsklima/wirtschaftstrends,t=wir

3000 3000 tschaftstrends-jahresmitte-

2500 2500 mance of altogether 3,267 MW. 2015--brasilien,did=1262032.html)

[5] Brazil Overhead Power Transmission

2000 2000 Cables Market Forecast & Opportunities,

1500 1500 Innovations 2019. May 2014. (http://www.

1000 1000

A way of increasing again Brazil’s techsciresearch.com/2791)

[6] Anne Litzbarski: Lateinamerika nutzt

500 500

competitiveness is via innovations. erneuerbare Energien noch wenig, gtai,

0 0

Up to now, the country has spent July 2015. (http://www.gtai.de/GTAI/

only a little bit more than 1 % of its Navigation/DE/Trade/Maerkte/

A r g ra z i l

Co tina

b ia

ne le

la

Ec u u

Ot r

rs

A r g ra z i l

Co tina

b ia

ne le

la

Ec u u

Ot r

rs

o

o

Per

Per

suche,t=lateinamerika-nutzt-erneuerba-

i

zu e

i

zu e

he

he

ad

ad

Ch

Ch

GDP for research & development,

lom

lom

en

en

B

B

re-energien-noch-wenig,did=1288630.

Ve

Ve

whereby the major part derives from html)

[7] Innovation als Ausweg aus Brasiliens

the public sector [7]. The Embrapii Wirtschaftsflaute, gtai, August 2015.

Fig. 1. The economic situation of South America is strongly determinded by Brazil, research centers and the Institutos (http://www.gtai.de/GTAI/Navigation/

the largest national economy of the subcontinent DE/Trade/Maerkte/suche,t=innovation-

Senai de Inovaçao could play a key als-ausweg-aus-brasiliens-

(Source: CRU market survey: Wire & Cable Market Outlook. January 2015) role. With modern, efficient produc- wirtschaftsflaute,did=1294310.html)

NIEHOFF Magazine 15/02 15Your partner in Latin America number of twists is 6,500 twists/

min, the maximum production

speed 300 m/min. A special fea-

NIEHOFF at the wire South America 2015 trade fair ture is the patented opto-electronic

NBAT system (NIEHOFF Bunch-

São Paulo, Brazil, 6 – 8 October 2015, booth 612 / 713 ing Automatic Traverse), which

allows spools to be perfectly filled.

Spooled wire can then be payed-

At the wire South America 2015 trade fair, Maschinenfabrik NIEHOFF and its along their entire length and exceed off tangle-free even at extremely

subsidiary NIEHOFF-Herborn Máquinas Ltda. (NHM) are showing an MMH 121 even highest processing require- high speeds with no damage. The

type multiwire drawing machine, an RM 201 type continuous annealer, an ments. We can adapt our multiwire service proven energy-saving single

SNH 801 type spooler and a D 631 type double-twist bunching machine with drawing lines flexibly to your specific bow (ECO-Bow) design scores with

ARP 630 pay-off (booth 612 / 713). All machines have been built by NHM under needs exactly meeting your require- lower energy costs, the contactless

NIEHOFF licence. ments. Customers all over the world transmission of machine data within

are using more than 1,100 MMH the machine saves spare parts and

lines – convinced by the MMH-ben- allows less maintenance. Our new

efits offered by NIEHOFF. NMI touch-screen display (NIEHOFF

Machine Interface) enables a simpli-

The SNH 801 type dynamic single fied and intuitive machine handling.

spooler is designed for wires with The ARP 630 type pay-off com-

an individual wire diameter of 0.15 pletes the NIEHOFF portfolio for the

… 4.50 mm (½ … 5 AWG) or multi- production of strands. You benefit

wire bundles with a cross section from fast and easy spool loading

of 0.018 mm² (34½ AWG) … 5.50 by clamping the spool with pintles,

mm² (10 AWG). The spooler can and you can use spools with various

accomodate spools with a maxi- bore diameters.

MMH 121 type multiwire drawing machine mum flange diameter of 800 mm.

More advantages of the SNH 801 NIEHOFF partner companies

The exhibits type drawing lines are copper wires are it’s long service-life and the easy at the booth

The multiwire drawing machine for highly flexible cables, automo- and comfortable spool loading and At the NIEHOFF booth, a complete

MMH 121 is designed to draw tive cables, battery cables and instal- unloading it allows. island booth, will be present:

simultaneously 28 wires with a final lation cables. But the machines are Bühler Würz Kaltwalztechnik (cold

diameter of 0.51 ... 0.20 mm (24 ... also suitable for aluminum wires, The D 631 type double-twist bunch- rolling mills), Strecker (wire welding

32 AWG) at a maximum production wires made from copper and alumi- ing machine is foreseen to produce machines), HFSAB (lead extruders

speed of 36 m/s (7086 fpm). The num alloys and from other non-fer- strands with 0.09 to 6.00 mm² and cable repair and recovery sys-

wires can be processed to inter- rous metals. (27 ½ ... 9 ½ AWG) cross section tems) and Reber Systematik (filtra-

mediate multiwire bundles. Typical All wires drawn on those lines show and a steplessly variable lay length tion systems).

wires you can produce on the MMH homogeneous physical properties of 6 to 100 mm. The maximum

16 NIEHOFF Magazine 15/02NIEHOFF in Latin America =

40 years of excellent service

Founding NIEHOFF-Herborn Máquinas Ltda. (NHM) in 1975 was the beginning of Maschinenfabrik NIEHOFF’s

international expansion. NHM is based in B

arueri, about 30 km west of São Paulo.

Production program Service

The factory with modern equip- NHM is responsible for customer

ment is used to build wire pro- services and has assumed repre-

cessing machinery such as draw- sentation of numerous renowned

ing machines, annealers, spoolers European suppliers for the wire

and other equipment according to and cable industry. Currently NHM

NIEHOFF standard, but adapted to employs five service engineers in

the particular requirements of the order to ensure its customers a reli-

customers in Brazil and neighbor- able technical assistance at any time.

ing countries. NHM imports other

types of machines from NIEHOFF in In-house-exhibitions

Germany to complement its product Every two years, NHM supported by

lines and prepare the equipment for NIEHOFF Germany and the enter-

installation at its customers’ produc- prises represented by NHM orga-

tion sites. nizes an in-house-exhibition. Besides

machine demonstrations the visitors

Brazil and beyond can attend lectures on current top-

Head of NHM Production equipment In view of Brazil’s economic and ics concerning the wire and cable

The wholly-owned subsidiary today NHM owns a building complex with technological importance NHM industry.

is directed by Alex Hoster, a Brazilian a floor of more than 6,500 m² in a has a strategic significance for the

by birth, who joined NHM as early property of 12,000 m². High invest- NIEHOFF Group. Although the

as in 1977. His career had led him ments in state-of-the-art production majority of NHM’s customers are

through all NIEHOFF departments equipment ensure highest qual- Brazilian wire and cable manufactur-

before he took his current position ity according to NIEHOFF standards ers, NHM supplies also customers in Niehoff-Herborn Máquinas Ltda.

in 1998. This fact has made him and contributed to making NHM the other Latin American countries such Rua Mar Vermelho, 1092

06412-140 Barueri, S.P., Brazil

an expert who is absolutely famil- market leader in South America. as Argentina, Bolivia, Ecuador, Uru- Phone +55 11 4199-3600

iar with all NIEHOFF processes and guay, Paraguay and Peru. Fax +55 11 4199-3624

technology. E-mail: info@niehoff.com.br

NIEHOFF Magazine 15/02 17Pursuing opportunities

that come out in

crisis-ridden times

Acome do Brasil, Irati, Paraná/Brazil

Irati is a town in the southeast of Paraná, a Southern Region State of

Brazil. The locality was founded in the 1890s as a railroad town along

the São Paulo–Rio Grande do Sul railroad line. The distance from Irati

to São Paulo in the northeast is about 600 km, while about 500 km west

of Irati, at the border triangle between Brazil, Paraguay and Argentina,

there are the famous waterfalls of the Iguazu River. Irati has about

60,000 inhabitants and is the home of Acome do Brasil, one of the

leading automotive wire manufacturers in Latin America.

French roots On the way to the world beyond two plants in China and operates all the products have the necessary

Acome do Brasil is a subsidiary of At the end of the 1970s, the com- sales offices in Germany, Italy, Spain technical qualification to be used

the Acome group with headquarters pany opened an export department and Russia. It is planned to create by any and all motorcar compa-

in Paris, France. The parent com- and years later started establish- two additional manufacturing units nies. Despite the current unfavour-

pany emerged in 1932 from Elec- ing subsidiaries outside France. In in the next year. able economic situation in Brazil and

tro-Câble, a small company which 1998 a Brazilian subsidiary named other countries in South America

was specialised in the manufacture Acome do Brasil was founded in Irati Lean and modern (s. page 14), the company plans

of electric cables. When this com- with the aim to supply exclusively Acome do Brasil, headed by Delmar producing in the year 2015 about

pany was in substantial financial customers in the Brazilian market, Fernando Voigt, has a workforce of 500,000 km of wires and generating

difficulties, its managers adopted mostly French motorcar companies only a little bit more than 100 per- a turnover of more than BR128 mil-

the financial commitments – as an installed there. sons. This is explained by the fact lion (more than USD36 million).

early example of what is now called Today as in the past, the most that production support and man-

a “management buy-out” – gave important plant of the Acome group agement support structures are very Automotive cables for South

the new company the structure of a is in Mortain in the Normandy, lean and the production is highly America and Mexico

cooperative society as indicated by France, while the management and automated. Since its foundation, the Acome do Brasil produces auto

the company’s name: Association the sales offices occupy a 5-storey company has doubled twice the pro- motive cables with 0.35 mm² to

Coopérative d’Ouvriers en Matériel building in Paris. Besides the Irati duction capacity of the plant. Owing 8.0 mm² cross section in three

Electrique (ACOME). plant in Brazil, the group owns also to the high technology employed, classes of temperature (from T2 up

18 NIEHOFF Magazine 15/02Acome do Brasil holds approvals Acome do Brasil and NIEHOFF

and supplies to most of the major

car manufacturers established in The NIEHOFF

South America and Mexico and has Group and its

received many awards from South Brazilian subsid-

American and Mexican automotive iary NIEHOFF-

companies. Herborn Máqui-

On the other hand, the economic nas Ltda. (NHM)

results can be seen as a way of and Acome

securing the group’s and its Brazil- do Brasil have

ian subsidiary’s continued existence. worked together in a mutually

Acome do Brasil follows a 4-year stimulating partnership. Within

strategic plan and has currently the context of the accelerated

focused on pursuing opportuni- growth of Acome do Brasil,

ties that come out in crisis-ridden NHM “has always been on our

times. The adverse situation which side as a great partner mak-

all are fighting now in Brazil and is ing delivery of ordered pieces

being experienced specifically by the of equipment within agreed

automotive market, represents new terms and giving a first quality

challenges and the Acome group is technical support”, says Delmar

to T3 and T4) according to the spe- nuclear energy research institute open to study new projects. Fernando Voigt, CEO of Acome

cific requirements of each car manu- IPEN. The motive for such partner- do Brasil. “To count on NIEHOFF

facturer. The production range com- ships is that two particle accelerators machines in times of cost-

prises more than 4,000 different can be used for manufacturing ele- trimmed manufacturing process

items. The direct customers are sup- vated-temperature cables by cross- is really a competitive advan-

plier companies established within linking methods. Furthermore there tage because NIEHOFF’s mod-

a motorcar industry hub in all South is a mutually advantageous know- ern equipment enables a single

America and Mexico. The customers how transfer. The most part of cable operator to control an array of

are delivered directly from the Irati development and engineering, how- machines at the same time, not

plant or through own logistics ware- ever, is centralized in Europe. to mention their durability and

houses, one of them located in São resistance, which make preven-

ACOME DO BRASIL LTDA

Paulo and the other one in Ciudad Strengths and future-orientation tive maintenance operations

Rue Vereador François Abib,

del Est, Paraguay. A specific feature of the Acome 400 - Vila São João faster and enlarge the time

group is its structure as an industrial CEP: 84500-000 - Irati - PR – Brasil interval between them.”

Technology partnerships cooperative. The employees hold Tel. +55 42 3421-2500

Fax +55 42 3421-2513

Acome do Brasil cultivates a solid shares in the company and partici- Web: www.acome.com.br

partnership with Unicentro Irati, pate actively in the decisions that E-mail: dfv@acome.com.br

the state university, and with the orient its future. One result is that Skype: dfv_acome.br

NIEHOFF Magazine 15/02 19Manufacturing and braiding

of automotive cables

Stranding and braiding

technology from NIEHOFF

Driver assistance systems in Double twist machines

motor vehicles enhance driving Since the early 1970s, NIEHOFF has

safety, supervise various param- been offering besides wire drawing

eters of a vehicle, enable an systems also a complete range of

efficient vehicle operation and double twist bunching machines in

increase passenger comfort. the sizes 400 to 1250. Since then,

these machines have undergone

As more and more of these elec- continuous development resulting

tronically controlled systems are in the D series double twist bunch-

installed in new vehicles (s. page ing machines whose characteris-

4), there is a growing demand for tics are described on page 16. The

conductors which are indispensable concept of these machines and the

for their operation. The manufac- experiences made with them were

turers need production equipment the basis for the development of

that works reliably and economically the double twist stranding machines

and can be adapted flexibly to the of the DSI series. These machines

customer specifications and the can be equipped with comprehen-

order situation. The double sive accessories and combined to

istockphoto © yuyanga

twist machines of the D and manufacturing lines which manufac-

DSI series and the rotary ture at high speeds all kinds of data

braiding machines of the cables and special cables – even of

BMV series meet these future generations – with utmost

requirements perfectly. precision.

20 NIEHOFF Magazine 15/02Rotary braiding machines

The lever arm rotary braiding

machines of the BMV series are

foreseen for the production of data

cables, control cables and coax-

ial cables as well as automotive

hybrid cables in which a foil must

be inserted before and after braid-

ing. The machines designed for 12,

16 or 24 bobbins in vertical opera-

tion can process bare or coated

round and flat wire made of copper,

aluminum and stainless steel with

single-wire diameters of 0.05 to

0.3 mm, as well as yarns and fibers

made of plastic. The BMV machines

feature an automatic central lubrica-

tion system and an infinitely variable

electronic control of braiding speed

and pitch. The new BMV machines

Photo: LEONI

are equipped with energy-efficient

components and energy-saving

motors and meet the current safety

regulations of the machinery direc-

tive RL 2006/42/EG. Several con-

trol system, some of them available tion. The experience of many cable D 801, symmetric conductors in the stranded pair and quad con-

as an option, ensure that the BMV manufacturers has shown that one pair or quad construction can be structions as well as on coax cables

braiders can be operated for a long BMV braider can be used to replace produced, for example. The pro- the rotary braiding machines of

time unattended and without an two to three older types of braiding duction of star quad conductors the BMV series are ideally suited.

operator. machine. can be realized at a typical speed of The mentioned conductors can be

The BMV machines can be com- 3,500 twists/min, the typical pro- braided at speeds of up to 175 rpm.

bined with different types of taping High performance duction speed of pair conductors is

systems so that braiding and taping With the double twist bunch- 4,000 twist/min and more. For the

can be performed in a single opera- ing machines type DSI 631 or type application of shielding braids on

NIEHOFF Magazine 15/02 21You can also read