INEOS TEAM UK Reducing optimization time from a day to an hour - OnePLM

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Marine

INEOS TEAM UK

Reducing optimization time from a day to an hour

Product

Simcenter Simcenter 3D and OptiAssist multihull catamaran to fixed configuration

Business challenges enable efficient analysis and monohull, but new limitations were imposed

on prototyping and physical testing, compel-

Adapt to changing rules and optimization of composites

ling teams to fully rely on a digital twin to

yacht types designs develop their boats.

Choose the proper engineering

direction for the design The world’s oldest international

Led by Sir Ben Ainslie, a previous America’s

sports trophy

Understand cross-disciplinary Cup winner and the most successful Olympic

The America’s Cup is the oldest international sailor of all time, INEOS TEAM UK was formed

tradeoffs

sports trophy in the world and the most in 2018 to bring the America’s Cup home to

expensive to win. It is a competing platform Britain for the first time.

Keys to success where the most advanced marine technolo-

gies, strategic decision-making and sailing A dramatically different design

Implemented Simcenter 3D for

skills all meet in the dramatic performance

efficient processes for develop- Class rules for the 36th America’s Cup of

of flying racing yachts. The AC75 class rule,

ing refined local models from 2021, announced in March 2018, introduced

which defines the parameters within which

global models a dramatic change in design. “These are

teams can design an eligible yacht to com-

Efficiently pre- and postprocess entirely new boats, the AC75 foiling mono-

pete in the next Cup, has introduced some

simulation models hull,” says Dave Jonson, Team Leader -

groundbreaking regulations. Not only has

Structures at INEOS TEAM UK. “It’s a large

Perform structural analysis of the type of craft changed dramatically, from

hull and other structural com-

ponents using Simcenter

Nastran

Optimize laminate composite

structural elements using

OptiAssist for Simcenter 3D

Results

Reduced optimization time

from a day to an hour

Rapidly evaluated and com-

pared different design schemes

Developed optimal ply shapes

and laminate schemes

Efficiently handled multiple

loading requirements of com-

ponents and assemblies

siemens.com/simcenter“The Siemens toolset, with boat at 75 feet long that travels at high structural performance for every piece of

NX on the CAD side and speeds. The challenge with developing the design, starting with the hull at a global

Simcenter on the analysis something from the ground up is that just level, and then at the subassembly and

side makes that a lot easier about everything needs to be invented. And component levels.

to deal with.” the first boat we build needs to be competi-

tive from the start.” That leaves only three For racing boats, weight management is a

Dave Jonson

years from the time the rules were fundamental aspect of the design process.

Team Leader – Structures

announced until the race begins, an The rules define a basic weight budget split

INEOS TEAM UK

extremely short time to conceptualize, between the major parts of the boat. The

design, manufacture and begin to race a competing teams then decide how to allo-

completely new boat from scratch. cate the weight in the various areas while

still conforming to the basic requirements.

Compounding the challenge is that the rules Weight distribution is critical to the perfor-

for the 2021 America’s Cup actually allow mance of the yacht, and a lightweight struc-

for lots of design freedom for the hull, sail, ture also means there is more weight to

hydrofoil and aero and control systems. spend in other areas and systems. How

“With so much freedom, the challenge is weight is managed and distributed through

choosing the right engineering direction for the yacht greatly impacts how it performs

the different areas of design, such as aero, and maneuvers.

flow and structure,” notes Jonson. In other

words, with such a limited amount of time,

INEOS engineers face a challenge to deter-

mine what will be the right engineering and

design path to take before working out the

details. With so many possible directions to

go, they must determine the best path that

won’t lead to a time-draining dead end.

Simulation and optimization for

structural performance

Jonson’s structures team is responsible

for all structural aspects of the yacht, includ-

ing defining load cases, performing struc-

tural simulation, conducting physical testing

and monitoring loads when the boat is

finally sailing. The team needs to consider

“Simulation is absolutely playing a key role in

developing the boats. The more concepts that

we can cycle through and evaluate, the more

value that adds.”

Dave Jonson

Team Leader – Structures

INEOS TEAM UK“Simcenter 3D assembly mod-

eling lets us easily swap out

different components in the

global model, which helps us

analyze different strategies.

Simcenter 3D has powerful

tools for transferring bound-

ary conditions between the

global model and the local

model.”

Dave Jonson

Team Leader – Structures

INEOS TEAM UK

Much of the structure is made of light- results, and then quickly make any needed

weight yet strong laminate composite mate- design changes and re-run the simulation to

rials, and one of the advantages of using compare performance differences. “The

laminate composites is the flexibility to ability to translate a model from one geom-

design the material to meet specific func- etry to another is critical,” notes Jonson.

tional performance objectives. But the com- “The parameterization of the model space

plexity of options for designing the right allows us to morph our models very quickly

composite material – number of ply layups, from one concept to another or to substi-

orientations and thicknesses – make it chal- tute in a new concept easily. The Siemens

lenging for engineers to determine the right toolset, with NX on the CAD side and

concept direction. “Simulation is absolutely Simcenter on the analysis side makes that a

playing a key role in developing the boats,” lot easier to deal with,” notes Jonson.

says Jonson. “The more concepts that we

can cycle through and evaluate, the more OptiAssist for Simcenter 3D works within

value that adds.” To accomplish this, INEOS the Simcenter 3D environment to optimize

TEAM UK turned to Simcenter™ 3D soft- composite laminates, automatically devel-

ware, NX™ software and Simcenter™ oping ply shapes and identifying the most

Nastran® software, part of the Xcelerator™ efficient orientations and number of plies.

portfolio of solutions and services from “OptiAssist allows us to define different

Siemens Digital Industries Software. The laminates on the fly and zone models in a

team also relied on OptiAssist for Simcenter flexible way, which makes the process a lot

3D, an add-on application from Siemens quicker,” says Jonson. “OptiAssist for

partner GRM Consulting, to unlock the Simcenter 3D ultimately automates the

power of structural optimization. optimization process and frees the engineer

from the manual task of iterating designs.”

Simcenter 3D and OptiAssist for

composites optimization In addition to the seamless connection

Simcenter 3D is a comprehensive, fully inte- between design and simulation, Jonson

grated computer-aided engineering (CAE) cites Simcenter 3D’s ability to efficiently

solution for addressing complex, multidisci- move from global assembly models to sub-

plinary product engineering performance. assembly and component models.

Jonson’s team can seamlessly transfer

geometry from NX computer-aided design “Simcenter 3D assembly modeling lets us

(CAD) into Simcenter 3D to efficiently edit easily swap out different components in the

and defeature geometry, create the finite global model, which helps us analyze differ-

element model, solve it using Simcenter™ ent strategies,” Jonson says. “Simcenter 3D

NASTRAN® software, evaluate and animatehas powerful tools for transferring boundary

conditions between the global model and

the local model.”

The primary benefit of easily moving from

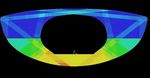

a global to a local model is that it allows Candidate reinforcing plies automatically

INEOS TEAM UK engineers to develop the generated for deck and hull divided into

banded regions using OptiAssist for

analyses in an efficient way. The global Simcenter 3D.

model is not overburdened with a lot of

detail that would slow down run times, but

on the other hand, the local model allows

for both global and local loading to be con-

sidered for refined analysis at the compo-

nent level.

Global level: optimization of hull stiffness

The hull is the predominant structure for the

entire yacht, and hull stiffness is critical to

the overall performance of the boat. It’s no

surprise that this was the initial focus for

INEOS TEAM UK’s structures team. For exam-

ple, consider that optimal sailing perfor- subjected to many large forces. These loads

mance is directly related to maintaining sail are primarily the result of the balancing of

shape. The sail rig is attached to the hull so the righting moment of the yacht with the

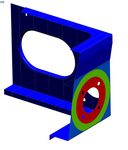

the stiffness of the hull directly influences the aerodynamic forces generated by the sail Identified optimal ply reinforcement

distributions to meet specific stiffness and

deflection of the rig and hence sail shape. plan. The sails loads produce tension in the

strength requirements.

Says Jonson, “You need to be cognizant of various rigging elements supporting the sails

the different failure modes that can poten- and the mast bulkhead is the primary struc-

tially manifest as you start pushing the ture connecting the hull with the mast. The

weight down, so developing a high-fidelity goal was to minimize the mass of the mast

finite element model at an early stage is key.” bulkhead while still meeting all structural

performance requirements without failing.

Jonson’s team used OptiAssist with

Simcenter 3D to determine candidate areas By using OptiAssist for Simcenter 3D, INEOS

of the hull that would require hull reinforce- was able to develop laminate reinforce-

ment to meet strength requirements and to ments in 25 iterations and identified optimal

also maintain an efficient sail plan. Jonson’s ply reinforcement distributions to meet spe-

team was able to optimize ply thickness for cific stiffness and strength requirements.

reinforcing unidirectional plies within the

structure to achieve the best performance- Component level: drivetrain brackets

to-weight tradeoff. On a racing yacht, drive train refers to vari-

ous functions like pumps and winches that Optimal bracket thickness achieved in less

Subassembly level: are powered by the human sailors on board. than an hour for carbon fiber/epoxy quasi-

mast bulkhead structure isotropic laminate.

At the component level, the drive train

Moving down the chain to the substructures brackets support the shafts that the sailors

of the boat, the team considered the design will be cranking during the race, and they

for the mast bulkhead, part of the primary need withstand the forces being generated

structure of the boat positioned under the by the sailors without adding unneeded

mast to support it. The mast bulkhead is weight to the boat.Solutions/Services The brackets are also designed from lami- simulation, evaluate results and iterate, it

Simcenter 3D nate composite materials, so Jonson’s team would easily take a day or more. But by

siemens.com/simcenter3d can engineer and optimize the material for automating this process with OptiAssist for

performance. In this specific case, they Simcenter 3D, Jonson was able to achieve

Simcenter Nastran looked to optimize the thickness distribution the optimal design in less than an hour.

siemens.com/simcenter-nastran of the quasi-isotropic laminate used for the

OptiAssist for Simcenter 3D bracket so as to minimize mass while still One shot

www.opti-assist.com achieving strength, displacement and rota- INEOS TEAM UK credits using simulation,

tion requirements. The load cases applied to especially efficient simulation, as early as

drive-train brackets can be complex, often possible in development to confirm that it

Customer’s primary business

requiring consideration of many different will have a competitive boat as soon as it

INEOS TEAM UK is a commercial combinations of moments and load vectors. hits the water. Dave Jonson sums up the

sporting team led by four-time It is difficult to optimize the structure effi- challenge best: “We only have one shot at

Olympic gold medalist and ciently without the use of a tool that allows this, and simulation is key to understanding

34th America’s Cup winner, simultaneous consideration of all the load many aspects of the boat.”

Sir Ben Ainslie. The team’s cases. If Jonson’ team were to try to manu-

long-term aim is to bring the ally adjust the composite thickness, run the

prestigious America’s Cup

back to Britain, where the first

challenge was held in 1851

off the Isle of Wight.

www.ineosteamuk.com

“We only have one shot at

Customer location

Portsmouth

this, and simulation is key to

understanding many aspects

United Kingdom

of the boat.”

Dave Jonson

Team Leader – Structures

INEOS TEAM UK

Siemens Digital Industries Software

Americas +1 314 264 8499 © 2020 Siemens. A list of relevant Siemens trademarks can be found here. Other trademarks belong to their respective owners.

82435-C4 10/20 A

Europe +44 (0) 1276 413200

Asia-Pacific +852 2230 3333

siemens.com/softwareYou can also read