Oris Caliber 400 - American Watchmakers - Clockmakers ...

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

TM

March 2021

HOROLOGICAL TIMES

Oris Caliber 400

AMERICAN WATCHMAKERS-CLOCKMAKERS INSTITUTE · SETTING SERVICE STANDARDS AND EDUCATING THE HOROLOGICAL COMMUNITY

Single Rollers, Double Rollers, and Their Roller Jewels

Restoration Projects Done at WOSTEP in 1991

Part 1: Gold Pocket Watch with CarillonSince 1920

CYCLOMOTION

STOCK #

ELMA-CYCLOMOTION $1,599

(arms not included)

Winds up to 12 to 24 watches

Winding speed 1 or 4 rpm

Features automatic on & off timer

Left or right winding rotation

CYCLOMOTION + 6 ARMS ELMA-CYCLO/5190 $1,929

HOLDS 12 WATCHES (as pictured)

CYCLOMOTION + 6 ARMS ELMA-CYCLO/5192 $2,109

HOLDS 24 WATCHES

JULES BOREL & COMPANY

PHONE 800-776-6858 WEB JULESBOREL.COM FAX 800-776-6862IN THIS VOLUME 45, NUMBER 3, March 2021

Official Publication of the American Watchmakers-Clockmakers Institute

AWCI News eBay’s Luxury Watch Market- TM

March 2021

EXECUTIVE & EDITORIAL OFFICES Board of Director’s place Exceeds Revenue Goals

American Watchmakers- By Kathleen Cardwell Oris Caliber 400

Nominations HOROLOGICAL TIMES

AMERICAN WATCHMAKERS-CLOCKMAKERS INSTITUTE · SETTING SERVICE STANDARDS AND EDUCATING THE HOROLOGICAL COMMUNITY

Clockmakers Institute (AWCI) page 4 page 30

701 Enterprise Drive

Harrison, OH 45030 President’s Message Show Dates: LVMH Watch

866-FOR-AWCI (367-2924) By Justin Harrell, CW21 Week, Watches and Wonders

or 513-367-9800 page 5 Geneva, and More

Fax 513-367-1414 By Kathleen Cardwell

awci@awci.com • www.awci.com

www.facebook.com/MyAWCI

Affiliate Chapter News page 31 Single Rollers, Double Rollers, and Their Roller Jewels

page 41 Restoration Projects Done at WOSTEP in 1991

In Summary Part 1: Gold Pocket Watch with Carillon

Donna Hardy

Managing Editor

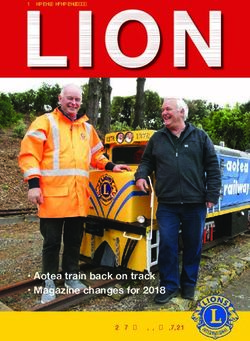

New Members/ELM Trust Oris Adds a Small Seconds The Oris Caliber 400. See page 15.

Ext. 305 donna@awci.com Donors/Memoriam Complication to the Caliber 400

page 43 By Donna Hardy

Janette Torres-Gomez page 32 Columns

Graphic Designer &

Assistant Technical Support

Technical Discussions Watchfinder Collects Watches from

From the Workshop

Ext. 302 jgomez@awci.com Restoration Projects Done at Single Rollers, Double Rollers,

Sellers’ Homes and Their Roller Jewels

WOSTEP in 1991 By Donna Hardy By Jack Kurdzionak, CW21, FAWCI

Jason Champion, CW21 Part 1: Gold Pocket Watch with page 32 page 23

Education Director and Watchmaking Specialist

Ext. 303 jason@awci.com

Carillon

By Bernhard Stoeber, CW21

Mike Carpenter, CC21

page 9

Patek Philippe Discontinues

Nautilus Reference 5711/1A

Classifieds

Clock Director By Donna Hardy Buy, Sell, Trade, and

clocks@awci.com Oris Caliber 400 page 32 Employment Opportunities

By Jordan P. Ficklin, CW21 page 44

HOROLOGICAL TIMES page 15 The Deep Space Resonance Watch

ADVISORY COMMITTEE

Bob Little, CC, CW, Chair

Industry News

By Donna Hardy AWCI Directory

Daniel Benson, CMW page 33 Advertisers’ Index

Paul Corn Industry Embraces Online page 46

Andrew DeKeyser, CW21

Platforms Education &

Dale LaDue, CMW21

Jason Ziegenbein, CW21 By Andrew DeKeyser, CW21

page 29

Certification Board of Directors

page 46

AWCI Educational Calendar

Fewer Jewelers Closed Doors in page 6 Fellows

2020, Despite the Pandemic page 46

By Kathleen Cardwell

Horological Education

Around the World Industry Advisory

page 29 Kelloseppäkoulu

Reprinting and reproduction is prohibited without written The Finnish School of Watchmaking Board Members

permission from the American Watchmakers-Clockmakers Espoo, Finland page 46

Institute. Copyright © 2021 by the American Watchmakers- By Kathleen Cardwell

Clockmakers Institute. page 35

Horological Times (ISSNO 145-9546) is published monthly

and copyrighted by the American Watchmakers-Clockmakers OUR VISION:

Institute, 701 Enterprise Drive, Harrison, OH 45030-1696. AWCI’s vision is to have an educated and passionate horological community practicing

Subscription price for the public is $175.00 per year the highest standards and with the resources to provide quality goods and services.

($15.00 per copy). Members subscription is $99.00 which

is included with annual dues of $175.00. Periodicals post- OUR MISSION:

age paid at Harrison, OH 45030 and additional entries. Setting service standards and educating the horological community.

POSTMASTER: Send address changes to Horological Times,

701 Enterprise Drive, Harrison, OH 45030.

Like us on Facebook! Follow us on Twitter! Follow us on Instagram!

www.facebook.com/HorologicalTimes www.twitter.com/AWCInstitute www.instagram.com/americanwatchmakers

Like us on Facebook! Check out our educational videos!

www.facebook.com/MyAWCI www.youtube.com/awci/videos 3You can shape the future of AWCI

and the horological industry.

The Nominating Committee is now accepting nominations for

individuals who would like to serve on the AWCI Board of Directors.

Deadline to submit your nomination: April 12, 2021

Who can I nominate?

Members may nominate themselves or others they feel are qualified to represent the membership on the board.

What are the qualifications?

Board members must be willing to serve, have been a member of AWCI for at least one year, and attest to the

duties of loyalty, confidentiality, and care.

What is required of board members?

; Board members must have email access and check it on a regular basis. They must be able to attend

monthly conference calls and travel to attend in person the midyear meeting and the annual meeting

of AWCI.

; Before they take office, board members should become familiar with the Constitution & Bylaws of

AWCI as well as the basics of parliamentary procedure.

; Board members serve for a term of 3 years.

Are board members compensated for their time?

Board members are not paid for their time but are compensated for travel and lodging expenses related to their efforts to

carry out their duties. It is hard work to serve on the Board of Directors and it takes commitment. However, participating

in shaping the future of AWCI and the industry can be incredibly rewarding.

How to submit your nomination:

Go online: www.awci.com/nomination

Scan QR Code: Nomination Form

Mail to:

Board of Directors Nominating Committee

American Watchmakers-Clockmakers Institute

701 Enterprise Drive

Harrison OH 45030

Or email to: nominatingcomm@awci.com

Or call: 866-367-2924/513-356-9800 ext. 303 www.awci.com/nomination

4 March 2021a message from the

president JUSTIN HARRELL, CW21

A nother month has passed, There are opportunities and jobs for horologists

and our headquarters in available all over this country. How can someone

Harrison, Ohio, is gearing start at ground zero in this industry and become

up to host one of the largest a clockmaker or watchmaker without attending a

cat-herding events of the last full-time program? It is not impossible, but almost.

decade. Many famous feline Before the lockdown, both the watch and clock

wranglers will be in atten- education committees and the Board of Examiners

dance and have met all the were developing tiered programs that would ulti-

Justin Harrell

jharrell@awci.com flying-saucer vaccination re- mately lead to certification. In the past, a mentor

828-551-0741 quirements. Now, if you’re would be willing to take on an apprentice to get

still reading this, you might wonder just what in the started in this field. That meant the mentor would

heck is going on. I just wanted to see who, if anyone, be willing to teach the apprentice at a slow pace,

is paying attention. and the apprentice would be willing to give his or

This month’s message is going to sound like her time to the mentor usually without compen-

a broken record, but here goes. I/WE sation. Labor laws and the squeeze of

WANT TO HEAR FROM YOU!!! How the American economy have prevented

is it possible that only two members have

I would many opportunities like that. So, how

contacted me after pleas for participation love to see can we sidestep this obstacle? If a men-

and input for three months? I’ve put my at least six tor or jewelry store owner could send

cell phone number in a magazine for a

reason. I/WE WANT TO HEAR FROM

candidates an apprentice to AWCI first to get the

fundamentals down, then the apprentice

YOU!!! This organization is only as good on the could return to the business as an asset.

as the level of participation it elicits. Send ballot. That is how tiered certification will work

me a note, a question, an idea, anything! for AWCI and the industry. It is all about

Please consider running for the Board of Direc- the money. Invest in the right candidate, and AWCI

tors. Our nominating committee is looking for vol- will turn that person into a profitable employee for

unteers to run as two spots need to be filled. On you. We also planned to have more advanced class-

the page opposite, you’ll find all the information you es for those who already hold certifications and

need to nominate someone or yourself. Our elec- want to push their skills to the next level. We must

tion is going to be slightly delayed this year due to get back on track with both of these goals as soon

the inactivity of the institute. If you have run in the as possible. The pendulum has stopped and needs

past, please try again. I would love to see at least six some impetus to start again.

candidates on the ballot. Since I have been involved Spring is on the horizon, vaccines are rolling out,

with AWCI, our Board of Directors has consisted of and watch lovers are as itchy as every other shop-

the same few people. It is great that these same peo- per to get back out there, spend a bit, and return to

ple are always willing to contribute. However, that some sense of normalcy. Let’s get ready together to

does not mean that it’s a “good old boys club” that is take our businesses to the next level after this dark

not open to change or new direction. If you have any season. We are the best resource for each other, our

interest in contributing to AWCI’s future, I implore industry, and the future of horology. Send me a text,

you to put your name in the hat. will ya?

Horological Times 5educational calendar

Check out AWCI’s complete line

of courses for watchmakers and See our catalog for more!

clockmakers! We can use your help

AWCI will not be holding classes in Harrison, Ohio, We are always looking to expand our course cata-

or on its mobile classroom until projections of the log and educational resources as well as increase our

virus subsiding have become more predictable or team of instructors. During this downtime, we want

there is a vaccine widely available. In the mean- to develop new courses and find new instructors who

time, we invite you to browse our course catalog, will collaborate with us. Reach out to us at education

www.awci.com/course-catalog, which offers 46 class- @awci.com if there is a class you would like to col-

es for watchmakers, including classes for beginners, laborate on as an instructor.

technicians, and, of course, experienced watchmakers We look forward to receiving your class requests

who want to sharpen their skills. and we hope to have a new list of classes to offer

In the catalog, you’ll find classes on: when the pandemic is under control.

h Introduction to Watchmaking

h Quartz

h Vintage Watch

Repair

h Tool Making

h Precision Timing

We also have 46 classes

for clockmakers, including

classes on:

h American Time-and-

Strike Movement

h Advanced Clock

Repair

h Introduction to the

Lathe

6 March 2021Reserve your spot today. Contact the education director, Jason Champion, CW21,

at 866-FOR-AWCI (367-2924), ext. 303.

Prices reflect members’ discount! Contact us so we can help you find the best course suited to your skill level, expertise, and interests.

$595

N August

Michael will share his knowledge gained from 40 years of experience through his

Herschede Tubular Bell Clocks extensive PowerPoint presentation with over 200 photos focusing on examples

E 11-13

Instructor: Michael Gainey, CC21 of issues before and after a rebuild that are unique to most common Herschede

AWCI Headquarters, Harrison, Ohio Tubular Bell movements.

W Come to AWCI’s well-equipped machine shop to join David Lindow for this prac-

$595 tical, hands-on class where gearing and gear cutting will be practiced. Students

D August Practical Gear Cutting for the Horologist

Session 1

will not only learn the basic setups for cutting horological gears, but they’ll also

learn multiple approaches to tooling as well as theory from a practical stand-

A 11-13 Instructor: David Lindow

AWCI Headquarters, Harrison, Ohio

point. Students will learn about wheel and pinion engagements and gain a fuller

understanding of horological gearing in general. While the focus of the class will

be on making gears and pinions, the skills taught will transfer to general repair

T and improve the success rate of all clock repairers.

E August

$595

Practical Gear Cutting for the Horologist

S 14-16

Session 2

Instructor: David Lindow

See description above.

AWCI Headquarters, Harrison, Ohio

October WATCH 420S:

Vintage Chronograph Short Course

$595 Back by popular demand. In this course, you will go through, theoretically and

practically, different vintage chronograph calibers with emphasis on trouble-

5-7 Instructor: Bernhard Stoeber, CW21

AWCI Headquarters, Harrison, Ohio

shooting, repair, and adjustments to each mechanism. Lemania, Landeron, and

Valjoux calibers will be covered.

https://www.awci.com/webinars

Free/discounted webinars for AWCI members!

You asked for it, you got it!

Many of you have asked for online education. While AWCI’s in-person education is on a hiatus, you can still learn from our excellent

instructors—Tom Schomaker, CMW21; Jason Champion, CW21; Jordan Ficklin, CW21; Bernhard Stoeber, CW21; David LaBounty; and Ken De Lucca.

Missed a webinar? No worries, check out the on-demand webinars. Choose a topic from a list of pre-recorded webinars.

Here are some of the topics we cover.

5 Watch Basics for Beginners and Collectors 5 Explore Watchmaking 5 Professional Essentials

(A Hands-On Digital Webinar for Beginners)

5 Basic Watch Repair Skills 5 Tool Maintenance

5 Hairsprings 5 Workshop 5 Clocks

And more!

Stay involved, sharpen your skills, ask questions, and so much more! Have a topic in mind for a webinar?

Send your suggestions to awci@awci.com!

For additional details about specific courses in comprehensive syllabi form, including complete tool lists,

visit: www.awci.com/classes or contact the education director, Jason Champion, CW21, at 866-FOR-AWCI

(367-2924), ext. 303. For additional calendar events visit: www.awci.com/calendar.

Horological Times 7INNOVATION

COMES ONCE.

INNOVATING

GOES FOREVER.

PRECISION IS PRECIOUS.

witschi.com

Distributed by: Jules Borel & Company: julesborel.com

Have you recently renovated your retail store?

If your retail store has undergone a transition over the

past couple of years, making your watch repair workshop

attractively visible from the retail sales floor, we want to hear

from you!

Send us a couple photos and let us know approximately

how much you invested in the renovations and what the

impact has been on sales and service revenue.

Email Editor@awci.com.

8 March 2021Technical Discussion: Restoration Projects Done at WOSTEP in 1991, Part 1

Restoration Projects Done at WOSTEP in 1991

Part 1: Gold Pocket Watch with Carillon

By Bernhard Stoeber, CW21

Introduction

The following series of articles was initially pre- in Neuchatel whenever I traveled to Switzerland.

pared as a presentation to be given at AWCI’s 60th- During the following years, our paths also crossed

anniversary convention in Cincinnati last March. As a few times in the US. For instance, when we both

we all know, the onset of the COVID-19 pandem- were presenters at AWI’s Mid-Atlantic Conference

ic forced the convention to be canceled. Late last in Lancaster, Pennsylvania, and at other events.

year, HT’s managing editor, Donna Hardy, asked if I grew up in West Germany where my family

I had ideas for articles that could be published in owned a watch and jewelry business that my

HT. Since it is unclear when it will again be possible grandfather had founded in 1894. Later, my Uncle

to have in-person meetings and conventions, I sug- Josef took over. Following his death in 1958, my

gested that I write articles based on the presentation parents continued the business. Unfortunately, my

that I was going to give at the convention: four res- father passed away in 1965, when I was 12 years old.

toration projects done at WOSTEP in 1991. My mother was able to run the business (with the

The origin of this story goes back to the summer assistance of a great team of dedicated employees)

of 1986 when Antoine Simonin (Tony) and his wife, because she had been involved for many years and

Josiane, came to New York to promote WOSTEP. handled the overall sales activity. She was able to

This was the first time we met in person, though I put my two brothers through college, and I was

had heard a lot about them and their great work at designated next-generation watchmaker, who would

WOSTEP. Subsequently, I went to visit WOSTEP continue the business.

Fig. 1. Antoine Simonin (right) and the author Fig. 2. My parents’ engagement in 1941 with my

at AWI’s Mid-Atlantic Conference in Lancaster, hometown in the background.

Pennsylvania.

Horological Times 9Technical Discussion: Restoration Projects Done at WOSTEP in 1991, Part 1

Fig. 3. The family of Theodor Stoeber Sr., ca. 1930. Three watchmakers in one photo: Uncle Josef (top left); my

father, Theodor Stoeber Jr. (top right); and my grandfather, Theodor Stoeber Sr. (middle row).

Well, life had other plans for me. I did be- After our mother passed away in 1988, my broth-

come a watchmaker and passed my German Master ers and I decided to sell the house and family busi-

Watchmaker exam in 1975, the same year I started ness to that young couple who had taken over earlier.

working for the West-German central service work- I thought about how to honor my family. Eventually,

shop of Omega and Tissot. In 1978, I did a three- I decided to invest in my professional training and

month internship at Omega in Biel/Bienne, followed applied to WOSTEP for the Course on Complicated

by a six-month work stay at Omega in Paris to im- Watches.

prove my French. In early 1991, I attended WOSTEP after my

In 1980, our mother retired from the business employer at the time, North American Watch

and leased it to young a couple with a background Corporation (today The Movado Group), granted

in watches and jewelry. In 1983, Omega Switzerland me a five-month leave of absence under very favor-

organized an inter-company transfer for me to join able conditions.

the Omega affiliate in New York City, and I moved

to the US.

10 March 2021Fig. 4. At the bench at WOSTEP in Neuchatel in May 1991.

Gold Pocket Watch

with Carillon

Description

This small, open-face pocket watch with car-

illon (music box) was made before 1800 by

Antoine Favre in the Vallée de Joux.

The push button in the pendant activates

the music box on command, and the watch

also has an alarm system. The alarm time is

indicated by the large, blue hand.

The case is made of 18 karat gold and bears

a hallmark used after 1797.

The white enamel dial has Arabic numerals

and an inner track for the alarm. The move-

ment has a cylinder escapement and a three-

armed brass balance wheel with flat hairspring.

Fig. 5. Front view of the watch with chain and Breguet key to

wind and set the watch.

Horological Times 11Technical Discussion: Restoration Projects Done at WOSTEP in 1991, Part 1

Fig. 6. The This carillon was described by Alfred

back cover Chapuis in his book Histoire de la Boîte à Musique

opened. et de Musique Mécanique published in 1955. It

There is one appears to be the first time that the drum is

arbor to wind vertical instead of horizontal, as is common in

the carillon

music boxes.

barrel and

one for the The movement is highly decorated with a

going train. floral pattern and has two distinctive sections:

the going train wheel (on the right) and the train

wheel for the music box (on the left), Figure 9.

Fig. 7. Side view of

the carillon drum

with reeds.

Fig. 8. A drawing

from the book

Histoire de la Boîte

à Musique et de

Musique Mécanique

by Alfred Chapuis.

12 March 2021Work Performed

• Complete service including refinishing of all

steel parts and polishing/bluing screws.

• New crystal and polished case.

According to Tony Simonin, Antoine Favre had

left the Vallée de Joux for the Val-de-Travers to ap-

prentice as a watchmaker. Upon his return, he and

other students who had moved back to the Vallée

de Joux started their own watchmaking businesses.

The pocket watch described here could be consid-

ered one of the first complicated watches produced

in the now famous Vallée de Joux, the “Cradle of

Complicated Watches,” in Switzerland.

Photo Credits

Fig. 1—Courtesy of Peter Wittle.

Figs. 2 and 3—From the author’s personal archives.

Fig. 4—From the author’s WOSTEP reports.

Figs. 5 and 6—Histoire de l’horlogerie à la Vallée de Joux by Marcel Piguet. Used

with Editions Simonin’s permission.

Fig. 7 and 8—From the author’s WOSTEP reports.

Fig. 9—See Figures 5 and 6.

Figs. 10 and 11—From the author’s WOSTEP reports.

Fig. 9. A view of the superbly decorated movement.

Fig. 10. The carillon section of the movement without Fig. 11. Under-dial view of the movement.

the going train.

Bernhard Stoeber is an experienced watchmaker who has worked for more than 40 years for the Swiss watch industry in

Europe, the US, and China (with Omega, Movado Group, and Rolex). He retired from his corporate activities in 2018 and now

lives in Mount Joy, Pennsylvania.

Horological Times 13FREE on-demand webinars!

Take advantage of this great benefit. Once you download the link, you can watch the webinar

any time, any place, as often as you like. You’ll also get the PowerPoint slides to keep as well

as other handouts. Here are just a couple of the great webinars you have at your disposal. See

www.awci.com/educationcareers/webinars/ for more!

Lubrication 1: General

Principles of Lubrication

This webinar, presented by Jason Champion, CW21,

is the first in a series of webinars on lubrication for

professional watchmakers. Topics include the latest

insights from the industry about types of lubricants

and their application and general guidelines for

applying lubricants when technical documentation

is not available. Also covered:

• History of watch lubricants • Sliding friction • Capillary action

• Best practices • Surface tension • Creeping

• Where and when to use lubricants • Stiction • Viscosity

• Oils for faster/low-torque and slower/ • Importance of cleanliness • Specific uses for lubricants

high-torque situations

Handouts

• General Lubrication Chart • Moebius Technical Data Sheet—SYNT-HP1300 9104

• Lubrication table • PowerPoint slides

• Moebius Technical Data Sheet—SYNT-A-LUBE 9010 AWCI Members—FREE Everyone else—$25

The Chronograph

Presented by Jordan Ficklin, CW21, this webinar

presents information on the chronograph, including:

• The history of the chronograph

• Types of chronograph dials

• Types of chronograph scales

• Types of mechanisms

• Operation of the chronograph—including demonstra-

tions with slow-motion video

• Identifying common chronographs, including ETA 7750

and variants, Omega 861 and 1143, modular chrono-

graphs, and Rolex Daytonas 4030 vs 4130

Handout

PowerPoint slides AWCI Members—FREE Everyone else—$25Technical Discussion: Oris Caliber 400

Oris Caliber 400

By Jordan P. Ficklin, CW21

As a watchmaker, I often ignore the hype when

a brand announces the release of a new cali-

ber. Especially since I know that most brands prob-

a solution to a problem that existed when the watch

was shipped from the factory. Also, the watch has

some interesting innovations I had not seen before.

ably won’t sell parts, and I probably won’t get the A full video review of the caliber is available at www.

opportunity to ever work on one. For the past cou- youtube.com/prowatches.

ple of weeks, however, I have had the opportunity When Oris announced the Caliber 400, one

to handle the new Oris Caliber 400. I have put it of the first things I noticed was the interesting

through its paces, partially disassembled it, and ana- way they chose to attach the oscillating weight. It

lyzed some of the concerns raised by collectors since caught my attention because so many brands are

it appeared in the Aquis Date last year. I’m sharing using ball bearings these days, and this movement

my experiences with other watchmakers because clearly did not. I was also a little nervous because a

what I’ve learned may prevent them from chasing two-dimensional picture doesn’t tell the whole story.

Fig. 1. Oris Caliber 400.

Photo used with permission https://www.oris.ch/en/press/detail/184/oris-aquis-date-calibre-400

Horological Times 15Technical Discussion: Oris Caliber 400

Depending on how the clip inter-

acted with the movement, it could

have been disastrous. They did it

right. The oscillating weight is rem-

iniscent of so many of the early au-

tomatic weights from the 1950s and

1960s that are still around today. The

weight is rigidly connected to a tube

that slides over a post that is fixed to

the watch movement. The clip (as ar-

tistic as it is) merely keeps the weight

from rising up, and it does that job

beautifully.

I feel that the overall quality of

the Caliber 400 is better than should

be expected for a brand’s first in-

house caliber. It isn’t perfect, but it

is a well-built machine. The finish is

quite industrial, which is fitting for

a movement that will probably be a

workhorse in the Oris lineup. I be-

lieve the movement will be durable.

Fig. 2. Arrows indicating how to release the stem.

One of the items that immediate-

ly caught my attention was the detent

mechanism for the winding stem. The Caliber 400 Timekeeping

features a stem held in place by two posts opposite First and foremost, a watch must keep time. Before

each other, one secured with a screw and the other opening up the watch or dismantling the movement,

held in place with spring tension. This double mech- I put it on the timing machine to observe its perfor-

anism reduces the likelihood that the stem will ac- mance. The watch had an average daily rate of +5

cidently come out of the watch. To release the stem, with a maximum deviation between positions of six

loosen the screw first and then press down on the seconds at full wind.

detent while pulling on the stem.

It looks as if they designed the Caliber 400

with after-sales service in mind. Often brands

don’t think about what will happen when the

watch needs to be serviced. In this case, how-

ever, it is apparent that the needs of the watch-

maker were considered. The watch comes

apart and goes together easily. Anything that

is out of the ordinary is clearly marked to aid

the watchmaker while servicing it. For exam-

ple, if a watch has two barrels, it can be more

difficult to figure out how to release the pow-

er stored by the mainsprings before servicing

the watch. The click is clearly labeled with an

arrow. Also, the double release for the wind-

ing stem (a feature exceedingly rare in watch-

making) is also well marked. Servicing these

watches should be straightforward for any

watchmaker.

Fig. 3. Arrow indicating how to let down the power.

16 March 2021watch is capable of storing enough energy and oper-

Position Rate

ates with sufficient efficiency to deliver the full five-

Dial Up +3 day power reserve with a little left in the tank. This

Dial Down +5 is important because it means that any issues with

Crown Up +9 power reserve are a result of insufficient winding. The

quality control test demonstrated that a day of stan-

Crown Left +6

dard motion is not enough to fully wind the watch.

Crown Down +3 It is, however, enough to both maintain and add ap-

proximately an additional day of reserve to the watch,

Satisfied with those numbers, I decided to put which varies depending on the customer’s level of

the watch through a full quality-control timing check activity. Having run down 48 hours, one day on the

while I examined the movement in more detail. For final test only wound up the watch enough for it to

the next seven days, I observed the watch’s perfor- run for 95 hours after removing it from the final test.

mance, testing both timing and the automatic wind- This may or may not be a deficiency in this watch.

ing system. The test consisted of the following: Since the design of an automatic winding system has

to balance the need to wind the watch sufficiently

Day 1: Fully wind the watch by hand and place dial up. while not causing too much wear, this may be by de-

Day 2: Crown left. sign. I mention it because some customers have com-

Day 3: 1 rpm final test simulator. plained, and I want to quantify the actual efficiency

Day 4: Crown left. of the winding. Having run down 48 hours, one day

Day 5: Dial up. on the final test only wound up the watch enough for

Day 6: Dial up. it to run for 95 hours after removing it from the final

Day 7: Watch stopped. test. But why?

Over the first five days of the test, the watch It seems that the automatic winding mecha-

averaged just under +5 seconds per day. However, nism on this watch is not as efficient as it needs to

when the watch was on the final test, which simu- be (based both on my tests and on the experiences

lates the constant motion of a watch on the wrist, of some owners). Two key factors in the design con-

the watch neither gained nor lost time. During the tribute to this. First, this watch has a unidirectional

sixth day of the test, as the watch wound down, it winding system: winding in one direction and idling

gained 17 seconds. or “free-wheeling” in the other direction. Plenty of

watch brands and horological textbooks indicate that

Position Daily Gain (Loss) unidirectional systems are equally as efficient as bidi-

rectional winding systems, but they have the advan-

Dial Up +4

tage of being simpler and comprised of fewer parts.1

Stem Left +8

Final Test Simulator +0

Stem Left +11

Dial Up +1

Dial Up +17

Average (five days) +4.8 seconds/day

Average (six days) +6.8 seconds/day

Power Reserve

This seven-day test brought to light one of the com-

plaints I have heard from individuals who have pur-

chased this watch—they don’t seem to get the full

five-day power reserve as advertised by Oris. I fully

Fig. 4. The oscillating weight mounted to the

wound the movement and observed that it ran for 125 movement.

hours before coming to a stop, so we know that the 1. Charles-Andre Reymondin, et al, The Theory of Horology (Neuchâtel: Swiss Federation of Technical

Colleges, Watchmakers of Switzerland Training and Educational Program, 2003).

Horological Times 17Technical Discussion: Oris Caliber 400

Fig. 5. Comparing the oscillating weight of the Oris Caliber 400 (bottom) with the ETA 2824 (top).

If this is the case, why do so many brands spend move the hand) before pushing the crown back in,

the extra money on more complicated bidirectional the hand will not jump. All of this has nothing to do

winding systems? Clearly there must be advantages with the five-day power reserve or double barrels. If

to a bidirectional winding system. Second, the os- anything, it may be related to their desire to keep the

cillating weight is light. In an effort to reduce the watch as slim as possible. Ultimately, this is a result

height of the movement, it appears that Oris has of the engagement of the intermediate setting wheels.

chosen a weight with limited mass around its perim- When you pull out the crown on most watches, the

eter. The weight does have a larger diameter, allow- sliding pinion moves straight in to engage with the

ing it to achieve the same moment of inertia as a setting wheel. Or it may swing in on an arc that tran-

smaller weight using less mass. But this weight falls sects the center of the setting wheel’s axis of rotation,

short. I’m not sure the watch would wind at all if you Figure 6, red circle. In this watch, the arc is too shal-

placed it on the inclined table used by Rolex to test low, and the intermediate setting wheel swings in on

the function of their winding system. an arc that transects the teeth of the setting wheel,

For customers who wear the watch daily, this Figure 6, blue circle, which causes the wheel to ro-

won’t be a problem. They can take it off on Friday tate as the two wheels engage or disengage. (This is

night, and it will still be running on Monday morn- much easier to see in the video, www.youtube.com

ing. By mid-week it should be back up to full wind. /prowatches.) The rotation can be mitigated by having

If, however, they have a full box of watches and plan a narrower or shorter tooth profile.

to wear it for just one day and then wait four or five

days and wear it again for one day, they will likely be

disappointed. As a watchmaker, you can’t resolve this.

It is inherent in the design of the caliber.

Hand Setting

Another concern raised by watch owners is the hand

setting. When you pull out the crown to set the

watch, the minute hand jumps as much as three or

four minutes. Even more concerning is that some-

times when you push the crown back in after having

set the time, the minute hand will jump again (about

one minute.) It can be frustrating when, after you

have meticulously set the time and made sure that all

the hands are in sync, the minute hand jumps!

Oris has indicated that this is a result of design

decisions made to accommodate the five-day power

reserve and the two barrels. Oris has also indicated

that the hand jump can be avoided by turning the

Fig. 6. Setting mechanism of the Caliber 400. The

crown slightly backward before pushing it in. They red circle shows the ideal arc for the engagement

are right about the work-around. If, after setting the without rotation. The blue circle shows the arc of the

time, you turn back the crown a little (not enough to intermediate setting wheel.

18 March 2021I believe this problem could have been avoided At first glance, this is a Swiss lever escapement

during the design phase and can probably be resolved constructed of silicon. Both the escape wheel and the

(or reduced) with some component updates. Ideally, pallet are made from silicon, which offers some ad-

Oris would accomplish this without redesigning the vantages in escapements, namely:

main plate. Until Oris comes up with an update for

the components, turning the crown backwards releas- 1. Silicon has a low coefficient of friction,

es the tension and positions the teeth so that they can which means the escapement, without

separate without forcing rotation. needing any lubricants, will perform ex-

actly the same on the first day of the ser-

The Escapement vice interval as it will on the last.

For a watchmaker, the most exciting thing about this 2. Silicon is antimagnetic.

new watch is the escapement design. It caught me by 3. It can be manufactured to very precise tol-

surprise, and I love what they have done. Oris claims erances.

to have designed an “entirely new escapement”—and

they did. Yes, it is still a Swiss lever escapement, but it Since the first advantage is probably the most im-

has some new and innovative features. portant, I was surprised to see lubrication on the es-

capement. I can’t say for certain why Oris decided to

lubricate the silicon escapement. Perhaps they found

it performs even better when lubricated and found

that the degradation over time had no significant im-

pact on the performance. Maybe the coefficient of

friction for this particular formula of silicon isn’t as

great as advertised. Ultimately, I think watchmakers

know that the main reason the brands are using sil-

icon more often is that it is inexpensive and easy to

produce.

Fig. 7. Illustration of the Caliber 400 escapement.

Used with permission https://www.oris.ch/en/press/detail/184/oris-aquis-date-calibre-400

Fig. 8. The escapement of the Caliber 400 with lubrication poorly applied.

Horological Times 19Technical Discussion: Oris Caliber 400

Certainly, the escapement continues to be antimag- Without the escape wheel in the watch, the pallet

netic (a fact they advertise heavily), but the third advan- can swing freely from side to side, well beyond the

tage is where Oris has made some drastic changes. normal travel of a pallet in a watch. This is because

In a traditional Swiss lever escapement, the pal- the banking is built into the pallet itself. Instead of

let has two adjustable ruby stones. The only reason an oversized locking face, they have designed a pre-

they are adjustable is because with traditional meth- cise locking notch in the pallet. The tooth bottoms

ods, it would be nearly impossible (or at least in- out in this notch, limiting the pallet’s travel. This is

credibly expensive) to machine the escapement with the first time I have seen this feature in an escape-

enough precision to eliminate the need for adjust- ment, and I don’t even know what we should call

ments. With silicon components, however, you can it. It fills the role of both the locking face and the

achieve amazing precision very inexpensively. Think banking surface.

about it: every year the computer industry manufac- I am curious to see how these escapements will

tures billions of silicon chips, each with millions of hold up over time. The banking action is the most

capacitors etched onto the surface with precision forceful of all the escapement actions. Normally that

that rivals anything required in a mechanical device. force is exerted away from any of the critical areas of

Using photoetching, two-dimensional components the escapement. In this design, however, the force is

like the escape wheel and pallet can be inexpensively absorbed by the escape wheel teeth. Will they hold

and precisely produced. Precision is the key word. It up? Only time will tell.

is easy to achieve precision of better than 1 micron Overall, it is exciting to see this type of innova-

with photoetching. In addition to the adjustable tion in a brand’s initial caliber. I think the Caliber

pallet stones, the traditional escapement has either 400 will withstand the test of time. It seems to be de-

banking pins or banking surfaces that limit the mo- signed with modularity in mind. We have already seen

tion of the pallet. This new escapement from Oris Caliber 401 with a sub-seconds, and I expect we will

does not have any traditional banking surfaces. see more complications added to this watch as well.

Fig. 9. The notch for locking and banking. Fig. 10. The escapement showing the tooth locked in

the notch of the exit stone.

Jordan P. Ficklin graduated from the Lititz Watch Technicum with a WOSTEP diploma in 2006. He is a co-owner of the

Cincinnati Watch Company where he designs and assembles watches, and the owner of Cincinnati Watch Repair, an indepen-

dent watch service center meeting the needs of the microbrand and collector communities.

20 March 2021RAPIDLY

GROWING

COMPANY

VORTIC WATCH COMPANY

SEEKING

The Smithsonian Magazine ranked Columbia, PA,

among the top 20 best small towns to visit in the United

States, in part, because of its strength in history.

The National Watch &

Clock Museum provides

a wealth of information

about the art and science

of timekeeping. When

you can’t visit the museum,

Visit NAWCC.ORG

check out the webinars and and click EVENTS

podcasts about horology to view upcoming

for everyone who loves

events and classes.

watches, clocks, and all

things to do with keeping

Contact the Education

time. Listen on Spotify, Department

iTunes, and Sound Cloud. at 717.684.8261, ext. 237

or education@nawcc.org.

Lititz Precision Products offers high quality

equipment for the watch repair

MATADOR 4000 Watch Freedom Ultrasonic Lititz Precision Lititz Wet Pressure

Cleaning Machine Small Parts Cleaner Preciso 47 Watch Tester

Introducing the ultimate Lititz Precision's NEW Preciso 47 heat Wet Pressure Tester for

in manual watch cleaning Freedom affordable source for testing watches, made in the USA

machines. Matador 4000 ultrasonic small parts condersation , 120v, by Lititz Precision. Tests up

from Lititz Precision Products cleaner saves you made in the USA by to 125 Bar.

consists of four stainless steel thousands of dollars! Lititz Precision. 550.000 $3,29500

cleaning/rinsing cups with 590.985 $7,49500 590.767 $43900

one movable ultrasonic

transducer head and a

variable speed/variable

temperature dryer.

590.874 $2,99900

590.874 590.985 590.767 550.000

1-800-487-0408 | CASKER.COM

SERVING JEWELERS & WATCHMAKERS SINCE 1927

Horological Times 21WHY CHOOSE ECKCELLS? STEP UP to the ultimate, fully programmable

six-jar cleaning machine.

“I have been a watchmaker since 1983, and the Wellner THE WELLNER L1 CLEANING MACHINE

Customer Comment:

MADE IN GERMANY

cleaning machine has the widest range of programmability,

best cleaning ability, most complete drying ability, and

quietest operation of any cleaning machine I’ve had the

One machine

opportunity to use. Superior engineering is evident at does it all!

every point in both software and hardware. The fact Quietly cleans,

that it keeps track of how many washes for each jar of rinses, and dries!

solution makes for the greatest ease of serviceability. It is

as if a watchmaker designed the machine to suit modern For more information

on pricing, options, and

production efficiency and the highest performance standards. ” delivery, please contact

~Stan, an AWCI member Jack Kurdzionak

603-726-7646

eckcells@gmail.com

Order line open 9 a.m.- 4 p.m., Mon-Fri, 603-726-7646

Email orders and/or questions ANYTIME to eckcells@gmail.com www.eckcells.com

Show off Your Passion for Horology-and AWCI!

Wear These with Pride! SHOP NOW

www.awci.com/online-store while supp

lies la

st!

Horology T-Shirt Become a m

ember

and save!

Cotton/Polyester Blend AWCI Shoulder Bag

Available in S, M, L, XL Regular $30

$25.00 – members get free shipping Members $27

The AWCI shoulder bag is the perfect

companion to keep everything organized,

secured, and readily accessible when away

from the shop. Constructed with 600 denier

polyester fabric for long-term durability, there

Patches is a roomy main compartment with pockets

and storage slots for electronic devices,

Sew on your apron or lab coat pens/pencils, small tools, business cards, and

$5.00 – Members Only supplies. Handy outside storage pockets can carry larger items. A key clip, durable snap buckles, and

a removable shoulder strap add additional versatility. The AWCI logo is embroidered directly onto the

Rocker $2.00 – Certified Members Only main flap, so it will remain visible for many, many years without peeling or chipping away.

Membership Pin Check out our website

$12.95 for these and other

great items!

If you need assistance, contact

AWCI at 513-367-9800.

22 March 2021From the Workshop

By Jack Kurdzionak, CW21, FAWCI

Single Rollers, Double Rollers,

and Their Roller Jewels

Previously, the study of roller tables and their jewels the large roller and can be used as a single roller or

was included in the curriculum of every watchmak- as part of a double roller which is comprised of the

ing school with good reason. A roller was, and still large roller and a small (safety roller). The American

is, a component of a balance complete that needs to watch factories used single rollers, one-piece double

be removed from the balance complete whenever a rollers, and two-piece double rollers. Some factories

balance staff is replaced or when a roller jewel be- called the large roller a roller table while others called

comes loose and must be secured with fresh shellac. it the roller.

If a roller jewel is broken or missing, the roller jewel

needs to be replaced with a properly sized new one, An Evolution of Skills in Roller Jewel and

and that involves removing and replacing the roller. Roller Table Services

A loose roller table also must be removed so it can be Because the skills needed to be a competent watch-

tightened to secure it to the balance staff. maker are constantly evolving, roller jewel and roll-

Roller table service was an integral skill needed by er table services have now moved from mainstream

a successful watchmaker, and it was a skill supported watchmaking to what I define as traditional or her-

by material houses and watchmaking tool suppliers. itage skills. There are numerous reasons for this evo-

At that time, material houses could supply roller lution. Watch manufacturers that supply spare parts

jewels in every size that a watchmaker would usually are no longer supplying every discreet movement com-

need. In addition to roller jewels, rollers complete ponent to watchmakers. Instead, they supply a larger

with roller jewels were available for just about every component of the watch that contains more than one

application. Tool suppliers contributed their support part. In the past, watchmakers could buy an individ-

with an array of specialized tools for servicing rollers. ual roller jewel. As time progressed, they had to buy

There were tools for measuring slots on pallet forks a complete roller with a jewel even if only the jewel

to determine the size of a needed roller jewel; roller was needed. Now, in many instances, the roller is no

table warmers for cementing roller jewels in place longer available except as part of a balance complete.

with melted shellac; special stakes and stumps for in- Possible rationales for this change might include

stalling roller tables onto the balance staff; and roller requiring fewer items for the spare parts department

tightening tools for adjusting loose double rollers. to stock, and a faster, simpler repair for the watch-

As I was writing this article, I realized that roller maker. If you need to buy a roller table for a modern

nomenclature could be confusing, so before proceed- movement made by ETA or Sellita, I can tell you

ing any further I will clarify what a roller is. Unlike that part is no longer available except as a component

the Swiss Ebauche Cartel, the American watch fac- of a complete balance.2 A missing or broken roller

tories did not have a unified system to either name jewel necessitates the purchase of a complete balance

or number their spare parts. Each factory used its except for a few luxury watch manufacturers that

own name and numbering system. While there were still supply a roller. It is no surprise that, because of

many commonalities in terminology, there were also these changes in material, many watchmakers have

numerous variations. Donald de Carle1 defines the little or no experience with roller service. The “tra-

roller as a disc with an impulse jewel (roller jewel or ditional” skills are just not required to service most

pin) that is attached to a balance wheel. This disc is mechanical watches produced in the past 30 years.

1. Donald de Carle, Watch and Clock Encyclopedia (Bonanza Books, 1977). 2. The same can be said for balance staffs, which are no longer available for ETA or Sellita balances.

Horological Times 23Column: From the Workshop

But for those watchmakers Fig. 1

who wish to service vintage

and antique watches, there is

no substitute for those skills.

You cannot call your favorite

material supplier and order

a new single roller for an 18

size Hamilton movement. You

need to repair it.

Types of Rollers and

Roller Jewels

As part of this larger story,

it helps to explain the var-

ious types of rollers and

roller jewels. At one time I

assumed that every watch-

maker was familiar with the

various configurations for

rollers until a watchmaker,

with decades of experience, Fig. 2

called to place an order for

an American pocket watch

balance staff. This staff was

made in both single and

double roller variations, so I

asked for the type of roll-

er in his watch. He replied

that it had a single roller, so

I supplied a staff for a single

roller balance wheel. After

he received it, he called to

tell me I had supplied an in-

correct staff. I was certain

I had sent the correct staff so

upon further conversation, I

realized he had a one-piece

combination double roller

rather than a single roller.

I exchanged the first staff I

had sent for the correct staff

and was once again reminded that accurate terminolo- pocket watches and wristwatches, Figure 1.3 These

gy is critical when ordering parts. In this case, a double were gradually phased out beginning in the late 19th

roller was a single part rather than a single roller. century until they finally became obsolete around

Perhaps better than detailed, written explanations, 1925. Double rollers were first used exclusively in

a series of pictures can illustrate the various roller the top-grade watches of most companies before

configurations and their matching pallet forks. Single they gradually replaced the single rollers in all other

rollers were most commonly found in old American grades and sizes of watches, Figure 2.4

3. Waltham Watch Company, Watchmaker’s Handbook. (Waltham, 1945), 11.

4. Waltham Watch Company, Watchmaker’s Handbook. (Waltham, 1945), 12.

24 March 2021The single roller did double Fig. 3

duty by supporting the roller

jewel and preventing the es-

capement from overbanking,

Figure 3.5 The roller jewel itself

is similar in profile to what is

used in a double roller, but it

may be somewhat longer. The

roller jewel’s function is to

unlock the escape wheel and

transmit energy from the pallet

fork to the balance wheel. The

passing crescent6 at the edge of

the roller provided the safety

to prevent overbanking. The Fig. 4

upright guard pin on the pal-

let fork blocks the pallet from

accidentally moving from one

banking pin to the other when

the roller jewel is not in the pal-

let fork slot.

The double roller serves

the same dual purpose but sep-

arates the two functions. The

large disc of the double roller

also supports the roller jewel,

and the overall appearance of

the disc is similar to a single

roller, but without the passing

crescent on its edge. The small-

er disc is the safety roller, which

is circular with a passing cres-

cent on its edge. The two rollers

are mounted in parallel planes

on the balance staff. Older

watches often had two-piece

double rollers, the discs of which were separated by a times, the safety roller blocks the pallet fork from

bushing or a shoulder on the balance staff, Figure 4.7 accidentally moving and overbanking. If both roller

One-piece double rollers have the two discs separated types perform the same function, why did the manu-

by a bushing integral to the two rollers, Figure 3. facturers transition to the double roller, which is more

Either execution—single roller or double roll- expensive to manufacture and not as easy to adjust?

er—performs the same function, which is to prevent The answer is clear: a double roller is far more reli-

overbanking of the escapement. The small safety able than a single roller. Due to the geometry of the

roller also has a passing crescent which is positioned two designs, the single roller guard finger was likely

directly in line with the axis of the roller jewel. The to bind on the edge of the roller table and stop the

passing crescent permits the dart (guard pin), po- watch more often than it would on a double roller.

sitioned beneath the pallet fork slot, to pass as the Also, the single roller guard finger could bend slight-

roller jewel is engaged with the fork slot. At all other ly and cause the escapement to overbank.

5. Henry B. Fried, The Watch Repairer’s Manual (New York: Van Nostrand, 1961), 96.

6. De Carle defines this as, “The hollow cut into the edge of a roller to permit the passage of the guard pin.”

7. Henry B. Fried, The Watch Repairer’s Manual (New York: Van Nostrand, 1961), 96.

Horological Times 25Column: From the Workshop

Asking the Right Questions roller to the staff. On occasion, a small piece of hair

Whenever I service an antique or vintage watch has been used to tighten a roller onto a staff. None

movement, I always pay close attention to the roller of these methods are acceptable. The roller must be

jewel and work through a series of questions. Is it either properly tightened for a secure friction fit or

the correct width? Too wide and it will bind in the replaced with a new one.

fork slot. Too narrow and power will be wasted. Is

its length OK? Too long and it could touch the dart Then and Now

of a double roller and stop the watch. The length of Please do not, for one moment, believe that every old-

the roller jewel for a single roller is not as critical as time watchmaker was a highly skilled craftsman or,

it is for a double roller. It needs to be long enough in today’s lingo, a highly skilled craftsperson. There

to function and a little extra length is not detrimen- were skilled watchmakers then and there were others

tal. Is the roller jewel secure or loose? A loose roller who probably wished to have been doing something

jewel wastes power and causes very erratic timekeep- else besides watchmaking. The late Irving Cohen, a

ing. Eventually if it falls out of the roller, the watch watchmaker as well as Boston’s most knowledgeable

will stop. Is it even a jewel? Although not common, material dealer, told me that the majority of Boston’s

someone has occasionally installed a steel needle or a watchmakers of his era (1912-1994) could not install

filed brass pin into the roller table to replace a jewel. a roller jewel. When they needed a roller jewel in-

Although these substitutes will function, they will stalled, they went to Cohen or one of a handful of

not work well or for an extended period. They need other watchmakers8 who had the necessary skills.

to be replaced with a proper roller jewel. Is the sin- Irving and his contemporaries who had those skills

gle roller table cracked? Old steel rollers were often have all passed away. For today’s watchmakers who

very hard and hence quite brittle. If they were forced wish to service vintage and antique watches, the

onto a staff that was slightly oversize, they often skills needed for roller and roller jewel service are a

cracked and could become loose on the balance staff. necessity.

Cracked rollers must be replaced. Finally, is the roller During the past several months, I have received

cemented to the balance staff? If so, it should not several requests from readers to explain how to select,

be. An adhesive, such as crystal cement, Super Glue, fit, and cement roller jewels. Watch for these topics

epoxy, or shellac, may have been used to cement the in an upcoming issue.

8. Irving’s father, Abraham (1885-1968), worked with Irving and was known in Boston as “The Watchmaker’s

Watchmaker” because he possessed almost every special skill needed by watchmakers of his era and was

always willing to assist his clients with difficult repairs.

Jack Kurdzionak, watchmaker and watch material specialist, owned a Boston-area watch sales and service shop for 40 years.

He has a BS (Northeastern University, 1967) and has studied at ETA, WOSTEP, BHI, SGUS, and AWCI, and works for Eckcells

Watch Materials.

26 March 2021Make a Fresh Start!

Let AWCI’s resources refresh your business.

Referrals. A great benefit of being an AWCI member is being in the Find a Professional directory.

Customers can find you simply by visiting www.awci.com or calling AWCI’s office. Let people know

your specialties and your certifications. It’s time to update your directory listing now!

Technical Guides and References. Don’t waste valuable time searching for the information you

need to complete a repair. The Technical Guides and References database is comprehensive, with

everything from Accutron to Zenith. No need to search all over the Internet for a tech guide when

we’ve got them all in one place—easy to download or view on screen.

Marketing Materials. Downloadable marketing materials on the website, such as an AWCI

window sticker and an AWCI Certified logo, will let customers know that you are honest,

reliable, and the best!

Horological Times. HT not only keeps you informed about changes in the industry, it

also is the best place to advertise. Use the classifieds to find a job, hire an employee,

or buy or sell equipment. Or use a display ad to advertise services and products

watchmakers and clockmakers use.

www.awci.com is the website you should be using in 2021!

would you

like to read

what makes

brits tick?

The Horological Journal – published monthly

without fail since 1858 – gives you exclusive

technical articles and practical updates on clock

and watch making.

You’ll find news on the latest issue and

how to get it at www.bhi.co.uk

Horological Times 27Your watch or clock is valuable.

Why take chances?

Your local AWCI Certified watchmaker and clockmaker are

dedicated to competent and professional service.

For more than 60 years, the members of the American

Watchmakers-Clockmakers Institute (AWCI) have

been providing the highest quality of care and service

for watches and clocks. Please use our professional

directory to find a watchmaker or clockmaker near you.

www.awci.com/find-a-professional

Find your local AWCI Certified watchmaker or clockmaker by visiting www.awci.com.

American Watchmakers-Clockmakers Institute

Phone: 513-367-9800, ext. 303 * Toll-Free: 866-367-2924 www.awci.comYou can also read