Freestanding Pellet Stove with Water Jacket 2-12 kW

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Freestanding Pellet Stove

with Water Jacket

2-12 kW

visioncomfort EKA

¾ Fully-automatic, modulating low-energy central heating (in the dwelling)

¾ Individual colour choice

¾ Higher safety (air-lock, discharge chute as standard …)

¾ Higher efficiency (15 % radiation, 85 % water capacity; efficiency rate of up to 94 %)

¾ Higher comfort (patented self-cleaning stainless steel comb grate)

Wood pellets according to ÖNORM M 7135 and DINplus

• Large integrated pellet hopper

• Fully-automatic, flexible fuel supply (optional, retrofitable) from

the pellet storage into the dwellingA CO2-neutral Fuel for a sustainable Future

Wood fuel has been used by humans for thousands of years. It is clean

cheap and non polluting, the ultimate environmental friendly fuel. Wood

fuel is CO2 neutral: CO2 released through combustion is captured by the

growth of next years forests. Our boilers tap into this cycle of nature,

warming your home with out harming the environment.

All your Requests ...

will perhaps not be fulfilled by us. However, we help you to feel

comfortable at home.

The visioncomfort EKA pellet stove with water jacket (= central

heating boiler) embodies a perfect combination of modern design,

sensual romance and comfortable heating technology.

Efficient central heating in a low energy house or elegant additional

heating – visioncomfort EKA is always a visual pleasure and an eye

catcher in any living room. A vision was born

Our Promise

The sustainable exploitation of natural resources demands responsibility,

heart and creativity. Our specialists have a decade of experience and

research expertise. This contribution to a livable energy future is a

promise to our customers and the next generations: We are doing

everything to ensure further development of non-polluting heating

systems and the generation of new ideas. This is one of the reasons why

we were honoured with the „ENERGY GENIUS“ innovation award by the

Austrian Federal Ministry for Environment.

Fuel from the Region

Wood fuel is plentiful in Europe and usually available from local

source providing security even in times of an energy crises.

Locally produced fuel boosts the local economy, and short

transport routes reduces road trafic and pollution.

High-quality pellets (certified according to ÖNORM M 7135 and

DINplus) are important for an efficient combustion. Regional

forest enterprises, pelletising factories and retailers take care

that the availability will cover the whole country.

2Low-E and stable Ignition

The pellets are ignited using an

electric ceramic heating element

(see picture). Air is heated by being

blown over the element and onto

the pellets in the combustion

Glow-Ignitor

chamber which ignite within a

couple of minutes. The system is

simple, reliable and has a low power

consumption.

Patented Grate Cleaning

The quiet stainless steel comb grate

ensures a regular, automatic deslagging

and ash removal as well as permanent

week-long operation and at the same time

Tilting Grate provides for highest operating efficiency

and ideal comfort. Due to the conical

burnout funnel, unburnt parts slide again

into the hot combustion chamber – giving

low ash development and consistent high

efficiency.

Burnout Funnel

Reliability and Safety

The device provides a comprehensive

safety package (standard airlock, Ruby Inox Azur Mint Beige Honey

discharge chute, upstream screw, (Standard)

active temperature control, adaptive

device control) in order to prevent

backburning into the hopper. Chose your individual Colour

An optional electrical heating rod can

be inserted into the boiler to prevent Since every living room is individually designed,

Air-Lock Unit freezing if not in use for prolonged you should also be able to adapt the colour of

periods over winter. your stove. For only a small surcharge you may

chose any available RAL colour.

Efficient Heat with a Breeze of Romance

Only about 15 % of the heat is released by radiation throughout the window in the front door directly into the

dwelling. That means, your living room will never get too hot, but will always be well temperated – Efficiency

combined with the romantic magic of fire!

Intelligent Device Control visioncontrol

It is important to dimension the boiler correctly, i.e. the boiler must be

chosen according to the calculated heat requirement. During operation,

the intelligent, capacity-modulating control unit ensures fine

adjustment. In combination with an exterior temperature control,

a maximum heating comfort and an ideal operating efficiency will be

achieved. Boiler capacity and combustion performance adapt in a

modulating way to the current heat requirement. Higher comfort and

higher operating efficiency thanks to more intelligence!

3Flexible Pellet Conveying System visionconvey AIR

The new visionconvey AIR suction conveying system provides a number of various application and combination

options for a comfortable automatic operation (see below). The flexible hose line (up to 15 meters horizontal and

5 meters vertical transport distance) permits a gentle pellet transport either from a basement storage room, from

a fabric tank or from an external terrestrial tank into the integrated hopper (capacity of about 50 liters) of the

boiler. A short insertion screw conveys the pellets to the standard air-lock, where fuel is dosed in a performance-

related way. Then pellets fall into the combustion chamber via a discharge chute. It is of course possible to

retrofit the automatic visionconvey AIR suction system.

Screw / Suction Combination

Fabric Tank / Suction Combination

4Individual Choice of the Room used for Pellet-Storage

Most pellets storage rooms are situated in the

basement. However, it is also possible to store the fuel

on other levels of the house. Ideally, the storage room

is a room with an external wall in order to ensure an

easy filling by means of two STORZ couplers. A tilted

bottom (with about 35-45° inclination) supports the

slipping of the fuel. Please comply with the technical

documentation and with the effective fire protection

regulations (e.g. TRVB H118).

The flexible visionconvey AIR pellet suction conveying

system allows for various storage options, satisfying

individual needs.

Integrated Pellet Hopper (Intermediate Hopper)

As with a log basket beside a traditional fireplace containing a

days worth of fuel, the visioncomfort EKA utilizes of an integrated

pellet hopper with a capacity of about 50 liters (= 35 kg pellets).

The hopper may be filled manually or may be combined with the

automatic visionconvey AIR pellet conveying system.

The visionconvey AIR system will automatically fill he hopper

as and when required.

Fabric Tank (GEObox) Terrestrial Tank (GEOtank)

The fabric (woven) tank was Due to its compact and solid

developed especially for construction, the terrestrial

in-house storage. Because tank (volume up to 11 m3),

of the simple assembly, the which has no grooves and

tank will be delivered in joints, is designed for exter-

separate parts. nal underground storage.

Due to its maximum size of The specially developed

2,5 x 2,5 meters, it can be discharge system ensures

installed in nearly every room. an efficient conveyance of

The fabric tank is adjustable the pellets into the heating

for heights between 2 and room. The inclined bottom

2,5 meters and thus may surfaces, which are aligned

individually be adapted to with the angle of repose of

room height. the filling material, ensure a

continuous conveyance.

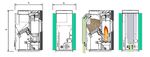

5Defined Technology: Reliable, Safe, Innovative

(1) Fireclay pellet combustion chamber

(2) Stainless steel grate (automatic self-

cleaning comb-grate)

(3) Thermo sensor

(4) Front door with temperature resistant window

(5) Water heat exchanger (and E-heating

rod position)

(6) Pellet hopper

(7) Upstream screw with drive

(8) Air-lock (backburning prevention)

(9) Discharge chute into the combustion chamber

(10) Low-E glow ignition

(11) RPM controlled draft fan

Examples for

(12) Mainboard (Microprocessor Control) individually designed

sideboards (airbrush)

(13) Standard ash box

(14) Side board (covering) with insulation

(15) Device control panel (with LCD display)

6Technical Data

TYPE EKA 6 EKA 9 EKA 12

Nominal Capacity 6,0 kW 9,0 kW 12,0 kW

Capacity Range 2,3 – 7,8 kW 2,7 – 9,0 kW 3,6 – 12,0 kW

Fuel Wood Pellets according to ÖNORM M 7135 and DINplus

Device Control visioncontrol; modulating micro-processed boiler control unit with

thermo sensor, flexibly upgradeable i.e. with an exterior

temperature, heat distribution or remote control

Measures (hxbxt) about 1050 x 600 x 700 mm

Boiler Weight about 160 kg about 160 kg about 160 kg

Efficiency Rate up to 94 %

Radiaton / Water Output Rate up to 15:85 %

Chimney: Smoke Tube Connection Ø 100 mm

Flue Gas Temperature 140-160°C

Min. Draft Requirement 0,05-0,15 mbar

Boiler Water Volume about 20 l

Combustion Insertion grate-combustion, high-quality fireclay

Permanent Operation, Grate Cleaning Patented, automatic deslagging and de-ashing by means of

stainless steel tilting comb-grate

Ignition Automatically by means of a glow-ignition (about 270 W)

Ash box 2,8 l

Integrated Hopper about 50 l (35 kg)

Burning Duration of 1 Hopper Charge Depending on heat output, max. 70 hours

Automatic Hopper Refilling Yes, flexible pellet supply with visionconvey AIR (suction conveyor)

Reverse Flow Mixing Valve (RFMV) External RFMV mandatory (minimum reverse flow temperature 55°C)

Safety Functions Upstream screw, discharge chute, air-lock, STL and optional

electric heating element (preventing freezing of system)

Accessories Automatic fuel supply, room device/remote control, mixing valve,

electric heating element, sideboards in different colours and

different individual design etc.

7Further products …

Special Pellet Boiler PN 15, 23, 30 kW

(51000, 78500, 102000 BTU)

• Fully automatic (ignition, energy modulation, draft-fan ...)

• “PEC” permanent emission control (lambda-probe)

• Automatic self-cleaning stainless steel tilting grate

• Centrifugal de-ashing,

• Modular heat exchanger

• Flexible pellet feeding kit (120/200 L adjoining hopper,

4x4 m screw or 20 m vacuum suction)

Logwood – Gasifier VN 22, 33, 44, 55 kW

(75000, 112500, 150000, 187500 BTU)

• ½ meter wood logs (firewood), 150-300 L loading volume

• About 6-7 hours continuous operation with only one load

• Stainless steel combustion grate

• Flue gas outlet (insures a smoke free fuel insertion)

• “PEC” permanent emission control system (lambda probe)

• 8 mm high-quality steel

Low-E Pellet Boiler CKA 6, 10 kW

(20500, 34000 BTU)

• Fully automatic (ignition, energy modulation, draft fan ...)

• “PEC” permanent emission control (thermo sensor)

• Patented quiet self-cleaning comb-grate

• High operation safety (integrated air-lock, adaptive control unit)

• Small space requirements (< 0,4 m2)

• Flexible pellet feeding kit (15 m horizontal, 5 m vertical distance)

Combi Boiler for Pellets & Logs TDA 15, 25 kW

(51000, 85000 BTU)

• Fully automatic (ignition for both fuels types, energy modulation,

draft fan ...)

• Automatic fuel recognition (no manual switch-over necessary)

• About 6-7 hours continuous operation with only one load

• Two stainless steel combustion grates (tilting grate for pellets)

• “PEC” permanent emission control system (lambda probe)

• Flexible pellet feeding kit (120/200 L adjoining hopper,

4x4 m screw or 20 m vacuum suction)

All our products are certified by authorized test institutes such as BLT Wieselburg, TÜV Bavaria,

ÅFAB Sweden or TGM University of Vienna according to EN 303-5. The efficiency rate goes up to

94 % due to clean combustion and low emissions (about 90 % reduction in relation to EN 303-5

standard).

Distributor:

sht-Heiztechnik aus

Salzburg GmbH

Rechtes Salzachufer 40

A 5101 Salzburg/Austria

Tel. +43-662-450444-0

Fax: DW 5/9

e-mail: info@sht.at

Misprint, technical changes and errors reserved 03-V1/2006

8You can also read