Dynasty - Automated 3D Printing: The Future of Production - Automated printfarm - Mass Portal

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Automated

Dynasty AMS overcomes the bottleneck of desktop 3D printing

by automating workflows for parallelized production of parts

or for semi-unattended printing of individualized objects.

Print Job Automation Materials Versatility

Dynasty AMS is the best answer to many The Dynasty AMS is designed from the ground

challenges in the low volume plastic products up to be ultimately flexible with material

industry — cost per part, initial tooling cost, choice — open materials from independent

personalization, excessive manual labor, pre- vendors can be used. Smart material dryers are

production re-engineering and more. integrated into FabControl® Workflow.

Bilde no priekšas

EXAMPLE APPLICATIONS

DENTAL CLEAR ALIGNER MOLDS FLEXIBLE SEALS AND GASKETS MATERIALS / APPLICATIONS

Automated system for production Production of low-volume custom TESTING

of molds for dental clear-aligners seals and gaskets for custom Automated system for development

— high geometrical precision prints hydraulics / pneumatics applications. / testing of material properties and

of similar, but individual models. Direct feed hotend option. printing applications. Integrated

Automated job preparation, slicing, reporting allows for automated data

printing, storage is provided. END-USE PRODUCTS entry for experiment analysis.

Production of customized end

ASSISTIVE DEVICES use objects. Simultaneous multi- SHARED PRINTLAB

A dual-material, dedicated system for material printing allows for tailored A mix of system capabilities for

production of end-use orthodontic performance of products such as 3D multiple applications in shared-

assitive devices. Integrated slicing, printed loudspeaker systems or shoe service environments such

material (PA6 / PLA) selection. inserts with personalized features. as printing shops, Fablabs or

educational laboratories. Material

use management and reporting.Modular. Adaptable. Scalable.

The Dynasty Additive Manufacturing System (AMS)

is an adaptable solution for low volume plastic production.

The system is built as a modular, extensible platform.

3D PRINTING UNITS PRINTER RACKS MATERIALS MANAGEMENT

Heavy duty versions of the Up to 21 Pharaoh 200 printing units Integrated smart materials drying,

Mass Portal Pharaoh 3D printers can be stacked in a single rack for storage and feeding system ensures

are the basis of the system. single sided configuration. material stability and availability.

Dryer rack Automation gantry with printer units Storage rack

Automation control Notifications Automatic job distribution

Automatic transportation of printbeds Configure the notifications sent out Distribute print jobs based on the

from the printer to the storage rack by the printfarm, such as running out printfarm machine configuration.

and exchange for new printbeds on of filament, order completion, storage

the printer. status and when operator attendance

is necessary.

Storage control Print job management Connect to online workflows

Follow storage status with estimate Print job management based on the Operate the printfarm in either online

time when it will be full. FabControl® Workflow. Schedule print operation mode with ability to add

jobs and estimate order completion. print jobs via FabControl® Workflow

or completely offline.FabControl OS

Easy touch screen control of printers & dryers

Deep control of system settings is accessible with just a few taps,

connection to online database of materials printing & drying settings

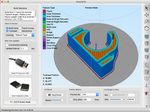

G code Preview Job Info File Transfer “Single-click” Precheck Overrides

Renders actual Print file name, Wireless workflows Check g-code Override

gcode on date or custom using FTP, via 3D printing file before temperature

screen, giving text in front of FabControl® workflows with printing and many other

you a visual way the printed part Workflow or embedded settings during

to check the file on the print through direct slicing for printing

before printing platform USB connection customised

or memory stick production

Simplify3D

Simplify3D’s advanced 3D printing

software allows deep control over

printing parameters, empowering you

to achieve highest print quality. Mass

Portal printers come with a full license.FabControl Workflow

Integrated systems management and workflow

Centralized information, notifications, system and job statuses

for all connected Mass Portal dryers & printers

Job Progress & Schedule Monitor Printers & Dryers Notifications

Add and schedule print jobs View machine status, built-in Receive notifications from all

using FabControl® Workflow. camera feeds from printers, your devices to your e-mail or

Completed jobs are archived and remotely control the via SMS — status change and

and logged automatically. systems when needed. operator attendance request.

Print Archiving & Reports

Print data can be

automatically uploaded to

the FabControl® Workflow

system.Open Materials

Work with most open-materials thermoplastic filaments

Processing temperature range of thermoplastics, °C

Maximum hotend temperature up to 475°C

Heated printbed temperature up to 120°C

Controlled printing environment

High airflow part cooling

Wrist Orthosis Loudspeakers CV Joint Boot Gear

3D printing can be Designed by Audiolens Replacement of a Example replacement part

used to produce with an aim to reduce constant velocity joint of a broken gear using

custom-made brace, interference anomalies. boot we selected FormFutura’s ApolloX™,

splint, or other artificial The open-cell internal DuPont’s material which combines good

external devices baffle structure provides Hytrel®, which combines strength and processability.

serving to support the a reduced weight the flexibility of rubber

limbs or spine. while maximizing the and the strength of

efficiency, while the non- plastic.

parallel walls lessen the

booming resonances.

Material by Material by Material by Material byDrying & Conditioning

Unlock the full potential of 3D printing materials

3D Benchy printed with undried and dried filament — same settings, same g-code, same hardware

Stable Processing Better Mechanical Fewer Cosmetic

Ensure a more stable Properties Defects

and reliable printing Reduce delamination or Eliminate a number

process with moisture- even structural failure of of visual defects in

sensitive materials like 3D printed parts. printed parts caused by

Nylon, PC or TPU. excessive moisture in

materials.

Robot Gripper Automotive Part High-Resolution Prosthesis

Engineering-grade For the production The parts shown were 3D printed assistive

Innofil3D’s ABS Fusion+ of the air induction printed using Polymaker devices gave a chance

material allowed quick system of a car engine Polyplus™ with a 0.01 mm to live on for a white

design iterations and a high-temperature and nozzle in 1:1 scale to stork with both damaged

evaluation of robot high-pressure resistant regular watch parts. legs. We used durable,

vacuum gripper material is required. yet flexible Verbatim’s

performance. Nexeo 3D Solutions Primalloy™ materials

NOVAMID® ID 1030 to design an efficient

combines high strength end-use devices with

and good processability. customized properties.

Material by Material by Material by Material byAutomated 3D Printing: The Future of Production™ Dramatically lowering the barrier of entry for automated low volume plastic parts production, Dynasty AMS is a perfect example of Industry 4.0 thinking — the future of production Low Cost of Entry Success Ensurance You can start a Dynasty AMS Included with every Dynasty AMS deployment with a single, standalone deployment is a complete range Pharaoh desktop 3D printer in the of customer benefits, including R&D lab — or even in your home application scoping, development office, for prototyping, testing, and piloting, on-site operator training, development and planning. installation and service. 3/11 Pulka str., Riga, LV-1007, Latvia E-mail sales@massportal.com MassPortal.com Document version: 09.05.2018

You can also read