Winter 2021 - Department of Defense

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

NEWSLETTER

Winter 2021

Rear Adm. Peter G. Stamatopoulos,

SC, USN

Commander

Naval Supply Systems Command

and Chief of Supply Corps

Kurt Wendelken

A Message from the NEWS FROM THE Vice Commander

Chief of Supply Corps Command Master Chief Naval Supply Systems Command

Capt. George E. Bresnihan,

SC, USN

Chief of Staff

Our supply community stayed the course while facing unprecedented logistics challenges Naval Supply Systems Command

during 2020. It was incredible to witness your unrelenting commitment to mission success Supply Family,

throughout the year. We must continue to win every battle we face and be prepared to flex as It’s a chilly winter here in Mechanicsburg, but we’ve only had one substantial snow, so I’m count- CMDCM (SW/NAC)

needed to meet existing and emerging mission requirements. ing it as a win so far. Shannon Howe, USN

This issue highlights our supply team’s contributions to the expeditionary and special operations Command Master Chief

A critical achievement to come out of 2020 was the establishment of Naval Sustainment

teams. I found it a bit daunting to pen this letter, but I know our talented public affairs team has pre- Naval Supply Systems Command

System- Supply (NSS-Supply). The Navy requires a single, strategic-scale, sustainable design

pared a brilliant spread that will go into greater depth.

for Navywide supply chain management with the right mix of commercial and organic activities

So, what do you do when you’re daunted by the unknown? Well, I read and read some more. And The Navy Supply Corps Newsletter (ISSN

to project and sustain the force required for warfighting. NSS-Supply is designed to unify then, I made some calls and connected with those who have lived it. Thank you for your input! 0360-716X) is published quarterly by the Naval

numerous independent supply chain functions with NAVSUP oversight to improve readiness My assessment is that it takes a special breed of officer, enlisted, and civilian supply warrior to Supply Systems Command, Code NOCC, 5450

and affordability. To create the supply chain performance the Navy needs, it is imperative that Carlisle Pike Suite 309-112, Mechanicsburg, PA

support the expeditionary and special operations commands. It takes a special kind of determination

17050-2411. Contents will under no circumstances

we align and manage all Navy supply chains, end to end, ensuring deliberate and coordinated and an unrelenting code of ethics when one is handed sometimes a complete unknown, in a warzone, to be construed as altering or superseding official

decision-making. “make it happen” when mission accomplishment means life over death for many of these warriors. instructions or as endorsing a company service

Moving forward requires an integrated, strategic approach to Navywide supply chains that I spoke with many to gather notes: officer, enlisted, and civilian. I asked them to tell me a little bit product or enterprise. Periodicals postage paid at

about their story and impact that supply experts make in these communities. Mechanicsburg, Pa., and additional mailing offices.

provides the process capabilities we need to achieve and sustain required mission performance. The Secretary of the Navy has determined that this

NSS-Supply success depends on all hands, at all levels, to be all in. Below are some of their words. Let their thoughts soak in and enjoy this edition of our Navy Supply publication is necessary in the transaction of business

A number of the articles in this issue take a deep dive into NSS-Supply. They explain the Corps Newsletter. required by law of the Department of the Navy. Use

“Their job is non-standard because of the constantly changing mission set. Their primary mission is of funds for printing of this publication have been

finer details of the initiative to help you understand your role in strengthening the Navy’s supply approved by the Navy Publication and Printing Policy

ensuring the SEALs have what they need, when they need it.”

chains and sustaining global Navy power. The time is now for logistics excellence, to secure our Committee.

(The following is from a retired Navy captain friend talking about a young female ensign.) “She was

competitive advantage in operational logistics, and hone our leadership foresight to make critical Editorial Office: Send mail to Navy Supply

a 22 year old ensign, fresh out of college and heard, ‘Congratulations, you’re going to go work with the Corps Newsletter, Naval Supply Systems Command,

and effective decisions at all times. special operation forces (SOF). I need you to establish a relationship with customs officials so we can 5450 Carlisle Pike, Mechanicsburg, PA 17050-

This issue also features articles from Naval Special Warfare Command led by Rear Adm. Hugh get what we need.’ She hadn’t been trained for that. She immediately established an in-country net- 2411. Material may be reprinted if proper credit is

W. Howard, U.S. Special Operations Command, and Navy Expeditionary Combat Command. work which at one point included a once-a-week tea with the port authority in Dubai because that given.

Distribution: Navy Supply Corps Newsletter

These communities are vital as we align our efforts to prepare for great power competition against relationship meant that FEDEX and DHL would reliably get supplies to the warfighter.” is distributed to official Navy shore commands

emerging threats to U.S. national security. “The mission can’t be accomplished without logistics. You’re alone and unafraid alongside the Sea- and ships. Requests to be added to the distribution

Looking at the year ahead, we must continue our efforts to succeed in the rapid and efficient bees, making sure they have the right parts to build that school in Africa or that bridge in Uganda.” and changes of address for all except those holding

“We’re the jack of all trades: husbanding, contracting, money, inventory, fuels, food, laundry, mail, subscriptions should be directed to the Office of

delivery of supplies, services and logistics solutions to the warfighter. I’m confident that our Corporate Communications, Naval Supply Systems

community will dominate any and all challenges we are faced with during 2021. We are superb parts. We had our hands in everything, I worked alongside SOF, Army, Navy, Air Force, Special Forces

Command, or by calling (717) 605-5564, or via

pilots; the joint relationship was incredible.” email to scnewsletter@navy.mil. The Newsletter

at what we do. You each have a role to play but we must act together to achieve our full potential

“My favorite thing about the command was the positional authority. Rank didn’t matter, it was is also online at scnewsltr. dodlive.mil, and a .PDF

to guarantee mission success. version can be accessed in the eSUPPO app.

about experience and getting the job done. We were a fast and flat organization that got the job done

Thank you for your continued support as we improve the lethality of our forces across the with speed and camaraderie. You build rapport, you build family.” Subscriptions: For sale for $31 (domestic)/

globe through the warfighting advantage only the entire supply community–Supply Corps officers, $43.40 (foreign) by the Superintendent of Documents,

I have much more, but I’m limited on space. I wanted to share a little of their heart to help you Government Publishing Office, Washington, D.C.

enlisted supply Sailors, and civilians–can provide. understand the gravity of our end-to-end logistics impact around the globe. I’ll close with thanking Subscribe online at bookstore.gpo.gov and search

those of you out there willing to sacrifice and serve within these incredibly important communities. for Navy Supply Corps or call (202) 512-1800.

You give me yet another reason to be proud and humbled to be your NAVSUP Command Master Chief. Address changes for subscription holders can

be made by writing GPO Customer Service, P.O.

Stay safe and healthy and continue to take care of each other. Know that I’m here if you need any-

Box 371954, Pittsburgh, PA 15250-7954, calling

thing, career or otherwise. (202) 512-1806 or faxing (202) 512-2104.

See ya in the fleet, soon, I hope. All Day, Every Day! Postmaster: Send address changes to Navy Supply

Corps Newsletter, c/o Department of the Navy,

P.G. STAMATOPOULOS Code NOCC, Naval Supply Systems Command,

RADM, SC, USN 5450 Carlisle Pike Suite 309-112, Mechanicsburg, PA

17050-2411.

CMDCM(SW/NAC) Shannon Howe, USN

Command Master Chief

II III

Naval Supply Systems CommandTHE PROFESSIONAL JOURNAL OF THE NAVY SUPPLY CORPS

Winter 2021 NAVSUP WSS Commander Discusses

NSS-Supply Pillar

By Brian Jones

NAVSUP WEAPON SYSTEMS SUPPORT PUBLIC AFFAIRS

I

n October 2020, the Navy introduced component but I think, historically, we’ve added time, is driving delays in the process.

Naval Sustainment System (NSS) – Supply, tended to view the RTATs to be what the We have to eliminate that to the fullest

which seeks to streamline the Navy’s supply vendors tell us they can do. I think we need extent possible.

chains by decreasing maintenance turnaround to flip that on its head. We need to take the The last lever we can pull is material

times and increasing end-to-end velocity of mindset that says, ‘This is what I need in delays. We need to be driving the supply

spares in order to improve readiness and reduce terms of an RTAT. Can the vendor support chain or driving the repair process for com-

costs. that and, if not, how can we work together ponents so when they go in for repair and

NSS-Supply focuses on six key pillars to get to that point? Being a demanding get onto an artisan’s bench, the repair flows

to drive increased performance. Those customer is our first strategy. through smoothly without interruption.

04

pillars: Demand Management, Optimize Second, we need to do a better job of really Where there are piece-part requirements

08 Working Capital Fund Portfolio, Shape drilling into our data and understanding what for repair, we need to make sure, whether

Industrial Base, Optimize Organic Repair, the data is telling us. That way we can better its parts that we manage, DLA manages, or

Increase End-to-End Velocity and Achieve arm ourselves to enter into negotiations and parts that the vendor provides, that we

End-to-End Integration work in concert to have productive discussions with vendors have a good structure in place so that a lack

integrate and synchronize the end-to-end that really drive the RTATs we need. As an

supply chain. example, during our sprints we took a deep

Rear Adm. Doug Noble, commander, dive into a couple of specific components and

NAVSUP Weapon Systems Support (WSS) saw huge variations in RTATs. Sometimes it

is leading the Increase End-to-End Velocity took 30 days, sometimes it took 130 days. If

pillar. The admiral recently took time to you graph this data out you see very disparate

answer a few questions on the early stages trends in turnaround times for the same item.

of the effort. So you unpack that data to see why it’s hap-

Q: Where is NAVSUP WSS in the Increase pening; in some instances, what we’ve been

End-to-End Velocity pillar and what have treating as one set of repairs is really two.

you discovered so far? Sometimes there’s a simpler (and faster) level

40

of repair needed, and other times there is a

A: We officially started our end-to-end

much more complex (and longer) repair

velocity efforts in December with a series

needed. But until you get into the data and

of sprints, which are focused, two-week Rear Adm. Doug Noble, commander,

really look at what’s happening with your

efforts targeting specific initiatives or anal- NAVSUP Weapon Systems Support,

item, you really don’t have the insight. If

yses. The team just wrapped up the second reviews notes during a briefing in

you’re armed with the data, then you can

sprint, so now we’re focusing in on specific Philadelphia.

see that we should probably need to treat

pilots we want to use to test some of the

these as separate requirements. Rather than

concepts that were teased out during the

trying to plan and forecast our supply chain of piece-parts is not allowed to slow the

first couple of sprints.

based on a single RTAT value, we are repair process.

lthough we are still relatively early in

having multiple values depending on the From our initial analysis in the sprints,

our efforts, there are some themes and some

situation. When we’re not armed with the those are some examples of themes or big

big takeaways that have already started to

data and we don’t have visibility of what’s areas we need to get after to drive better

emerge.

happening, we limit our ability to effectively

Editorial Staff First, we need to be a more demanding

drive the outcomes we need. We find our-

outcomes along each of those lines of effort.

customer. When establishing contracts, Q: What is the goal for RTAT?

JANICE DERK

50

selves responding to the system rather than

when we’re engaging with industry or

Publisher when we’re talking to our organic repair

driving change, and we need to flip that A: Our goal is to get to 55 days. That’s

around. pretty aggressive. We’re currently averag-

MATTHEW MORRISON providers, we need to be very clear and very

Another strategy I’ll talk about is

demanding in terms of what we need. ing 110 days. We looked at commercial best

RUSSELL STEWART administrative delays. We have to be ruthless

Historically, we tended to focus on the practice benchmarks for similar items and

HANNAH RAINEY in driving out administrative friction, whether the comparable commercial benchmark is

LEE MUNDY quantity needed at the best price. We have

that’s internal Navy time, the time it takes 45 days. So, we have a comparison point

Editors not always placed as much focus on Repair

the requirement to flow through the system, that gives some confidence that our 55-day

Turnaround Time (RTAT) as a specific

LEE MUNDY or the time with the vendor or industry goal is within reason. It will take a huge

outcome. This is a generalization; it’s not

Layout & Design partner. All that white space, or non-value

the case for every contract or every ...continued on page 2

The Navy Supply Corps Newsletter 1culture change and a lot of work to get there,

both for us internally on how we approach

fleet is able to effect some change within

demand management where demands drop,

There’s a similar thread you can pull

with Optimizing Organic Repair. In our

What is NSS-Supply?

things, including our engagements with we’re going to be stuck with a bunch of pursuit to drive down RTAT and make the

industry partners. We can look at how inventory we don’t need or takes a very system work faster, we’ll also be asking

commercial industry does it and see they long time to burn down. what we can we do within organic repair

are able to do it in 45 days. That gives me a That flows directly into the next pillar that we’re not doing today, or as much of What is NSS-Supply?

sense of confidence that our goal to get to of Optimizing the Working Capital Fund today, as we could be. Does that mean • Naval Sustainment System-Supply (NSS-Supply) is a combination

55 days is a reasonable goal. Portfolio. That’s all about our financials having new or expanded capability within

Naval Sustainment System – Supply of commercial best practices, process improvements, governance

and making sure that we have a good cash our organic repair providers? It could be

Q: How does the Increase End-to-End and oversight to maximize efficiencies and effectiveness within

allocation and cash management structure figuring out how to better support those

Velocity pillar tie into the other pillars of available means.

to maximize readiness. The more I can put organic providers so they can move things

NSS-Supply?

dollars to those requirements that are going more quickly through the process by making “As we implement • A new “Supply Effectiveness Figure of Merit” (SEFoM) will be central

sure they have the piece parts required so NSS-Supply, we will to this effort; this is a new way of looking at supply performance.

the repair line can move without having integrate, orchestrate, The SEFoM provides data that can be applied to supply chains and

material delays.

and synchronize Navy- reveals where we can index readiness and cost.

So those are examples of how this

wide supply chains

complicated ecosystem all comes together Why NSS-Supply?

through NSS-Supply. among SYSCOMS,

• The Navy requires a single, strategic-scale, sustainable design for

Q: What are we going to realize with TYCOMS, organic and Navy-wide supply chains with the right mix of organic and commercial

NSS-Supply and, more specifically, with commercial repair activities to project and sustain a warfighting force.

the end-to-end velocity initiative? activities, and other • Governing end-to-end (E2E) Navy supply chains through collaboration,

A: By pushing all the levers within each of NSS efforts.” integration, and synchronization will amplify readiness.

these pillars, you can see they are all inter-

related in this complex supply chain. We

–Rear. Adm. Pete Stamatopoulos, • NSS-Supply is a crucial node of NSS, a Navy-wide initiative embracing

Commander NAVSUP industry best-practices tailored for specific Navy requirements and

want to have a broad-based approach to

get after multiple initiatives and push on fleet operations.

multiple lines of effort to drive improve-

ments at large and not just focusing on

one thing. There’s a balanced approach to Leveraging our supply chains to run more effectively and affordably to generate greater readiness.

NSS-Supply that ultimately, and at the

highest levels, effectuates an end-to-end

supply chain that is well integrated and is

Rear Adm. Frank Morley (right), director of Navy International Programs Office in responsive. We’re driving toward a supply

Philadelphia greets Rear Adm. Doug Noble, commander, NAVSUP Weapon Systems chain that is moving as quickly, agilely,

and rapidly as it can to meet the warfighter

Support (WSS). During the visit, Morley was briefed on NAVSUP WSS’s International

requirements and doing so in the most

NSS-SUPPLY FOCUSES ON

Programs Directorate, as well as, given an overview on NAVSUP WSS’s role within

cost-effective manner.

6 KEY PILLARS TO DRIVE HIGHER PERFORMANCE

Naval Systems Sustainment-Supply.

GOVERNANCE

Q: What are the next stages in End-to- NSS-SUPPLY and E2E Integration

End Velocity pillar?

A: I would describe NSS-Supply as a very to deliver readiness outcomes and don’t Govern, coordinate, and synchronize strategic supply chain decisions by leadership across Navy.

complex ecosystem. It has a lot of interde- have dollars tied up in non-productive or A: We’ve just finished our second sprint. As

pendent parts where changes in one area less productive areas, the better. If the we’ve gone through these first two sprints,

each of which is a two-week evolution, we

affect another. So, when we talk specifically demand management pillar is able to reduce Achieve E2E Integration

about increasing end-to-end velocity, the demand, but we’re stuck with excess inven- started by looking at all of our components

Integrate existing Supply Chain resources (i.e., neural network) to sustain the force.

initial focus is going to be reducing RTATs. tory because we have these long turnaround to find those high priority NIINs (parts)

In demand management, we’re looking times, there’s going to be a financial impact that have the potential for significant fleet

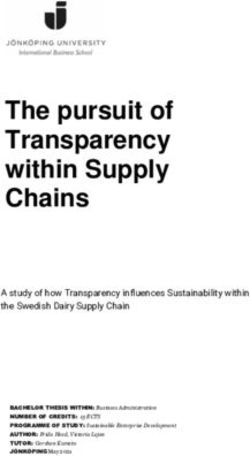

at the demands coming from the fleet. One there. Funds tied up inefficiently are a lost impact. As we continue to drill down and Demand Optimize WCF Shape Optimize Increase

of the things demand management is trying opportunity for investment in other things. look at both aviation and maritime, we’re Management Portfolio Industrial Base Organic Repair E2E Velocity

PILLARS

to drive is a reduction in demand. That Part of what we need to drive with honing in on a set of candidates to pilot. Take a portfolio Expand competition Increase organic Shorten E2E repair

Reduce demand

pillar needs to reveal why we see the demands increasing end-to-end velocity is under- The next step will be to go forth and do a and increase approach to managing with suppliers and depot repair TATs in line with

we see. What are the fleet behaviors, main- standing where we have requirements and handful of pilots. We haven’t settled on a predictability cash allocation to deepen partnership volume to fully commercial, and

tenance practices, et cetera, that are driving what is holding us back from getting faster specific number of pilots yet, but I anticipate through design, maximize readiness. with strategic suppliers. utilize capacity. move parts in the

demands and how do we drive change? turnaround times. This won’t always be the between five and 10 specific components. engineering, system faster.

From the end-to-end velocity perspective, We’ll engage with the vendors and set out maintenance, etc.

case, but where we have items that have

the longer our RTATs, the more vulnerable capacity constraints, this is where shaping the requirements for new repair turnaround

we are to demand shifts. If all of a sudden the industrial base pillar comes into play. times. We’ll collect those lessons learned,

demands spike, it takes us a long time to be Whether that’s expanding capacity within document them and figure out what we can Executive Reliability Control Board (E-RCB), Sustainment Program Baseline (SPB), Maintenance Operations Center (MOC) Aircraft-

ENABLERS

able to surge and get those repairs through existing vendors or expanding to have more implement into our processes and proce- on-Ground (AOG), NAVSUP WSS Logistics Cell Operations Model (WSS LOGCELL OpModel), NAVSUP BSC, NAVSUP FLCs, supply

dures and basic business moving forward. community, tools for E2E visibility such as: Integrated Supply Chain Management (ISCM), machine learning (ML), Enterprise

and fill those demands. Conversely, if the vendors available to work those items. Resource Planning (ERP), Naval Operational Business Logistics Enterprise (NOBLE).

2 Winter 2021 The Navy Supply Corps Newsletter 3

REVISED 19JAN2021NAVSUP Weapon Systems During the deep dive, the team took a

four-question approach to conducting the

The EMALS and AAG review also

revealed opportunities to improve data

“The team was able to add a mainte-

nance requirements card (MRC) to enable

Support Leveraging NSS-Supply deep dive analysis. flows between mission partners and to fuse support that hadn’t seemed possible just by

Initiative to Make Ford Ready

“First, what part are we looking at, data systems that were not otherwise inter- revisiting assumptions. Ford will be able to

what does it do, and what capability connected, most notably through including carry some critical batteries on board cou-

does that system deliver? Next, what is Electronic Maintenance Log (EML) data pled with a trickle-charge MRC that previ-

By Brian Jones NAVSUP WSS’ as-is state, and are our held with NAWC AD Lakehurst. ously presented risk of downing a wire on

I

OFFICE OF CORPORATE COMMUNICATIONS, NAVSUP WEAPON SYSTEMS SUPPORT

planning factors for procurement lead “A lot of our repair turnaround times AAG, highlighting the importance of the

n January, Acting Secretary of the Navy Thomas B. Modly implemented the “Make Ford Ready” times, repair times, etc. correct? If not, were assumptions based on aged process Integration of End to End Supply Chain

initiative to bolster repair and operational testing efforts on the $13 billion, first-in-class we changed it on-the-spot and re-ran the maps and we’ve been able to improve some partnership under the NSS-Supply

carrier, USS Gerald R. Ford (CVN 78). Recently, the Navy introduced Naval Sustainment numbers,” said Couchman. “Then we dove of our forecasting,” according to Couchman. framework.”

System-Supply (NSS-Supply) to streamline supply chains, decrease maintenance turn- specifically into what’s going on with each “The Navy also wasn’t feeding DLA the Within NAVSUP WSS, the EMALS/

around times, increase end-to-end velocity of spares and reduce costs. part, asking if demand was above where we right demand signal early on in the ship’s AAG end-to-end review was not only the

“Naval Sustainment System-Supply is on the hunt for leverage to make our supply chains thought it would be initially while firmly life span, so we fixed that on the spot by first-ever dedicated to the systems, but

run more effectively and affordably to improve readiness,” said Rear. Adm. Peter Stamatopoulos, coupling reliability and sparing efforts in pulling in EML data; in lock step with the the first to be firmly entrenched in the

Commander, NAVSUP and 49th Chief of Supply Corps. real-time with engineers, the program NSS-Supply pillar of Demand Management NSS-Supply framework. Using this as a

NAVSUP Weapon Systems Support’s office, DLA, TYCOM, the ship, and across the sustainment enterprise.” launching point, this standardized, repeat-

(WSS) Aviation Launch and Recovery industry partners.” able process is the launch point

(ALRE) team leveraged NSS-Supply to The final question the team for a recurring, holistic review of

enable rapid program improvement on the looked to answer was how to all the parts associated with

first-of-its-kind Electromagnetic Aircraft make the entire process better both systems that integrates the

Launch System (EMALS) and Advanced together. NAE sustainment enterprise

Arresting Gear (AAG), with the ultimate Through the focused deep toward a common vision.

goal of shaping both the sustainment enter- dive and end-to-end review, the Whether leading from the

prise and class-wide support. team was able to draw a num- front in “Making Ford Ready,” or

“A frequent comment from Naval Aviation ber of conclusions. They first looking for efficiencies across the

Enterprise (NAE) leadership has surrounded addressed the critical Navy enterprise, NSS-Supply seeks to

the sparing posture on Ford and the risks to Working Capital Fund. strengthen the Navy’s supply

schedule execution that inadequacy might “First, we are generally well chain to increase readiness and

present,” said Lt. Cmdr. Dave Couchman, postured to support sustain global navy power.

NAVSUP WSS ALRE branch head. “Under- demand through PDT&T and

standing Ford experienced a minimal beyond and we were able to use

interim support period and initial sparing validated data to support that

was accomplished with engineering estimates point. About $1.6 million in cost

prior to having meaningful operational run avoidance was accomplished

time, and given realized failures in Post- through Purchase Request

Deployment Trials and Testing (PDT&T), is reductions,” said Couchman.

she spared properly for cyclic operations “Ensuring working capital fund Russ Knaub, product support manager, PMA-251 (left),

through deployment and beyond?” solvency while delivering cost- and Lt. Cmdr. Dave Couchman, NAVSUP WSS Aviation

wise readiness is not only a core Launch and Recovery branch head, review data during an

NAVSUP WSS coordinated with

end-to-end review of the F/A-18 Electromagnetic Aircraft

sustainment partners to identify parts with mission for us at NAVSUP

Launch System and Advanced Arresting Gear. –photo by

Elizabeth Gordon, NAVSUP WSS highest risk; stratifying by impact to primary mission sets, according to Couchman. The team WSS, but an NSS-Supply

Fox Murray

Philadelphia LOGCELL (left), and dedicated a full day to each system, fully aligned with NSS-Supply initiatives to focus specifi- imperative.”

Russ Knaub, product support cally on increasing end-to-end velocity, leaning on repair pipelines, understanding demand Keeping with the core focus

manager, PMA-251, take part in an profiles, improving vendor partnerships, and addressing working capital fund solvency issues of the event, delivering readiness,

end-to-end review of the F/A-18 in order to ultimately unify the sustainment enterprise toward a common goal. ALRE was able to rapidly affect a projected The initiative also uncovered additional

Electromagnetic Aircraft Launch “This is the largest single end-to-end effort I’ve ever been a part of, hands down,” said Russ 25-percent reduction in unfilled customer savings and benefits to Ford-class carriers

System and Advanced Arresting Knaub, product support manager at NAVAIR PMA-251. orders without additional working capital beyond NAVSUP.

Gear. The meeting pulled in “We pulled in stakeholders from PMA-251, Naval Air Warfare Center Aircraft Division funds outlays. “We found that there was an engineer-

stakeholders from PMA-251, Naval

(NAWC AD) Lakehurst, Commander, Naval Air Forces Atlantic, Defense Logistics Agency “Through negotiation of throughputs ing change proposal that was no longer

Air Warfare Center Aircraft Division

(DLA) Land and Maritime, General Atomics, and had USS Gerald R. Ford dial in from at-sea to with our industry partners, accelerating needed as the failure modes experienced

Lakehurst, Commander, Naval Air

conduct a focused deep dive,” said Couchman. needed material, looking at timing to need at commissioning haven’t come to light

Forces Atlantic, Defense Logistics

Agency Land and Maritime, Gener- “We did an end-to-end on a total of 69 parts – 39 for EMALS and 30 for AAG, encompass- and coordinating in real-time with our pri- with run time, so this effort will save the

al Atomics, and the USS Gerald R. ing all critical parts that could independently cause potential loss or degradation of primary mary customer, we were able to ensure both program office funding to allocate toward more

Ford.–photo by Fox Murray. mission capability, or “single downers” as coordinated with PMA-251. This is all about deliver- the requirements and program support prescient needs,” said Couchman.

ing readiness to the fleet through data-driven decision making.” were right-sized to need,” said Couchman.

4 Winter

Winter 2021

2021 The Navy Supply Corps Newsletter 5It is my honor to contribute to the Navy Supply

Corps Newsletter, especially as the Supply Corps A Message from the Assistant Chief of Staff

community celebrates its 225th anniversary.

for Logistics, Engineering & Combat Systems

(N4) at Naval Special Warfare Command

Suffice it to say, much has changed since the law creating the U.S. Navy

Office of the Purveyor of Public Supplies within the Treasury Department

was enacted on Feb. 23, 1795. What has not changed is the need for the

Navy to have the platforms, weapons, gear and supplies its needs, when By Capt. Mick Wilson

and where it needs them in order to execute its enduring mission to defend ASSISTANT CHIEF OF STAFF (N4) LOGISTICS, ENGINEERING, AND COMBAT SYSTEMS, NAVAL SPECIAL WARFARE COMMAND

our nation and protect national interests.

I

As a student of naval history, I am reminded of Fleet Adm. Ernest J.

King’s official report to the Secretary of the Navy in 1946 in which he n the winter edition of the 1999 Supply Corps Newsletter, now and 2 will celebrate their 20th anniversaries and to date 17 Supply

described World War II. “The war has been variously termed a war of pro- retired Capt. Gerry Harms penned a foreword similar to this Corps officers have been awarded the prestigious Vice Adm. Robert

duction and a war of machines. Whatever else it is, so far as the United one when he was in the same position F. Batchelder award, since 2000, for their efforts supporting

States is concerned, it is a war of logistics.” Our communities fought I now occupy. He worked for then Rear Adm. Eric T. Olson, the deployed NSW, Joint Special Operations Forces (SOF) and the

together with courage, grit and integrity as we trace our lineage back to commander of Naval Special Warfare (NSW) Command, the first Navy Expeditionary Combat Command (NECC). We celebrate those

the time of Fleet Admiral King, the Chief of Naval Operations from 1942 – SEAL to attain the rank of four-star admiral and command U.S. achievements as part of our legacy, but also keep our focus to over-

1945, during which Lt. Cmdr. Draper L. Kauffman, U.S. Navy Reserve, Special Operations Command (USSOCOM). the-horizon challenges and innovations.

established the Navy Combat Demolition Units (NCDUs) at Fort Pierce, Rear. Adm. Olson led a transformational force structure Second, that generation of another military super power Harms

Florida. The NCDUs were composed of volunteers from the Bomb and change called NSW 21, which also created LOGSU-1 & 2. Harms referenced is upon us as the Department of Defense and the nation

Mine Disposal School, Washington, D.C. (which he organized), and the stated, “The decade of the 90’s has made it abundantly clear that turn their collective attention to great power competition (GPC).

Civil Engineering Corps and Naval Construction Corps (Seabees) School the mosaic of threats to U.S. security USSOCOM and NSW now orient

at Camp Peary near Williamsburg, Virginia. and interests has evolved dramati- toward the future to counter GPC

Admiral King’s sentiment remains as relevant now as it was during the cally from the polarized world of and align the SOF Enterprise with

Second World War. Today, our Navy takes lessons from the past as it the Cold War. While re-emergence the 2018 National Defense Strategy to

endeavors to advance expeditionary sustainment concepts with a sense of of another military superpower is prepare for the next decade, through

urgency to meet new mission imperatives, while simultaneously addressing unlikely for at least a generation, we 2030, as China and Russia emerge as

enduring conflicts stemming from violent extremist organizations, and remain increasingly vulnerable to a peer competitors, and Iran and North

providing crisis response support around the world. variety of unconventional threats Korea continue to present challenges

Large organizations like the Navy, to include Naval Special Warfare from smaller rogue nations and to U.S. national security interests.

(NSW), require fully modernized and integrated supply chains, intercon- other non-state actors throughout Rear Adm. Pete Stamatopoulos’

nected support networks and experts in logistics, contracting, acquisition the world.” concept of Naval Sustainment

and financial management to be successful. We have that in our world- Those words were prescient and System-Supply aligns to this effort

class, highly-reliable, creative, and resolute Navy Supply Corps commu- proved true on two fronts. as the importance of supply chain

nity, thanks to the tremendous advancements made in the last

Message from

First, the unconventional threat decisions are elevated to the Navy’s

three-quarters of a century and where we’re accelerating logistics effects Harms mentioned arrived on our highest leadership levels. NSW will

Rear Adm. H.W.

with innovative artificial intelligence and machine learning approaches. shores on Sept. 11, 2001, just 18 seek to leverage this effort in areas

It is fitting that NSW and Navy Expeditionary Combat Command months later. It set the USSOCOM where sustainment measures need

Howard III, (NECC) are jointly contributing to this edition of the Supply Corps News-

letter. Rear Adm. Peter G. Stamatopoulos at NAVSUP, Rear Adm. Joseph

Enterprise, to include NSW, on a improvement.

Commander,

trajectory of unprecedented growth As the articles submitted to this

A. DiGuardo Jr. at NECC and I are aligned on the nation’s challenges as we and operational employment. In issue from USSOCOM J4, NSW and

Naval Special

focus on countering China, Russia and the challenges Iran and North 1999, there were 5,400 personnel NECC will attest, logistics tours in

Korea continue to present to U.S. national security interests. within NSW. Today there are well the Joint expeditionary environment

Warfare Command I am humbled by the men and women of the Supply Corps and the

thousands of Combat Service Support personnel that make possible Naval

over 10,800. Thirty one Supply

Corps officers and 170 supply

are dynamic and ever evolving to sup-

port the hyper-enabled SOF and

Special Warfare’s contributions to the nation. The Supply Corps enlisted rates supported the NSW Navy maritime warrior communities.

is relentless in its support of the warfighter and agile in its creative solu- mission. Today, there are roughly double the number of Supply They aim to convey the diversity of experiences, excitement and

tions to the hardest logistical challenges. What you bring to the expedi- Corps officers, three of whom are in O5 Commander Milestone challenges inherent in the NSW/NECC logistics and support

tionary fight is simply extraordinary and could not be more crucial as commanding officer billets at LOGSUs-1, 2 and 3. There are nearly assignments. For those interested in an atypical tour that will hone

we work with common purpose to build and sustain a lethal and diverse 2,300 Combat Service Support professionals from the fleet, made your leadership skills, test your ability to solve problems and operate

force–with unwavering standards of professionalism–for a future opera- up of 21 officer designators, 31 enlisted rates and 30 civilian in volatile, uncertain, complex and ambiguous environments, then I

tional environment that will stress our ability to sustain the force. As my specialty codes throughout the NSW enterprise, led by Supply encourage you to contact us for additional information!

mentor Adm. Eric T. Olson wrote in this publication in 1999, the Navy Corps and Civil Engineering Corps leadership. In 2021, LOGSU-1

Supply Corps is a force multiplier and major contributor to our combat

readiness. NSW–anywhere, anytime, prepared to win. The Deed is All–

Not the Glory

6 Winter 2021 The Navy Supply Corps Newsletter 7Left: President Obama visited

USSOCOM in 2016, where he was The J4 shapes and sets conditions for all to include close relationships with the J3

hosted in the USSOCOM Wargame USSOCOM Enterprise logistics and materiel (operations), J5 (plans and strategy), J8

Center to say his farewell to the solutions to sustain global SOF operations. (requirements), PEOs, SOF service compo-

U.S. Military by then USSOCOM The Logistics Directorate (J4) consists nents, and TSOC J4s.

Commander, Gen. Tony Thomas of roughly 100 personnel and is led by a The J4 is made up of six divisions and

(left) and former USSOCOM post-brigade Army O6 (equivalent to a one U.S. Air Force Squadron:

Commander and then current Supply Corps O6 post-major commander) J41 Material Management maintains

USCENTCOM Commander and a GS-15 civilian deputy. The J4 is made awareness of asset posture worldwide and

Gen. Joseph Votel (right). up of active duty from all four services, is the project lead in developing, coordi-

Below: President Obama civil service, and contractor personnel and nating, and implementing the utilization of

addressed a group of senior leaders is predominantly guided by fundamental the Defense Property Accountability System

from USSOCOM and USCENTCOM mantras called the “Five SOF Truths”. (DPAS) as the Accountable Property System

(collocated on MacDill Air Force The fifth SOF truth, ‘Most SOF Opera- of Record (APSR) for SOF-peculiar (SO-p)

Base) in the USSOCOM Wargame tions Require Non-SOF Support,’ is realized material. SO-p is defined as equipment,

Center during his farewell to the through coordination and synchronization material, supplies, and services required for

U.S. Military in 2016. with DoD’s Joint Logistics Enterprise, con- special operations missions for which there

sisting of the Joint Staff J4, all Geographic is no service-common requirement. The

Combatant Command (GCC) J4s, U.S. implementation of DPAS as the command’s

Transportation Command (USTRANSCOM), accountable property system of record

Defense Logistics Agency (DLA), and service enables an enterprise solution to meet

logistics arms, such as Army Materiel auditability requirements and provide

Command (AMC) and NAVSUP. enterprise-wide total asset visibility. Naval

These collective organizations ensure Special Warfare Command (WARCOM)

United States

worldwide SOF operations are logistically is the first service component to start the

“The Line between Disorder and Order USSOCOM’s mission is to synchronize

the planning of special operations and provide supported and assist USSOCOM J4 in transition to a single APSR.

Lies in Logistics”–Sun Tzu

Special Operations SOF to support persistent, networked, and shaping policies, doctrine, material acqui- J42 Product Support Management

Command This article provides a broad logistics distributed global combatant command sition and sustainment, planning guidance, verifies sustainability of SOF systems, and

overview from the United States Special operations in order to protect and advance and equipment readiness analysis in support systematically conducts independent

The World is Operations Command (USSOCOM) head-

quarters perspective. Points of contact are

our nation’s interest. SOF provides unique of SOF TSOCs. The majority of Supply

Corps officers assigned to J4 will work

assessments of life cycle sustainment, read-

iness, and supportability of SO-p equipment

Our Area of

capabilities, especially in competition below

listed at the end of the article for those inter- the level of armed conflict. Countering violent closely with all USSOCOM directorates, and systems procured with Major Force

Responsibility

ested in learning more about USSOCOM extremist organizations that threaten U.S.

or the expeditionary logistics community! national interests remains USSOCOM’s top

By Cmdr. Mike Malone

USSOCOM’s five priorities:

1. Compete and Win for the Nation

priority; however, USSOCOM is also assessing

its role in long-term strategic competition

USSOCOM J4 Organization

USSOCOM J4X DIVISION CHIEF

2. Preserve and Grow Readiness per the National Defense Strategy. Logistically,

and Lt. Cmdr. Paul Kloepping 3. Innovate for Future Threats

USSOCOM J4 is re-orienting to operate

W J44 DIVISION inside contested logistics environments.

STAFF ACTION OFFICER 4. Advance Partnerships

USSOCOM is unique as it has both com- USSOCOM J4

5. Strengthen our Force and Family batant command and service-like responsibilities. Director of Logistics Defense Logistics Agency LNO

DLA EnergyLNO

These priorities are aligned to the National With its service-like responsibility comes US Army Materiel

Command LNO

Defense Strategy as Special Operation Forces acquisition authority, which procures and

USTRANSCOM LNO

(SOF) optimizes special operations for today manages SOF systems and services through USSOCOM Deputy J4

and tomorrow’s fight. As a whole, the United Special Operations Forces Acquisition,

States Special Operations Enterprise, formally Technology and Logistics (SOF AT&L).

established in 1987, is globally composed of Established in 1991, SOF AT&L is led by a COCOM/ COCOM/ COCOM/ COCOM/

SERVICE COCOM

SERVICE SERVICE SERVICE SERVICE

approximately 70,000 active duty Army, Navy, senior acquisition executive and is responsible

Air Force, Marines, Reserve, and National for all USSOCOM research, development, Materiel Plans & Operations Sustainment Strategy & Policy Sensitive Activities Deployment Cell

Management Division Division Integration Division Division Division (“D-Cell”)

Guard, and Department of Defense civilians acquisition, procurement, and life-cycle logistics (J41) (J43/5) (J44) (J47) (J4X)

and contractors. The enterprise is USSOCOM planning, which includes life-cycle operations

HQ, located at MacDill Air Force Base in and sustainment costs and material manage-

Tampa, Florida, its four service components, ment. Eight program executive offices (PEOs) USSOCOM J4 JLOC

SA Programs

Core Logistics SA Log Planning

Authorization Mgt Embedded with J3/J5 Policy/Doctrine/Strategy

and eight sub-unified commands Theater and five specialized functions, including the Cataloging Mgt Current/Future Ops

Property Oversight SOF Logistics Education

SA Policy and Oversight USAF Command

Futures/Innovation SA Log Education Bare Base Unit

Supply Chain Mgt Contingency/CCMD/ Exercises

Special Operations Commands (TSOC). J4, make up SOF AT&L. Program Mgt Global Campaign Plans

Strategic Transportation OCS Support

IA/IC Strategic Partnerships Exercise Support

Maintenance & Munitions Secure Property ContingencySupport

Equipment Readiness

Ancillary personnel are located at USSOCOM’s LOG IT Mgt Security Assistance/ACSA

GSOS/GFM

Operational Engineering Accountability Policy,

Monitoring, and Use

Washington, D.C., office in the Pentagon, and

as liaisons attached to U.S. embassies.

8 Winter 2021 The Navy Supply Corps Newsletter ...continued on page 10 9...continued from page 9

Program-11 (MFP-11) funds, interfacing with operation. The Joint Petroleum branch lever- JS J4 and training SOF enablers at every level USSOCOM J3 Joint Collective Training we learned the critical importance of training Cmdr. Mike Malone – USSOCOM J4X

SOF AT&L PEOs program offices, other ages DLA Energy’s capabilities to support of war across the Joint Logistics Enterprise, Division (JCT): Lastly, there is one Supply and deploying as a Joint force. Congress Division Chief and former Joint Special

USSOCOM organizations and components SOF global fuel requirements. The Strategic the J47’s span of influence covers the gamut. Corps officer working in USSOCOM’s J3 JCT, recognized this and directed the creation of Operations Command J4 CHOPS / JLOC

to support, sustain and modernize SOF Transportation branch interfaces with J47 also oversees Joint SOF Logistics educa- which is the premier Joint trainer that pro- USSOCOM on April 16, 1987. The disaster at Division Chief.

worldwide. These touchpoints are maintained USTRANSCOM to ensure SOF’s require- tion/training. Supply Corps officers, and vides planning, designing, coordinating, syn- the Desert One landing strip has been called

Cmdr. Mike Augustine – SOCOM J47

through product support managers and ments are included in strategic planning. The potentially senior enlisted, assigned to Naval chronizing and execution of exercises across “the most successful failure.” A tale of both

Strategy and Policy Officer and former

acquisition logisticians being nested within Maintenance branch orchestrates sustain- Special Warfare are candidates to attend the Special Operations Enterprise to increase tragedy and triumph, it was the primary

SOCPAC J43 Logistics Operations

each of the PEO program offices. ment efforts across the TSOCs and service USSOCOM J4’s Joint SOF Logistics Course. operational readiness. They are responsible catalyst in generating the superb special

Division Chief.

Previously, one Supply Corps officer components to ensure maintenance actions It is held at USSOCOM’s Joint Special Opera- for developing, coordinating and executing a operations team we have today.

served in PEO-Maritime, which supports are factored into life cycle sustainment plans. tions University (JSOU) in Tampa and serves comprehensive Joint SOF collective training Throughout USSOCOM’s storied 33-year Cmdr. Doug Jenkins – J43/5 action officer

acquisition of SO-p maritime assets. Due to The Futures branch oversees logistics digital as a 101 level introduction to expeditionary program globally that ensures the supported history, the J4 and Joint logisticians throughout and former Naval Special Warfare Unit

logistics in support of SOF. Although not command’s readiness to perform Combatant the enterprise have provided time and again TWO N4.

Navy specific, this course provides many new Command wartime tasks. Also, they support proven results to support the SOF warfighter, Lt. Cmdr. Travis Miller – WGC Lead

SOF logisticians their first exposure to the theater SOF and component exercise pro- wherever he or she may be around the globe. Planner and former NECC Coastal

Joint SOF community. If you are assigned to grams, and provide a mechanism to exercise Listed below are the Supply Corps and Joint Riverine Group ONE N4A, Coastal

become an N4 or an N4A at a LOGSU, this is SOF and conventional force battle staff in logistics professionals currently on the Riverine Squadron 3 N4.

a great course for you to enroll in to develop a service and GCC exercises. This branch is USSOCOM team. While there is no require-

Lt. Cmdr. Paul Kloepping – J44

broader understanding of how SOF logistics focused on the down and in engagements ment to have SOF experience to join the

Acquisition Cross Service Agreement PM

truly is different. and maintaining the relationships with the SOCOM team, a majority of members bring

and USSOCOM Security Cooperation

J4X Logistics Support to Sensitive Activi- TSOC’s, GCC’s and components. some SOF and/or expeditionary background.

ties plans, coordinates, synchronizes, de-con- In 2020, USSOCOM celebrates its 33rd If you have any questions or comments about Logistics Lead.

flicts, and when directed, executes logistics anniversary. Also this year, USSOCOM sol- the overview or interested in a Joint assignment Lt. Cmdr. Mike Nelson – Reservist

support to sensitive activities, unconventional emnly remembered the 40th anniversary of in general please direct them to Lt. Cmdr. activated and currently serving as J44

warfare, and compartmented Operations, Operation Eagle Claw. On November 4, 1979, Paul Kloepping. Action Officer / JLOC OIC and formerly

Actions, and Activities on behalf of com- Iranian militants seized the U.S. embassy in mobilized to support USSOCOM J4,

mander, USSOCOM. J4X also serves as the Tehran and took 53 Americans hostage. On SOJTF-A, SOCAF SOCFWD-North

office of primary responsibility for secure April 24, 1980, after weeks of planning and West Africa, and NSW Group TWO.

property accountability for the USSOCOM. preparation, an element of Army, Navy,

J4X also provides oversight for the JSOU Marine, and Air Force special operators

its acquisition and submarine focus, this transformation and modernization, proposi- hosted Logistics Support to Sensitive Activi- embarked on an audacious plan to rescue the

officer functioned as an Undersea Systems tioning of SOF equipment to support ongoing ties course, which instills graduates with hostages. While the mission did not succeed,

Acquisition Program Manager, focused on and future operations, and all equities for all advanced skills, knowledge, and abilities to

providing a Host Submarine interoperable MFP-11 Acquisition Cross Service Agreements stimulate the innovative thinking required to

Dry Combat Submersibles capability to orders and Security Cooperation Logistics. support SA across a full spectrum of logistics.

WARCOM. Other SO-p maritime mobility The J44 also publishes a SOF Global USSOCOM’s Wargame Center (WGC),

programs include Dry Deck Shelters, Seal Logistics Estimate, a demand signal for SOF built under Adm. William McRaven’s tenure

Delivery Vehicles, Combatant Craft, Dry and global force management requirements to as USSOCOM commander, focuses on policy

Wet Combat Submersibles, and SOF-Combat enable GCCs and Services to do advance and strategy decisions, emphasizing dis-

Diving. planning support. Additionally, DLA, course, creative problem visualization, and

J43/5 Plans and Operations provides USTRANSCOM, and AMC maintain full time innovative solutions. One Supply Corps offi-

operational support and oversight of SOF Liaison Officers in the J4 to maintain close cer is assigned in the WGC as a lead planner

logistics and coordinates logistics support working relationships between USSOCOM for events and has both designer and opera-

to SOF through the J3 and J5 with the Joint and their organizations for mutual benefit. tions research/systems analysis like responsi-

Staff, Military Services, GCCs, TSOC, and This provides value not only in day to day bilities that include USSOCOM provided

other government agencies. Desk officers are operations, but also in the event of emergen- professional training in the areas of decision

assigned to each GCC, which is sometimes cies or short notice contingencies such as the science, design thinking, visual thinking,

filled by one of the USSOCOM supply retrograde operations in Syria, Iraq, Afghani- facilitation, public speaking, and political sci-

officers. stan, and Africa or supply chain disruptions ence. This enables the Supply Corps officer to

J44 Sustainment Integration covers a during COVID-19. lead a specialized team through all phases of

wide array of core logistics functions within J47 Strategy & Policy is a team of mili- innovative solutions while mitigating our

the J4. The Property Oversight branch tary, DoD civilian, and contractor personnel. inherent cognitive biases. Right: USSOCOM’s

provides asset visibility for SO-p property, J47’s primary lines of effort cover: Operational USSOCOM’s WGC is the only organiza- Wargame Center, built under

improves accountability and auditability, Contracting Support, Strategic Resourcing/ tion across the whole of government that Adm. William McRaven’s

updates and enforces policy with USSO- Gap Analysis, Readiness Reporting, Policy combines these disciplines into creative prob- tenure as USSOCOM

COM’s Inspector General Office. The Muni- and Doctrine Management and Exercise Sup- lem framing, solution ideation, visualization, commander, focuses on policy

tions branch manages $1.7 billion in worldwide port. J47 interacts frequently outside of presentation, vignettes, and ultimately–war and strategy decisions,

assets, and supports 14 active concepts of SOCOM – between working directly with the gaming. emphasizing discourse,

creative problem visualization,

and innovative solutions.

10 Winter 2021 11Logisticians and engineers on the NSWC and train. Remote, austere, and logistically training facilities, classroom and hands-on Requirement (SPEAR) consisting of more and identifying the most effective and effi-

N4 staff provide policy, training and over- challenging, San Clemente Island, located tactics instructional space, storage and than 159,000 pieces of equipment and serial- cient ways to get the job done!

sight for NSW’s eight subordinate com- approximately 80 miles west of San Diego, is administration offices. ized assets valued at more than $349 million

mands, not unlike other Navy type home to some of NSWCEN’s most important NSWG 1 is a NSW Task Force headquar- spread across ten subordinate commands

commanders or SOF component headquar- training sites. NSWCEN ensures their train- ters for ten subordinate commands to and detachments. A high level of oversight

ters. WARCOM’s man, train and equip mis- ing ranges and support networks are ready include SEAL Teams 1, 3, 5, 7 and command and procedural compliance is required to

sion supports 10,877 Navy Special Warfare for Naval Special Warfare forces to success- and control deployed Joint SOF. NSWG 1 maintain accountability and ensure the avail-

(NSW) personnel made up of active duty, fully train all year round. trains and deploys fully-enabled SEAL Teams ability of equipment critical to warfighters.

Streamlining Reserves, civilians, and contractors, with Lt. Cmdr. Stephen Cuff and Lt. William and provides maritime SOF assets in support At the beginning of fiscal year 2020, NSWG 1

Resources

Navy SEALs and Special Warfare Combat- Newman, BTC and ATC supply officers, use of U.S. Central and U.S. Indo-Pacific Com- began executing the completion of quarterly

Naval Special Warfare Group 2 (NSWG

ant-craft Crewmen (SWCC) being its pri- their fleet experiences and BQC and/or mands. A persistent focus on resource effi- wall-to-wall inventories of more than 11,000

2), located at Joint Expeditionary Base Little

and Sustaining mary warfighting customers.

In this article, we will highlight the

SODHC training but also are picking up new

logistics skills on a monthly basis to keep up

ciencies and capability sustainment is

required to support both garrison and opera-

serialized assets at the direction of WAR-

COM N4. NSWG 1 Accountable Property

Creek in Virginia Beach, Virginia is the east

Capabilities

coast equivalent to NSWG 1 supporting east

robust missions and the great work that is with NSWCEN’s high standards of training tional responsibilities. System of Record Manager, retired United

coast operational teams which include SEAL

to Support the

done by Supply Corps officers, Civil Engineer requirements. The NSW community, partic- Lt. Cmdr. Aaron Thornton, NSWG 1 N4, States Marine Corps Major Armando

Teams 2, 4, 8 and 10. NSWG 2 N4, Civil Engi-

Corps officers and multi-faceted Combat ularly its training branches, present a variety prioritizes force optimization execution and Budomo, focuses on the reconciliation pro-

neer Corps Officer Lt. Cmdr. Billy Woodward

U.S. Navy and Service Support personnel made up of 12 offi-

cer designators, 31 enlisted ratings and 30

of ever-changing logistics challenges, con-

stantly keeping pace with the demand for

equipment accountability reform. Force opti-

mization enables the deployment of tailor-

cess, physical accounting and proper DPAS

inventory verification during each quarterly

works closely with the LOGSU 2 Command-

U.S. Special

ing Officer Cmdr. Dave Huber and his more

civilian specialties throughout the NSW cutting-edge training for our future special able, flexible and sustainable 06-led NSW inventory. These efforts ensured operational

than 360 personnel Echelon IV command.

Operations

community. We hope you learn something operators. Coupled with the unforeseeable Task Forces in support of competition, crisis, readiness and provided NSW leadership

Lt. Tim Landry is the J4 director of

new and welcome you to inquire into the constraints of the COVID-19 global pan- and contingency requirements. Parallel with accurate information to make strategic

NSWG 2’s Task Force 2 (TF 2). Like its sister

Command expeditionary logistics community.

It all starts with training. From the day

demic, the reality of providing real-time

training support in simulated wartime sce-

implementation of increased equipment

accountability efforts proves to be critical to

resource decisions.

NSWG 1 N4, working hand in hand with

unit at TF 1, TF 2 is a newly constructed

Maritime SOF

model born from four recently decommis-

Navy SEAL and SWCC recruits arrive in narios has proven to closer resemble that of the rapid availability of assets in support of their largest Echelon IV command at LOGSU

sioned forward-based Naval Special Warfare

Warriors

Coronado, California for Basic Underwater an operational command than a training force optimization realignment objectives. 1 under Cmdr. Joe Bossi and his more than

Units. TF 2 fills a role within NSW that is

Demolition/SEAL (BUD/S), and SWCC facility. Along with the traditional supply NSWG 1 uses the Defense Property 370 personnel, expeditionary logisticians are

dynamic, flexible and continuously evolving.

training which includes Basic Crewman functions of inventory management, contract Accountability System (DPAS) and Special facing resource constraints and equipment

By Cmdr. Robert Salire Selection (BCS); Basic Crewman Training procurement, and warehousing, BTC pro- Operations Forces Equipment Advance accountability challenges head on ...continued on page 14

DIRECTOR OF LOGISTICS N41, (BCT); and Crewman Qualification Training vides logistics support to more than 1,200

NAVAL SPECIAL WARFARE COMMAND

(CQT), they are taught the value of taking SEAL and SWCC candidates annually, and

care of their gear. Well before executing a continuous support to more than 200

high altitude parachute jump or a dive under instructors and staff. The training consists of

Naval Special Warfare Command a naval vessel, operators are taught to “take nine different phases of varying topics, rang-

(NSWC), known affectionately as care of your gear and your gear will take care ing from land warfare, marine operations,

WARCOM, is an Echelon II command of you.” That means preventative mainte- diving, and mountaineering in Kodiak,

that reports to two Echelon I nance and property accountability are liter- Alaska just to name a few. As a Supply

ally life-saving measures. Corps officer in the NSW community, one

commands, Office of the Chief quickly gains an appreciation and under-

of Naval Operations (OPNAV) and standing for the need to improvise, adapt and

U.S. Special Operations Command overcome in order to complete the mission.

(USSOCOM) as their maritime

special operations force

(SOF) component.

Cmdr. Paul Benishek, Naval Special

Above: U.S. Navy Special Warfare Warfare Center (NSWCEN) N4, leads his

Operators and Special Warfare team of 94 military, government civilians,

Combatant-craft Crewman aboard a and contractors to deliver much needed Naval Special Warfare Group 1 (NSWG

Combatant Craft Assault boat board

expeditionary logistics products and services 1) is located at the Silver Strand Training

a maritime vessel.

to its two subordinate commands, Basic Complex-South in Imperial Beach, Califor-

Training Command (BTC) and Advanced nia, a 10-year, $1 billion plus military con-

Training Command (ATC), to execute their struction (MILCON) effort that, when

training missions. This support begins with completed, will provide NSW with approxi-

the planning and construction of modern, mately 24 state-of-the-art logistical support

safe, and efficient facilities in which to work buildings, equipment use and maintenance

12 Winter 2021 The Navy Supply Corps Newsletter 13You can also read