Limitations for work on the chassis General

←

→

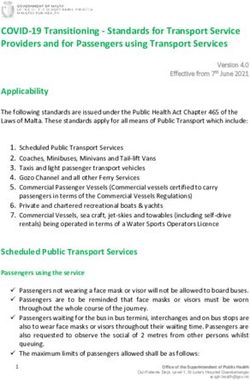

Page content transcription

If your browser does not render page correctly, please read the page content below

Limitations for work on the chassis

General

General

When planning bodybuilding work, it is important to know at an early stage what is

permitted and not permitted for a vehicle.

This document describes some of the limitations that apply when fitting extra equip-

ment and during bodywork.

More information can be found in the document for each application:

• Example of a search term: Box trucks.

• Examples of filters:

– Type of work: Bodywork assembly.

– Type of product: Tipper trucks.

More information on locating chassis components can be found on the vehicle’s

chassis drawing, ICD (Individual Chassis Drawing).

IMPORTANT!

Follow legal requirements regarding what modifications are permitted on the vehi-

cle.

More information on what modifications are permitted on a vehicle can be found in

the document “Modifying Scania components and systems covered by a certificate”.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 1 (18)Limitations for work on the chassis

Blocking of moving components

Blocking of moving components

WARNING!

Ensure that no loose objects can fall down from the load. Also ensure that, for exam-

ple, load securing equipment is fastened. Falling objects may obstruct moving com-

ponents such as the gearbox’s gear shift linkage, propeller shafts and power take-

offs.

Hot components

IMPORTANT!

Hot components require a safety clearance or heat shield to protect components

which are not heat resistant.

More information is found in the document Risk of fire and damage in connection

with hot components.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 2 (18)Limitations for work on the chassis

Accessibility requirements

Accessibility requirements

IMPORTANT!

The design of the bodywork must not prevent or impair the following:

• Maintenance.

• Repairs.

• Lifting the engine, gearbox, shafts or other components in and out.

• Tilting the cab.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 3 (18)Limitations for work on the chassis

Ventilating valve on the automatic gearbox

Ventilating valve on the automatic gearbox

Water must be prevented from entering the ventilating valve on the automatic gear-

box.

Move the ventilating valve to another location if there is a risk of it being splashed

with water, e.g. on fire engines, military vehicles and refuse collection trucks.

When moving the ventilating valve, the following applies:

• Use an adapter that converts the original connection from M10 to M12.

• Use a hose with internal diameter of at least 9.5 mm.

• Position the ventilating valve in a location which is well above the water level.

Note:

367 909

The new venting system must not impair the air flow.

Location of ventilating valve.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 4 (18)Limitations for work on the chassis

The radar’s field of view must not be obstructed

The radar’s field of view must not be ob-

structed

WARNING!

The radar covers must be protected during re-painting or anti-corrosion treatment.

The vehicle's radar, located at the front and on the sides, is very sensitive to interfer-

ence and must not be covered or painted over. Its functionality depends on the thick-

ness of the radar cover and its material properties. Obstructing the radar's field of

view by, for example, covering with paint or stickers risks negatively affecting the

vehicle's safety functions, resulting in unwanted braking or no braking.

420 996

Location of radar.

WARNING!

• The radar’s field of view must not be blocked by, for example, the frontal protec-

tion system or auxiliary lights.

• Snow or other obstructions can reduce the radar’s field of view.

• It is not permissible to move the radar.

• If the radar is temporarily removed from its bracket, the plastic bushings must be

renewed before the radar is refitted.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 5 (18)Limitations for work on the chassis

The radar’s field of view must not be obstructed

Systems that are affected by the radar:

• Option Advanced emergency braking (AEB) (variant code 4335A). AEB in vehi-

cles with front-mounted equipment may be switched off before the vehicle is driv-

en away. The system can only be switched off momentarily, and must therefore

be switched off every time the engine is started.

• Option Adaptive cruise control (variant code 3583A) depends on the radar to

work. If the radar’s field of view is blocked, AICC should not be used.

More information on AEB can be found in the Driver’s Manual.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 6 (18)Limitations for work on the chassis

The radar’s field of view must not be obstructed

A B 78

o

o o

30

o

30 12

o

12

o o

60 60

376 840

o

78

Area scanned by the radar:

A: Radar’s horizontal field of view. B: Radar’s vertical field of view.

22

11

70 70

65 75 60 83

383 681

392 608

Area where the radar cuts the protective cover on vehicles with a standard front. Area where the radar cuts the protective cover on vehicles with a HD front.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 7 (18)Limitations for work on the chassis

The radar’s field of view must not be obstructed

An extended area must be left radar free if there is a risk of the area shrinking during

operation, for example due to dirt, snow or ice. The size of this area depends on the A B

prevailing conditions in which the vehicle will be operated and also on how the o

structure is designed, e.g. whether there are compartments or openings where snow 25

can accumulate.

o

25

o o

67,5 67,5

409 824

A. The radar’s horizontal field of view. B. The radar’s vertical field of view.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 8 (18)Limitations for work on the chassis

The camera’s field of view must not be obstructed

The camera’s field of view must not be ob-

structed

WARNING!

• Obstructing the camera’s field of view risks negatively affecting the vehicle's

safety functions, resulting in unwanted braking or no braking.

• It is not permissible to move the camera.

The camera has safety-critical functions. Auxiliary equipment on the front of the cab

376 864

and stickers on the windscreen must not obstruct the camera. Blocking the camera

can impair functionality and may cause the camera to shut down. Camera location.

A camera is fitted in vehicles with any of the following options:

• Advanced emergency braking (AEB) (variant code 4335A).

• Adaptive cruise control (variant code 3583A).

• Scania lane departure warning (LDW1(variant code 3601A).

The camera scans the following area:

• Horizontal field of view: ±25° (calculated from the windscreen) 14°

• Vertical field of view: +14°/-21° (calculated from the horizontal plane).

21°

25° 25°

376 865

Horizontal field of view and vertical field of view.

1. Lane Departure Warning)

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 9 (18)Limitations for work on the chassis

The rain sensor's and light sensor’s field of view must not be obstructed

The rain sensor's and light sensor’s field of

view must not be obstructed

The Rain sensor (variant code 5121A) and Automatic dipped beam (variant code

5058A) options comprise a combined rain sensor and light sensor. Both options have

safety-critical functions. The field of view of the sensors must not be obstructed by

auxiliary equipment on the front of the cab or stickers on the windscreen. A blockage

can impair functionality and may cause the sensors to shut down.

The sensors are located in front of the driver area on the lower edge of the wind-

screen; see illustration. Leave 100 mm free space around the sensors.

376 866

WARNING!

Location of rain sensor and light sensor.

Obstructing the rain sensor's and light sensor’s field of view risks negatively affect-

ing the vehicle’s safety functions.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 10 (18)Limitations for work on the chassis

Air intakes must not be obstructed

Air intakes must not be obstructed

WARNING!

If the air intakes are obstructed, there is a risk of the engine overheating.

The air intakes have safety-critical functions. Auxiliary equipment on the front of the

cab must not block the radiator or the engine's air intake on the front grille panel. This

can cause an increase in temperature and may overheat the engine.

376 867

Location of the air intakes.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 11 (18)Limitations for work on the chassis

The brake control unit must not be moved

The brake control unit must not be moved

WARNING!

Moving the brake control unit, EBS (Electronic Brake System), can cause impaired

braking or no braking action at all. It can also negatively affect the vehicle's safety-

critical functions.

376 868

Location of the brake control unit.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 12 (18)Limitations for work on the chassis

Space above the side skirts

Space above the side skirts

Note:

To be able to remove the side skirts, there must be at least 100 mm of free space be-

tween the bodywork and the side skirt attachments.

The bodywork must not hinder removal of the side skirts. It must be possible to re- ≥100

move the side skirts, e.g. during maintenance of the vehicle.

376 869

Minimum of 100 mm free space between side skirt and bodywork.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 13 (18)Limitations for work on the chassis

Space above the silencer

Space above the silencer

Note:

To be able to remove the silencer, at least 10 mm of free space must be present be-

tween the silencer heat shield and the bodywork.

The bodywork must not prevent the silencer from being removed; it must be possible

to remove the silencer during, for example, vehicle maintenance.

When removing the silencer, it should be angled up before being pulled straight out.

≥10

367 870

Minimum of 10 mm free space between the silencer heat shield and the bodywork.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 14 (18)Limitations for work on the chassis

Space above the reductant tank

Space above the reductant tank

Note:

Scania recommends testing with a filler nozzle to ensure there is adequate free space.

Extra space is required between the reductant tank and the bodywork when filling re-

ductant. The reductant nozzle requires more space than the fuel nozzle.

376 871

Filling reductant.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 15 (18)Limitations for work on the chassis

Space around the air bellows

Space around the air bellows

R

IMPORTANT!

Leave space around the air bellows The table shows the minimum permitted meas-

urements.

Type of bellows Positioning Distance R (mm)

376 872

Air spring. By the front axle. 190

Dimension R is from the centre of the air bellows.

2-bellows air spring. By the driving axle. 185

4-bellows air spring. In front of the driving axle. 150

Behind the driving axle. 185

Air spring. By the tag axle in front of the driving axle. 160

By the tag axle behind the driving axle. 185

Tag axle lift. By the tag axle in front of the driving axle. 145

By the tag axle behind the driving axle 160

(non-steered tag axle).

By the tag axle behind the driving axle 190

(steered tag axle).

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 16 (18)Limitations for work on the chassis

Space around propeller shaft

Space around propeller shaft

30

IMPORTANT!

376 873

Leave a space of at least 30 mm around all propeller shaft components so there is ad-

equate clearance for the propeller shaft's movements. Minimum of 30 mm free space around all parts of the propeller shaft.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 17 (18)Limitations for work on the chassis

Space above the fuel tank

Space above the fuel tank

The bodywork must be adapted for fuel tanks that protrude above the top of the chas-

sis frame. The table shows how much different types of fuel tanks protrude above the

chassis frame.

The normal and high positions depend on how the tank is installed vertically.

Variant Normal position (mm) High position (mm)

Standard 22 72

Wide 22 72

Cylindrical 39 -

Extra wide 33 -

348 084

348 086

348 085

348 087

Standard. Wide. Cylindrical. Extra wide.

Scania Truck Bodybuilder 22:10-686 Issue 5 2021-02-10

© Scania CV AB 2021, Sweden 18 (18)You can also read