Design for your floor coatings - HEUCOSIN Special - Heubach

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Polymer floor coatings Multi-pigment preparations

HEUCOSIN™ Special pigment preparations The HEUCOSIN™ Special products are rea- In comparison to straight pigment blends the

is our principal product line developed to dy-to-use pigment preparations which have HEUCOSIN™ Special preparations also exhi-

meet the specific requirements of thickfilm been pre-dispersed and adjusted to the bit outstanding batch-to-batch consisten-

systems especially for polymer floor coatings. most commonly used RAL shades. cy which enables the user to create colors

In most cases the desired color shades can All grades exhibit universal processing cha- which are perfectly uniform. This can even

only be obtained by blending color pigments racteristics and can easily be dispersed in be achieved with simple stirring equipment

with significant differences regarding surface solvent-free EP, PU, PMMA systems and often found on construction sites.

characteristics and specific weights. waterborne EP formulations..

As a consequence they tend to separate It is worthwile to mention that this ease

during the film forming process. This well- Unique finish technology of processing is based on the physi-

known phenomenon is either called floating cal modification of the pigment surfaces.

(horizontal separation) or flooding (vertical The very specific properties of HEUCOSIN™ Consequently, there is no negative influence

separation). Special preparations result from a unique on general film properties which is frequently

The first causes undesirable surface texturing finish technology. A combined co-finishing observed when using ionic dipersing additives.

(Bénard cells) whereas the latter alters the process including the mix mulling technolo-

color shade as a result of pigments being gy allows for intensive mixing and grinding.

distributed unevenly in the direction per-

pendicular to the pigment surface (rub-out The resulting physical interlocking of the pig-

test). These effects are especially observed in ment surfaces minimizes the separation of

thickfilm formulations. the predispersed pigments and the floating

and flooding phenomenon later during the

film formation.

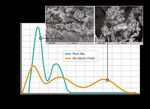

Polymer floor coatings 1Mix Mulling Technology

Excellent fastness properties

Easy dispersion even at construction sites

HEUCOSIN™ Special pigment preparations

Weather

PMMA

Alkali

Particle size distribution

Light

Acid

are designed for exterior use and therefore

PU

exhibit very good light and weather fastness 12,00

as well as excellent resistance to solvents,

acids and alkalines. 10,00

8,00 Product Full Shade RAL Application Fields Fastness Properties

Volume %

Value-in-use Plain Mix HEUCOSIN™ Special Beige G 10121

Mix-Muller Finish 1001 8 5 5 5

6,00 (Beige RAL 1001)

HEUCOSIN™ Special Yellow G 6514 N

Formulation costs with HEUCOSIN™ Special 1002 8 5 5 5

(Sand yellow RAL 1002)

4,00

are lower when compared to the total costs HEUCOSIN™ Special Beige G 6515 N

1011 8 5 5 5

(Brown beige RAL 1011)

of handling and testing of several monopig- 2,00

HEUCOSIN™ Special Yellow G 6530 N

ments or monopigmented pastes on a com- (Olive yellow RAL 1020)

1020 8 5 5 5

mercial scale. 0,00 HEUCOSIN™ Special Red G 10345

3013 7-8 4-5 5 5

0,00 2,00 4,00 6,00 8,00 10,00 12,00 (Tomato red RAL 3013)

HEUCOSIN™ Special Blue G 10248

Particle Diameter [ m ] 5009 7-8 4 5 5

(Azure blue RAL 5009)

HEUCOSIN™ Special Tomato Red G 10345 HEUCOSIN™ Special Green G 6557 N

6002 7-8 4-5 5 5

(Leaf green RAL 6002)

HEUCOSIN™ Special Green G 6516 N

6021 8 5 5 5

(Pale green RAL 6021)

Minimized floating & flooding due to interlocking of the pigment surfaces

HEUCOSIN™ Special Grey G 6555 N

7001 8 5 5 5

(Silver grey RAL 7001)

HEUCOSIN™ Special Grey G 10256

7012 7-8 4 5 5

(Basalt grey RAL 7012)

HEUCOSIN™ Special Grey G 10120

7016 8 5 5 5

(Anthracite grey RAL 7016)

HEUCOSIN™ Special Grey G 6556 N

7023 8 5 5 5

(Concrete grey RAL 7023)

HEUCOSIN™ Special Grey G 6517 N

7030 8 5 5 5

Tomato Red (Stone grey RAL 7030)

Blend Blue Grey Concrete Grey Leaf Green

G 10345 Blend Blend Blend

G 6528 N G 6556 N G 6557 N

HEUCOSIN™ Special Grey G 6528 N

7031 7-8 4-5 5 5

34.9 L* 38.4 40.0 L* 44.5 50.6 L* 54.6 32.2 L* 35.4 (Blue grey RAL 7031)

56.2 a* 55.1 -2.6 a* -4.6 -1.6 a* -1.3 -33.0 a* -32.0 HEUCOSIN™ Special Grey G 6518 N

7032 8 5 5 5

(Pebble grey RAL 7032)

40.3 b* 40.4 -1.9 b* -3.6 6.9 b* 9.0 -24.3 b* 26.9

HEUCOSIN™ Special Grey G 6531 N

7033 8 5 5 5

(Cement grey RAL 7033)

HEUCOSIN™ Special Grey G 10139

7035 8 5 5 5

(Light grey RAL 7035)

HEUCOSIN™ Special Grey G 10140

7037 8 5 5 5

Guide formulation: Self-levelling floor coating with solvent-free epoxy resin and (Dust grey RAL 7037)

HEUCOSIN™ Special pigment. HEUCOSIN™ Special Grey G 10135

7038 8 5 5 5

(Agate grey RAL 7038)

Recommended Potential Use > Special shades available on request

325 g Epilox-T19-38/700 (epoxy resin, Leuna Harze Gmbh)

+ 451 g Quartz flour (Quarzwerk Frechen) Due to limitation of printing process some slight variations between the color as illustrated may be observed.

+ 1 g Anti Terra 204 (dispersing agent, Byk-Chemie)

+ 10 g Byk 501 (deaerating agent, Byk-Chemie)

+ 50 g HEUCOSIN™ Special Pigment (corresponding to 5%)

+ 163 g Epilox curing agent H10-34 (curing agent, Leuna Harze GmbH)

= 1.000 g total weight

2 Our products 3Our Service

At Heubach, customer satisfaction comes Custom color adjustments play a significant

first. As a supplier of high-quality pigment role both in coatings and plastics applica-

and pigment preparation solutions we sup- tions.

port our customers anywhere where pig-

ments are in use. We have extensive expertise in the develop-

ment of colors for a variety of plastics, paint

With active service centers both globally and and coating systems. Depending on fastness

regionally we provide our customers with properties, application or processing requi-

the technical support essential for the imple- rements, we can deliver the right color for

mentation of customer-specific requirements your application, plastic compounds or even

and solutions. a specific paint system.

Fully equipped technical laboratories and

centers enable us to carry out tests for all

relevant applications, such as printing inks,

paints and coatings, including corrosion

protection, coil and powder coatings and

plastics.

4Our product specifications, application information and any other information in this document is based on our current state of knowledge at the Revision Date mentioned below. They are non-binding and cannot be taken as a guarantee. The processing company must establish the suitability of individual products itself. As their use lies beyond our knowledge and control, we cannot accept any liability relating to the use of our products in particular applications. In addition to that, the legal rights of third parties must always be considered. The specification agreed between the customer and ourselves is the basis upon which our general sales and delivery conditions are set and is the deciding factor concerning any liabilities. Our standard specification is then valid if no specification has been agreed upon between the customer and ourselves. sales@heubachcolor.de www.heubachcolor.com 01/2019

You can also read