SolidFlow 2.0 Solid mass fl ow measurement - EN - SWR engineering

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

EN

SolidFlow 2.0

Solid mass flow measurement

Product Information

SWR engineering Messtechnik GmbH PART OF THE ENVEA GROUPUse

SolidFlow 2.0 has been specially developed for

measuring solid volumes conveyed through pipelines.

SolidFlow 2.0 is used for online measuring:

• all types of dust, powder, granulates, etc.

• with particle sizes between 1 nm and 10 mm

• which are conveyed pneumatically

• or in free fall after mechanical conveyor systems

SolidFlow 2.0 is extremely easy to install and has a wear-

resistant design.

SolidFlow 2.0 is the latest generation of microwave-based

measuring systems for measuring the flow of solids.

Based on our many years of expertise, SWR has devel-

oped a second generation version of this sensor.

SolidFlow 2.0 is a reliable sensor which eliminates the dis-

advantages encountered in current technologies available

on the market.

f≠f0

Function

The SolidFlow 2.0 sensor uses the latest microwave tech-

nology. The sensor is used exclusively in metal pipelines.

The special integration of microwave technology creates

the measurement field together with the metal pipeline.

The microwave radiation in the pipeline is reflected by the

Amplitude

Amplitude

solid particles and received by the sensor.

The frequency and amplitude of the received signals are

analysed.

The sensor works like a particle counter, counting the

quantity of flowing particles per unit of time. The frequen-

0 90 200

cy-selected evaluation system ensures that only flowing Frequency

Doppler Frequency fD

particles are measured while deposits are suppressed.

SolidFlow 2.0 features active stratification compensation

which compensates measurement errors caused by strati-

fication, in particular while materials are being pneumati-

cally conveyed. Spectrum during

stratification

Based on new processing technology, the measurement

signal is converted into its frequency spectrum which is

Amplitude

Amplitude

used to detect the material's flow pattern. The sensor is

calibrated during installation by entering the reference

quantity and pressing a button.

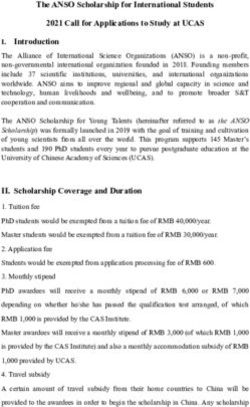

The illustrations show two frequency spectra for different

flow conditions with similar mass flows. A software algo-

rithm ensures that the measuring result is correct even Frequency

Doppler Frequency fD

with different flow conditions.

2System

A complete measuring point consists of the following

Sensor C-Box Transmitter

components:

• Transmitter in the DIN Rail housing or field housing

• Sensor mount for welding to the pipe

max. 300 m or

• Sensor (union nut, spacer rings, sealing ring for adjust-

ing to the wall thickness)

• Installation instructions

DIN rail transmitter

• Teflon sleeve (depend on application)

• C1- or C3-Box (optional)

Applications – Practical Examples

• Compounding plant

500 kg/h

Mixtures are created using the sandwich technique with

a weighing container. The existing weighing device was 1 1 1

M Exhauster

not designed for dosing small quantities of additional

components, which meant that measured doses could not

be reproduced. Rotary value

2 Balance

Benefits:

3

SolidFlow 2.0 enables the dosing of additional com-

ponents to be reproduced and better balancing of the

1 different types of malt (0,3 – 1 mm Ø) 2 Mixer 3 DN 50 stainless steel

quantities used.

• Fuel delivery

1,5 t/h

In a boiler, dust is conveyed as fuel to the combustion

chamber. As there is no information about the distribu- Fuel (-dust)

tion of fuel quantities in the different supply lines, setting

optimum combustion is not always possible

Compressed

gas

Benefits: 1

2

3

Each supply line is monitored by a SolidFlow 2.0 system, approx. 1.5 t/h

Granulation approx. 1 m

and the supply of fuel quantities is regulated in each

individual supply line. This enables accurate and uni- Fluid-Gas (N2) 1 Pressure bin 2 Combustion chamber 3 DN 50 steel pipe Primary fuel

form distribution of fuel quantities which is an essential

requirement for optimum combustion.

3• Quantity balancing

10 t/h

The supply of materials to the grinding system is subject

to significant fluctuations.

Benefits: 1

to the mill

2

With SolidFlow 2.0, the progress of the mass flow can be

measured and documented. for further processing

If necessary, adjustments can be made. 40 m DN 150

riser,

By measuring the coarse grain between the grinding granulation

approx. 5 – 10 m

1 Lime hopper

system and the mill, the grinding quality can also be 2 Classifier

monitored.

• Free-fall application

300 kg/h

A belt weigher records the amount of cement conveyed.

This measurement is used as a guide value when meter-

Iron-II-Sulphate hopper

ing the addition of iron(II) sulphate.

This must be metered with a proportion of 0.2 … 0.3 %.

Benefits:

With SolidFlow 2.0, the actual value of the metered iron(II)

sulphate is recorded and regulated by adjusting the screw

DN 150 sheet metal pipe

conveyor's speed. Granulation 40 – 60 m

The result is uniform product quality.

• Granulate dosing system

400 kg/batch

The existing dosing tank is too inaccurate, that means the

plant can only operate intermittently.

M

Benefits:

SolidFlow 2.0 enables transparent monitoring of the con- 3

1

veyed quantities and the process can be turned into one 2

Granulation

continuous operation. 100 m

1 Granulation hopper

2 Proportioning weigher (no longer necessary)

4

3 Mixing chamber

4 DN 50 steel pipe

4Mounting and installation

To install the sensor, the installation location must be de-

termined according to the required inlet and outlet areas.

With pipe diameters larger than 200 mm, 2 or 3 sensors

are used per measuring point and the sensors are ar-

ranged at angles of 90° or 120° to each other.

In free-fall applications (for example after screw conveyors

or rotary feeders), an infeed section (drop height) of at

10 x DN

8 x DN

8 x DN

least 300 mm is ideal.

3 x DN

The sensor socket is welded on at the specified installation

location. After this, a 20 mm-borehole is drilled through

10 x DN (min. 1 m)

the sensor bracket and through the pipe wall.

8 x DN (min. 1 m)

8 x DN (min. 1 m)

The sensor is then adjusted to the wall thickness, inserted

and fixed with the aid of union nuts. Done!

5 x DN DN

Hopper

300

1 2 3

A

B

A

B

Commissioning

Commissioning of the measurement takes place via the The menu language can be freely selected, German,

evaluation unit. The field housing provides a convenient, English and French are available.

menu-driven entry of the parameters on the touch display.

An analogue output with 4 ... 20 mA, a changeover relay When using the DIN Rail transmitter, the parameters are

contact as well as a pulse output (open collector) are entered via the SWR software.

available for the evaluation of the sensor signals.

5Technical data

Sensor

Housing Stainless steel 1.4571

IP 65, DustEx zone 20 or

Protection category

GasEx zone 1 (optional)

Front end of sensor: -20… +80 °C

Operating temperature Optional: -20 … +200 °C

Sensor electronic: 0 … +60 °C

Max. working pressure 1 bar, optional 10 bar 271

Working frequency K-Band 24.125 GHz, ±100 MHz

Transmitting power Max. 5 mW

Weight 1.3 kg

Dimensions Ø 60, Ø 20, L 271 mm

Accuracy ± 2 … 5 % in calibrated range

78

certificated

according to ATEX

Transmitter (DIN Rail) Transmitter (field housing)

110 / 230 V AC 50 Hz

Power supply 24 V DC ±10 % Power supply

(optional 24 V DC)

Power consumption 20 W / 24 VA Power consumption 20 W / 24 VA

Protection type IP 40 to EN 60 529 Protection type IP 65 to EN 60 529/10.91

Ambient operating temperature -10 … +45 °C Ambient operating temperature -10 … +45 °C

Dimensions 23 x 90 x 118 mm (W x H x D) Dimensions 258 x 237 x 174 mm (W x H x D)

Weight Approx. 172 g Weight Approx. 2.5 kg

DIN rail fastening DIN 60715 TH35 Cable screw connectors 3 x M20 (4,5 - 13 mm Ø)

Connection terminals cable Connection terminals cable

0.2-2.5 mm2 [AWG 24-14] 0.2-2.5 mm2 [AWG 24-14]

cross-section cross-section

1 x 4 … 20 mA (0 … 20 mA), 3 x 4 … 20 mA (0 … 20 mA),

Current output Current output

load < 500 Ω load < 500 Ω

Interface RS 485 (ModBus RTU) / USB Interface RS 485 (ModBus RTU) / USB

Pulse output Open collector - max. 30 V, 20 mA Pulse output Open collector - max. 30 V, 20 mA

Max. rated load: Max. rated load:

250 V AC 250 V AC

Max. peak current: Max. peak current:

6A 6A

Max. rated load 230 V AC: Max. rated load 230 V AC:

Relay contact Relay contact

250 VA 250 VA

Max. breaking capacity DC1: Max. breaking capacity DC1:

3/110/220 V: 3/0.35/0.2 A 3/110/220 V: 3/0.35/0.2 A

Min. switching load: Min. switching load:

500 mW (10 V / 5 mA) 500 mW (10 V / 5 mA)

Data backup Flash memory Data backup Flash memory

SWR engineering Messtechnik GmbH

(All rights reserved.)

Gutedelstraße 31 · 79418 Schliengen (Germany)

Fon +49 7635 827248-0 · Fax +49 7635 827248-48 · www.swr-engineering.com

PART OF THE ENVEA GROUP

6 EN 26/02/2019You can also read