SAP Innovation Awards 2020 Entry Pitch Deck - The Digital Transformation of a Global Supply Chain Delta Airlines - Pitch Deck template for the ...

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

SAP® Innovation Awards 2020 Entry Pitch Deck The Digital Transformation of a Global Supply Chain Delta Airlines

Company Information

Headquarters Atlanta, Georgia

Industry Airlines

Web site www.delta.com

Delta Airlines is one of the world’s largest global airlines. The company operates over 5,400 flights daily and

serves 325 destinations in 52 countries on six continents. The company’s strategic goals include:

Put Safety First - Always

Be The Airline Of Choice For Customers including:

– Utilize technology to deliver more personalized service and optimized operations

Run The Industry’s Best Operation

Live Our Values And Rules Of The Road including:

– Achieve at least 85% positive employee engagement

– Invest in our people through training, development, and engagement

Deliver Industry Leading Financial Results

Invest For The Future

Expand Global Reach

Be a Good Corporate Citizen

© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ PUBLIC 2The Digital Transformation of a Global Supply Chain

Delta Airlines

Challenge

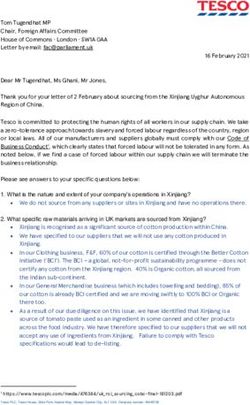

“The SAP team executed a Catering logistics was managed by an outside vendor using six different disparate systems across 155 different

very complex in-sourcing catering locations. Systems and processes were antiquated and service levels were consistently below the

exercise of activities that had company’s target of 95%, reaching as low as 88% and getting worse. A consultant study identified $8M to $22M

been outsourced for 17+ yrs. in potential annual savings by insourcing their catering logistics operation.

This involved the need for IT Solution

to work closely with the The decision was made to bring the solution in-house and leverage Delta’s longstanding partnership with SAP.

business to design all the The core components of the solution included SAP ERP (implemented in 2001), SAP Cloud Platform, SAP

business processes and Integrated Business Planning (IBP), and SAP HANA Platform.

provide training to both a

brand new SC team and Outcome

across 156 stations globally. 155 locations, 255 suppliers, and 8 warehouses went live November 2019 on a single unified platform. The

The team is now poised to company now has visibility into the stock levels, supply chain, and more so they can eliminate shortages and

finish this effort in 2Q and waste while improving operational efficiency and running analyses for continuous improvement.

provide us with the tools

necessary to make a positive

impact for all our FAs and

customers on a daily basis.” 1860 employees,

2020 savings Shortages have

$8M 33% 1860

vendors, and

should be at already been partners enabled

Ash Dhokte least $8M reduced by 1/3 in

Managing Director with a global

the first month supply chain

view

© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ PUBLIC 3Business Challenges and Objectives

Catering logistics, procurement, transportation, billing, and payment were managed by an outside vendor

using seven disparate systems across 155 different catering locations, 8 warehouses, and 255 vendors

around the world. Specific problems included:

Supply service levels were consistently below target at 88% and getting worse.

No insight into stock levels. Stock levels were inaccurately reported in the field.

Out of stock situations occurred frequently.

Unknown overstock situations occurred where supply couldn’t be matched to demand.

Supply waste.

Project objectives:

Migrate from six disparate systems and an outside vendor to a single unified in-house solution.

Visibility into global stock levels and deliveries to optimize the logistics operation.

Better inventory planning to reduce waste and eliminate supply shortages.

Potential $8M to $22M in potential annual savings.

© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ PUBLIC 4Project or Use Case Details

• Example one: No visibility at the station level across 155 locations. In some cases the regional

manager would call the station manager and, without any available data, the local manager

would guess the inventory. These guesses could be wildly inaccurate. As a result, products like

catering carts would run out of stock and the re-order lead time was 6 months. Plastic cup

shortages were also a problem, and re-order lead times were 180 days.

• Example two: At a major consolidation center in Asia, they had $500K in headsets in stock that

were not tracked in inventory. Yet flights were running out and procurement kept ordering more.

• Example three: There was a large stock of blankets at Heathrow that were not visible in

inventory when marketing was launching a new brand campaign and brand color. When

marketing checked the inventory system to determine what items were low that they could

prioritize for replacement, being unaware of the large inventory at Heathrow they selected

blankets for priority replacement. Once they switched the blanket requirements to the new

color, Heathrow’s blankets became obsolete, which cost over $1M.

© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ PUBLIC 5Benefits and Outcomes

Business or Social IT Human Empowerment

• Improvement in supply service • Consolidation from six systems • Visibility went from 0 to 360

levels and elimination of down to one globally across degrees for managers

shortages and waste. Service 155 stations, 8 warehouses, responsible for logistics.

levels were 88% pre-launch and and 255 vendors. • The supply chain management

already up to 92% in December, • Access to data went from one team now has data to manage

which represents a 33% month (which was often 255 vendors and negotiate

reduction in shortages in the inaccurate) to same-day where better contracts.

first month. needed. • 255 vendors have their own

• Expense reduction from: • Efficiencies in training, portal for real-time access into

transportation efficiencies operations, and extensibility orders, order response,

(where orders can now be from a single unified cloud invoicing, and payment.

combined on the same based system. Before, vendor management

truckload); optimized inventory was all email.

levels; reduced outages and • Global visibility and access to

waste. data for analysis and • 1860 total employees,

continuous improvement. vendors, and partners are

• Expected 2020 savings is now empowered with visibility,

between $8M to $22M. • 418 total locations and vendors

migrated to a single unified management tools, and

platform. analytics capability.

© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ PUBLIC 6Architecture © 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ PUBLIC 7

Deployment

Deployment status Live

Date Nov 17, 2019 Number of users 1800. 60% 3rd party

SAP technologies used: Deployment status

SAP product (live or proof of concept [POC]) Contribution to project

1 SAP ERP Live Integrating billing and payments

SAP Integrated Business Planning Optimize logistics and inventory planning based on the

2 (IBP)

Live

Delta flight schedule

3 SAP Cloud Platform Live Custom-built portal access

4 SAP SLT Live Real-time system replication on SAP Cloud Platform

Communication between the UI5 application and On-prem

5 SAP Gateway Live

ECC

If you have used one of the services or support offerings from SAP Digital Business Services during the implementation or

deployment phase, please select with X one or more of the following offerings:

SAP MaxAttention™ SAP ActiveAttention™ SAP Advanced Deployment

SAP Value Assurance SAP Model Company Others:

SAP Innovation Services SAP Innovative Business Solutions

© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ PUBLIC 8Advanced Technologies

The following advanced technologies were part of the project.

Technology or use case Yes or No Contribution to project

1 3D printing No

2 Blockchain No

Plan to use for tracking carts to manage cart lifecycles. Also

3 Internet of Things (IoT) Planned

planned for sensors to detect what is on food trays

4 Machine learning or AI Planned Plan to use for IBP and consumption optimization

Planned to be used for communication between Delta and the

5 Conversational AI Planned

Catering Locations.

6 Robotic process automation No

7 Data anonymization No

8 Augmented analytics No

© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ PUBLIC 9You can also read