In no va tion Modular vs. traditional - Jan Snel

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

The most flexible magazine ever!

Modular vs.

traditional

If the end result is the same, then the

journey towards it becomes interesting

Earthquake-

resistant

construction

More current than ever

JNSNL - Nº 9, October 2016

in·no·va·tion

Not an obligation but a state of mind 8 713818 000362 >Snel contents

CONTENTS

in this issue... The circle is getting rounder and rounder

Snel in pictures Buy, use, throw away. Buy, use, throw away ... The old linear economy has run its course.

More and more people and businesses are embracing the circular economy. This is taking

22 After-school care, Kruibeke (B)

us towards an era in which renewable energy, the recycling of raw materials, the sharing of

23 Oleon, Oelegem (B)

solutions and retaining the value of materials will be put first. It will come as no surprise to

24 Bayards Aluminium Constr., Heijningen

you that all this is getting us excited.

26 DuPont de Nemours, Mechelen (B)

27 Fire station, Falck Fire Services, Delfzijl For many years, we at Jan Snel have been supplying flexible buildings that can be used

28 Doc-Direkt, Winschoten again and again. Our units stay in place for as long as they are needed, after which they are

30 Ajax (De Toekomst), Amsterdam collected and prepared for their next purpose. This circular approach is practical, sustainable

32 Sint-Hiëronymus, Sint-Niklaas (B) and efficient, and it creates a constant flow of unique, temporary buildings. Once again this

33 Genzyme Flanders, Geel (B) issue of JNSNL is brimming with examples!

34 De Nessevliet, Oud Verlaat

Our units are not bound to a function, time or industry. Sometimes we may be building a

36 De 2-stroom, Hendrik-Ido-Ambacht

new wing on a hospital (pg. 52), and at other times it might be a school that can withstand

38 UniQure, Amsterdam

earthquakes (pg. 46). Increasingly, our units are travelling across the borders and nowadays

40 Wij Teams, Hoogkerk

they can even be found as far away as Australia.

The buzz of circular initiatives is all around us and we feel hugely energised by it all. Take,

Snel dictionary

for example, the way architect Thomas Rau so consciously deals with the life cycle of the

in•no•va•tion free•dom em•ploy•ee 05 Innovation products that he uses and the way he is always looking for new ways of getting the most out

13 Freedom of them. We are greatly inspired when we see that an architect is so committed to recycling

45 Employee and the re-use of space. Even real estate is becoming more and more liberated from old

habits.

Snel other

All this only makes us even more ambitious to reach our own sustainability targets, which we

06 Snel Flexibles have set out in a sustainability report. For instance, we are aiming to recycle 90% of materials

10 Snel Transport within four years. It is very specific and measurable, so rest assured that you will be able to

14 Snel International hold us to our promises.

16 Snel boy: Dirk-Jan

In this issue of JNSNL, you can read more about our vision on sustainability. More than

18 The latest developments

anything, however, we want to inspire you with some great examples of the circular economy

20 Modular vs. traditional

in which we have been proudly leading the way for years. You can be absolutely certain that

42 Sustainability is better for everyone

we will continue to do so!

44

Het meest flexibele magazine ooit!

Exchange of words

46 Earthquake-resistant construction

48 Sint-Paulus School, Drongen (B) Modulair vs.

traditioneel

Als het eindresultaat hetzelfde is,

wordt de weg ernaartoe interessant

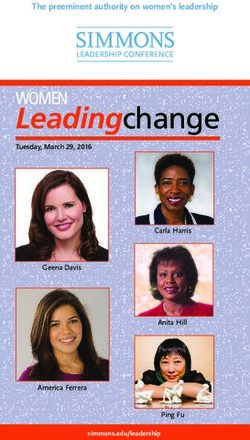

On the cover: Harry and Jacqueline van Zandwijk

50

Aardbevings-

Snel internal: new K3000 module bestendig

bouwen

Actueler dan ooit

JNSNL - nr. 9, oktober 2016

De 2-stroom,

52

in·no·va·tie

Centre for Nuclear Medicine Hendrik-Ido-Ambacht

Geen moetje, maar een ‘state of mind’ 8 713818 000362 >

02 magazine magazine 03Snel in figures

The figures

WE ARE CURRENTLY PRODUCING 400 M² OF NEW BUILDINGS A DAY

in•no•va•tion

We are putting up a 2,000 m² school building in

20 working days on site

In our warehouse, we have over

6,000 items in stock

This is our word of the year for 2016.

Leading the way is a constant challenge.

In order to maintain a high level of quality, It is not an obligation but a state of mind.

Seeing opportunities and daring to grab

we arrange 12 toolbox meetings a year them. Innovation is a broad concept

covering products, processes, engineering,

markets and partnerships. By focusing on

innovation, we maintain the impetus and

AT PEAK TIMES, WE USE 22 TONS OF STEEL PER DAY we stay ahead of the field.

23% of our production staff have been with us for

less than 5 years, 32% between 5 and 12½ years, 24%

between 12½ and 25 years and 21% for 25 years or more

The total age of the staff in our production department is 3,519 years

04 magazineSnel flexibles

Flexibles

Paper sofa

A flexible couch that very much resembles

an old-fashioned paper streamer (the

accordion type). You pull it out and you

have yourself a love seat, a two-seater or a

circular sofa. Made from sturdy cardboard

but really comfortable and sustainable.

It can even be used as garden furniture,

although we think it might not be such a

great success in a Dutch garden.

Flexibles

At Jan Snel, we love flexibility in all

shapes and sizes. For example, there

are countless innovative products

that are at least as flexible as our

solutions. Let us introduce you to just

a few of the flexible gadgets that we

have spotted.

magazine 07Snel flexibles Snel flexibles

Flexibles Flexibles

Flexible light cable

City Nomad We are all familiar with the Ivy plant.

Meet Nomad, a modern-day wallet for You know the one; it climbs up and

the modern city nomad. Featuring lots of curls through everything. The reason

compartments for bank passes (because why they chose the name for this lamp

money is more and more often of the is pretty obvious. The eight-metre long

plastic variety), and built-in telephone cable has a flexible part that can easily

charger and RFID blocker so you can be hung over things or shaped into a

never make an unintentional contactless word or symbol. The small LED lamp at

payment. If that isn’t flexible, then we the end of it shines a warm white light

don’t know what is. to illuminate your own creation.

08 magazine magazine 09Snel Transport

to the Jan Snel Group and that appeals to were. After a couple of productive talks we

me. I also like the family business culture reached an agreement.”

that is so prevalent here.”

What is your background? In

What makes your job so interesting? practice, a lot of people at Jan Snel

“I am given the freedom to change things have been through considerable

and make improvements. My focus is growth. Was this also the case for

on the future. I get the opportunity to you?

tackle things and see them through. The “Yes, when I was sixteen, I started working

conditions of my job position are clear, but as a commercial vehicle mechanic. I got

I also have the management’s confidence my truckdriver’s and planner’s diploma and

to determine how I fulfil them. Besides, decided to take things further in logistics.

this job is also a step forward for me. The I went from driving to planning and was

long-term challenge for me is to succeed

Jos Voorbij as head of Jan Snel Transport.

always getting encouraged by my parents.

I became head planner, operational

“ I’ve found my

I am keen to learn, curious, ambitious and manager, and I spent time living in Sweden place here.”

determined to live up to expectations.” where I worked for Van Maanen Transport,

Barneveld. After they went bankrupt, the future and I would like to bring about

How was the introduction to Harry their staff and business relations asked me some changes. This leads to the occasional

and Jacqueline? what was going to happen next. I got in discussion, but that is no problem. We

“I had a long chat with them and am full touch with a fellow haulier in Barneveld respect each other, learn from each other

of admiration for their entrepreneurship and they took over the staff and the and form a united front towards the rest of

Glimpse into the

and enthusiasm. They are the figureheads business relations as well as me. I started the organisation.

Future

of the organisation, both internally and working as the Commercial/Operations

externally. They work hard at making the Manager. Again, I was determined to The transport industry has just

business succeed while safeguarding the further my development, especially in managed to scramble back out of a

family atmosphere. They know all the staff, terms of its breadth. This job enabled me deep hole. Is it plain sailing now?

make sure anyone moving house receives to do just that. I’ve found my place here; “We have indeed been through some

a bouquet and they enquire about people’s I‘ve managed to achieve what I’d always tough years. It isn’t all plain sailing yet

families. I think what they do is marvellous. wanted: to be at the head of an ambitious though. Now, there are new challenges

My motto is: take everyone seriously. Harry logistics organisation.” that we have to face, such as the influx of

and Jacqueline do this like no-one else I’ve new drivers. We have already made plans

ever met. Workers can knock on their door You are Deputy Head alongside for this though (read more about these

at any time, knowing they will be listened Jos Voorbij. How does the division plans on pg. 55 of this JNSNL).”

Since February, there has been How are you enjoying your new What made you choose Jan Snel to.” of duties work and what is your

a new Deputy Head at Jan Snel job? Transport? partnership like? What else are you going to tackle?

Transport. Since that time he “From day one onwards, I have felt “Well, it’s because it isn’t any old transport Did you already know the “We already knew one another, so our “There is plenty to do. I want to take a

has not stood still. Fired by right at home in the organisation. There company. It is broader than that. Obviously company? introduction went smoothly. We spar well lead in our business and the focus is on

passion, focus and enthusiasm, had already been communication in the we work closely with Jan Snel Flexible “My father worked here as a driver for together even though our backgrounds are the long term, so we are tackling things

he got down to business. company about my arrival, for instance in Building Solutions and that was something more than thirty years. During my working different. Jos has an extensive knowledge step by step. The development of the new

Simeon Roodenburg took some the staff magazines the Snelbinder and the I found interesting. Together, we examine life, I worked with Jan Snel Transport and when it comes to transporting recycling articulated lorry is one of the first things

time out for an interview in JNSNL Special. It worked. People knew that how we are able to accomplish Jan Snel’s had regular contact with Jos Voorbij (head materials as well as laws and regulations. and the introduction of the new on-board

which he answered the questions I would be starting here and that was really targets as a whole. We think about new of Jan Snel Transport). So I already knew He also knows Jan Snel Transport’s computers is another. There is a lot more

we asked him. great. It also underlines the warmth you transport solutions, on a national and inter- how things worked at Jan Snel. When I customers inside and out. I also have my lying ahead, but we can discuss that in

get at this family business which makes you national level. As well as being a transport heard that Jan Snel Jr was leaving, I very knowledge, experience and goals with Jan another interview.”

feel so welcome.” company, we are also logistics consultants cheekily called to find out what the plans Snel Transport. I concentrate strongly on

10 magazine magazine 11Snel Transport

Successful overtaking manoeuvre

We are also seeing growth at Jan Snel Transport. The crisis in the transport industry has

now made way for optimism and increasing volumes, so the time has come to concentrate

investments on building a leading position in the sector with efficiency and sustaina-

bility as the key words. The Head of Jan Snel Transport, Jos Voorbij and Deputy Head

Simeon Roodenburg explain:

New on-board computers

Besides a perfect fleet of vehicles, good

communication between Planning and

free•dom

drivers is crucial. “Here too, we have

developed an innovative system that

matches our current strategy,” says

Simeon. “After looking at different

systems, we invested in new on-board

computers that enable our drivers to stay

in close touch with Planning, and operate

in such a way that fuel consumption is as

efficient as possible. The system includes

driving style evaluation, track & trace and

a handy navigation function, and commu- 365 days, 24/7. Whether it concerns the

“We have made two key investments over to share ideas with us to come up with nicates with Planning. It is a step towards world in general or our own domain in

the past six months,” says Jos. “Due in the new articulated vehicle. The biggest complete fleet management. The system particular: freedom is a basic human need.

part to changing requirements at Jan Snel way it differs from existing lorries is that allows us to guide the driver better and For clients, freedom means having the

Flexible Building Solutions and efficient the new articulated lorry can transport enables us to inform our customers more unlimited possibility of making their own

transport, we developed a new type of lorry, two student flats at a time instead of one. completely and accurately about delivery choices in terms of design, materials and

two of which have since been purchased. It goes without saying that this means times, etc. Our lorries will probably start finishing. After being provided with excel-

The reason behind this is the success of Jan huge cost savings. In addition, it is also using this new system from November lent advice by our professionals, of course.

Snel’s student accommodation. Through great news as far as sustainability and CO2 onwards.” 100% customisation. More, not less.

projects like Ravel Residence and the recent emissions are concerned. We are going for

construction of 461 student flats in Vaals, maximisation on all fronts: for example, our These innovations show that the company

we have examined how we might transport drivers undergo training that teaches them is ready for a new phase. “This investment

units of this kind as efficiently and sustai- to drive these new vehicles as economically was also necessary in the area of com-

nably as possible. We certainly didn’t rush as possible. Two of these new articulated munications. We shall indirectly reap the

into anything. Along with colleagues who vehicles went into service at the beginning benefits of these investments, since we are

work with us in any way whatsoever – for of September. With a Service Level Agree- using them to build specifically towards

example, forklift truck drivers, the head of ment (SLA) and by formulating KPIs, we sustainability. We are keen to continue to

production, lorry drivers and planners – we are introducing a new way of collaborating lead the way in transporting products for

formulated the requirements. Then we with our suppliers. It helps us keep each recycling. Our new lorries and on-board

found the most suitable companies for other on our toes so we can continue to computers are certainly a step in the right

the job. The company that was awarded improve.” direction.”

the contract was also the one that wanted

12 magazineSnel international

Jan Snel

across the border

Jan Snel is not only doing well at home; our fame

is growing abroad too. The success of our newly

developed products, including the Blast Resistant

Module (BRM), is creating more and more

opportunities across all of our divisions and

solutions. Monique Los, European Sales Manager,

tells us about the partnership models, our step-by-

step approach and our prospects.

“The renting of our Blast-Resistant Modules has been a great

success. These temporary buildings have been specially developed

to protect workers at hazardous sites in the petrochemical

industry in areas where the risk of explosions is high. It is a

product that has won us attention throughout Europe. Thanks

to the success of the BRM, we hold regular meetings with

customers to talk about supplying this type of accommodation

The power of local

Besides Germany, Jan Snel now also

“ Not only does are we able to offer customers optimal

service on both straightforward and complex

for use during special projects or Turnarounds. It frequently turns operates in England and Spain. Monique: involving local busi- technical issues.”

out that besides the BRM, they also require other buildings for “Here we work with our partner in renting

temporary or permanent use. Our customers are often surprised out our BRM to the industry. We also work

nesses engender a Careful now

to find out that besides our highly specialised buildings, we can with subcontractors and partners who are better mutual under- As far as growth abroad is concerned, we

also provide them with an extensive and complete package of actually based in those countries. Together are not into being over-hasty. Monique: “We

temporary and permanent accommodation. We are also getting with these parties, we can ensure that all standing with our are growing quickly at the moment, but we

asked more and more frequently whether we can look after the turnkey projects are completed as promised clients, it also has its are taking things one step at a time. This

whole package: from furniture right up to fully-fitted temporary and our local partners/subcontractors are means thinking carefully before making final

or permanent residential buildings for workers. They benefit from ideally placed to provide our clients with practical benefits.”.” decisions regarding our strategy. We remain

having a single supplier and a single point of contact for all their excellent, rapid service. Not only does calm, in control and we do not let ourselves

accommodations, including the complete interior. It gives us the involving local businesses engender a better mutual understanding get carried away. At the moment, we have an excellent basis and

opportunity to demonstrate our qualities abroad. We currently with our clients, it also has its practical benefits. The customer has great projects, and we are working really well with local companies

operate mainly in the chemical and petrochemical industries. a local point of contact who is able to provide any assistance in and partners. We are also busy making continual improvements to

As more and more people use our solutions, we are building the same language. This way of working creates the right sense of our products, such as the BRM. Above all, we keep on listening to

awareness of our brand.” collaboration among our partners and subcontractors. Only together our clients and focusing on our own targets.”

magazine 15Snel boy Snel boy

This is Dirk-Jan Team player

“My career started in the middle of the Better

financial crisis. I graduated in HBO - level Working at Jan Snel is different from

Construction at Amsterdam University in working at a firm of architects. As far as

2010. I started at a small firm of architects, I’m concerned, it’s better! I am given a

but after six months they no longer had lot of freedom with my designs; the fact

a place for me. Then I landed a job as a that we work with a modular system

draughtsman with Jan Snel on a second- takes nothing away from that. These

ment basis. Now we are six years down days, so many things are possible that you

the line and I have grown in my job. For have a lot of flexibility and many of the

example, in 2010 I started on projects like projects are custom-built. In my work as a

drawing a porter’s lodge, but these days draughtsman, I also get a lot of freedom

I design hotels and schools. I am proud of and more and more jobs involve me

a project in Loppersum where I designed being responsible for the way a building

and drafted earthquake-resistant tem- functions and looks. of pride when you achieve something

porary accommodation for two primary together. We are all down-to-earth go-

schools and a childcare centre. getters who keep our feet on the ground

It involved 3,500 m² in total. Knowing “ They pay and our eyes on the prize. As for me, I am

that somewhere in the Netherlands there attention to you, a team player who is glad to say YES to

is now a whole school that I designed, my colleagues.

and that its users are really happy with it, your career and

is a great feeling.

your development.” Rush hour

When I am at home, I leave work far

Variety behind. I live alone and enjoy football.

The job is highly varied. I am handed Team I’m a team player on the pitch too and

assignments to design buildings and I also The great thing about working at Jan Snel although I’m a striker, I like to pass the

produce drawings for planning permission is that you don’t feel as though you’re just ball to others so that they can score too.

requests, I make detailed drawings of a number. They pay attention to you, your The game is all about who has the biggest

interiors and/or exteriors and I develop career and your development. We work chance rather than who has the biggest

entire buildings. Among other things, I as a small team, which is nice because we ego.

Snel boy

Dirk-Jan Ruiter produce floor plans, façades and building are familiar with each other’s strong points

cross sections based on the schedule of and that improves our collaboration. It is Room for growth

Marital status In a relationship requirements and regulations. We also busy, but there is always enough time to As far as I’m concerned, Jan Snel has got

Position Draughtsman work regularly with an architect on a hand in good work. Speed never comes at everything a young graduate could wish

With Jan Snel since 2010 collegial basis so we can ensure that the the expense of quality. The no-nonsense for. Room to implement your own ideas,

Each issue, a member of Education HBO - level Construction design can be implemented using our culture in the company as well as in our room to grow and room to score. Together

Jan Snel’s staff tells their story Hobby Football building systems. team is tangible. It gives you a sense with your team.”

magazine 17Snel developments Snel developments

the latest Briljantlaan Utrecht

Utrecht is the student city par excel-

DEVELOPMENTS

lence. In 2017, the Briljantlaan is where a

permanent, six-storey building designed

by architect Jillis Krinkel will rise up. This

building also has a very contemporary look;

Master of housing

the extraordinary façade and the structure

In the past, students used to live The construction of these student flats is students a year come to study. Here we of the building give it the appearance of

in digs. You would live in what was not one of a kind. We increasingly build are building two complexes that house a ship’s bow. There will be space for 232

often an ancient student house flexible homes that can be linked and a total of 461 student flats for I Love flats, with the ground floor intended to

where you’d share a shower, toilet stacked in a practical way. They have Vols. The first complex has now been provide space for catering businesses or a

and telephone. How different it multipurpose functions, they can be built completed and the second one will gym. A modern building with 232 flats on the Briljantlaan in Utrecht

all is nowadays. At least, it is if quickly and they are suitable as both open its doors in mid-2017. Besides very

you get to live in one of Jan Snel’s temporary and permanent residences. In well-equipped flats, the building features Rent subsidy At home and abroad looking at how we can get the most out

student flats. Then you get a whole terms of student housing, last year we built various meeting areas. The architecture It is of course fantastic for students; a The popularity of this type of student of the system. For instance, Briljantlaan has

flat to yourself, complete with Ravel Residence and AmstelHome. is by MH1 Architects in Maastricht. They completely self-contained flat with all mod accommodation is really taking off. There a storey more than Ravel Residence and

shower and your own kitchen. The designed the extraordinary façade with its cons. A significant incidental benefit of this is also a great deal of interest being shown AmstelHome. We are also investigating

success of this concept is conque- Katzensprung in Vaals Eternit cladding in partnership with Studio type of housing is that due to the self- in student cities abroad. Whilst being the possibility of larger or connectable

ring student cities at home and Another project is Katzensprung in Vaals. Job. contained nature of the flats, they qualify busy constructing these homes, we are homes. Setting out a successful concept

abroad. There are two new com- This town in just 3.5 kilometres from for rent subsidies. This can keep the total continuing to examine how we might is great, but we would not be Jan Snel if

plexes scheduled for construction. Aachen, the city with one of Europe’s costs quite low. develop them even further, for example for we didn’t continue to look for possible

Would you like to have a look? largest universities where 40,000-45,000 other target groups. However, we are also improvements.

Katzensprung Student complex in Vaals

with a total of 461 student flats.

18 magazine magazine 19Snel tells Snel tells

Modular vs. Traditional

See the brochure at If the end result is the same, then the a flexible building in half the time and almost 20% cheaper. A

www.jansnel.com or journey towards it becomes interesting building that meets the current Building Decree and therefore all

request the brochure via: Traditional building feels familiar, but we cannot carry on building the conditions to remain permanently in place, but one that offers

‘If I had asked people h.luinge@jansnel.com in the same way we used to 80 years ago. Compare our modular much more freedom to be modified over time to be relocated or

building system objectively with traditional constructions and you removed if necessary. The ground can be cleared in no time so it

what they wanted, they would will be amazed at the similarities and differences. We can erect is ready for its next purpose.

have said faster horses.’

Henry Ford Concrete piles Concrete elements

It’s not the materials we use We manufacture all elements

that are innovative; it’s the way of the building under controlled

we build that is innovative. conditions in our factory in

Our buildings are supported Montfoort. This benefits the rate

by concrete piles and concrete and quality of construction.

foundations.

This statement sums up in a nutshell what Jan Snel thinks about the discussion on

modular versus traditional building. People cannot want what does not yet exist.

That is why they need inventors like Henry Ford who introduce something new that Main load bearing Controlled conditions

is initially received with scepticism but later embraced. Jan Snel embraces flexible structure for each module We manufacture all elements

building and it is high time the rest of the world did so too. Our buildings’ strong main load of the building under controlled

bearing structure consists of an conditions in our factory in

independent structure for each Montfoort. This benefits the rate

module. The rooms that we and quality of construction.

There’s more than one way to skin a cat place inside are made to a size

How much is 4 + 3? And 5 + 2? The answer is the same The new way of building has started that enables them to be hoisted,

but it is reached by different methods. This is exactly the If we were to hold on to existing mind-sets and practices, nothing transported and stacked.

same with flexible building. Let’s take a closer look at the would change. We would just carry on looking for the metapho-

outcome. rical faster horses. Jan Snel proves that the future lies with flexible

building. We have done this, for instance, with Ravel Residence Prefab concrete floors Full compliance with the

– Europe’s largest modular building: 28,000 m², 800 student flats, The concrete floors leave our current Building Decree

five storeys, completed in 325 calendar days and intended to factory fitted with all pipelines There is no difference in quality

stand for twelve years. Then there is AmstelHome: 17,000 m², five and connections. These form or durability; it just takes half

storeys and 520 student flats. the basis of the rooms, which the amount of time and is on

Where does the future lie? Are we going to continue betting we also construct in Montfoort average 20% cheaper than

on old horses or shall we choose new solutions with more before sending them ready- traditional construction.

horsepower? made to the building site.

20 magazine magazine 21Snel in pictures Snel in pictures

childhood joy

600 m of

building

2

Slick

After-school care, Kruibeke (B) Oleon, Oelegem (B)

The onset of the summer holidays marked The Belgian company Oleon is Europe’s

the start of this project. Within eight most important player in the oleochemical

weeks, Jan Snel had demolished the industry: processing organic raw materials

existing building and put up an entirely (vegetable oils and animal fats) into semi-

new building to house the after-school finished products. It was for this market

care facility. The building contains 32 leader that we built a permanent building

KOMA HL3 type modules with façade in 2.5 months. The building is 325 m2 and

cladding. Thanks to the permanent cha- is home to two multifunctional spaces, four

racter of this building, it meets all Belgian offices, a conference room, a rinsing area, a

standards relating to energy consumption, stock room, a cold room and a hot kitchen.

fire resistance and child-friendliness. The The building has an interior stairway that

whole interior has been adapted to the connects the two storeys. We constructed

size of its mini-occupants. this building using the Movix system.

22 magazine magazine 23Snel in pictures flash & unusual Quick as a Bayards Aluminium Constructies, Heijningen We needed no more than three weeks to complete four offices, a lobby and sanitary facilities. 144 m², split between two storeys, featuring an exterior alumi- nium stairway. An unusual feature is the steel cladding, the sand cement floor, the ceiling and the marble that was installed on site. The system used is K1500 and the building is kept cool in the summer by retractable awnings. 24 magazine

Snel in pictures Snel in pictures

Safety first

Bon appétit

Fire station, Falck Fire Services, Delfzijl

At Chemie Park Delfzijl, safety is para-

mount. Jan Snel has signed a fifteen-year

DuPont de Nemours, Mechelen (B) contract for the design, funding and

maintenance of a new fire station. The

For plastics manufacturer DuPont de site of the operations is Poort 3. The fire

Nemours in Mechelen, we have built a station will house five crews of five people,

canteen of more than 200 m². various vehicles and support services such

This canteen provides space for 60 as the breathing apparatus workshop.

employees. In addition to a large dining Thanks to its favourable location, the

area, the building contains a small office fire station will also house the Security

space and the essential sanitary facilities. department. Access to the public highway

This permanent, single-storey building was will possibly be the first step towards a

completed in just two weeks using the public-private collaboration between the

KOMA RF30 system. company fire brigade and the government.

26 magazine magazine 27Snel in pictures space More Doc-Direkt, Winschoten The home of the Winschoten branch of Doc-Direkt was in need of a thorough renovation. To make this possible, the workers and operations would need to be housed in temporary accommodations on the same site during the refurbishment. On 24 April 2016, we drove in the first pile for the foundations. We are putting up 110 units in total (Movix and K1500). There are fifteen offices, two toilet blocks, a pantry and four large workrooms. Aspects that are particular to this project include the reinforced floor that we installed here and there and the time frame within which this accommodation was ready for use: we completed the job in five weeks. 28 magazine

Snel in pictures

and sport

Study

Ajax (De Toekomst), Amsterdam

AFC Ajax commissioned Jan Snel to

construct a building on De Toekomst (The

Future) Sports Park at the Arena where 120

Dutch and overseas players would be able

to pursue their studies. As soon as youth

players move up to secondary school, they

take part in the Ajax study programme.

This means that after training they are able

to do their homework under supervision.

The 1,000 m2 building was constructed

using the Movix system and contains a

kitchen, study rooms, classrooms, toilets,

offices, a dormitory and an Ajax TV room.

The building was completed in just three

months, it will remain standing for several

years and it can be relocated if necessary.

magazine 31Snel in pictures Snel in pictures

under one roof

psychiatric centre

Everything

New

Sint-Hiëronymus, Sint-Niklaas (B) Genzyme Flanders, Geel (B)

In just six weeks, we completed a new, On the grounds of the pharmaceutical

permanent building on the site of a company Genzyme, we were com-

psychiatric centre at Sint-Niklaas. It missioned by Genzyme, PM Group,

contains twelve rooms, each with its Daalderop, Bilfinger and STS to build a

own toilet and shower room, connected small village in three months. The various,

by a central corridor. Each room comes mostly two-storey buildings contain

equipped with its own camera call system. offices, sanitary facilities, changing rooms,

In collaboration with Deceuninck we also conference rooms and canteens. In total,

directly handled the exterior cladding, we completed 3,528 m2 of new buildings

enabling us to complete a fully fitted using the KOMA HL and K1500 RF 60

permanent building in a short time. systems.

32 magazine magazine 33Snel in pictures

school building

Red brick

De Nessevliet, Oud Verlaat

We were commissioned by ‘De Vier

Windstreken’ foundation to construct a

complete school building in seven weeks

using our Movix system to supplement

their existing classrooms. The building is

permanent and contains two classrooms,

four toilet areas, a technical area and a

hall with stairs. The project presented us

with specific challenges; due to the tight

space on the building site we even had to

build a complete bridge over the water so

we could access it. The building is finished

with masonry featuring distinctive string

courses.

magazine 35Snel in pictures

year, new school

New academic

De 2-stroom children’s centre,

Hendrik-Ido-Ambacht

After the demolition of the old school

building, only twelve weeks were needed

for the completion of the new children’s

centre, ‘De 2-stroom’. The project was

scheduled so that the children would be

able to start in the new school building

immediately after the summer holidays.

Comprising 1,100 m2 in total, the school

premises include eight classrooms and

accommodate primary school, after-school

care and a pre-school playgroup. This

permanent building has a masonry façade.

magazine 37Snel in pictures & brains Beauty UniQure, Amsterdam Biotech company UniQure has a new laboratory with offices. We used our Movix system to construct a semi- permanent yet fully-fledged building. Of course, the building complies with all current regulations covering labora- tory safety. The 865 m2 block contains fourteen laboratories, ten offices, two conference rooms, storage rooms, toilet blocks, a shower, pantries, a server room, broom cupboards, technical areas and an outdoor storage shelter for the various gas bottles. Worthy of note is that the different laboratories feature fifteen-fold and five-fold ventilation. What is striking about the exterior are the prominent, orange-coloured window-frames. 38 magazine

Snel in pictures

Happy

users

Wij Teams, Hoogkerk

Satisfied users are the reason we exist. A

great example of this is the construction of

Hoogkerk council’s WIJ Teams temporary

offices and meeting rooms in Groningen.

These teams provide assistance and

support to people who have problems

they are unable to resolve themselves.

The teams are made up of both volunteers

and professionals. The 900 m2 building

that will remain standing for three years

contains various consultancy rooms,

conference rooms, a lounge, meeting

areas, sanitary facilities, pantries and

offices.

magazine 41Snel tells

ility

inab

sta

su

bl

e

sa

re u

Sustainability begins with our products. training and we are an official training productivity, collaboration, reputation

Our flexible building concept means we company for the business sector. We and innovation. All these elements are

are able to meet fluctuating demand also offer people with poor job prospects reflected in our everyday processes; from

for temporary or permanent space. Our the opportunity of gaining some work being awarded a contract right up to and

buildings are durable and can be reused experience. including completion and aftercare. We

without any problems. That is sustainability set out our objectives and a strategy for

in a nutshell. Refit or relocate? Child’s play. Planet achieving our sustainability goals. We

We are able to respond rapidly to changing Flexible building is sustainable. Our draw up a strategy roadmap to help us

requirements and applications. After all, permanent and semi-permanent buildings unburden the customer, optimise profit

why put up a building that is only suitable last longer. We transform them and give and monitor our results. The outcome of

for a single purpose? With one of our them a new purpose. Bearing repurposing all our efforts is a system that we use to

permanent or semi-permanent buildings in mind is a key principle when designing test our objectives, which enables us to

you can make modifications depending new buildings if we are to ensure that steer towards improvement, monitoring

on the required function, whether it is a they are going to be future-proof. Building progress and assessing results.

school, hospital or office. We have noticed flexibly is building with prefabricated

that, in the construction industry, the elements. It means there is less activity at Future

demand for our way of building is on the the building site, so fewer vehicle move- Sustainable entrepreneurship means

increase due, for example, to changes in ments are required and there are fewer examining what we can do better today

our society or continuing new insights. dust emissions. We manage our waste and tomorrow. It means we have control

Flexible building is where the future lies efficiently on our own site and recycle over the future and that we always lead

and we are leading the way. whenever possible. Most of the material the way. What is certain is that, at Jan

we use comes from responsible sources Snel, sustainability is no one-day wonder

Sustainability is better People: attention to courtesy

People are our capital. They make the

and we pay a great deal of attention to

the smart fuel consumption of our lorries

or marketing term, but a solid basis for

the success which will allow us to make a

for everyone

difference and we are grateful to them for as well as implementing energy- and difference.

it. We also take social entrepreneurship water-saving measures.

MVO

very seriously. We attach great importance vrslg If you would like to

to courtesy and stick to the principle that Profit know more about

Sustainability. We are pioneers when it comes to Corporate Social Responsibility (CSR). Thanks to our if people feel good about themselves, they Our CSR targets contribute to our com- sustainability, our

flexible building concept, sustainability is part of our DNA, and we manage to guarantee it at all levels will perform better. What’s more, we are pany’s profits. The skill is in maintaining a CSR report can

by running our business while paying attention to people, the planet and profit. As happens with many active in the area of health and safety in balance between people, the planet and Flexibel

bouwen

is

be found online

duurzaam

things, however, we never used to talk about it very much; at least until now. We are eager to talk to you the workplace; we encourage participation profit. Profit is an economic benefit – as

bouwen

at jansnel.com/

about our sustainability ambitions and the objectives we have already accomplished. in courses, development and continual are commitment, quality, employment, publicaties.

magazine 43Snel in conversation

Two people, one theme. In this section, two people shed light on one subject. This time we have been talking to

Rick Dika, a Calculator at Jan Snel, and Jacob Travaille, Engineering/Technical Consultant at TPM Drachten. They

discuss the success of ‘medical modular systems’, the new standard in medical construction.

Exchange of words

Rick Dika Jacob Travaille

“Medical modular “During our joint projects, I

construction is on the rise. supervise the construction

em•ploy•ee

We don’t mean temporary process. I match the client’s

ward buildings, but high- wishes and requirements

tech units that house to the options Jan Snel

entire sterilisation rooms or can provide. We have been

operating theatres, or units working together for around

in which complex examina- 5 years. My experience in the

tions can be carried out. A number of years ago we started medical sector means I am very familiar with building,

out with a mobile operating theatre in our warehouse at refurbishing or renovating hospitals.

Montfoort. We have since moved on from the learning

process and are now able to commit fully to the units. The medical world has been converted when it comes to modern The most important capital in the

construction. It is great that modular construction has become organisation. We cherish everyone:

The strength of the medical modular units is that they are of so popular, even in this conservative sector. If it were up to the experienced generation that hand

a particularly high quality. Our designs can easily compete me, I would opt for modular construction for every suitable down their knowledge, and the younger

with ‘normal’ operating theatres, except they can be built in construction project in the medical sector. The reasons for this are generation bursting with plans, ambitions

a fraction of the time. The units have a well speed, flexible interiors and possibilities in terms and new ideas. To a significant extent, our

of reuse.

Medical

thought out design and a high-quality finish, products are thought up by human minds

and they are equipped with all the systems that and created by human hands. This is the

Reliability is key with this kind of project, which is

modular

you will also find in a conventional operating reason why we are so proud of all 263 of

theatre. We prefabricate the units in Montfoort why all units meet the most stringent standards. our colleagues at Jan Snel and Jan Snel

before transporting them to the required We have put up temporary sterilisation units Transport.

location. Medical modular construction is ideal (CSA) in the car park of the Heilig Hart Regional

during refurbishments as well as when supplementing existing Hospital in Tienen, Belgium. The unit then left for Switzerland.

capacity. The possibilities in the area of exterior cladding are Miele Germany asked us to build a modular CSA, which has been

so extensive and versatile that a new building can seamlessly shipped to Australia. Other countries have also showed interest.

merge into an existing one.

Unusual is the Centre for Nuclear Medicine in Goes. After

Of course, a lot of expertise is needed in the construction of 2 months of preparation, the centre was completed in just 4

this kind of highly specialised units. Although to some extent months. We are also planning a new operating theatre complex

we have our own home-grown expertise, when necessary we in Goes, which will contain 5 universal and 1 interventions

can call on people from outside Jan Snel. Jacob Travaille is one operating theatre. We will complete this project at the end of

such specialist.” 2016, which is unprecedented in healthcare.”

44 magazineSnel tells Snel tells

Earthquake-resistant construction

There are developments that we important characteristics? They recently commissioned by the a temporary site. It holds 14 classrooms

would never have predicted ten absorb shocks from any quakes to Nederlandse Aardolie Maatschappij covering an area totalling 2,106 m2.

years ago, such as earthquake- prevent them from collapsing. (NAM) to build two temporary schools

resistant construction. However, The units consist of a rigid construction. to resist earthquakes in the Groningen Zuidwolde: transition year

the soil conditions in Europe are Using expertise gained abroad, our towns of Bedum and Zuidwolde The temporary school in Zuidwolde has

changing and governments and special team designed a system of sliding (municipality of Bedum). been standing for 1.5 years to bridge the

companies are amending their rubber and steel blocks that absorbs the period during which renovations were

construction policies accordingly. lateral movements of an earthquake Bedum: home to several schools being carried out at the current site.

The demand for buildings that like a sort of horizontal shock absorber. In Bedum itself, we spent just fifteen This involved 16 units and four class-

are literally shock-resistant is Building to Richter guidelines. We were weeks building a temporary school which rooms which came to a total of 288 m2.

growing in the Netherlands too. over the coming years will house various Since this project was carried out

And Jan Snel wouldn’t be Jan Snel

if we didn’t have a fitting solution

“ Building to primary schools. In the meantime, the

school buildings were thoroughly

simultaneously, it took only seven weeks

to complete.

to meet it. Richter renovated, adapted to meet the latest

We have several types of units that are able

guidelines” building standards or completely rebuilt.

It goes without saying that the school is

Shock-proof partnership

The partnership extends beyond the

this region. There are also plans for shock-

resistant banks, sports facilities and homes.

project will be completed in mid-December.

Other projects are likely to follow shortly.

to resist earthquakes. What are their most earthquake-resistant and is located on schools in Bedum, Zuidwolde and a recently Our three-year partnership with NAM was At Jan Snel, we are proud to be able to

completed children’s facility in the municipa- confirmed in a framework agreement. contribute to safe housing, workplaces and

lity of Loppersum. There are other plans to The next project is the construction of a educational establishments in this region.

build more earthquake-resistant schools in school in Middelstum. It is expected that this

46 magazine magazine 47Snel tells Snel tells

De Broeders van Liefde

care, social economy and child day-care

centres fall within the scope of their

activities. The Broeders van Liefde is a

love flexibility and speed

professional organisation whose services

include a Building Services department that

takes care of the infrastructure of all the

institutions. They put the provision of flexible

accommodation at the Sint-Paulus School

The Sint-Paulus free primary school’s building in the Belgian town of Drongen is dated and needs to undergo a out to tender and Jan Snel came out on top.

thorough renovation. This will be done gradually over a period that will partly depend on the current subsidy

applications. What is certain is that the refurbishment will last several years, during which time additional Thinking in terms of options

accommodation is required. Jan Snel builds four classrooms in five weeks and even manages to complete them Mrs Jocqué has happy memories of the

before the summer holidays. times she was in contact with Jan Snel: “It

was a really nice firm to work with. The

Relocating before the holidays

Mrs Jocqué, head of the Sint-Paulus

facilities, a fire alarm system and four heat

pumps. Mrs Jocqué: “These units don’t “ These units Building Services architects carried out the

main work and we did the rest locally. Jan

School, is delighted that Jan Snel met the

deadline. She explains:

feel like a temporary solution at all. They

are perfectly finished inside and out. All of don’t feel like very well known in Belgium. Founded by 50 schools for regular and special primary

Snel came up with a range of options, with

the way we wanted to use the classrooms

“We couldn’t afford any delay because

the renovation of the main building was

the facilities are present; the classrooms

have a pleasant overall appearance and

a temporary a Ghent priest in 1807, the Broeders van

Liefde currently operate in 31 countries

and secondary education, together with 15

psychiatric hospitals and 15 orthopaedic

prevailing. I can only hope that the

refurbishment we have ahead of us runs

scheduled to begin immediately after the

summer holidays and I didn’t want to

a high level of comfort. I was personally

involved in the design of the interior and

solution at and in Belgium alone they run more than centres. In addition, elderly care, addiction just as smoothly.”

have to move four classes in the midst of shared my ideas on the positioning of all. They are

perfectly

demolition work. Now, everything was windows, doors and even the location

finished and ready for use before all the of the power sockets. Everything can be

teachers and staff headed off to their

holiday destinations.” At Jan Snel, we are

flexibly arranged, so now the classrooms

have everything we wished for.” finished

fully aware that there are innumerable

reasons to push ahead with the develop- Continually changing uses inside and

ment of accommodations, whether it is for

temporary or permanent use. We stepped

The four classrooms will gradually be used

for different purposes. First of all, they will

out.”

up our efforts and managed to complete accommodate remedial classes for children

the classrooms so they would be ready for in need of more individual attention or

use on time. an extra challenge. They work in small

groups outside the regular class and will

New K3000 units be able to work in Jan Snel’s units over the

The new classrooms were constructed coming time. When another part of the

entirely on-site using K3000 units. These main building is being renovated, the pupils

units have been further developed with affected will move to the flexible classrooms.

improvements to the versatile concrete

floors and a ceiling height which has been Broeders van Liefde

raised to 2.50 metres (or 2.60 metres You may be wondering how a primary

without a suspended ceiling system). The school in a remote Belgian village ended

primary school in Drongen is the very first up getting in touch with Jan Snel. Well,

project constructed using K3000 units. it went like this: the school is part of the

The classrooms are equipped with sanitary Broeders van Liefde foundation which is Mrs Jocqué, headmistress Sint-Paulus Stchool

48 magazineSnel internal Snel internal

New K3000:

Down-to-earth type with possibilities 07 So far, we have made 2,500 frames for the K3000

units. They are stored in building system form at

various sites. When they come back from being rented

The demand for more luxurious units is on the rise. What’s more, we intend to continue out, they can be used to make another complete unit.

developing and, as such, we are always looking for ways of improving our products. The most

recent example of this is the new K3000 system, a down-to-earth member of our rental fleet

which offers everything you need. This unit can be used anywhere where short-term additional

space is required: healthcare, education, offices or industry. At the same time, the K3000

system has so many great features that it is also excellent for use in permanent applications.

Scene: ort

n Montfo

Productio

Mission: ization

et modern 01 Units are starting to look more like permanent

Rental fle 06 At the moment, we design and build the units at our

or semi-permanent buildings. This is what we have

been working towards with the K3000. As such, it Montfoort and Hulst sites. In time, we shall replace all current

can be fitted with a selection of outer walls ranging units with new K3000 system. This will be done gradually in a

from rebating to masonry work. process that will take years.

02 The new concrete floor has been developed by Jan Snel 05 The K3000 has an insulation

under guidance from Delft University of Technology. The rating that exceeds current

loading capacity of the floor has been optimised for its requirements and has a

purpose and it meets all fire safety and insulation standards. performance-enhancing effect.

03 From now on, the new K3000 system will only have inner walls. This will 04 The ceiling has been raised by ten centimetres to 2.60 metres

make the units easier to connect to larger buildings. The exterior wall is added (without a suspended ceiling system). Despite this new height,

later as a customised shell. This means we can make savings on the relatively the units can still easily be transported two at a time on a lorry.

expensive ‘outer walls’ that often serve no purpose as outer walls.

50 magazine magazine 51Snel innovations Snel innovations

Outsourcing care buildings, for healthcare? Which functionalities belong there and which

including equipment technology will make it all possible? It was around this that we

“Throughout the country, hospitals are set up the building and the building technology. Jan Snel’s Movix

undergoing transformations; meanwhile system is perfectly suited to this type of construction because it

a lot of attention is being paid to the way does not restrict us to fixed container sizes, and it is a high-quality

in which they handle their facilities and solution offering an excellent price to quality ratio.”

buildings.” Talking is Sjaak van der Pouw,

Sjaak van der Pouw Enterprise Services & Business Innovation

Director at Siemens Healthineers – the

healthcare branch of the global concern. “We and our partners

are capable of building, managing and maintaining a smart and

sustainable hospital infrastructure. As such, we offer a complete

service while hospitals are able to focus on the medical process

surrounding the patients. Furthermore, a close collaboration in

all aspects of the relationship is of major importance. We are not

a construction company ourselves; instead, we get our expertise

from our partner network. In Goes, working with Jan Snel has been

highly enjoyable.”

No more room for nuclear medicine Financially ground-breaking too

In Zeeland, the Admiraal De Ruyter Hospital is well-known. It is To make the short-term construction process financially feasible

spread across four sites: Vlissingen, Goes, Middelburg and Zierikzee. as well, Siemens Healthineers signed a user agreement with the

Owing to the refurbishment and rebuilding of the main site in Vlis- hospital. The hospital is leasing the building and all systems for a

singen, there is no more room for nuclear medicine. This particular period of ten years which means it does not have to make a capital

medicine discipline is concerned with the imaging that is crucial to investment itself and can therefore use its money in other ways.

proper diagnosis of conditions such as cancer, cardiovascular disea- Consequently, the inhabitants of Zeeland were able to keep their

ses and problems with muscles, bones or joints. Siemens Healthi- nuclear imaging facility instead of being forced to drive dozens

neers proposed constructing a new centre alongside the existing of kilometres to hospitals outside the province for a scan. The

hospital in Goes. Time was of the essence because the nuclear centre is now fully operational and the patients and doctors are all

medicine department would be moving from Vlissingen forever exceptionally enthusiastic about it.

within four months. At the same time, the new Centre for Nuclear

Medicine would have to meet the most stringent quality standards. The future is speed and flexibility

This combination of speed and quality is music to Jan Snel’s ears. This development is being closely followed throughout the country:

In collaboration with Siemens Healthineers, Lean & mean: bringing all specialists together

is this the way forward in dealing with healthcare premises and

facilities? Zeeland says yes, because a new order has already been

Jan Snel builds Centre for In designing the centre, Siemens Healthineers has opted for a

whole new approach. Sjaak van der Pouw: “The traditional way

placed for the construction of a new operation complex. It will

use the same methods and the flexible solutions provided by Jan

Nuclear Medicine in Goes is: a sit down with an architect and many sketch designs and

numerous consultants later, tender for a construction company

Snel. Sjaak van der Pouw: “Jan Snel’s way of working seamlessly

matches our philosophy: first we say what we are going to do,

while hardly looking at the integration of the subsectors. We have then we do what we say. This no-nonsense attitude appeals to

Dutch healthcare is under pressure. Budgets are tight, whereas the demand for care is only going to brought together all the knowledge and expertise of Siemens the imagination. Before embarking on the construction of the

increase over the coming years. In order to safeguard the quality of healthcare, hospitals are looking for Healthineers, Jan Snel, Engie (systems) and the medical and new Centre for Nuclear Medicine together, Harry van Zandwijk of

fresh solutions such as outsourcing part of their amenities. For instance, the Admiral de Ruyter Hospital technical specialists from the hospital. Together, we examined the Jan Snel said to me: “We will do it for the agreed price and you

in Goes found a partner in Siemens Healthineers who would completely take on the construction and optimal workflow of patients and staff as well as making intelligent will get a free ‘no-moaning’ warranty thrown in.” He has kept his

management of a new Centre for Nuclear Medicine. There was an additional challenge: the building had choices with regard to management and maintenance. However, word to this day. Together, we will be able to give healthcare in the

to be operational in 16 weeks. In turn, Siemens found a reliable partner in Jan Snel. we based everything on the medical process: what is the demand Netherlands a considerable boost.”

52 magazine magazine 53You can also read