Flexible automation office depot's

←

→

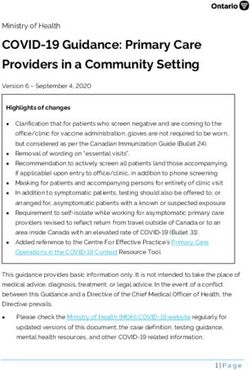

Page content transcription

If your browser does not render page correctly, please read the page content below

modern system report

Office

Depot’s

flexible

automation

W

By Bob Trebilcock, hen Office Depot decided president of global network strategy

Executive Editor to consolidate three dis- and transportation. “We are in a com-

tribution centers and a modity business and the supply chain

crossdock facility into is a differentiator. We plan to be on the

one, new state-of-the-art DC in Newville, front end of that.”

Pa., the office supplies retailer looked for While some brick-and-mortar and

an automated materials handling solu- dot.com retailers have implemented

tion that was efficient and flexible. More robotic solutions similar to the one in

importantly, they wanted a system that Newville to manage their direct-to-con-

would deliver a competitive edge in the sumer orders, Office Depot is taking

marketplace. the technology deeper into its opera-

They found that edge in a goods-to- tions than other early adopters. “Most

person picking solution featuring two implementations are focused on one

different mobile robots (Kiva Systems, process, like each picking,” explains

781-221-4640, www.kivasystems.com). Juan Guerrero, senior vice president of

One robot handles cases while a larger supply chain. “Along with each picking,

robot moves pallet loads in the facility we are also doing case picking and full

that went live just a few months ago. pallet movements with the robots. We

Betting a part of your distribution will handle everything but non-convey-

strategy on robotic materials handling ables or items that are just too heavy to

may seem like a risky move, especially go through the system.”

given the conservative nature of retail What’s more, Office Depot is using

distribution. But, Office Depot is the robotic system to manage order ful-

convinced that the time has come for fillment across all of its sales channels

robotics in the DC; after three decades and not just direct-to-consumer. This

on the manufacturing line, robotics includes store replenishment and bulk

technology is proven, reliable and, says deliveries to business customers.

Office Depot, a potential game changer In all, 100,000 square feet of the

Bob Zelis, senior director (left) (for more on robotics, see p. 26). 600,000-square-foot building are devoted

and Brent Beabout, vice president “We believe that the future belongs to the system including the picking sta-

of global network strategy and to the brave,” says Brent Beabout, vice tions, which feature 300 robots and

transportation

20 Au g u s t 2 0 1 0 / Mo d e rn Mate r ials Hand ling mmh.comMobile robotics is powering Office Depot’s

new demand-driven distribution center.

PHOTOGRAPHY BY XXXXX/GETTY images

Photos by Alan Wycheck/Getty Images

enough portable shelving space to man- time has been reduced from 2 hours to office products and services, with more

age three days of inventory. To minimize 20 minutes. “This system is going to than $12 billion in revenue, 1,500 retail

lift truck travel time, the mobile robotic move us from where we were, which store locations and 42,000 associates

system is augmented by a takeaway con- was industry-leading customer service worldwide. The company does business

veyor system and sliding shoe sorter. levels, to a point well beyond that of our in 52 countries.

Beabout and Guerrero say the robots competitors,” says Guerrero. The Newville DC was a result of a

have reduced the average travel by an growth strategy that has been driven

associate from 7 miles per shift in a Starting from scratch by acquisitions for much of the past

typical distribution center to less than Founded in Boca Raton, Fla., in 1986, 25 years. Those deals not only brought

half a mile; meanwhile the order cycle Office Depot is a leading supplier of new retail locations under the Office

mmh.com Modern Mat eria l s Ha ndl ing / A u g u s t 2010 211

2

3

4 5

1. Picking instructions are delivered to a touchscreen. 2. Associates pick items from a portable module. 3. Picked items

are placed on a portable module. 4. Mobile robots deliver the modules to the conveyor system (5) for induction. 6.

Cartons are sorted to a packing station.

Depot umbrella, they also added ware- ties in remaining facilities. Newville, from a transportation standpoint, and it

houses and distribution centers. As of which currently serves 107 stores in had an available pool of highly skilled

a few years ago, Office Depot had 33 the Northeast, was different. In that potential employees: The company

buildings in its network, including sev- region, where the retailer operated four received 4,000 applications and inter-

eral low-volume facilities. Typically, facilities with a total of 829,408 square viewed 1,200 candidates to fill 250

these came in two flavors: crossdock- feet, there was a unique opportunity to slots. “You don’t get that kind of job

ing centers to replenish retail locations reduce the overall footprint of opera- pool in every area,” says Beabout.

and distribution centers to service busi- tions by building a brand-new facility

ness customers and direct-to-consumer because the leases were coming due on New facility, new technology

Internet and catalog orders. some of the buildings. Building a Greenfield facility also pre-

The collection of facilities was less “We wanted to take a holistic view sented an opportunity to optimize the

than optimal. “We decided to use the of our supply chain, and not just what materials handling systems inside the

recession to take a hard look at our happens within the four walls of the DC with a new distribution model fea-

network and optimize our systems,” DC,” says Beabout. “As we did the turing two distinguishing characteristics.

says Guerrero. Today, the company has research, we realized that none of the Instead of operating separate DCs

reduced that number to 17, with an existing facilities in the Northeast was for store replenishment and direct-

ultimate goal of reducing the number of really centrally located to where we to-customer deliveries, Office Depot

facilities in the network to 12. were doing most of our business from wanted a system that could integrate

To reach that number, Office Depot a transportation standpoint. It made with its homegrown warehouse man-

has closed and consolidated some more sense to start fresh.” agement system (WMS) to handle

facilities and upgraded the capabili- Newville had several advantages every line of business and sales chan-

22 Au g u s t 2 0 1 0 / Mo d e rn Mate r ials Hand ling mmh.commodern system report

our new pull model, every store will get Flexible and scalable: There is no

a just-in-time delivery nearly every day question that other automated materi-

of the week,” says Guerrero. “We’re als handling solutions are effective in a

beginning with the 107 stores served by goods-to-person environment, includ-

Newville, and then we’ll roll this con- ing mini-load automated storage and

cept out across the country.” retrieval systems (AS/RS) and horizon-

After looking at traditional pick and tal carousels. What tipped the scales in

pack solutions, including voice-directed favor of mobile robotics was the flexibility

pick modules similar to those used at to handle pieces, cartons and pallets and

other Office Depot facilities, Guerrero to easily scale in the future. “Reliability

and Beabout chose mobile robotics, a was important, but any solution had to be

technology they had been investigating reliable for us to even consider it,” says

for several years. The system uses a small Beabout. “We justified the system on

robot to move mobile storage devices productivity, the ability to co-mingle and

to and from associates at workstations, pool inventory and the ease of adding to

and a larger vehicle designed to handle the system in the future. If your through-

full pallets. Once picks have been com- put or inventory grows in the future, all

pleted, the robots deliver the units to a we have to do is allocate more floor space

conveyor induction station, where the to the robotic system and add robots. We

shipping containers are placed on a con- can do that overnight.”

veyor and sliding shoe sortation system According to Guerrero and Beabout,

and are sorted to a shipping lane. the building was also designed to fur-

Several factors led to this choice: ther Office Depot’s sustainability goals.

Goods-to-person: In traditional pick T5 lighting and energy efficient HVAC

modules, associates walk to pick loca- are used throughout the DC along with

tions. In the robotic solution, the robots recycled materials wherever possible.

bring the product to the associate’s work- Energy consumption is monitored, and

station, saving steps. “A lot of the waste Office Depot will use renewable energy

6 in the DC has to do with walking,” says resources to offset consumption. Finally,

Beabout. “In this case, that’s gone.” In it was designed to have the lowest envi-

addition to productivity improvements, ronmental footprint possible while still

the system was very accurate, which meeting throughput requirements. The

nel where it operates. What’s more, it would reduce picking errors. company intends to seek Leadership

wanted the flexibility to scale the busi- Dynamic slotting: The robotic in Energy and Environmental Design

ness during seasonal periods, or, ulti- system monitors the movement of (LEED) certification from the U.S.

mately, to easily scale up as the overall SKUs and slots the inventory according Green Building Council.

business managed by the system grows. to how fast the product turns over: The Robotics may play a role there as

“We have a lot of common SKUs across fastest moving items are stored closest well. “The facility is eerily quiet,” says

our different lines of business,” says to the workstations. That leads to bet- Guerrero. “You don’t hear the robotics

Guerrero. “By pooling the inventory ter use of the robots and minimizes the at work, so the only sounds are people

in one facility managed by a common size of the fleet required. talking, lift trucks or the outbound

WMS, we can reduce the amount of Proven and reliable: The robots sorter, which is pretty quiet as well.”

inventory we have on hand.” were up to the task. “There was a con- While mobile robotics is providing

Finally, and most important, the sys- cern about going away from a traditional answers to the distribution requirements

tem had to have the capabilities to man- automated materials handling system,” in Newville, that doesn’t mean Office

age Office Depot’s transition to a true, says Guerrero. “But, we did our due Depot will adopt the technology every-

demand-driven distribution network. diligence. We visited systems that have where. “We don’t have stars in our eyes

Instead of delivering a pallet load of been in operation in existing facilities, and we don’t pretend that robotics is the

material that a store will sell through, the and we asked the hard questions you right solution for all of our facilities,”

goal is to start the season with a minimal would ask about an automated sys- says Beabout. “We will assess each facil-

amount of product and then make store tem. The performance, recovery times ity individually going forward. However,

deliveries five days a week to replace from failure and risk management were this was the right fit for this facility and

only what was sold the day before. “In robust enough for our operation.” our overall supply chain objectives.” M

mmh.com Modern Mat eria l s Ha ndl ing / A u g u s t 2010 23modern system report

Putting robotics to work

A goods-to-person picking solution managed by 300

mobile robots is at the heart of a new Office Depot

distribution center.

By Bob Trebilcock, Executive Editor

While a fleet of mobile robots sounds Putaway: The WMS directs

complex, the processes designed and putaway and can choose three Office Depot

implemented by Office Depot are paths for newly arrived product. Newville, Pa.

deceptively simple. The distribution Product that isn’t needed right

Size: 600,000 square feet

center also includes a regional print away is transferred by lift truck

facility (13) for printing jobs that are too to a bulk storage area, where pal- Products: Office supplies, technology

large for an Office Depot retail location. lets are stored on the floor (2) or and furniture

Receiving: When a trailer arrives in a pallet rack (3). The facility Throughput: 60,000 lines per day

at the receiving area (1), pallets are includes traditional pallet rack Shifts: 5 days; 2 shifts

unloaded by lift truck. A scan of the pal- and sections of very narrow aisle

Employees: 250

let label enters the pallet into the ware- (VNA) rack. Pallets with heavy

house management system (WMS). or bulky materials such as paper

Once the contents have been compared are temporarily stored in a flow area ing units and stored in the robotic stor-

against an electronic advanced ship (4) and then crossdocked directly to age and picking area (6) serviced by

notification (ASN) and accepted in the the shipping area (5). The remaining the mobile robots.

WMS, the product is ready for putaway. product is putaway into portable shelv- When a pallet of material is deliv-

Regional 13

print facility Shipping

Sliding shoe

sorter 5

Outbound

11 conveyor

12 Shipping lanes

workstations

3 9

2 Storage 10 Outbound conveyor

rack 3

Floor

Storage

storage

8 rack

Robotic storage

Case and picking

7 4

pick

6

area Picking and Flow area

replenishment

workstations

7 Picking and

replenishment

1 workstations

Receiving

Daniel Guidera

24 Au g u s t 2 0 1 0 / Mo d e rn Mate r ials Hand ling mmh.comered to a picking and replenishment

workstation (7) near the picking System suppliers

area, the associate chooses the put-

Mobile robotic picking solution: Kiva Systems, 781-221-4640, www.kivasystems.com

away function for the system. That

Conveyor, dock conveyor and sliding shoe sorter: Dematic, 877-725-7500,

signals a robot to retrieve a storage

www.dematic.com/na

unit from the storage and picking

Rack: Unarco Material Handling, 800-862-7261, www.unarcorack.com

area (6) and present it at the work-

Lift trucks: Crown, 419-629-2311, www.crown.com

station (7). The associate scans the

Bar code scanning: Motorola, 800-722-6234, www.motorola.com

bar code label on a carton and places

Print and apply: Pyramid Controls, 513-679-7400, www.pyramidcontrols.com

a device with a light on the carton.

System design and integration: Office Depot, including a proprietary warehouse

When the storage unit arrives at the management system

workstation (7), a laser directs the

associate to the right location on the

storage unit. The associate presses a be palletized for shipping (5) or it may number, the number of items to be

button at the workstation to confirm be floor-loaded for parcel shipments. picked and the bin location where the

the putaway. Everything else, including totes for product is located. A light also identi-

When all the cartons for that unit store replenishment, direct-to-con- fies the picking location.

have been stored, the robot returns sumer Internet orders and orders for When the associate scans the item,

the unit to the storage area (6) and Office Depot’s business customers, are a light on the unit with shipping con-

delivers the next unit to the worksta- managed by the robotic picking system tainers begins to flash to identify the

tion (7). The system determines the (6). The process is similar to putaway. right shipping container. Once the

putaway location for the unit based on The WMS system receives orders from items are placed in the shipping con-

the velocity for that SKU. Fast-moving Office Depot’s order management tainer, the associate pushes a button

items are stored closest to the worksta- system and forwards that data to the on the unit to confirm the pick. When

tions, slow-moving SKUs are stored robotic system. The system then pri- all of the orders for that unit have been

further away. oritizes the orders that must be picked completed, the robot delivers it to one

Picking: A limited number of large first to meet shipping cut-off times or of six lanes in the outbound conveyor

non-conveyables are picked from stor- customer requirements. induction area (9).

age by lift trucks and delivered to the To initiate picking, an associate Packing/shipping: At the conveyor

shipping area (5). Similarly, cases of logs into a workstation (7) and chooses induction station (9), an associate places

product that are too heavy for the the picking function. That signals the the cartons on the outbound conveyor

robotic picking system, such as paper system to retrieve a pod with empty (10). They are automatically scanned,

or bottled water, are picked to a pal- shipping cartons for orders (6) and which generates a shipping label that is

let in a case pick area (8) and are then deliver them to the workstation (7). automatically applied. The sorter (11)

delivered to an outbound conveyor Meanwhile, the system also delivers then sorts the carton to the correct ship-

induction workstation (9) where they the storage units (6) with the inven- ping lane (12). As with other product,

are placed on the outbound conveyor tory for those shipping cartons to the cartons may be palletized for delivery to

(10). They are then sorted by a sliding workstation (7). When a unit presents a store, or they may be floor-loaded for a

shoe sortation system (11) to an out- itself, a terminal at the workstation will parcel shipment to a business or direct-

bound shipping lane (12). Product may display a picture of the SKU, the SKU to-consumer order (5). M

mmh.com Modern Mat eria l s Ha ndl ing / A u g u s t 2010 25You can also read