Airbus Group Innovations - Aerospace and defense

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Aerospace and defense

Airbus Group Innovations

Realizing technological excellence and breakthroughs in aircraft composite

design using Siemens PLM Software technology

Product

LMS

Business challenges

Reduce fuel consumption and

emissions

Increase structural efficiency

and reliability

Minimize aircraft weight

Keys to success

Utilize the full potential of

composites

Identify delamination and

damage in composite

structures

Image courtesy of Airbus.

Use nonlinear analysis to

determine adequate safety

margins Airbus Group Innovations structural components made of composites.

leverages the value of composites Compared to metals, composites exhibit

very specific failure modes. In order to pro-

with LMS Samtech Samcef vide safe designs that fully exploit the

Results

potential of these new materials, aircraft

Improved ability to design Maintaining a leadership position

stress engineers need to identify possible

composite parts right the first Today the main challenge for aircraft man- delamination as well as damages that may

time ufacturers is reducing fuel consumption appear inside the plies of the layered com-

Facilitated the engineering and emissions. The best way to accomplish posite structures.

and analysis of complex that is by increasing the structural effi-

composite structures ciency and reliability of aircraft and using Additionally, the nonlinear geometric

Used improved understanding new, lighter composite materials to mini- effects of thin-walled composite structures

of composites to increase lead mize weight. are complex to analyze and cannot be

over competitors ignored. Advanced expertise in nonlinear

Within this framework, engineers need to analysis is required to obtain accurate

Enhanced ability to perform

maintain control of the design by predict- results so that realistic safety margins can

composite damage analysis

ing all types of potential defects in the be determined.

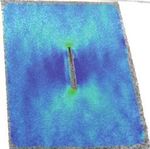

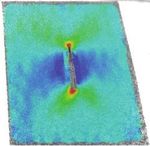

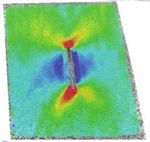

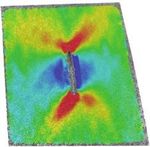

www.siemens.com/plm/lmsResults of experimental testing.

Strain along blade axis

Increasing loading

Results of simulation with LMS Samtech Samcef.

Correlation between LMS Samtech Samcef and test results showing damage on a helicopter blade. Images

courtesy of Airbus Group Innovations.

Airbus Group Innovations (formerly EADS and Airbus Helicopters on its composite

Innovation Works) is the corporate analysis research, which requires an inno-

research and technology department of vative and advanced concept for design

Airbus Group. Its primary mission is to and deployment in new aircraft programs.

develop technological excellence and

breakthroughs to support industrial inno- Virtual testing is an essential tool to

vations within its divisions: Airbus, Airbus decrease the number of physical tests on

Defence and Space (formerly Cassidian composite components and to support air-

and Astrium) and Airbus Helicopters (for- craft certification, and Siemens PLM

merly Eurocopter). Software plays a vital role in this process

for Airbus Group Innovations by providing

Its secondary objective is to share compe- LMS Samtech Samcef™ software, a finite

tencies between these commercial entities element analysis (FEA) package dedicated

to help Airbus Group maintain its leader- to mechanical and structural virtual proto-

ship position in an increasingly competi- typing. LMS Samcef is used in numerous

tive global environment. Airbus Group industrial fields for everything from basic

Innovations primarily works with Airbus to advanced projects.Indeed, during the past 20 years, the LMS simulation is used to incorporating engi- “The LMS Samtech develop-

Samtech software development team has neers from the French university Ecole ment team is the corner-

built a strong relationship with Airbus Normale Supérieure de Cachan (ENS stone of these partnerships,

Group Innovations, especially in the area Cachan), especially from its Laboratoire de contributing to the dissemi-

of composite technologies. Mécanique et Technologie (LMT Cachan),” nation of these new material

says Didier Guedra-Desgeorges, vice presi- laws thanks to the imple-

Providing a foundation dent and head of the Technical mentation of these

With more than 35 years of experience Capabilities Center Structure Engineering, advanced concepts into its

working with leaders in the aerospace Production & Aeromechanics at Airbus LMS Samcef solver.”

industry, Airbus Group Innovations experts Group Innovations. ”The very high level of

Didier Guedra-Desgeorges

perform research and assist aircraft origi- the research programs and the number of

Vice President and Head of the

nal equipment manufacturers (OEMs) with new composite material laws and models

Technical Capabilities Center

the implementation of dedicated structural for composite structure damage devel-

Structure Engineering,

analysis technology and optimization sce- oped by LMT Cachan explains the strong

Production & Aeromechanics

narios as well as solid predictive solutions relationship between us.”

Airbus Group Innovations

for composites. Airbus Group Innovations

improves its knowledge by enabling the Guedra-Desgeorges adds, “Laboratoire de

simulation of composite material damages Mécanique et d’Acoustique, Aix-Marseille

so it can analyze large composite thin- University (LMA Marseille), another French

walled structures. For full-fledged pro- university laboratory working in the same

grams, efficiency improvement projects field, is also a research partner of Airbus

include developing dedicated and Group Innovations. The LMS Samtech

improved models, which take into account development team is the cornerstone of

modeling possible failures in the compos- these partnerships, contributing to the dis-

ite structure. semination of these new material laws

thanks to the implementation of these

“The Airbus Group Innovations team dedi- advanced concepts into its LMS Samcef

cated to advanced composite analysis and solver.”

“The successful implementation

of these laws in the nonlinear

LMS Samcef finite element

solver was completed with the

support of the Siemens PLM

Software team.”

Serge Maison Le-Poec

Head of Structure Analysis

Airbus Group InnovationsBuilding block approach including the composite structure and virtual and experimental material testing.

“Thanks to the implementa- Gaining a deeper understanding element solver was completed with the

tion into LMS Samcef of Given the growing competitive pressure, it support of the Siemens PLM Software

advanced composite mate- is important that the Airbus Group reacts team,” says Serge Maison Le-Poec, head of

rial laws developed in collab- extremely quickly to the needs of the mar- Structure Analysis at Airbus Group

oration with LMT Cachan ket by designing products right the first Innovations. “Even if openness is available

and LMA Marseille, Airbus time and by using new methodologies for via material user routines, a native imple-

Group gained much deeper integrating advanced modeling of mentation in commercial software pro-

physical insights, thus composites. vides a more reliable solution.”

extending the gap with its

competitors by positioning “Thanks to the implementation into LMS He notes, “Advanced numerical regulariza-

itself as the first and leading Samcef of advanced composite material tion techniques have been set up in order

research department able to laws developed in collaboration with LMT to preserve good convergence properties

offer such advanced Cachan and LMA Marseille, Airbus Group of such highly nonlinear analyses, includ-

expertise.” gained much deeper physical insights, thus ing strong discontinuities. The fact that

extending the gap with its competitors by LMS Samcef software provides a robust,

Didier Guedra-Desgeorges

positioning itself as the first and leading state-of-the-art technology environment in

Vice President and Head of the

research department able to offer such an industrial context is strategic for us.”

Technical Capabilities Center

advanced expertise,” says

Structure Engineering,

Guedra-Desgeorges. This new functionality has been success-

Production & Aeromechanics

fully tested by Airbus Helicopters for the

Airbus Group Innovations

The formulation of the selected model has prediction of the nonlinear structural

been extensively validated against experi- behavior of a composite blade, including a

mental results. It allows for taking into transverse crack. The precise correlation

account the different kinds of failure between the simulation and the physical

modes and damages of composite materi- test results confirm that it is possible to

als, as well as the interdependencies of analyze complex scenarios on composite

these phenomena. structures. Thanks to the demonstration of

its methods and models reliability and the

“The successful implementation of these extension of the spectrum of analyses to

laws in the nonlinear LMS Samcef finite real-life complex behaviors on compositeSolutions/Services structures, Airbus Group Innovations has the deployment of massive parallel com-

LMS Samtech Samcef positioned itself as a leader when applying puting based on the LMS Samcef nonlinear

www.siemens.com/plm/lms- for existing and new industrial programs. solver in order to run large scale models

samtech for composite damage analysis.

Realizing clear benefits

The trend is to use simulation of composite “Further validations are running with

Customer’s primary business components in parallel or as a complement Airbus within the European MAAXIMUS

Airbus Group is a global leader to physical testing. Within the full aircraft project,” says Maison-Le-Poec. “Airbus

in aerospace, defense and re- design process, the use of simulation tools Group and LMS Samtech software experts

lated services. In 2013, the is now virtually essential in order to satisfy are also partners in several research and

Group – comprising Airbus, the requirements of the certification development (R&D) projects on composite

Airbus Defence and Space and authorities, while saving time and money. damage analysis.”

Airbus Helicopters – generat- The accurate analysis models for compos-

ed revenues of € 59.3 billion ites provide a better understanding of the “Airbus Group Innovations is clearly recogni-

and employed a workforce of physics of failure. With the knowledge of zed for having set a high standard for engin-

around 144,000 people. what the effects of a failure are on the eering service activities to provide tailor-

www.airbus-group.com composite structure, better designs can be made solutions,” says Guedra-Desgeorges.

proposed with more precise safety margins. “The fast adoption of its methods by the

aviation industry will improve the industrial

Customer location This provides significant benefits to aircraft design process. Since composite material

Suresnes OEMs. The definition of more accurate behavior and life duration are different

France safety margins by the stress department of from the traditional metallic material frac-

aircraft OEMs enables lighter weight com- ture mechanics phenomena, current air-

posite structures and a reduction in costs. worthiness methodologies are being

Together with the support and expertise of adapted to take into account virtual testing

the LMS Samtech development team, of specific failure effects on aircraft com-

Airbus Group Innovations is working on posite structures.”

“The fact that LMS Samcef

software provides a robust,

state-of-the-art technology

environment in an industrial

context is strategic for us.”

Serge Maison Le-Poec

Head of Structure Analysis

Airbus Group Innovations

Siemens PLM Software

Americas +1 248 952 5664 © 2014 Siemens Product Lifecycle Management Software Inc. Siemens and the Siemens logo are registered trademarks of

Europe +32 16 384 200 Siemens AG. LMS, LMS Imagine.Lab, LMS Imagine.Lab Amesim, LMS Virtual.Lab, LMS Samtech, LMS Samtech Caesam, LMS

Asia-Pacific +852 2230 3308 Samtech Samcef, LMS Test.Lab, LMS Soundbrush, LMS Smart and LMS SCADAS are trademarks or registered trademarks of

LMS International N.V. or any of its affiliates. All other trademarks, registered trademarks or service marks belong to their

respective holders.

www.siemens.com/plm Z7 40538 4/14 HYou can also read