670 series 2.0 IEC SPA Communication Protocol Manual - ABB Group

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Document ID: 1MRK 511 306-UEN

Issued: May 2014

Revision: -

Product version: 2.0

© Copyright 2014 ABB. All rights reservedCopyright

This document and parts thereof must not be reproduced or copied without written

permission from ABB, and the contents thereof must not be imparted to a third

party, nor used for any unauthorized purpose.

The software and hardware described in this document is furnished under a license

and may be used or disclosed only in accordance with the terms of such license.

This product includes software developed by the OpenSSL Project for use in the

OpenSSL Toolkit. (http://www.openssl.org/)

This product includes cryptographic software written/developed by: Eric Young

(eay@cryptsoft.com) and Tim Hudson (tjh@cryptsoft.com).

Trademarks

ABB and Relion are registered trademarks of the ABB Group. All other brand or

product names mentioned in this document may be trademarks or registered

trademarks of their respective holders.

Warranty

Please inquire about the terms of warranty from your nearest ABB representative.Disclaimer

The data, examples and diagrams in this manual are included solely for the concept

or product description and are not to be deemed as a statement of guaranteed

properties. All persons responsible for applying the equipment addressed in this

manual must satisfy themselves that each intended application is suitable and

acceptable, including that any applicable safety or other operational requirements

are complied with. In particular, any risks in applications where a system failure and/

or product failure would create a risk for harm to property or persons (including but

not limited to personal injuries or death) shall be the sole responsibility of the

person or entity applying the equipment, and those so responsible are hereby

requested to ensure that all measures are taken to exclude or mitigate such risks.

This document has been carefully checked by ABB but deviations cannot be

completely ruled out. In case any errors are detected, the reader is kindly requested

to notify the manufacturer. Other than under explicit contractual commitments, in

no event shall ABB be responsible or liable for any loss or damage resulting from

the use of this manual or the application of the equipment.Conformity

This product complies with the directive of the Council of the European

Communities on the approximation of the laws of the Member States relating to

electromagnetic compatibility (EMC Directive 2004/108/EC) and concerning

electrical equipment for use within specified voltage limits (Low-voltage directive

2006/95/EC). This conformity is the result of tests conducted by ABB in

accordance with the product standard EN 60255-26 for the EMC directive, and

with the product standards EN 60255-1 and EN 60255-27 for the low voltage

directive. The product is designed in accordance with the international standards of

the IEC 60255 series.Table of contents

Table of contents

Section 1 Introduction.......................................................................3

This manual........................................................................................3

Intended audience..............................................................................3

Product documentation.......................................................................4

Product documentation set............................................................4

Document revision history.............................................................5

Related documents........................................................................6

Document symbols and conventions..................................................7

Symbols.........................................................................................7

Document conventions..................................................................8

Functions included in 670 series IEDs..........................................9

Section 2 SPA application..............................................................19

SPA communication protocol...........................................................19

Application...................................................................................19

Setting guidelines........................................................................20

Section 3 SPA operation principle..................................................21

Operation principle...........................................................................21

Introduction of SPA protocol...................................................21

SPA protocol..........................................................................21

Communication ports...................................................................28

Design..............................................................................................28

Section 4 SPA settings...................................................................31

Settings.............................................................................................31

Section 5 SPA technical data.........................................................33

Technical data..................................................................................33

Section 6 Establishing connection and verifying the SPA/IEC-

communication ..............................................................35

Establishing connection and verifying the SPA/IEC-

communication ................................................................................35

Entering settings..........................................................................35

Entering SPA settings............................................................35

Verifying the communication.......................................................36

Verifying SPA communication................................................36

Fibre optic loop............................................................................36

Optical budget calculation for serial communication with

SPA/IEC .....................................................................................36

670 series 2.0 IEC 1

Communication Protocol ManualTable of contents

Section 7 SPA functions.................................................................39

Event function EVENT......................................................................39

Identification................................................................................39

Function block.............................................................................39

Signals.........................................................................................40

Settings........................................................................................41

Operation principle......................................................................43

Setting guidelines.............................................................................44

EventMask (Ch_1 - 16)...........................................................44

LONChannelMask or SPAChannelMask................................44

MinRepIntVal (1 - 16).............................................................44

Logical signal status report BINSTATREP.......................................45

Identification................................................................................45

Functionality................................................................................45

Function block.............................................................................45

Signals.........................................................................................46

Settings........................................................................................47

Operation principle......................................................................47

Section 8 Glossary.........................................................................49

Glossary...........................................................................................49

2 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 1

Introduction

Section 1 Introduction

1.1 This manual

The communication protocol manual describes the communication protocols

supported by the IED. The manual concentrates on the vendor-specific

implementations.

1.2 Intended audience

This manual addresses the communication system engineer or system integrator

responsible for pre-engineering and engineering for communication setup in a

substation from an IED perspective.

The system engineer or system integrator must have a basic knowledge of

communication in protection and control systems and thorough knowledge of the

specific communication protocol.

670 series 2.0 IEC 3

Communication Protocol ManualSection 1 1MRK 511 306-UEN -

Introduction

1.3 Product documentation

1.3.1 Product documentation set

Deinstalling & disposal

Planning & purchase

Decommissioning

Commissioning

Maintenance

Engineering

Operation

Installing

Engineering manual

Installation manual

Commissioning manual

Operation manual

Application manual

Technical manual

Communication

protocol manual

Cyber security

deployment guideline

IEC07000220-4-en.vsd

IEC07000220 V4 EN

Figure 1: The intended use of manuals throughout the product lifecycle

The engineering manual contains instructions on how to engineer the IEDs using

the various tools available within the PCM600 software. The manual provides

instructions on how to set up a PCM600 project and insert IEDs to the project

structure. The manual also recommends a sequence for the engineering of

protection and control functions, LHMI functions as well as communication

engineering for IEC 60870-5-103, IEC 61850 and DNP3.

The installation manual contains instructions on how to install the IED. The

manual provides procedures for mechanical and electrical installation. The chapters

are organized in the chronological order in which the IED should be installed.

The commissioning manual contains instructions on how to commission the IED.

The manual can also be used by system engineers and maintenance personnel for

assistance during the testing phase. The manual provides procedures for the

checking of external circuitry and energizing the IED, parameter setting and

4 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 1

Introduction

configuration as well as verifying settings by secondary injection. The manual

describes the process of testing an IED in a substation which is not in service. The

chapters are organized in the chronological order in which the IED should be

commissioned. The relevant procedures may be followed also during the service

and maintenance activities.

The operation manual contains instructions on how to operate the IED once it has

been commissioned. The manual provides instructions for the monitoring,

controlling and setting of the IED. The manual also describes how to identify

disturbances and how to view calculated and measured power grid data to

determine the cause of a fault.

The application manual contains application descriptions and setting guidelines

sorted per function. The manual can be used to find out when and for what purpose

a typical protection function can be used. The manual can also provide assistance

for calculating settings.

The technical manual contains application and functionality descriptions and lists

function blocks, logic diagrams, input and output signals, setting parameters and

technical data, sorted per function. The manual can be used as a technical reference

during the engineering phase, installation and commissioning phase, and during

normal service.

The communication protocol manual describes the communication protocols

supported by the IED. The manual concentrates on the vendor-specific

implementations.

The point list manual describes the outlook and properties of the data points

specific to the IED. The manual should be used in conjunction with the

corresponding communication protocol manual.

The cyber security deployment guideline describes the process for handling cyber

security when communicating with the IED. Certification, Authorization with role

based access control, and product engineering for cyber security related events are

described and sorted by function. The guideline can be used as a technical

reference during the engineering phase, installation and commissioning phase, and

during normal service.

1.3.2 Document revision history

Document revision/date History

-/May 2014 First release

670 series 2.0 IEC 5

Communication Protocol ManualSection 1 1MRK 511 306-UEN -

Introduction

1.3.3 Related documents

Documents related to REB670 Identify number

Application manual 1MRK 505 302-UEN

Commissioning manual 1MRK 505 304-UEN

Product guide 1MRK 505 305-BEN

Technical manual 1MRK 505 303-UEN

Type test certificate 1MRK 505 305-TEN

Documents related to REC670 Identify number

Application manual 1MRK 511 310-UEN

Commissioning manual 1MRK 511 312-UEN

Product guide 1MRK 511 313-BEN

Technical manual 1MRK 511 311-UEN

Type test certificate 1MRK 511 313-TEN

Documents related to RED670 Identify number

Application manual 1MRK 505 307-UEN

Commissioning manual 1MRK 505 309-UEN

Product guide 1MRK 505 310-BEN

Technical manual 1MRK 505 308-UEN

Type test certificate 1MRK 505 310-TEN

Documents related to REG670 Identify number

Application manual 1MRK 502 051-UEN

Commissioning manual 1MRK 502 053-UEN

Product guide 1MRK 502 054-BEN

Technical manual 1MRK 502 052-UEN

Type test certificate 1MRK 502 054-TEN

Documents related to REL670 Identify number

Application manual 1MRK 506 338-UEN

Commissioning manual 1MRK 506 340-UEN

Product guide 1MRK 506 341-BEN

Technical manual 1MRK 506 339-UEN

Type test certificate 1MRK 506 341-TEN

6 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 1

Introduction

Documents related to RET670 Identify number

Application manual 1MRK 504 138-UEN

Commissioning manual 1MRK 504 140-UEN

Product guide 1MRK 504 141-BEN

Technical manual 1MRK 504 139-UEN

Type test certificate 1MRK 504 141-TEN

670 series manuals Identify number

Operation manual 1MRK 500 118-UEN

Engineering manual 1MRK 511 308-UEN

Installation manual 1MRK 514 019-UEN

Communication protocol manual, IEC 1MRK 511 304-UEN

60870-5-103

Communication protocol manual, IEC 61850 1MRK 511 302-UEN

Edition 1

Communication protocol manual, IEC 61850 1MRK 511 303-UEN

Edition 2

Communication protocol manual, LON 1MRK 511 305-UEN

Communication protocol manual, SPA 1MRK 511 306-UEN

Accessories guide 1MRK 514 012-BEN

Cyber security deployment guideline 1MRK 511 309-UEN

Connection and Installation components 1MRK 513 003-BEN

Test system, COMBITEST 1MRK 512 001-BEN

1.4 Document symbols and conventions

1.4.1 Symbols

The caution icon indicates important information or warning related

to the concept discussed in the text. It might indicate the presence

of a hazard which could result in corruption of software or damage

to equipment or property.

The information icon alerts the reader of important facts and

conditions.

The tip icon indicates advice on, for example, how to design your

project or how to use a certain function.

670 series 2.0 IEC 7

Communication Protocol ManualSection 1 1MRK 511 306-UEN -

Introduction

Although warning hazards are related to personal injury, it is necessary to

understand that under certain operational conditions, operation of damaged

equipment may result in degraded process performance leading to personal injury

or death. It is important that the user fully complies with all warning and

cautionary notices.

1.4.2 Document conventions

• Abbreviations and acronyms in this manual are spelled out in the glossary. The

glossary also contains definitions of important terms.

• Push button navigation in the LHMI menu structure is presented by using the

push button icons.

For example, to navigate between the options, use and .

• HMI menu paths are presented in bold.

For example, select Main menu/Settings.

• LHMI messages are shown in Courier font.

For example, to save the changes in non-volatile memory, select Yes and

press .

• Parameter names are shown in italics.

For example, the function can be enabled and disabled with the Operation setting.

• Each function block symbol shows the available input/output signal.

• the character ^ in front of an input/output signal name indicates that the

signal name may be customized using the PCM600 software.

• the character * after an input/output signal name indicates that the signal

must be connected to another function block in the application

configuration to achieve a valid application configuration.

• Logic diagrams describe the signal logic inside the function block and are

bordered by dashed lines.

• Signals in frames with a shaded area on their right hand side represent

setting parameter signals that are only settable via the PST or LHMI.

• If an internal signal path cannot be drawn with a continuous line, the

suffix -int is added to the signal name to indicate where the signal starts

and continues.

• Signal paths that extend beyond the logic diagram and continue in

another diagram have the suffix ”-cont.”

8 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 1

Introduction

1.4.3 Functions included in 670 series IEDs

Table 1: Main protection functions

IEC 61850 or function ANSI Description

name

Differential protection

BBP3PH4B 87B Busbar differential protection, 2 zones, three phase/4 bays

Package including functions BUTPTRC_B1-BUTPTRC_B4, BCZTPDIF, BZNTPDIF_A,

BZNTPDIF_B, BZITGGIO, BUTSM4

BBP3PH8B 87B Busbar differential protection, 2 zones, three phase/8 bays

Package including functions BUTPTRC_B1-BUTPTRC_B8, BCZTPDIF, BZNTPDIF_A,

BZNTPDIF_B, BZITGGIO, BUTSM8

BBP1PH12B 87B Busbar differential protection, 2 zones, single phase/12 bays

Package including functions BUSPTRC_B1-BUSPTRC_B12, BCZSPDIF, BZNSPDIF_A,

BZNSPDIF_B, BZISGGIO, BUSSM12

BBP1PH24B 87B Busbar differential protection, 2 zones, single phase/24 bays

Package including functions BUSPTRC_B1-BUSPTRC_B24, BCZSPDIF, BZNSPDIF_A,

BZNSPDIF_B, BZISGGIO, BUSSM24

BDCGAPC 87B Status of primary switching object for busbar protection zone selection

T2WPDIF 87T Transformer differential protection, two winding

T3WPDIF 87T Transformer differential protection, three winding

HZPDIF 87 1Ph High impedance differential protection

GENPDIF 87G Generator differential protection

REFPDIF 87N Restricted earth fault protection, low impedance

L3CPDIF 87L Line differential protection, 3 CT sets, 23 line ends

L6CPDIF 87L Line differential protection, 6 CT sets, 35 line ends

LT3CPDIF 87LT Line differential protection 3 CT sets, with inzone transformers, 23 line ends

LT6CPDIF 87LT Line differential protection 6 CT sets, with inzone transformers, 35 line ends

LDLPSCH 87L Line differential coordination function

LDRGFC 11REL Additional security logic for differential protection

Impedance protection

ZMQAPDIS, ZMQPDIS 21 Distance protection zone, quadrilateral characteristic

ZDRDIR 21D Directional impedance quadrilateral

ZMCPDIS, ZMCAPDIS 21 Distance measuring zone, quadrilateral characteristic for series compensated lines

ZDSRDIR 21D Directional impedance quadrilateral, including series compensation

FDPSPDIS 21 Phase selection, quadrilateral characteristic with fixed angle

ZMHPDIS 21 Full-scheme distance protection, mho characteristic

ZMMPDIS, ZMMAPDIS 21 Fullscheme distance protection, quadrilateral for earth faults

ZDMRDIR 21D Directional impedance element for mho characteristic

ZDARDIR Additional distance protection directional function for earth faults

ZSMGAPC Mho Impedance supervision logic

FMPSPDIS 21 Faulty phase identification with load enchroachment

ZMRPDIS, ZMRAPDIS 21 Distance protection zone, quadrilateral characteristic, separate settings

FRPSPDIS 21 Phase selection, quadrilateral characteristic with settable angle

Table continues on next page

670 series 2.0 IEC 9

Communication Protocol ManualSection 1 1MRK 511 306-UEN -

Introduction

IEC 61850 or function ANSI Description

name

ZMFPDIS 21 High speed distance protection

ZMFCPDIS 21 High speed distance protection for series compensated lines

ZMCAPDIS Additional distance measuring zone, quadrilateral characteristic

ZMRPSB 68 Power swing detection

PSLPSCH Power swing logic

PSPPPAM 78 Pole slip/out-of-step protection

OOSPPAM 78 Out-of-step protection

ZCVPSOF Automatic switch onto fault logic, voltage and current based

LEXPDIS 40 Loss of excitation

PPLPHIZ Phase preference logic

ROTIPHIZ 64R Sensitive rotor earth fault protection, injection based

STTIPHIZ 64S 100% stator earth fault protection, injection based

ZGVPDIS 21 Underimpedance protection for generators and transformers

Table 2: Backup protection functions

IEC 61850 or function ANSI Description

name

Current protection

PHPIOC 50 Instantaneous phase overcurrent protection

OC4PTOC 51_67 Four step phase overcurrent protection

PH4SPTOC 51 Four step single phase overcurrent protection

EFPIOC 50N Instantaneous residual overcurrent protection

EF4PTOC 51N_67 Four step residual overcurrent protection

N

NS4PTOC 46I2 Four step directional negative phase sequence overcurrent protection

SDEPSDE 67N Sensitive directional residual over current and power protection

LCPTTR 26 Thermal overload protection, one time constant, Celsius

LFPTTR 26 Thermal overload protection, one time constant, Fahrenheit

TRPTTR 49 Thermal overload protection, two time constants

CCRBRF 50BF Breaker failure protection

CCSRBRF 50BF Breaker failure protection, single phase version

STBPTOC 50STB Stub protection

CCPDSC 52PD Pole discordance protection

GUPPDUP 37 Directional underpower protection

GOPPDOP 32 Directional overpower protection

BRCPTOC 46 Broken conductor check

CBPGAPC Capacitor bank protection

NS2PTOC 46I2 Negative sequence time overcurrent protection for machines

AEGPVOC 50AE Accidental energizing protection for synchronous generator

Table continues on next page

10 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 1

Introduction

IEC 61850 or function ANSI Description

name

VRPVOC 51V Voltage restrained overcurrent protection

GSPTTR 49S Stator overload protection

GRPTTR 49R Rotor overload protection

Voltage protection

UV2PTUV 27 Two step undervoltage protection

OV2PTOV 59 Two step overvoltage protection

ROV2PTOV 59N Two step residual overvoltage protection

OEXPVPH 24 Overexcitation protection

VDCPTOV 60 Voltage differential protection

STEFPHIZ 59THD 100% Stator earth fault protection, 3rd harmonic based

LOVPTUV 27 Loss of voltage check

PAPGAPC 27 Radial feeder protection

Frequency protection

SAPTUF 81 Underfrequency protection

SAPTOF 81 Overfrequency protection

SAPFRC 81 Rate-of-change frequency protection

FTAQFVR 81A Frequency time accumulation protection

Multipurpose protection

CVGAPC General current and voltage protection

Table 3: Control and monitoring functions

IEC 61850 or function ANSI Description

name

Control

SESRSYN 25 Synchrocheck, energizing check, and synchronizing

SMBRREC 79 Autorecloser

TR1ATCC 90 Automatic voltage control for tap changer, single control

TR8ATCC 90 Automatic voltage control for tap changer, parallel control

TCMYLTC 84 Tap changer control and supervision, 6 binary inputs

TCLYLTC 84 Tap changer control and supervision, 32 binary inputs

SLGAPC Logic Rotating Switch for function selection and LHMI presentation

VSGAPC Selector mini switch

DPGAPC Generic communication function for Double Point indication

SPC8GAPC Single Point Generic Control 8 signals

AUTOBITS AutomationBits, command function for DNP3.0

SINGLECMD Single command, 16 signals

Command function block for LON and SPA

VCTRSEND Horizontal communication via GOOSE for VCTR

GOOSEVCTRRCV Horizontal communication via GOOSE for VCTR

Table continues on next page

670 series 2.0 IEC 11

Communication Protocol ManualSection 1 1MRK 511 306-UEN -

Introduction

IEC 61850 or function ANSI Description

name

I103CMD Function commands for IEC60870-5-103

I103GENCMD Function commands generic for IEC60870-5-103

I103POSCMD IED commands with position and select for IEC60870-5-103

I103IEDCMD IED commands for IEC60870-5-103

I103USRCMD Function commands user defined for IEC60870-5-103

Apparatus control and interlocking

SCILO 3 Logical node for interlocking

BB_ES 3 Interlocking for busbar earthing switch

A1A2_BS 3 Interlocking for bus-section breaker

A1A2_DC 3 Interlocking for bus-section disconnector

ABC_BC 3 Interlocking for bus-coupler bay

BH_CONN 3 Interlocking for 1 1/2 breaker diameter

BH_LINE_A 3 Interlocking for 1 1/2 breaker diameter

BH_LINE_B 3 Interlocking for 1 1/2 breaker diameter

DB_BUS_A 3 Interlocking for double CB bay

DB_BUS_B 3 Interlocking for double CB bay

DB_LINE 3 Interlocking for double CB bay

ABC_LINE 3 Interlocking for line bay

AB_TRAFO 3 Interlocking for transformer bay

SCSWI Switch controller

SXCBR Circuit breaker

SXSWI Switch controller

RESIN1 Reservation input 1

RESIN2 Reservation input 2

POS_EVAL Evaluation of position indication

QCRSV Bay reservation

QCBAY Apparatus control

Function for handling the status of Local/Remote switch

LOCREM Handling of LRswitch positions

LOCREMCTRL LHMI control of PSTO

Function for handling Internal Local/Remote switch

Secondary system supervision

CCSSPVC 87 Current circuit supervision

FUFSPVC Fuse failure supervision

VDSPVC 60 Fuse failure supervision based on voltage difference

Logic

SMPPTRC 94 Tripping logic

TMAGAPC Trip matrix logic

ALMCALH Logic for group alarm

WRNCALH Logic for group warning

Table continues on next page

12 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 1

Introduction

IEC 61850 or function ANSI Description

name

INDCALH Logic for group indication

AND Configurable logic blocks, AND

OR Configurable logic blocks, OR

INV Configurable logic blocks, inverter

PULSETIMER Configurable logic blocks, PULSETIMER

GATE Configurable logic blocks, controllable gate

TIMERSET Configurable logic blocks, timer

XOR Configurable logic blocks, exclusive OR

LLD Configurable logic blocks, LLD

SRMEMORY Configurable logic blocks, set-reset memory

RSMEMORY Configurable logic blocks, reset-set memory

ANDQT Configurable logic blocks Q/T, ANDQT

ORQT Configurable logic blocks Q/T, ORQT

INVERTERQT Configurable logic blocks Q/T, INVERTERQT

XORQT Configurable logic blocks Q/T, XORQT

SRMEMORYQT Configurable logic Q/T, set-reset with memory

RSMEMORYQT Configurable logic Q/T, reset-set with memory

TIMERSETQT Configurable logic Q/T, settable timer

PULSETIMERQT Configurable logic Q/T, pulse timer

INVALIDQT Configurable logic Q/T, INVALIDQT

INDCOMBSPQT Configurable logic Q/T, single-indication signal combining

INDEXTSPQT Configurable logic Q/T, single-indication signal extractor

FXDSIGN Fixed signal function block

B16I Boolean 16 to Integer conversion

BTIGAPC Boolean 16 to Integer conversion with Logic Node representation

IB16 Integer to Boolean 16 conversion

ITBGAPC Integer to Boolean 16 conversion with Logic Node representation

TIGAPC Delay on timer with input signal integration

TEIGAPC Elapsed time integrator with limit transgression and overflow supervision

Monitoring

CVMMXN, CMMXU, Measurements

VMMXU, CMSQI

VMSQI, VNMMXU

AISVBAS Function block for service value presentation of secondary analog inputs

SSIMG 63 Gas medium supervision

SSIML 71 Liquid medium supervision

SSCBR Circuit breaker condition monitoring

EVENT Event function

Function for event reporting for LON and SPA

Table continues on next page

670 series 2.0 IEC 13

Communication Protocol ManualSection 1 1MRK 511 306-UEN -

Introduction

IEC 61850 or function ANSI Description

name

DRPRDRE, A1RADR- Disturbance report

A4RADR, B1RBDR-

B6RBDR

SPGAPC Generic communication function for Single Point indication

SP16GAPC Generic communication function for Single Point indication 16 inputs

MVGAPC Generic communication function for Measured Value

BINSTATREP Logical signal status report

RANGE_XP Measured value expander block

LMBRFLO Fault locator

I103MEAS Measurands for IEC60870-5-103

I103MEASUSR Measurands user defined signals for IEC60870-5-103

I103AR Function status auto-recloser for IEC60870-5-103

I103EF Function status earth-fault for IEC60870-5-103

I103FLTPROT Function status fault protection for IEC60870-5-103

I103IED IED status for IEC60870-5-103

I103SUPERV Supervison status for IEC60870-5-103

I103USRDEF Status for user defiend signals for IEC60870-5-103

L4UFCNT Event counter with limit supervision

Metering

PCFCNT Pulse-counter logic

ETPMMTR Function for energy calculation and demand handling

System protection and control

SMAIHPAC Multipurpose filter

Table 4: Station communication functions

IEC 61850 or function ANSI Description

name

Station communication

SPA SPA communication protocol

ADE LON communciation protocol

PROTOCOL Operation selection between SPA and IEC60870-5-103 for SLM

CHSERRS485 DNP3.0 for TCP/IP and EIA-485 communication protocol

DNPFREC DNP3.0 fault records for TCP/IP and EIA-485 communication protocol

IEC61850-8-1 Parameter setting function for IEC61850

GOOSEINTLKRCV Horizontal communication via GOOSE for interlocking

GOOSEBINRCV Goose binary receive

GOOSEDPRCV GOOSE function block to receive a double point value

GOOSEINTRCV GOOSE function block to receive an integer value

GOOSEMVRCV GOOSE function block to receive a measurand value

Table continues on next page

14 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 1

Introduction

IEC 61850 or function ANSI Description

name

GOOSESPRCV GOOSE function block to receive a single point value

GOOSEVCTRCONF GOOSE VCTR configuration for send and receive

VCTRSEND Horizontal communication via GOOSE for VCTR

GOOSEVCTRRCV Horizontal communication via GOOSE for VCTR

MULTICMDRCV, Multiple command and transmit

MULTICMDSND

FRONT, LANABI, Ethernet configuration of links

LANAB, LANCDI,

LANCD

MU1_4I_4U MU2_4I_4U Process bus communication IEC61850-9-2

MU3_4I_4U MU4_4I_4U

MU5_4I_4U MU6_4I_4U

PRP Duo driver configuration

Scheme communication

ZCPSCH 85 Scheme communication logic for distance or overcurrent protection

ZC1PPSCH 85 Phase segregated Scheme communication logic for distance protection

ZCRWPSCH 85 Current reversal and weak-end infeed logic for distance protection

ZC1WPSCH 85 Current reversal and weak-end infeed logic for phase segregated communication

ZCLCPSCH Local acceleration logic

ECPSCH 85 Scheme communication logic for residual overcurrent protection

ECRWPSCH 85 Current reversal and weak-end infeed logic for residual overcurrent protection

Direct transfer trip

LAPPGAPC 37_55 Low active power and power factor protection

COUVGAPC 59_27 Compensated over- and undervoltage protection

SCCVPTOC 51 Sudden change in current variation

LCCRPTRC 94 Carrier receive logic

LCNSPTOV 47 Negative sequence overvoltage protection

LCZSPTOV 59N Zero sequence overvoltage protection

LCNSPTOC 46 Negative sequence overcurrent protection

LCZSPTOC 51N Zero sequence overcurrent protection

LCP3PTOC 51 Three phase overcurrent

LCP3PTUC 37 Three phase undercurrent

Table 5: Basic IED functions

IEC 61850 or function Description

name

INTERRSIG Self supervision with internal event list

SELFSUPEVLST Self supervision with internal event list

TIMESYNCHGEN Time synchronization module

Table continues on next page

670 series 2.0 IEC 15

Communication Protocol ManualSection 1 1MRK 511 306-UEN -

Introduction

IEC 61850 or function Description

name

SYNCHBIN, Time synchronization

SYNCHCAN,

SYNCHCMPPS,

SYNCHLON,

SYNCHPPH,

SYNCHPPS,

SYNCHSNTP,

SYNCHSPA,

SYNCHCMPPS

TIMEZONE Time synchronization

DSTBEGIN, GPS time synchronization module

DSTENABLE, DSTEND

IRIG-B Time synchronization

SETGRPS Number of setting groups

ACTVGRP Parameter setting groups

TESTMODE Test mode functionality

CHNGLCK Change lock function

LONGEN Misc Base Common

SMBI Signal matrix for binary inputs

SMBO Signal matrix for binary outputs

SMMI Signal matrix for mA inputs

SMAI1 - SMAI20 Signal matrix for analog inputs

3PHSUM Summation block 3 phase

ATHSTAT Authority status

ATHCHCK Authority check

AUTHMAN Authority management

FTPACCS FTP access with password

SPACOMMMAP SPA communication mapping

SPATD Date and time via SPA protocol

DOSFRNT Denial of service, frame rate control for front port

DOSLANAB Denial of service, frame rate control for OEM port AB

DOSLANCD Denial of service, frame rate control for OEM port CD

DOSSCKT Denial of service, socket flow control

GBASVAL Global base values for settings

PRIMVAL Primary system values

ALTMS Time master supervision

ALTIM Time management

ALTRK Service tracking

ACTIVLOG Activity logging parameters

FSTACCS Field service tool access via SPA protocol over ethernet communication

PCMACCS IED Configuration Protocol

SECALARM Component for mapping security events on protocols such as DNP3 and IEC103

Table continues on next page

16 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 1

Introduction

IEC 61850 or function Description

name

DNPGEN DNP3.0 communication general protocol

DNPGENTCP DNP3.0 communication general TCP protocol

CHSEROPT DNP3.0 for TCP/IP and EIA-485 communication protocol

MSTSER DNP3.0 for serial communication protocol

OPTICAL103 IEC60870-5-103 Optical serial communication

RS485103 IEC60870-5-103 serial communication for RS485

IEC61850-8-1 Parameter setting function for IEC61850

HORZCOMM Network variables via LON

LONSPA SPA communication protocol

LEDGEN General LED indication part for LHMI

670 series 2.0 IEC 17

Communication Protocol Manual18

1MRK 511 306-UEN - Section 2

SPA application

Section 2 SPA application

2.1 SPA communication protocol

2.1.1 Application

SPA communication protocol as an alternative to IEC 60870-5-103. The same

communication port as for IEC 60870-5-103 is used.

When communicating with a PC connected to the utility substation LAN, via WAN

and the utility office LAN, as shown in figure 2, and using the rear Ethernet port on

the optical Ethernet module (OEM), the only hardware required for a station

monitoring system is:

• Optical fibres from the IED to the utility substation LAN.

• PC connected to the utility office LAN.

Utility LAN

Remote monitoring

WAN

Substation LAN

IED IED IED

IEC05000715-3-en.vsd

IEC05000715 V3 EN

Figure 2: SPA communication structure for a remote monitoring system via a

substation LAN, WAN and utility LAN

The SPA communication is mainly used for the Station Monitoring System. It can

include different IEDs with remote communication possibilities. Connection to a

computer (PC) can be made directly (if the PC is located in the substation) or by

telephone modem through a telephone network with ITU (former CCITT)

characteristics or via a LAN/WAN connection.

glassSection 2 1MRK 511 306-UEN -

SPA application

Functionality

The SPA protocol V2.5 is an ASCII-based protocol for serial communication. The

communication is based on a master-slave principle, where the IED is a slave and

the PC is the master. Only one master can be applied on each fibre optic loop. A

program is required in the master computer for interpretation of the SPA-bus codes

and for translation of the data that should be sent to the IED.

For the specification of the SPA protocol V2.5, refer to SPA-bus Communication

Protocol V2.5.

2.1.2 Setting guidelines

The setting parameters for the SPA communication are set via the local HMI.

SPA, IEC 60870-5-103 and DNP3 uses the same rear communication port. Set the

parameter Operation, under Main menu /Settings /General settings /

Communication /SLM configuration /Rear optical SPA-IEC-DNP port /

Protocol selection to the selected protocol.

When the communication protocols have been selected, the IED is automatically

restarted.

The most important settings in the IED for SPA communication are the slave

number and baud rate (communication speed). These settings are absolutely

essential for all communication contact to the IED.

These settings can only be done on the local HMI for rear channel communication

and for front channel communication.

The slave number can be set to any value from 1 to 899, as long as the slave

number is unique within the used SPA loop.

The baud rate, which is the communication speed, can be set to between 300 and

38400 baud. Refer to technical data to determine the rated communication speed

for the selected communication interfaces. The baud rate should be the same for the

whole station, although different baud rates in a loop are possible. If different baud

rates in the same fibre optical loop or RS485 network are used, consider this when

making the communication setup in the communication master, the PC.

For local fibre optic communication, 19200 or 38400 baud is the normal setting. If

telephone communication is used, the communication speed depends on the quality

of the connection and on the type of modem used. But remember that the IED does

not adapt its speed to the actual communication conditions, because the speed is set

on the local HMI.

20 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 3

SPA operation principle

Section 3 SPA operation principle

3.1 Operation principle

The SPA bus uses an asynchronous serial communications protocol (1 start bit, 7

data bits + even parity, 1 stop bit) with data transfer rate up to 38400 bit/s. For

more information on recommended baud rate for each type of IED, refer to

Technical reference manual. Messages on the bus consist of ASCII characters.

3.1.1.1 Introduction of SPA protocol

The basic construction of the protocol assumes that the slave has no self-initiated

need to talk to the master but the master is aware of the data contained in the slaves

and, consequently, can request required data. In addition, the master can send data

to the slave. Requesting by the master can be performed either by sequenced

polling (for example, for event information) or only on demand.

The master requests slave information using request messages and sends

information to the slave in write messages. Furthermore, the master can send all

slaves in common a broadcast message containing time or other data. The inactive

state of bus transmit and receive lines is a logical "1".

3.1.1.2 SPA protocol

The tables below specify the SPA addresses for reading data from and writing data

to an IED with the SPA communication protocol implemented.

The SPA addresses for the mA input service values (MIM3 to MIM16) are found

in table 6.

Table 6: SPA addresses for the MIM function

Function block SPA address

MIM3-CH1 4-O-6508

MIM3-CH2 4-O-6511

MIM3-CH3 4-O-6512

MIM3-CH4 4-O-6515

MIM3-CH5 4-O-6516

MIM3-CH6 4-O-6519

MIM4-CH1 4-O-6527

MIM4-CH2 4-O-6530

MIM4-CH3 4-O-6531

Table continues on next page

670 series 2.0 IEC 21

Communication Protocol ManualSection 3 1MRK 511 306-UEN -

SPA operation principle

Function block SPA address

MIM4-CH4 4-O-6534

MIM4-CH5 4-O-6535

MIM4-CH6 4-O-6538

MIM5-CH1 4-O-6546

MIM5-CH2 4-O-6549

MIM5-CH3 4-O-6550

MIM5-CH4 4-O-6553

MIM5-CH5 4-O-6554

MIM5-CH6 4-O-6557

MIM6-CH1 4-O-6565

MIM6-CH2 4-O-6568

MIM6-CH3 4-O-6569

MIM6-CH4 4-O-6572

MIM6-CH5 4-O-6573

MIM6-CH6 4-O-6576

MIM7-CH1 4-O-6584

MIM7-CH2 4-O-6587

MIM7-CH3 4-O-6588

MIM7-CH4 4-O-6591

MIM7-CH5 4-O-6592

MIM7-CH6 4-O-6595

MIM8-CH1 4-O-6603

MIM8-CH2 4-O-6606

MIM8-CH3 4-O-6607

MIM8-CH4 4-O-6610

MIM8-CH5 4-O-6611

MIM8-CH6 4-O-6614

MIM9-CH1 4-O-6622

MIM9-CH2 4-O-6625

MIM9-CH3 4-O-6626

MIM9-CH4 4-O-6629

MIM9-CH5 4-O-6630

MIM9-CH6 4-O-6633

MIM10-CH1 4-O-6641

MIM10-CH2 4-O-6644

MIM10-CH3 4-O-6645

MIM10-CH4 4-O-6648

MIM10-CH5 4-O-6649

MIM10-CH6 4-O-6652

Table continues on next page

22 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 3

SPA operation principle

Function block SPA address

MIM11-CH1 4-O-6660

MIM11-CH2 4-O-6663

MIM11-CH3 4-O-6664

MIM11-CH4 4-O-6667

MIM11-CH5 4-O-6668

MIM11-CH6 4-O-6671

MIM12-CH1 4-O-6679

MIM12-CH2 4-O-6682

MIM12-CH3 4-O-6683

MIM12-CH4 4-O-6686

MIM12-CH5 4-O-6687

MIM12-CH6 4-O-6690

MIM13-CH1 4-O-6698

MIM13-CH2 4-O-6701

MIM13-CH3 4-O-6702

MIM13-CH4 4-O-6705

MIM13-CH5 4-O-6706

MIM13-CH6 4-O-6709

MIM14-CH1 4-O-6717

MIM14-CH2 4-O-6720

MIM14-CH3 4-O-6721

MIM14-CH4 4-O-6724

MIM14-CH5 4-O-6725

MIM14-CH6 4-O-6728

MIM15-CH1 4-O-6736

MIM15-CH2 4-O-6739

MIM15-CH3 4-O-6740

MIM15-CH4 4-O-6743

MIM15-CH5 4-O-6744

MIM15-CH6 4-O-6747

MIM16-CH1 4-O-6755

MIM16-CH2 4-O-6758

MIM16-CH3 4-O-6759

MIM16-CH4 4-O-6762

MIM16-CH5 4-O-6763

MIM16-CH6 4-O-6766

The SPA addresses for the pulse counter values PCFCNT:1 to PCFCNT:16 are

found in table 7.

670 series 2.0 IEC 23

Communication Protocol ManualSection 3 1MRK 511 306-UEN -

SPA operation principle

Table 7: SPA addresses for the PCFCNT function

Function block SPA address CNT_VAL SPA address NEW_VAL

PCFCNT:1 6-O-2788 6-O-2787

PCFCNT:2 6-O-2794 6-O-2793

PCFCNT:3 6-O-2800 6-O-2799

PCFCNT:4 6-O-2806 6-O-2805

PCFCNT:5 6-O-2812 6-O-2811

PCFCNT:6 6-O-2818 6-O-2817

PCFCNT:7 6-O-2824 6-O-2823

PCFCNT:8 6-O-2830 6-O-2829

PCFCNT:9 6-O-2836 6-O-2835

PCFCNT:10 6-O-2842 6-O-2841

PCFCNT:11 6-O-2848 6-O-2847

PCFCNT:12 6-O-2854 6-O-2853

PCFCNT:13 6-O-2860 6-O-2859

PCFCNT:14 6-O-2866 6-O-2865

PCFCNT:15 6-O-2872 6-O-2871

PCFCNT:16 6-O-2878 6-O-2877

I/O modules

To read binary inputs, the SPA-addresses for the outputs of the I/O-module

function block are used, that is, the addresses for BI1 – BI16. For SPA addresses,

refer to section Related documents in Product Guide.

Single command, 16 signals

The IEDs can be provided with a function to receive signals either from a

substation automation system or from the local HMI. That receiving function block

has 16 outputs that can be used, for example, to control high voltage apparatuses in

switchyards. For local control functions, the local HMI can also be used.

Single command, 16 signals function consists of three function blocks;

SINGLECMD:1 to SINGLECMD:3 for 16 binary output signals each.

The signals can be individually controlled from the operator station, remote-control

gateway, or from the local HMI on the IED. For Single command, 16 signals

function block, SINGLECMD:1 to SINGLECMD:3, the address is for the first

output. The other outputs follow consecutively after the first one. For example,

output 7 on the SINGLECMD:2 function block has the 5O533 address.

The SPA addresses for Single command, 16 signals functions SINGLECMD:1 to

SINGLECMD:3 are found in table 8.

24 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 3

SPA operation principle

Table 8: SPA addresses for SINGLECMD function

Function block SPA address CMD Input SPA address CMD output

SINGLECMD1-Cmd1 4-S-4639 5-O-511

SINGLECMD1-Cmd2 4-S-4640 5-O-512

SINGLECMD1-Cmd3 4-S-4641 5-O-513

SINGLECMD1-Cmd4 4-S-4642 5-O-514

SINGLECMD1-Cmd5 4-S-4643 5-O-515

SINGLECMD1-Cmd6 4-S-4644 5-O-516

SINGLECMD1-Cmd7 4-S-4645 5-O-517

SINGLECMD1-Cmd8 4-S-4646 5-O-518

SINGLECMD1-Cmd9 4-S-4647 5-O-519

SINGLECMD1-Cmd10 4-S-4648 5-O-520

SINGLECMD1-Cmd11 4-S-4649 5-O-521

SINGLECMD1-Cmd12 4-S-4650 5-O-522

SINGLECMD1-Cmdt13 4-S-4651 5-O-523

SINGLECMD1-Cmd14 4-S-4652 5-O-524

SINGLECMD1-Cmd15 4-S-4653 5-O-525

SINGLECMD1-Cmd16 4-S-4654 5-O-526

SINGLECMD2-Cmd1 4-S-4672 5-O-527

SINGLECMD2-Cmd2 4-S-4673 5-O-528

SINGLECMD2-Cmdt3 4-S-4674 5-O-529

SINGLECMD2-Cmd4 4-S-4675 5-O-530

SINGLECMD2-Cmd5 4-S-4676 5-O-531

SINGLECMD2-Cmd6 4-S-4677 5-O-532

SINGLECMD2-Cmd7 4-S-4678 5-O-533

SINGLECMD2-Cmd8 4-S-4679 5-O-534

SINGLECMD2-Cmd9 4-S-4680 5-O-535

SINGLECMD2-Cmd10 4-S-4681 5-O-536

SINGLECMD2-Cmd11 4-S-4682 5-O-537

SINGLECMD2-Cmd12 4-S-4683 5-O-538

SINGLECMD2-Cmd13 4-S-4684 5-O-539

SINGLECMD2-Cmd14 4-S-4685 5-O-540

SINGLECMD2-Cmd15 4-S-4686 5-O-541

SINGLECMD2-Cmd16 4-S-4687 5-O-542

SINGLECMD3-Cmd1 4-S-4705 5-O-543

SINGLECMD3-Cmd2 4-S-4706 5-O-544

SINGLECMD3-Cmd3 4-S-4707 5-O-545

SINGLECMD3-Cmd4 4-S-4708 5-O-546

SINGLECMD3-Cmd5 4-S-4709 5-O-547

SINGLECMD3-Cmd6 4-S-4710 5-O-548

Table continues on next page

670 series 2.0 IEC 25

Communication Protocol ManualSection 3 1MRK 511 306-UEN -

SPA operation principle

Function block SPA address CMD Input SPA address CMD output

SINGLECMD3-Cmd7 4-S-4711 5-O-549

SINGLECMD3-Cmd8 4-S-4712 5-O-550

SINGLECMD3-Cmd9 4-S-4713 5-O-551

SINGLECMD3-Cmd10 4-S-4714 5-O-552

SINGLECMD3-Cmd11 4-S-4715 5-O-553

SINGLECMD3-Cmd12 4-S-4716 5-O-554

SINGLECMD3-Cmd13 4-S-4717 5-O-555

SINGLECMD3-Cmd14 4-S-4718 5-O-556

SINGLECMD3-Cmd15 4-S-4719 5-O-557

SINGLECMD3-Cmd16 4-S-4720 5-O-558

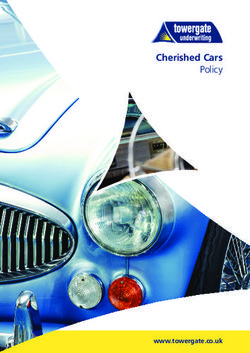

Figure 3 shows an application example of how the user can, in a simplified way,

connect the command function via the configuration logic circuit in a protection

IED for control of a circuit breaker.

A pulse via the binary outputs of the IED normally performs this type of command

control. The SPA addresses to control the outputs OUT1 – OUT16 in SINGLECMD:

1 are shown in table 8.

SINGLECMD PULSETIMER

BLOCK ^OUT1 INPUT OUT To output board, CLOSE

^OUT2 #1.000 T

^OUT3

^OUT4

^OUT5

^OUT6

^OUT7 AND PULSETIMER

^OUT8 INPUT1 OUT INPUT OUT To output board, OPEN

INPUT2 NOUT T

^OUT9 #1.000

INPUT3

^OUT10

INPUT4N

^OUT11

^OUT12

^OUT13

^OUT14

^OUT15

^OUT16

SYNCH OK

IEC05000717-2-en.vsd

IEC05000717 V2 EN

Figure 3: Application example showing a simplified logic diagram for control

of a circuit breaker

The MODE input defines if the output signals from SINGLECMD:1 is off, steady

or pulsed signals. This is set in Parameter Setting Tool (PST) under: Setting /

General Settings / Control / Commands / Single Command.

Event function

Event function is intended to send time-tagged events to the station level (for

example, operator workplace) over the station bus. The events are there presented

in an event list. The events can be created from both internal logical signals and

binary input channels. All the internal signals are time tagged in the main

26 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 3

SPA operation principle

processing module, while the binary input channels are time tagged directly on

each I/O module. The events are produced according to the set event masks. The

event masks are treated commonly for both the LON and SPA channels. All events

according to the event mask are stored in a buffer, which contains up to 1000

events. If new events appear before the oldest event in the buffer is read, the oldest

event is overwritten and an overflow alarm appears.

Two special signals for event registration purposes are available in the IED,

Terminal Restarted (0E50) and Event buffer overflow (0E51).

The input parameters can be set individually from the Parameter Setting Tool

(PST) under: Setting / General Setting / Monitoring / Event Function as follows:

• No events

• OnSet, at pick-up of the signal

• OnReset, at drop-out of the signal

• OnChange, at both pick-up and drop-out of the signal

• AutoDetect, event system itself make the reporting decision, (reporting criteria

for integers has no semantic, prefer to be set by the user)

The Status and event codes for the Event functions are found in table 9.

Table 9: Status and event codes

Single indication1) Double indication

Event block Status Set event Reset Intermedi Closed 10 Open 01 Undefined

event ate 00 11

EVENT:1

Input 1 22O1 22E33 22E32 22E0 22E1 22E2 22E3

Input 2 22O2 22E35 22E34 22E4 22E5 22E6 22E7

Input 3 22O3 22E37 22E36 22E8 22E9 22E10 22E11

Input 4 22O4 22E39 22E38 22E12 22E13 22E14 22E15

Input 5 22O5 22E41 22E40 22E16 22E17 22E18 22E19

Input 6 22O6 22E43 22E42 22E20 22E21 22E22 22E23

Input 7 22O7 22E45 22E44 22E24 22E25 22E26 22E27

Input 8 22O8 22E47 22E46 22E28 22E29 22E30 22E31

Input 9 22O9 22E49 22E48 - - - -

Input 10 22O10 22E51 22E50 - - - -

Input 11 22O11 22E53 22E52 - - - -

Input 12 22O12 22E55 22E54 - - - -

Input 13 22O13 22E57 22E56 - - - -

Input 14 22O14 22E59 22E58 - - - -

Input 15 22O15 22E61 22E60 - - - -

Input 16 22O16 22E63 22E62 - - - -

EVENT:2 230.. 23E.. 23E.. 23E.. 23E.. 23E.. 23E..

EVENT:3 240.. 24E.. 24E.. 24E.. 23E.. 24E.. 24E..

- - - - - - - -

- - - - - - - -

- - - - - - - -

EVENT:20 410.. 41E.. 41E.. 41E.. 41E.. 41E.. 41E..

These values are only applicable if the Event mask is masked ≠ OFF.

670 series 2.0 IEC 27

Communication Protocol ManualSection 3 1MRK 511 306-UEN -

SPA operation principle

Connection of signals as events

Signals coming from different protection and control functions and must be sent as

events to the station level over the SPA-bus (or LON-bus) are connected to the

Event function block according to figure 4.

EVENT

Block BLOCK

ILRANG ^INPUT1

PSTO ^INPUT2

UL12RANG ^INPUT3

UL23RANG ^INPUT4

UL31RANG ^INPUT5

3I0RANG ^INPUT6

3U0RANG ^INPUT7

FALSE ^INPUT8

^INPUT9

^INPUT10

^INPUT11

^INPUT12

^INPUT13

^INPUT14

^INPUT15

^INPUT16

IEC07000065-2-en.vsd

IEC07000065 V2 EN

Figure 4: Connection of protection signals for event handling

3.1.1 Communication ports

The serial communication module (SLM) is a mezzanine module placed on the

analog/digital conversion module (ADM) and is used for LON, SPA,

IEC60870-5-103, or DNP communication.

There are two types of IO connectors: 1) snap-in for plastic fibre cables and 2) ST/

bayonet for glass fibre cables. The SLM can be equipped with either type or a

combination of both, which is identified by a tag.

Connect the incoming optical fibre to the RX receiver input, and the outgoing

optical fibre to the TX transmitter output. Pay special attention to the instructions

concerning handling and connection of fibre cables.

For setting the transfer rate (baud rate) and slave number, please refer to the

Application Manual and Commissioning Manual respectively.

3.2 Design

Using the rear SPA port for either local or remote communication with a PC

requires the following equipment:

• Optical fibres

• Opto/electrical converter for the PC

• PC

28 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 3

SPA operation principle

The software needed in the PC, either local or remote, is PCM600. (Note! SPA

cannot be used with PCM600 2.6).

When communicating between the local HMI and a PC, the only hardware required

is a front-connection cable. Note! SPA cannot be used from LHMI front, except for

using "FSTACCS", that is, Field Service Tool Access.

670 series 2.0 IEC 29

Communication Protocol Manual30

1MRK 511 306-UEN - Section 4

SPA settings

Section 4 SPA settings

4.1 Settings

Table 10: SPA Non group settings (basic)

Name Values (Range) Unit Step Default Description

SlaveAddress 1 - 899 - 1 30 Slave address

BaudRate 300 Bd - - 9600 Bd Baudrate on serial line

1200 Bd

2400 Bd

4800 Bd

9600 Bd

19200 Bd

38400 Bd

Table 11: LONSPA Non group settings (basic)

Name Values (Range) Unit Step Default Description

Operation Off - - Off Operation

On

SlaveAddress 1 - 899 - 1 30 Slave address

670 series 2.0 IEC 31

Communication Protocol Manual32

1MRK 511 306-UEN - Section 5

SPA technical data

Section 5 SPA technical data

5.1 Technical data

Table 12: SPA communication protocol

Function Value

Protocol SPA

Communication speed 300, 1200, 2400, 4800, 9600, 19200 or 38400

Bd

Slave number 1 to 899

670 series 2.0 IEC 33

Communication Protocol Manual34

1MRK 511 306-UEN - Section 6

Establishing connection and verifying the SPA/IEC- communication

Section 6 Establishing connection and verifying the

SPA/IEC- communication

6.1 Establishing connection and verifying the SPA/IEC-

communication

About this chapter

This chapter contains instructions on how to establish connection and verify that

the SPA/IEC-communication operates as intended, when the IED is connected to a

monitoring or control system via the rear SPA/IEC port.

6.1.1 Entering settings

If the IED is connected to a monitoring or control system via the rear SPA/IEC

port, the SPA/IEC port has to be set either for SPA or IEC use.

6.1.1.1 Entering SPA settings

The SPA/IEC port is located on the rear side of the IED. Two types of interfaces

can be used:

• for plastic fibres with connector type HFBR

• for glass fibres with connectors type ST

When using the SPA protocol, the rear SPA/IEC port must be set for SPA use.

Procedure

1. Set the operation of the rear optical SPA/IEC port to “SPA”.

The operation of the rear SPA port can be found on the local HMI under

Main menu/Configuration/Communication/Station communication/Port

configuration/SLM optical serial port/PROTOCOL:1

When the setting is entered the IED restarts automatically. After the restart

the SPA/IEC port operates as a SPA port.

2. Set the slave number and baud rate for the rear SPA port

The slave number and baud rate can be found on the local HMI under Main

menu/Configuration/Communication/Station communication/SPA/SPA:1

Set the same slave number and baud rate as set in the SMS system for the IED.

670 series 2.0 IEC 35

Communication Protocol ManualSection 6 1MRK 511 306-UEN -

Establishing connection and verifying the SPA/IEC- communication

6.1.2 Verifying the communication

To verify that the rear communication with the SMS/SCS system is working, there

are some different methods. Choose one of the following.

6.1.2.1 Verifying SPA communication

Procedure

1. Use a SPA-emulator and send “RF” to the IED. The answer from the IED

should be the type and version of it, for example, “REL670 2.0...”.

2. Generate one binary event by activating a function, which is configured to an

event block where the used input is set to generate events on SPA. The

configuration must be made with the PCM600 software. Verify that the event

is presented in the SMS/SCS system.

During the following tests of the different functions in the IED, verify that the

events and indications in the SMS/SCS system are as expected.

6.1.3 Fibre optic loop

The SPA communication is mainly used for SMS. It can include different

numerical IEDs with remote communication possibilities. The fibre optic loop can

contain < 20-30 IEDs depending on requirements on response time. Connection to

a personal computer (PC) can be made directly (if the PC is located in the

substation) or by telephone modem through a telephone network with ITU

(CCITT) characteristics.

Table 13: Max distances between IEDs/nodes

glass < 1000 m according to optical budget

plastic < 25 m (inside cubicle) according to optical budget

6.1.4 Optical budget calculation for serial communication with

SPA/IEC

Table 14: Example

Distance 1 km Distance 25 m

Glass Plastic

Maximum attenuation - 11 dB - 7 dB

4 dB/km multi mode: 820 nm - 62.5/125 um 4 dB -

0.16 dB/m plastic: 620 nm - 1mm - 4 dB

Margins for installation, aging, and so on 5 dB 1 dB

Losses in connection box, two contacts (0.5 dB/contact) 1 dB -

Table continues on next page

36 670 series 2.0 IEC

Communication Protocol Manual1MRK 511 306-UEN - Section 6

Establishing connection and verifying the SPA/IEC- communication

Distance 1 km Distance 25 m

Glass Plastic

Losses in connection box, two contacts (1 dB/contact) - 2 dB

Margin for 2 repair splices (0.5 dB/splice) 1 dB -

Maximum total attenuation 11 dB 7 dB

670 series 2.0 IEC 37

Communication Protocol Manual38

1MRK 511 306-UEN - Section 7

SPA functions

Section 7 SPA functions

7.1 Event function EVENT

7.1.1 Identification

Function description IEC 61850 IEC 60617 ANSI/IEEE C37.2

identification identification device number

Event function EVENT -

S00946 V1 EN

When using a Substation Automation system with LON or SPA communication,

time-tagged events can be sent at change or cyclically from the IED to the station

level. These events are created from any available signal in the IED that is

connected to the Event function (EVENT). The event function block is used for

LON and SPA communication.

Analog and double indication values are also transferred through EVENT function.

7.1.2 Function block

EVENT

BLOCK

^INPUT1

^INPUT2

^INPUT3

^INPUT4

^INPUT5

^INPUT6

^INPUT7

^INPUT8

^INPUT9

^INPUT10

^INPUT11

^INPUT12

^INPUT13

^INPUT14

^INPUT15

^INPUT16

IEC05000697-2-en.vsd

IEC05000697 V2 EN

Figure 5: EVENT function block

670 series 2.0 IEC 39

Communication Protocol ManualYou can also read