TURBO GEARBOXES - Pekrun Getriebebau GmbH

←

→

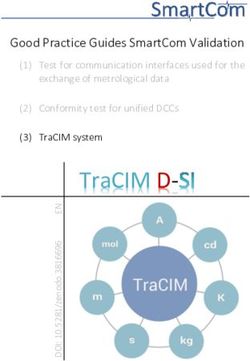

Page content transcription

If your browser does not render page correctly, please read the page content below

TURBOGETRIEBE

PROGRAM The oldest pekrun gearboxes have now outlived us - they have been operating for more than 100

years. We are of course particularly proud of our history. Every pekrun gearbox, as well as every

gearbox manufactured by a third-party company, can be reconditioned by us, adapted to other requi-

rements or retrofitted with the latest monitoring technology. This means that we can secure your

investment and conserve your budget.

SERVICE However, the prerequisite for reliable and continuous operation is careful maintenance and quick

customer service provision - and our employees will be on site with you in 24h worldwide.

We are permanently striving to optimise every last detail - and it is these details that you learn to

appreciate over the lifetime of your pekrun gearbox. Material quality, manufacturing capabilities and

many years of design experience have now made our gearboxes into reliable high-tech tools. Now as

MÜHLENGETRIEBE

then, the final assembly and the test run are still an exhilarating moment. Therefore, you will continue

to find a certain passion in every pekrun employee as a proud gearbox manufacturer.

KNOW HOW We share this combination of know how and passion with selected partners and can now look back

on very successful synergies.

If you visit us you will feel the power of a 150t aggregate, the precision of a gear wheel or the aesthe-

tics of a turbo gearbox. This aesthetic is a common thread throughout all areas of the company at

pekrun. It is the living expression of our corporate identity and can be found of course in our buildings,

our internet presence and naturally our image brochures and this catalogue.

Pierre Holly, Gearbox Manufacturer

WALZWERKGETRIEBE

FÖRDERTECHNIK

ONDERGETRIEBETURBO GEARBOX SERIES

T U RB O G E T RI EBE

Areas of application pekrun has built turbo gearboxes since 1950 and followed the trend for greater performance, the highest rotatio-

nal speeds and longer product life cycles, while at the same time delivering the maximum level of operational safety.

Our fast-running spur gearboxes can be found worldwide across the energy generation sector. pekrun turbo gear-

boxes have been installed in the oil, gas, petroleum and chemical industries. They are driven by electrical motors,

combustion engines, gas turbines, steam turbines or water turbines. The processing machines include generators,

compressors, pumps or blowers that require high to very high rotational speeds.

Characteristics Extremely quiet operation, low vibration

Designed for continuous operation

High level of operational safety, long life cycle, low maintenance

pekrun advantages Environmentally friendly due to the high level of efficiency in the transfer of very high performance and rotational

speeds

Decades of know how and the latest calculation methods enable optimal adaptation to the customer‘s requirements

Certified quality management system

Quality testing including gearing measurement, ultrasound and non destructive test, noise, vibration, bearing clea-

rance and run-out measurements, 3D measuring arm, contact patterns and test runs

Comprehensive level of service with inspections and noise and vibration measurements

Quick repairs and provision of spare parts for our own and third-party products

All industry standards are available: DIN, API, AGMAASR

Models Spur gearbox

Sizes Center distance in standard version of 100mm to 800mm, larger on request

Transmission ratios freely selectable, up to 1:10 single-stage, up to 1:25 two-stage

Performances 50 kW to 30 MW, higher performance on request

Nominal torque Up to 100 kNm and more

Installation position Horizontal or vertical

BSR

Rotational speed Up to approx. 30,000 min-1

Circumferential speed max. 145 m/s

Standard type code ASR (A=single-stage, S=spur, R=Ratiopek)

BSR (B=two-stage, S=spur, R=Ratiopek)

Integral special models AVT (A=single-stage, V=half flange for attaching turbine or impeller housing & impeller

directly attachable to gearbox shaft, T=driven by turbine)

AVK (A=single-stage, V=half flange for attaching compressor housing & spiral directly attachable

to gearbox shaft, K=driven by a compressor)

Thrust collar version available for all models

Versions Wheel sets in double or single helical gearing, manufactured out of high alloy case-hardened

steels

All wheel sets are dynamically balanced. Single helical gearing can be realised with or without

thrust collars, for a highly stable operating performance the shafts are supported by low-mainte-

AVT

nance, split, two and four-surface friction bearings as standard, tilting pad bearings are fitted for

higher rotational speeds

Special versions External axial forces or those caused by the gearing can either be absorbed through combined

axial/radial bearings or separate special axial bearings (if required, with load compensation)

Gearboxes with low rotational speeds can be fitted with antifriction bearings made out of espe-

cially high quality materials

Seals on the shaft ends are normally fitted with non-contact labyrinth seals, special seals such as

slide ring seals or radial carbon ring seals are fitted for special applications

Lubrication All gearboxes require a pressurised oil lubrication and can also be connected to a central lubrica-

tion system, the oil pump can be flange-mounted to a free shaft end in the form of a gear wheel

or screw spindle pump and be directly driven by the gearbox

Separate pressurised oil lubrication when no central lubrication system is available

Options Monitoring facilities: Resistance thermometer, machine thermometer, oil pressure indicator,

AVK

vibration sensor, acceleration sensor, rotational speed sensor, axial position sensor

Rotor turning gear to break-away from line shafts or slow running of rotors in standby operation

Installation of a return stop mechanism

Holding brake

Fitting for the connection of an oil-tight coupling casing

EX-protection or ATEX conform version

SERVICEASR

Series Single-stage, free-standing turbo gearbox

Different sizes

pekrun features High process reliability, highest gearing quality, safe design

Monitoring facilities according to customer requirements

Example application ASR 400

P = 1,700 kW

i = 1/5.25

n1 = 1,490 revs/min

n2 = 7,830 revs/min

SF = according to DIN

BSR

AVT

AVK

SERVICE

Pump drive Oil supply for turbo test stand ASR 400 with rotor turning gearASR

Labyrinth seal

Series Two-stage, free-standing turbo gearbox

Different sizes

BSR

pekrun features High process reliability, highest gearing quality,

Safe design

Monitoring facilities according to customer requirements

Example application BSR 450

P = 2,230 kW

i = 9.8/1

n1 = 508 revs/min Return stop mechanism

n2 = 4,981 revs/min

SF = according to AGMA

AVT

AVK

Temperature sensor

SERVICE

Gearing geometryAVT

AVT series Single-stage, integrated turbo gearbox for generators

High process reliability, highest gearing quality, safe design

pekrun features Monitoring facilities according to customer requirements

Half flange for integration into the system

Hirth serration for connecting to turbine wheel

Example application AVT 72

P = 2,500 kW

i = 6.3/1

n1 = 9,500 revs/min

n2 = 1,500 revs/min

SF = according to AGMAASR

Axial bearing with load compensation

BSR

AVT 59v on test stand

AVT

AVK

SERVICEAVK 305 AVK

AVK series Single-stage, integrated turbo gearbox for compressor

ASR

pekrun features Integrated gearbox with compressor wheel on input shaft

High process reliability, highest gearing quality, safe design

Monitoring facilities according to customer requirements

Half flange for integration into the system

Hirth serration for connecting to compressor wheel

Example application AVK 305

P = 200 kW

i = 1/8.72

n1 = 2,983 revs/min

n2 = 26,012 revs/min

SF = according to AGMA

BSR

AVT

Hirth serration

AVK

SERVICE

Pinion shaft with thrust collarStandard dimensions for ASR gearbox

Narrow version, dimensions in mm

Type of gearbox A B C D1 D2 E F G H H1 L1 L2 kg

max max

ASR 200 200 450 260 70 90 230 230 640 580 280 105 130 440

ASR 250 250 530 315 80 100 250 350 790 620 315 130 165 650

ASR 280 280 520 305 90 110 300 300 780 770 400 130 165 850

ASR 320 320 580 330 100 120 300 300 900 800 410 165 180 1100

ASR 360 360 660 370 130 160 370 370 965 890 450 200 240 1800

ASR 400 400 810 500 130 170 460 460 1200 1030 550 200 240 2300

ASR 450 450 850 560 140 180 460 460 1400 1150 560 220 260 3300

ASR 500 500 870 620 160 200 470 470 1530 1300 630 240 280 4200

ASR 560 560 900 650 170 210 470 470 1650 1400 660 240 280 4800

ASR 630 630 920 800 190 230 500 500 1695 1500 800 280 300 5800

ASR 710 710 1040 830 220 260 550 550 1800 1700 850 280 330 7600

ASR 800 800 1160 830 250 300 610 610 2150 1800 850 330 380 9100

Wide version, dimensions in mm

Type of gearbox A B C D1 D2 E F G H H1 L1 L2 kg

max max

ASR 200 200 450 260 70 90 230 230 640 580 280 105 130 440

ASR 250 250 530 315 80 100 250 350 790 620 315 130 165 650

ASR 280 280 720 305 120 130 380 380 780 770 400 165 200 980

ASR 320 320 770 330 130 150 420 420 900 800 410 200 220 1600

ASR 360 360 850 370 140 170 460 460 965 890 450 200 240 2300

ASR 400 400 930 500 160 190 520 520 1200 1030 550 240 280 2900

ASR 450 450 940 560 170 200 520 520 1400 1150 560 240 280 3700

ASR 500 500 1020 620 190 220 530 530 1530 1300 630 280 310 4700

ASR 560 560 1060 650 220 250 570 570 1650 1400 660 280 330 5300

ASR 630 630 1180 800 240 260 600 600 1695 1500 800 330 350 6400

ASR 710 710 1250 830 240 280 660 660 1800 1700 850 330 410 8100

ASR 800 800 1350 830 280 320 710 710 2150 1800 850 380 470 10500Service

ASR

Provision of services Reconditioning and repair of our own and third party gearboxes

Manufacture and procurement of spare parts

Replacement gearbox for existing installation space

Construction, calculations and design

Test run including documentation

BSR

Gearbox inspection on site

Vibration, temperature and noise measurements

Oil analyses

Pekrun advantages Fast reaction time

Worldwide service

Quick supply of spare parts

AVT

AVK

SERVICEPEK RUN GE TR IE BE BAU G MBH K ÖBBI NGSE R MÜ HLE 14 5 86 40 ISE R LOHN DEUT SCHL AND PHO N E +49 2371/945-0 T ELEFAX +49 2371/94 5 -2 99 www.p ekrun.de i nf o@ p ekrun.de

You can also read