Product portfolio Interior Exterior New Mobility Autoneum Pure. Measurement Systems Simulation Tools

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Product portfolio

Interior · Exterior

New Mobility · Autoneum Pure.

Measurement Systems · Simulation ToolsOVERVIEW

17

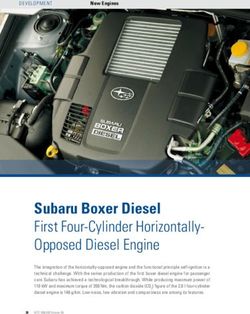

Product portfolio · Exterior · Engine Bay

Engine

top covers

Hoodliners

Engine Bay

Engine bay is the vehicle area where most of the noise and

heat sources are concentrated. With innovative lightweight and

multifunctional components, Autoneum helps automobile

manufacturers to address new regulations for pass-by noise Outer

dashes

and CO2 emissions.

Engine

encapsulations

These products include a variety of features and benefits

Autoneum supplies exterior components to these customers

For further information, please contact:

Autoneum | Global Product Management Engine Bay

engine-bay@autoneum.comE-motor- and body-mounted parts Engine- and body-mounted parts, engine top covers 19

Hybrid-Acoustics PET Theta-FiberCell

Product portfolio · Exterior · Engine Bay

Sustainable noise protection in the engine bay Key technology for engine encapsulations

Innovative engine encapsulations enhance the efficiency BENEFITS

and sustainability of vehicles: The heat storage in the

engine bay achieved with the encapsulations reduces fuel Lightweight fiber-foam

BENEFITS Hybrid-Acoustics PET is used to encapsulate electric consumption at the next cold start, which in turn leads to

motors, thereby reducing noise directly at the source lower vehicle emissions.

solution

Outstanding acoustic and particularly attenuating high-frequency sounds of

the electric drive unit. This key technology accordingly Theta-FiberCell, the key technology for engine encap-

High acoustic

insulation ensures optimum noise protection in the passenger cabin sulations, combines the benefits of the fiber carrier absorption

and greater driving comfort. Theta-Fiber and foam absorber Theta-Cell and is based

Best-in-class on Autoneum’s long-standing experience. It takes into Resistant to engine

sustainability At the same time, components made of Hybrid-Acoustics account customer-specific product requirements such as vibration

PET convince with their low weight. Compared to optimum noise protection and integrated thermal insu-

conventional insulators, they are up to 40 % lighter, lation. For instance, Theta-FiberCell is barely flammable

40 % thereby contributing to a greater driving range. They and can withstand temperatures of up to 200°C. Heat insulation and

are also flameproof and find application as powertrain- temperature stability

mounted insulators for combustion engines thanks As well as the acoustic absorption of interior (by up to

lighter than alter‑ up to

to their temperature resistance of up to 180°C. 4 decibel) and exterior (by up to 8 decibel) noise, the

native powertrain-

mounted insulators The parts, which consist to a large extent of recycled PET

fibers, are produced waste-free and are completely

fiber-foam solution enables heat to be stored for long

periods after the vehicle has been parked. After having

been switched off for 12 hours, the temperature of an

200°C

recyclable – an outstanding life cycle assessment engine with Theta-FiberCell encapsulation is up to six

compared to equivalent components in the engine bay. degrees higher than of one without this special insulation.Hoodliners, outer dashes, battery insulators Engine-mounted parts, engine top covers 21

Theta-Cell Theta-Fiber

Product portfolio · Exterior · Engine Bay

Durable and lightweight foam absorber Multifunctional non-woven technology

The engine bay compartment is a major source of heat BENEFITS

and noise in any vehicle. Therefore, it has to be acousti-

cally and thermally isolated in order to increase passen- Robust and

gers’ comfort. For that, Autoneum offers Theta-Fiber, a

BENEFITS Theta-Cell is an innovative polyurethane foam material robust and multifunctional non-woven material.

multifunctional

developed by Autoneum. It is used for different applica-

High

Low weight tions such as lightweight and multifunctional hoodliners, Theta-Fiber stands out against conventional non-woven

outer dashes, tunnel insulators and battery covers. Com- components, above all thanks to its high temperature

pared with conventional acoustic absorbers, Theta-Cell resistance: While traditional thermoplastic materials are

Premium temperature stability

components can be used to achieve weight reductions of able to withstand temperatures of up to 150°C, noise and

up to 60 % as well as high thermal insulation. thermal insulation parts based on Theta-Fiber can also

be applied at temperatures of up to 200°C.

acoustic absorption Products based on Theta-Cell are able to withstand

temperatures of up to 180°C at peak; they meet customer Compared to traditional heavy engine covers made

requirements and legal provisions with regard to the of solid plastic, Theta-Fiber engine covers achieve

non-flammability of components for the engine bay. weight savings of up to 60 %, reduce the interior and

They are also oil- and water-repellent and help to reduce exterior noise of vehicles and insulate heat generated

the interior and exterior noise of vehicles. by the engine.You can also read