Indian Air Force acquisition - Dassault Aviation Rafale fighters Getting greener

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

MOBILITY

ENGINEERING

AUTOMOTIVE, AEROSPACE, OFF-HIGHWAY

TM

A quarterly publication of and

Indian

Air Force Getting greener

HCCI vs. conventional

acquisition engine technologies

Dassault Aviation

Rafale fighters Student competitions

• Baja SAEINDIA highlights

• Rise of the underdogs

Volume 2, Issue 2

June 2015

1506ME.indb 1 5/11/15 5:25 PMME Molex Ad 0615.qxp_Mobility FP 4/29/15 8:00 PM Page 1

Decades of automotive experience and innovations

developed for the consumer and telecom industries give

Molex the right expertise to help you develop the next

generation of vehicles.

What will we make together?

molex.com/automotive

1506ME.indb 2 5/11/15 5:25 PMCONTENTS

Features

38 Getting greener AUTOMOTIVE 49 Slick solutions for friction

POWERTRAIN reduction AUTOMOTIVE POWERTRAIN

To meet upcoming fuel economy and emissions regulations, Suppliers and engine designers are attacking every

the developmental homogeneous charge compression potential source of internal friction—no longer a “low-

ignition (HCCI) engine shows promise, but pursuit of more hanging fruit”—as the battle to squeeze more mechanical

conventional engine technologies may be the better path. work from less fuel intensifies.

40 Highlights of Baja SAEINDIA 53 Hydraulics still in control of

STUDENT COMPETITIONS off-highway needs OFF-HIGHWAY

The 2015 event, the 8th edition with the theme of Beyond ELECTRONICS | HYDRAULICS

Boundaries, was won by the College of Engineering, Pune.

Engineers continue to master electronic controllers and

software to help systems manage engine speeds and

43 Rise of the underdogs STUDENT boost efficiency to the ultimate benefit of both OEMs and

COMPETITIONS end users.

Problem-plagued effort last year spurs Baja SAE team from

VIT University of India to overhaul itself and its car.

45 Testing reality in an increasingly

Cover

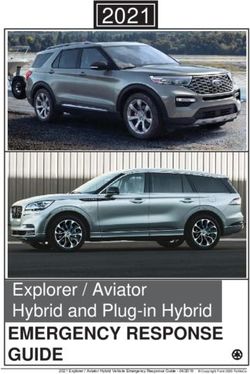

The Indian Air Force plans to

complex design space acquire 36 Rafale fighters.

AEROSPACE SIMULATION The cover image shows a

single-seater in full “Air-Air”

Digital simulation tools have transformed the designing and

configuration and a two-seater

testing of new aircraft, as well as the way they are

in mixed configuration.

manufactured and sustained.

follow us @SAEAutoMag

MOBILITY ENGINEERING JUNE 2015 1

1506ME.indb 1 5/11/15 5:25 PMME Alta

CONTENTS

Departments

4 Editorial 26 Denso displays more compact HVAC design

AUTOMOTIVE INTERIORS

High-voltage developments

27 Automakers see possibilities, limits for gesture

6 Focus controls AUTOMOTIVE ELECTRONICS

Building the SAEINDIA brand 28 The quest for the self-cleaning car AUTOMOTIVE BODY

8 SAEINDIA News 30 Brunel pursues ultrasound for ‘greener’ production of

aluminum alloys AUTOMOTIVE MATERIALS

8 AWIM National Olympics held in Chakan

31 MTU develops new turbine blade material in record

10 KLU hosts National Student Convention

time AEROSPACE MATERIALS

12 New 3D printing event

32 Lightweight steel is stronger than titanium

13 Industry News AUTOMOTIVE | AEROSPACE MATERIALS

34 Automatic collision avoidance added to inspection

15 Technology Report software AUTOMOTIVE SIMULATION

15 Schaeffler developing novel powertrain for 2015/2016

35 X-ray testing for large composites AEROSPACE

FIA Formula E season MOTORSPORTS POWERTRAIN TESTING

16 New yeast strain enhances biofuel production 36 NanoSteel powder alloys advance 3D printing of

ENERGY

high-hardness parts MANUFACTURING

17 Cummins in production with ‘simplified’ Tier 4 Final

37 Altair optimizes 3D-printed structures for complex,

engines OFF-HIGHWAY POWERTRAIN

lightweight designs MANUFACTURING

18 Aerojet Rocketdyne gets a boost from additive

manufactured components AEROSPACE PROPULSION 56 Global Vehicles

19 Military technologies aid the fight for improved 56 Next-gen NSX: A twin-turbo, multi-material

off-highway efficiencies OFF-HIGHWAY ELECTRONICS Ferrari-fighter

21 Audi details piloted driving technology AUTOMOTIVE 60 Cabin key to Komatsu America’s new T4F hydraulic

ELECTRONICS excavator

22 Flight vision system for rotary-wing aircraft AVIONICS 61 New XF moves to Jaguar’s aluminum architecture

23 Counterfeit electronic parts: Manufacture of and 63 Companies Mentioned

avoidance AEROSPACE ELECTRONICS

63 Ad Index

24 Johnson Controls presents interior concept for

autonomous driving at 2015 NAIAS AUTOMOTIVE 64 Q&A

INTERIORS Michael Tinskey, Ford’s Global Director of Vehicle

25 Portable shade proposed for cooler interiors Electrification and Infrastructure

AUTOMOTIVE INTERIORS

© SAEINDIA and SAE INTERNATIONAL reserves all rights .

No part of this publication and/or website may be reproduced, stored in a retrieval system or

transmitted in any form without prior written permission of the Publisher. Permission is only deemed

valid if approval is in writing. SAEINDIA and SAE International buys all rights to contributions, text and

images, unless previously agreed to in writing.In case of Address/addressee not found return to SAE

INDIA, No 1/17Ceebros Arcade, 3rd Cross, Kasturba Nagar, Chennai -600 020. Telefax: 91-44-2441-1904,

Phone: 91-44-4215 2280.

2 JUNE 2015 MOBILITY ENGINEERING

1506ME.indb 2 5/11/15 5:25 PMME Sain

EDITORIAL

EDITORIAL

Kevin Jost

Editorial Director

kevin@sae.org

Asit K. Barma

High-voltage developments

SAE India Editor

C. V. Raman

ED, MSIL

CV.Raman@maruti.co.in

Arun Jaura The concept of higher-voltage vehicle electrical Validation Manager for Controlled Power

VP, SAEINDIA

arunjaura@gmail.com networks between those for 12-V conventional and Technologies, because 48-V hybrids are cur-

Bala Bharadvaj 200- and 600-V full hybrids and electric vehicles is rently the most cost-effective way of meeting

MD, Boeing R & T

bala.k.bharadvaj@boeing.com not new, with development experiencing fits and stringent CO2 emissions in the buildup to 2020

Mathew Abraham starts over the past few decades. However, tight- European regulations. This is compounded

Sr. GM, Mahindra

ABRAHAM.MATHEW@mahindra.com ening efficiency and emissions regulations and potentially by a shift from the current NEDC to

Dr. Venkat Srinivas increasing demand for onboard electrical power the more aggressive WLTP test.

Vice President & Head - Engineering

& Product Development, Mahindra & means that higher voltages, in the form of supple- Electric engine boosting could benefit from

Mahindra Truck and Bus Division

srinivas.venkat@mahindra.com mental 48-V subsystems, are nearing production. 48-V networks. Hyundai and Kia are developing

Jean L. Broge One sign of this was on display at the 2014 Los a mild-hybrid diesel powertrain using an electric

Managing Editor

jbroge@sae.org Angeles Auto Show. The Audi Prologue show car, supercharger in conjunction with a 48-V net-

Lindsay Brooke which provided a glimpse of the company’s work. According to Bloore, electric boosting

Senior Editor

abrooke@sae.org design future, also more quietly previewed a new using energy recuperated, rather than lost in fric-

Ryan Gehm

Associate Editor

48-V electrical system coming to future Audis. tion from the brakes, not only reduces emissions,

rgehm@sae.org The company attributed some of the large but also can have a positive impact on vehicle

Zach Nocera

Editorial Assistant show car’s relatively low fuel consumption and performance and drivability.

Patrick Ponticel CO2 emissions to the new 48-V system. Powered The rapidly growing interest in 48-V networks

Membership Editor

ponticel@sae.org by a belt starter generator, the set up enables was also discussed at the SAE International 2015

Lisa Arrigo mild powertrain hybridization with brake-energy Hybrid & Electric Vehicles Technologies

Custom Electronic

Products Editor recovery. The displacement of high-wattage Symposium held in Los Angeles in February. Dr.

larrigo@sae.org

loads to more efficient 48-V networks is Mazen Hammoud, Ford’s Chief Engineer for

Contributors expected to be the next step in the development Electrified Powertrain Systems and SAE Fellow,

Kami Buchholz

Detroit Editor of a new generation of mild hybrid vehicles. said that the 48-V working voltage is the best com-

Stuart Birch In addition to improved fuel economy and promise for mild hybridization. (See http://articles.

European Editor

Jack Yamaguchi reduced emissions, 48-V systems could poten- sae.org/13908.)

Asian Editor tially save costs on new electrical features and Although the higher voltage provides no real

Steven Ashley

Dan Carney

help better address the emerging needs of future electric-only drive capability, there is better

Terry Costlow drivers. A new report from Autelligence on 48-V capacity for capturing braking regen energy, and

Richard Gardner

Jenny Hessler automotive electrification analyzes the technol- it’s a good stop-start enabler, Hammoud said. A

John Kendall

Bruce Morey ogy and provides an outlook on future introduc- mild hybrid can provide more than 3% increased

Jennifer Shuttleworth

Linda Trego tions. The report notes that the new technology engine-off time versus a 12-V stop-start vehicle

Paul Weissler

is “extremely economical because it can be easily in real-world driving conditions. In addition,

DESIGN integrated into an existing vehicle architecture according to ECE-R 100 regs for direct current

Lois Erlacher and the small 48-V battery means battery costs under 60 V, shock protection is not required for

Art Director

Ray Carlson

are reasonable,” said Christopher Breitsameter, 48 V, helping to lower cost.

Associate Art Director Head of Business Development and Strategy, The consensus of global forecasts suggests

Continental Powertrain Division. that 48-V mild hybrids will soon come to domi-

SALES & Challenges to 48-V system implementation nate the market. Compared with 200-600 V full

MARKETING remain. At the 2nd International Conference on hybrid and battery electric vehicles, the low-

K. Shriramchandran

SAE India Advanced Automotive 48V Power Supply er-voltage approach avoids the need for high-

No.1/17, Ceebros Arcade

3rd Cross Kasturba Nagar Systems organized by IQPC Automotive in cost safety features and large battery packs.

Chennai

India 600 020 Düsseldorf last November, experts from car mak- CPT estimates that if 48-V and related emis-

(T)91-44-42152280

(E) ddg@saeindia.org

ers and suppliers discussed the need for an inter- sions-reduction strategies could be universally

Marcie L. Hineman national 48-V standard. Initial steps have already applied to the more than 100 million vehicles

Global Field Sales Manager

+1.724.772.4074

been taken with a LV148 standard proposed by forecast to be produced per year from 2020—

hineman@sae.org Audi, BMW, Daimler, Porsche, and Volkswagen. 98% of them with gasoline and diesel engines—

It makes sense to have a common global annual CO2 emissions could be reduced by 100

standard, according to Paul Bloore, Product million t globally per year.

4 JUNE 2015 MOBILITY ENGINEERING

1506ME.indb 4 5/11/15 5:25 PMME Saint-Goban Bearings Ad 0615.qxp_Mobility FP 4/29/15 7:25 PM Page 1

Anything for a quiet ride

We believe seat adjustment systems

are there to enhance driver comfort, not

to make distracting noises during driving.

By dampening structure-borne vibrations

in the seat height adjustment system

Saint-Gobain helps you deliver a quieter

drive. We can also reduce component wear

for a longer life.

It’s just one of the ways our teams are working

with the world’s automotive engineers to improve

the driving experience.

Find out how we’re making

a difference on every scale:

makingabigdifference.com

makingabigdifference@saint-gobain.com

1506ME.indb 5 5/11/15 5:25 PMME AR

FOCUS

SAEINDIA

BOARD OF DIRECTORS

Dr. Aravind S. Bharadwaj

President

Mr. Shrikant R. Marathe

Immediate Past President

Dr. R.K. Malhotra

Sr. Vice President & Chairman,

Finance Board

Dr. Bala Bharadvaj

Vice President & Chairman,

Building the SAEINDIA brand Aerospace Board

Dr. K.C. Vora

Vice President & Chairman, Sections

In retrospect, the 2014-15 season for and the fun, excitement, and joy of children Board

SAEINDIA has been truly one of consolida- who participated in the competition and won Mr. I.V. Rao

tion in putting systems in place, evolving prizes should be seen to be believed. Chairman, Meetings & Expo Board

policies for the future, resolving long out- We have made important decisions to Dr. Venkat Srinivas

Secretary & Vice Chairman,

standing issues in administration. We creat- acquire premises for SAEINDIA Western and Development Board

ed Operating Boards to plan and decide Bangalore Sections, which will help our offices Mr. C.V. Raman

Vice Chairman, Sections Board

their activities and empowered them to bud- to function with lot more autonomy and pro-

Dr. Arun Jaura

get their plans and implement them. fessionalism and accelerate our programs and Chairman, Automotive Board

activities. This has been amply proved by Mr. Prakash Sardesai

SAEINDIA Southern Section, which is func- Chairman, PDP Board

tioning from its own premises and conducting Mr. Sanjay Deshpande

Chairman, Membership Board

many programs and workshops strengthening

Mr. Asit K. Barma

its operations and finances. Chairman, Publications Board

We are also making all preparations to Mr. Devendra Bahirat

organize ITEC INDIA 2015, a unique event Chairman, Off-Highway Board

Dr. S. Thrumalini

partnering with IEEE IAS (Industry Chairman, Engineering Education Board

Applications Society), and we expect the Mr. B. Bhanot

event to galvanize the electric mobility indus- Chairman, Development Board

try to double up its pace in the coming years. Mr. P.K. Banerjee

Jt. Secretary, Vice Chairman,

We have lined up professional development Engineering Education Board

programs including the International Lecture Dr. Arunkumar Sampath

Series and are also planning webinar programs Treasurer, Vice Chairman,

Meetings & Expo Board

through a newly created web platform.

Mr. M. Kannan

The Aerospace Board and Off Highway Vice Chairman, PDP Board

Board are planning major programs during the Mr. Arun Sivasubrahmaniyan

proposed visit of Mr. Richard Greaves, President, Jt. Treasurer & Vice Chairman,

Publications Board

SAE International to India in July 2015. The

Aerospace Board is planning a seminar on the Representing

Make in India concept announced by Mr. SAE International

Narendra Modi, Prime Minister of the country. Dr. David. L. Schutt

Chief Executive Officer

The symposium organized by SAEINDIA’s

Mr. Murli M. Iyer

Northern Section on fuels, lubricants, and Executive Advisor-Global Affairs

after-treatment devices in April 2015 in Delhi Office of the Chief Executive Officer

Dr. Aravind Bharadwaj received robust support from the Industry and

Presented by SAEINDIA

President, SAEINDIA the registration of delegates. This symposium Media, Communications and

will address issues critical to the industry as Publications Committee

As a new initiative, we started Knowledge government is making the manufacturers Mr. Asit K. Barma

Chairman

Round Tables in Mahindra Research Valley and compliant to Euro IV emissions, bringing India

Mr. Arun Sivasubrahmaniyan

UCAL Fuels and provided a forum for the in tune with the global norms. Vice Chairman

members within the organization to exchange We are chalking out a plan to build the Mr. Rajesh Kumar

Vice Chairman

ideas and information on cross functional dis- brand SAEINDIA as a professional society Dr. Ramesh

ciplines and invite experts to address them on committed to the cause of development of Member

topics of current relevance and importance. the mobility community by creating knowl- Dr. Saravanen

Member

Plans are also underway to start a similar edge-sharing platforms and conferences that Prof. J.M. Mallikarjuna

forum at WABCO and for other major indus- address issues of critical importance for the Member

tries where we have sizable members. future to make SAEINDIA move forward as a Dr. S.S. Thipse

Member

AWIM National Olympics was organized in society with deep and abiding concern for the Prof. Sudhir Gupte

the month of January in Chakan, Maharashtra, industry as a technology leader. Member

Mr. Anupam Dave

Member

Mr. Vasanth Kini

Member

Prof. Ravishankar

Member

Mr. Deepak Panda

Member

6 JUNE 2015 MOBILITY ENGINEERING

1506ME.indb 6 5/11/15 5:25 PMME AR Associates Ad 0615.qxp_Mobility FP 4/29/15 8:09 PM Page 1

AR’s EMC solutions make complicated test processes easier and more accurate. Everything is simplified – calibration, testing processes, DUT troubleshooting,

and generation of reports directly into convenient formats, such as Microsoft Word or Excel.

These products also have excellent speed, feature a modular design approach and allow their integrated components to be used in a variety of automotive test

standards such as ISO, SAE, CISPR, and OEM requirements. These products have the flexibility to handle engineering development, mitigation and testing to

numerous other standards such as: MIL-STD-461, RTCA DO-160, CISPR, EN, ETSI, FCC, ICES, AS/NZS, and VCCI.

The DER2018, with 140 MHz instantaneous bandwidth, is the One Receiver that catches short duration transient disturbances, and scans in seconds.

By streamlining testing, this CISPR 16 compliant EMI receiver will change the way you approach testing.

AR’s AS4000 radiated immunity system gives you a turnkey package to perform susceptibility tests, in one self-contained unit up to 40 GHz.

Our standard systems can also be customized to include testing to both radiated and conducted immunity and emissions requirements.

The Conducted Immunity (CI) platform offers flexibility to address any Bulk Current Injection (BCI) test method, as well as the ability to access components

from the CI housing, such as the power meter and amplifier, to use in other test applications. With three Conducted Immunity Test Systems to choose from, you

should never again have to perform laborious manual CI test procedures or worry about the accuracy of the results.

AR supplies a multitude of unique RF solutions to some of the best-known companies worldwide. Our products are backed by the strongest,

most comprehensive warranty in the industry, and a global support network that’s second to none. Call your local AR sales associate for a demonstration.

To learn more, visit www.arworld.us/totalEMC.

In India, contact Complus Systems at www.complus.in

ISO 9001:2008

or call 91-80-416-83883 Certified

www.arworld.us

Other divisions: modular rf • receiver systems • ar europe

Copyright © 2015 AR.

USA 215-723-8181. For an applications engineer, call 800-933-8181. The orange stripe on AR products is

In Europe, call ar United Kingdom +44 1908 282766 • ar France +33147917530 • ar Deutschland +49 6101 80270 0 • ar Benelux +31 172 423000 Reg. U.S. Pat. & TM. Off.

1506ME.indb 7 5/11/15 5:25 PMME Borg

SAEINDIA

News

AWIM National Olympics held in Chakan

A World In Motion (AWIM), abiding by its

unique name, rightly amalgamates fun,

challenge, teamwork, and leadership. The

7th AWIM National Olympics was held

from the 10th to 12th of January 2015 at

Mahindra Vehicle Manufacturers Ltd. in

Chakan.

This was a great opportunity for little

champions’ dreams to come true by

taking their machines to an automobile

manufacturing proving grounds. A total

of 152 students, 76 teachers, and many

industry volunteers from 17 cities across

the nation attended this event.

On the 10th of January, the teams

were registered for the event, and all

teams were briefed on the rules and

marking format. AWIM National Olympics inauguration.

On the 11th of January, the main

event began, for which student design

teams from class 5th and 6th grade par-

ticipated by making “skimmer” and “jet-

toy” vehicles for the track, and they also

designed dream cars that they per-

ceived as future cars of the science age.

About eight teams for skimmer and 30

teams for jet-toy participated in the

grand finale.

Mr. Vijay Dhongde, CEO, MVML, wel-

comed Dr. Pawan Goenka, Executive

Director, Mahindra & Mahindra, and

briefed how his vision helped to increase

the AWIM initiative from two cities to 17

cities across India.

Dr. Pawan Goenka’s presence raised

the energy among the children (they were

pumped with enthusiasm); his vision of

benefiting children getting a boost. He

visited the skimmer and jet-toy tracks and

also witnessed presentations made by the Students’ presentation.

little champs. Later he shared his

thoughts, interacted, and guided children

to be better engineers in the future, and

expressed that these children are the

future of our country.

He also appreciated the efforts of the

volunteers across the country who

invested their time in teaching children

beyond their textbook knowledge. He

visualized how seeds of “Make in India”

have been well sown at schools with

activities such as AWIM. He relived his

school days while spending time with

Dr. Powen Goenka’s interactions during the AWIM Olympics. these children. He also reiterated the fact

8 JUNE 2015 MOBILITY ENGINEERING

1506ME.indb 8 5/11/15 5:25 PMME BorgWarner Ad 0615.qxp_Mobility FP 4/29/15 5:40 PM Page 1 1506ME.indb 9 5/11/15 5:25 PM

ME Sma

SAEINDIA

News

that the automobile industry has helped

Indian society to grow and develop day

by day.

On 12th of January, teams visited the

Chakan plant with a lot of enthusiasm;

the bright minds excited to see the plant.

They were on a tour to Maxximo BIW,

Maxximo TCF, and Gyanodaya where

they were explained vehicle manufactur-

ing details.

AWIM National Olympics winners.

KLU hosts National Student Convention

The host school, Kalasalingam University,

Student presentations. put on a bike show.

The 9th SAEINDIA National Student Balasubramanian, Chairman, SAEISS, These events were focused on the

Convention was held at Kalasalingam and the Presidential address was given nation’s goal of “Make in India.”

University (KLU) in Krishnankoil, by Thiru. K. Sridharan, Chancellor, Technology Theatre: SAEINDIA SS

Virudhunagar Dist., on the 30th and 31st Kalasalingam University. The chief guest conducted the 4th Technology Theatre

of January 2015. Every year, the for this prestigious event was Mr. Oba for student members. The topics

SAEINDIA collegiate chapters get an op- Noboru, Vice President, RNTBCI, and the included “Challenges in Integrating High

portunity to discuss, display, and cele- vote of thanks was given by Dr. M. Voltage on Automobile” by Mr. R.

brate their success of the past year. This Uthayakumar, Organising Head, KLU. Ramachandran from Mahindra &

is also the occasion when the winners On day 1, the winners of Tier 2 Mahindra, Chennai; “Digital

from the six zones meet and battle it out regional events competed at the national Manufacturing for Automotive Industry”

to find the best in the competitions held. level, the battle among the six divisions by Mr. Aiyappan Ramamoorthy from

This year’s event saw active participation of SAEINDIA SS (Southern Section). The Siemens, Chennai; “Automotive crash”

of over 1000 students from 86 colleges. events were: Business Plan Contest, Aero by Mr. Aditya Malladi from Mahindra &

The inaugural function began with the Design and Fabrication Contest, Auto Mahindra, Chennai; and “New Product

welcome address by Dr. S. Saravana Quiz, Technical Paper Contest, Modeling Development of Passenger Car” by Mr.

Sankar Vice-Chancellor, Kalasalingam and Animation Contest, Computer Aided Shanmugavel from Renault Nissan

University. The student convention brief Manufacturing Contest, and Analysis Technical Business Centre India, Chennai.

was given by Dr. D. Muruganandam, Contest & CAE. Along with the existing Collegiate Club Presentation &

Student Convention-Champion; the events, SAEINDIA SS made history by Display: The club presentation show-

inaugural address given by Mr. N. successfully conducting 12 new events. cased the achievements, strengths, and

10 JUNE 2015 MOBILITY ENGINEERING

1506ME.indb 10 5/11/15 5:26 PMME Smalley Ad 0615.qxp_Mobility FP 4/29/15 7:46 PM Page 1 1506ME.indb 11 5/11/15 5:26 PM

SAEINDIA

News

high power bikes of above 1000 cm3, which

really attracted the student members.

Valediction & Prize Distribution

Ceremony: The convention was brought

to a close in the valedictory function later

in the evening. The welcome address

given by Dr. V. Vasudevan, Registrar,

Kalasalingam University; the Presidential

address was given by Dr. S. Saravana

Sankar Vice-Chancellor, Kalasalingam

University; and the review of convention

by Dr. R Kannan, EEC, Champion.

The Chairman of the SAEINDIA SS,

Mr. N. Balasubramanian, addressed the

gathering by giving a glimpse of future

The convention was brought to a close in the prize distribution and valedictory function. mega events by the section like Baja

South and an additional 10 events at the

unique activities of various SAE colle- met and discussed the various aspects next student convention. The chief guest

giate chapters. The club display compe- of running a collegiate club, ways to for the valedictory function was Dr.

tition and technology theatre ran in improve the SAE activities, and also the Aravind S. Bharadwaj, Sr. Vice President,

parallel at different venues. Various new SEC members for the year 2015- M&M, and President, SAEINDIA. This was

working mechanical models, presenta- 2016 were announced. followed by the distribution of prizes and

tions, and charts were put on display. KLU Bike Show: The host college also mementos and the vote of thanks by Mr.

The SAEI SS Students Executive Council conducted a bike show where they displayed S. Shanmugam, Secretary, SAEI SS.

New 3D printing event

A new advanced technology called additive manufacturing/3D

printing (AM/3DP) is transforming engineering. 3D printing is

an innovative manufacturing technology that can transform

digital designs into tangible parts in one step without using

conventional tools.

The International Conference on Additive Manufacturing, 3D

Printing, and 3D Scanning (ICAM-3D) was conducted at Vel

Tech University and The Hilton, Chennai, India, on February

5th to 8th, 2015, along with ICAM-3D Car Design Challenge for

Opening ceremony of the ICAM 3D car design challenge.

young engineers. Forty teams were registered from all over

the country for this event, and six of them were selected to

present their model at the event. The top three teams were

selected on the basis of their design and knowledge.

Dr. Chidambaram, The Principal Scientific Advisor to the

government of India, was the chief guest and inaugurated the

ICAM-3D Conference. Dr. Tim Morris, NAFEMS Global, gave the

Inauguration By Dr. P. Chidambaram, Principle Scientific Advisor awards for the winners and short listed teams of ICAM-3D Car

for the government of India. Design Challenge.

12 JUNE 2015 MOBILITY ENGINEERING

1506ME.indb 12 5/11/15 5:26 PMIndustry

NEWS

Truck racing demonstrates new Indian Air Force to acquire 36 Rafale fighters

technology, aero design

The Indian Government recently announced its intention to fi-

Season two of the T1 Prima Truck Racing Championship took nalize the acquisition of 36 Rafale fighter aircraft from Dassault

place this spring at India’s F1 track, the Buddh International Aviation at conditions necessary to meet the security needs of

Circuit (BIC), with Stuart Oliver of Team Castrol Vecton winning India. Dassault Aviation, which has been a supplier to the

for the second year in a row in the 16-lap final race, helping Indian Air Force for more than 60 years, is grateful for the op-

Team Castrol Vecton win the team title. Steve Thomas of Team portunity to pursue and extend their partnership, said Eric

Allied Partners, who qualified fastest on the first day, was the Trappier, Chairman and CEO of Dassault Aviation. “Just as we

first runner-up, with Steven Powell of Team Tata Technologies are delivering the first upgraded Mirage 2000, I am delighted

Motorsports clinching the second runner-up spot. by the decision of the Indian Authorities which gives a new im-

petus to our partnership for the next decades and comes with-

The Tata Prima 4038.S in the scope of the strategic relationship gathering France and

for the T1 Prima Truck

Racing Championship India,” he said in a statement announcing the deal.

features 370 bhp at

2100 rpm and an Patrol flight of two Rafales: a single-seater

increased top speed of in full “Air-Air” configuration—6 MICA + 3

130 km/h over last supersonic drop tanks of 1250 L—

year’s 110 km/h. and a two-seater in mixed

configuration—2x SCALP

+ MICA + 3 drop tanks of

2000 L. (Dassault

Aviation - K. Tokunaga)

Six teams—also including Team Cummins, Team Dealer

Warriors, and Team Dealers Daredevils—each raced two Tata

Prima Model 4038.S trucks built for purpose. Compared to

Season 1, the Tata Prima race truck boasts 10% increased top

speed—up to 130 km/h (81 mph)—10% increased acceleration,

and 10% weight reduction, along with a new aerodynamic

design. Key modifications made to the trucks to meet a mix of

safety and performance guidelines per the British Truck

Racing Association included significant changes to the fuel

tank, brake cooling system, propeller shaft guards, seats and

safety belts, exhaust, and steering wheel. The trucks went

through multiple quality checks, with major testing being

undertaken at the BIC and Tata Motors Jamshedpur’s testing

facility, for high speed run and control.

Tata Motors also introduced a new strategic driver selection

and training program in conjunction with the race, to induct and

mold Indian truck drivers for future T1 races. Cummins, WABCO,

JK Tyres, Castrol, and Tata Technologies were the main sponsors

of the truck racing championship. Setco Automotive was one of Zen Technologies, Rockwell Collins

the sponsors for Team Allied Partners. The T1 Prima Truck Racing

Championship is organized by Madras Motor Sports Club and

develop next-gen flight simulator for

conducted under the aegis of FIA (Federation Internationale de Indian market

l’Automobile) and the Federation of Motor Sports Clubs of India. Zen Technologies and Rockwell Collins recently unveiled a

next-generation rotary wing simulator to serve the “burgeoning

need” of the military flight simulation market in India. The com-

panies had previously signed a Memorandum of Understanding

(MOU) to combine their strengths in simulation and training to

offer advanced and high-fidelity aviation solutions. With the

rotary wing platform launch, both companies plan to become

key partners to the Indian armed forces. The configurable

Rotary Wing Simulator is housed in an ergonomically de-

Key modifications made to meet safety and performance signed cockpit and addresses both the flight and mission as-

guidelines included significant changes to the fuel tank, brake pects of rotary wing aircraft. Realistic training scenarios are

cooling system, propeller shaft guards, seats and safety belts, provided using geo-specific cultured terrains, operations

exhaust, and steering wheel. flight profiles, and avionics that can be used to train both new

MOBILITY ENGINEERING JUNE 2015 13

1506ME.indb 13 5/11/15 5:26 PMIndustry

NEWS

and experienced pilots before missions.

The training continuum is customizable

for all types of military platforms.

The jointly developed simulator was

revealed within four months of signing

the MOU, noted Colin Mahoney, Senior

Vice President, International & Service

Solutions for Rockwell Collins. “This is

just the first step in our collaboration,” he

said. “We see tremendous opportunity

to provide indigenous, affordable, and

highly effective simulation and training

solutions to India’s defence forces

through our alliance with Zen.”

“Over the next few years, the Indian The EC130 T2’s cabin is suitable

defence forces will be strengthening their for one pilot and up to seven

aircraft portfolio, both fixed and rotary passengers. More than 70% of

wing. Moreover, there are a number of exist- the EC130 T2’s airframe structure

has been modified from the

ing simulators which may need some mid- previous EC130 B4 version.

life upgrades both in terms of technology

and aircraft concurrency,” said Ashok Atluri,

Managing Director, Zen Technologies. has approximately 8890 m2 (95,700 ft2) Airbus Helicopters’ EC130

“Therefore, we see a very large opportunity of manufacturing space and the capaci- T2 enters Indian market

for full mission simulators, flight training ty to produce 2 million units consisting

devices, and part task trainers, amongst of heat exchangers, HVAC modules, and

with two launch customers

others...Our alliance with Rockwell Collins air-conditioning lines. HVCC claims it Airbus Helicopters has signed Indian mar-

marks the first time that a global simulator has the ability to double its capacity at ket launch orders for its single-engine EC130

[OEM] has teamed with an Indian simulator this facility based on business needs. T2 with Sanjay Ghodawat Group and

manufacturing company to cater to the The company has a regional office in Global Vectra Helicorp Ltd. (GVHL), which

Indian defence market.” Chennai and operates four plants in plan to introduce the single-engine EC130’s

India—Chennai, Pune, Bhiwadi (near enhanced version later this year for passen-

Halla Visteon expands Delhi), and Gujarat. ger transport services in Kolhapur and Delhi,

HVAC production “India is one of the fastest growing respectively. The customers ordered one

capability in India economies in the world and is poised to EC130 T2 apiece. The Sanjay Ghodawat

emerge as one of the top passenger Group is a diversified conglomerate with

Halla Visteon Climate Control Corp. vehicle markets in near future, and we presence in consumer products, energy,

(HVCC) recently began production at its want to be prepared for the tremendous mining, chemicals, and agribusiness. GVHL

new facility in Sanand, in the state of growth opportunity this market offers,” is India’s largest private helicopter company,

Gujarat, India. The full-line supplier of said YH Park, President and CEO, HVCC. which will assign the EC130 T2 to Birdie—its

automotive thermal management solu- “This new plant in Gujarat expands our on-shore operations division offering char-

tions is using the Gujarat facility to sup- manufacturing footprint to encompass ters and religious tourism services.

port its growing business with global all of the major automotive hubs in India The EC130 T2’s cabin is suitable for one

vehicle manufacturers and to cater to and allows HVCC to bring world-class pilot and up to seven passengers. More than

the requirements of OEMs in the state thermal management technology to 70% of the EC130 T2’s airframe structure has

of Gujarat and western India. The facility vehicle manufacturers in India.” been modified from the previous EC130 B4

version. New and updated features include

the use of a more powerful Turbomeca

Arriel 2D turboshaft engine and upgraded

main gearbox, along with the incorporation

of an active vibration control system and

Halla Visteon Climate Control’s improved air-conditioning, distribution, and

new facility in Gujarat, India, demisting systems. Performance of the

can produce 2 million units

EC130 T2 has been improved for a higher

consisting of heat exchangers,

HVAC modules, and A/C maximum gross takeoff weight (2500 kg for

lines—and has the ability to internal loads, and 3050 kg when external

double its capacity based on loads are carried), and a speed increase of

business needs. up to 10 kts from the EC130 B4.

14 JUNE 2015 MOBILITY ENGINEERING

1506ME.indb 14 5/11/15 5:26 PMTECHNOLOGY

Report

MOTORSPORTS POWERTRAIN

Schaeffler developing novel powertrain for 2015/2016

FIA Formula E season

All FIA Formula E cars are using

identical specification

technologies in the inaugural

2014/2015 season. Cars are

built by Spark Racing

Technologies. The chassis is

from Dallara. McLaren

Electronic Systems supplies the

electric motor and electronics.

Williams Advanced Engineering

provides the 28-kW/h Li-ion

battery pack. Racecars get

unique powertrains for the

2015/2016 season.

All 40 cars in the world’s first all-electric

racing circuit run a standardized power-

train, but the uniformity ends in the

2015/2016 season when each carbon

fiber/aluminum monocoque chassis FIA

Formula E racecar can be fitted with a

unique electric powertrain.

“We are in the process of developing

an electric motor and a new transmission

in the defined specification that FIA

came up with,” said Prof. Dr.-Ing. Peter

Gutzmer, Deputy CEO and Chief

Technology Officer for Schaeffler AG.

Gutzmer and Schaeffler’s CTO for the A race crew member prepares dry ice for In the paddock area, Schaeffler’s Jeff

Americas, Jeff Hemphill, sat down with the air intake ports of the Audi Sport ABT Hemphill looks at an Audi Sport ABT

Automotive Engineering prior to all-electric racecars. (Kami Buchholz) racecar with the electric motor, battery

Formula E’s March 14 street race in pack, and other electrified powertrain

Miami, the first U.S. stop in the 2014/2015 apply that systems approach to this components exposed. All FIA Formula E

racecars in the 2014/2015 season have a

inaugural season of all-electric racing in development task.”

power output for practice and qualifying

Europe, Asia, and the Americas. Each Formula E racecar in the of 200 kW. The power output for the race

As Team ABT Sportsline’s exclusive 2014/2015 season uses a 57-lb (26-kg) is 150 kW, plus an additional power

technology partner, Schaeffler is develop- motor to accelerate the single-seat car output of 30 kW by fan voting for three

ing a novel power unit to replace the from 0 to 62 mph (100 km/h) in 3 sec- drivers. (Kami Buchholz)

McLaren Applied Technologies power- onds. The motor mates to a Hewland

train. “We are now starting to get parts in Engineering five-speed paddle shift under-development powertrain are being

for the prototype model,” said Gutzmer. sequential gearbox. publicized. “I hesitate to talk too much.

Schaeffler technical specialists are Audi Sport ABT driver Daniel Abt There are seven competitors producing

leveraging their extensive application told Automotive Engineering that the electric motors for next season, so it’s

development know-how together with electric racecar’s instant torque means getting very interesting,” said Gutzmer.

the ABT race team and other technology “whenever you hit the throttle, it just Jacky Eeckelaert said the next race

experts to develop jointly a powertrain goes. There is no delay. And there’s a lot season is all about increasing the power-

for Team ABT Sportsline. Said Hemphill, less noise than if you had a screaming train efficiency. “And the whole package

“One of our strengths in the automotive V8 engine behind your back.” will be lighter and at a lower center of

arena is systems engineering, and we’ll Virtually no technical details about the gravity,” Eeckelaert, race engineer for

MOBILITY ENGINEERING JUNE 2015 15

1506ME.indb 15 5/11/15 5:26 PMTECHNOLOGY

Report

ENERGY

New yeast strain enhances biofuel production

A team of researchers from the Cockrell lipids at a rate that was more than 2.5

School of Engineering at The University of times as fast as the previous strain.

Texas at Austin have developed a new, mu- “This significant improvement in our

tant yeast strain that could lead to a more cell-based platform enables these cells

efficient and economical biofuel production to compete in the biofuels industry,”

process, and from non-food sources. Alper said. “We have moved to concen-

Hal Alper, Associate Professor in the tration values that begin to align with

McKetta Department of Chemical those in other industrial fuel processes.”

Engineering, and his team engineered a Alper and his team improved the per-

special type of yeast cell, Yarrowia lipo- formance of Yarrowia through a combi-

lytica, to significantly enhance its ability nation of metabolic engineering and

to convert simple sugars into lipids that directed evolution, which involves muta-

Audi Sport ABT drivers Lucas Di Grassi, could then be used in place of petro- tion and selection to identify and culti-

left, and Daniel Abt. During FIA Formula

leum-derived products. vate the high-performing cells. The

E races, all drivers make a mandatory pit

stop to swap racecars. There are 10 race “Our re-engineered strain serves as a researchers recognized that cells with

teams, each with two drivers and four stepping stone toward sustainable and high lipid content would float to the top

racecars. Each temporary street course renewable production of fuels such as of a tube, whereas cells with lower lipid

race lasts about one hour. biodiesel,” Alper said. content would settle down to the bot-

Previously, the team successfully tom. The researchers used this “floating

ABT team driver Lucas Di Grassi, told combined genetically engineered yeast cell scheme” to identify the best-per-

Automotive Engineering. cells with ordinary table sugar to pro- forming cells. Researchers used those

While Schaeffler has supplied bearing duce what Alper described as “a renew- high-performing cells, which produced

components and alternator overrun sys- able version of sweet crude,” the more lipids and at a faster rate, to obtain

tems for baja, endurance, and touring premium form of petroleum. Building the final yeast.

series cars powered by internal-combus- upon that approach, “a combination of In addition to using lipids for biofuels,

tion engines, developing an electric race- evolutionary engineering strategies” was the cell-based platform is able to pro-

car powertrain is new territory. Said used to create the new strain of Yarrowia duce oleochemicals, including nutritional

Gutzmer, “This is the first time that that produces 1.6 times as many lipids as polyunsaturated fatty acids, waxes, lubri-

Schaeffler will be providing a functional, their previous strain in a shorter time, cants, oils, and industrial solvents.

complete unit.” reaching levels of 40 grams per liter, a The researchers’ method and plat-

One desirable for the Schaeffler pow- concentration that could make yeast form are patent pending. Alper’s lab is

ertrain is improved cooling efficiency. cells a viable platform in the creation of continuing to work on ways to improve

Team owner Hans-Jurgen Abt spoke biofuels. The strain’s high lipid yield how the yeast strain converts sugar into

with Automotive Engineering while a makes it one of the most efficient organ- lipids, and on the types of lipid products

crew member put dry ice inside the air isms for turning sugar into lipids. In addi- they can produce.

intake ports for the battery cooling sys- tion, the resulting cells produced these Jean L. Broge

tem and the engine cooling system.

“The dry ice can lower the tempera-

ture about 25°C. We need to pull the

temperature down because then you can

increase the power. In the race you have

only the cooling from the air, and it

doesn’t help if you have not the right

temperature to start,” Abt said prior to

the 39-lap, 1.34-mi (2.16-km) Miami race.

Developing an electric powertrain for

a racing application will mean challenges

and victories.

“You have to work with suppliers on

different materials; that’s a challenge.

You have to have a very fast loop of

re-engineering if re-engineering is nec-

essary,” Gutzmer said, referencing some

of the challenges. “But the knowledge Researchers at The University of Texas at Austin used a combination of metabolic

that we gain during this process will be engineering and directed evolution to develop a new, mutant yeast strain that could

fruitful for future developments.” lead to a more efficient biofuel production process and potentially make biofuels more

Kami Buchholz economically competitive with conventional fuels.

16 JUNE 2015 MOBILITY ENGINEERING

1506ME.indb 16 5/11/15 5:26 PMTECHNOLOGY

Report

OFF-HIGHWAY POWERTRAIN

Cummins in production with ‘simplied’ Tier 4 Final engines

Cummins is in production with the Tier 4

Final versions of its four-cylinder QSF2.8, The Tier 4 Final QSF2.8, QSF3.8, and QSB4.5

(shown) are fully integrated with exhaust

QSF3.8, and QSB4.5 engines will that offer aftertreatment systems designed and

a “simplified technology approach” fo- manufactured by Cummins Emission

cused on compact installation packages for Solutions with “right sizing”

space-constrained construction and mate- efficiency to match the aftertreatment

rial handling equipment across the 49- to size and technology to the engine

173-hp (37- to 129-kW) output range. output and the equipment types they

are intended for.

The 2.8-, 3.8-, and 4.5-L engines offer a

range of engine displacements and incre-

mental performance across a broad prod-

uct range. The ability to power-match is

also realized with the potential for instal-

lation downsizing at two pivotal points—

with a new, lower 74-hp (55-kW) rating

for the QSF3.8 and a higher 173-hp (129-

kW) rating for the QSB4.5.

“With these downsizing opportunities,

Cummins is redefining the ability of

four-cylinder engines to power compact

equipment with simpler technology for

applications including skid steers, forklifts,

excavators, wheel loaders, telehandlers, The Tier 4 Final QSF2.8 (shown), QSF3.8,

air compressors, and more,” said Brian and QSB4.5 are fully integrated with exhaust

Wilson, Cummins General Manager— aftertreatment systems designed and

Global Compact Business. “We antici- manufactured by Cummins Emission Solutions

pated the need to reduce the impact of with “right sizing” efficiency to match the

aftertreatment size and technology to the engine

Tier 4 Final at specific power points, as

output and the equipment types they are intended for.

that option would allow some types of

equipment to move to a much simpler

and more cost-effective installation solu- fuel consumption savings of up to 10%. works as an integrated system with the

tion without any loss in performance.” The QSB4.5 is performance-upgraded engine combustion so that DEF use is

Equipment positioned in the 75- to for Tier 4 Final with a compact variable reduced to as low as 3% of fuel consumed.

90-hp (56- to 67-kW) power band can geometry turbocharger specifically devel- The SCR system is designed to last the life

transition to the new QSF3.8 rating at 74 oped by Cummins Turbo Technologies for of the engine, helping to enhance the resid-

hp (55 kW) and take advantage of using the engine platform to provide higher ual value of the equipment.

a simple Cummins diesel oxidation cata- boost at all engine speeds with impres- The SCR system is used in combina-

lyst (DOC) in place of selective catalytic sive levels of torque response. tion with a DOC for higher outputs up to

reduction (SCR) aftertreatment or a die- The QSF2.8, QSF3.8, and QSB4.5 are the 173-hp (129-kW) QSB4.5 for premium

sel particulate filter (DPF) system. The fully integrated with exhaust aftertreat- performance equipment. The Cummins

3.8-L displacement ensures that machine ment systems designed and manufac- DOC-SCR system allows a greater latitude

capacity and low-end torque perfor- tured by Cummins Emission Solutions within the in-cylinder combustion formula

mance are retained at the lower 74-hp with “right sizing” efficiency to match to realize faster engine response and

(55-kW) rating. the aftertreatment size and technology improved fuel efficiency.

Compared to an SCR system, the to the engine output and the equipment Emissions control of the exhaust is com-

Cummins DOC reduces the aftertreat- types they are intended for. plemented by a light-flow, cooled EGR sys-

ment space claim by more than 50% and For QSF2.8 and QSF3.8 ratings below 75 tem, sized to fit within the QSF and QSB

eliminates the onboard diesel exhaust hp (56 kW), the Cummins DOC provides a engine envelopes. Due to the high efficiency

fluid (DEF) tank and the associated cost “fit and forget” solution, completely trans- of the aftertreatment in removing emis-

of replenishing the fluid. parent to the equipment user as it functions sions, the EGR system needs to recirculate

Increasing the top rating of the as a filter-free device able to reduce emis- only a low proportion of the exhaust gases

QSB4.5 to 173 hp (129 kW) for Tier 4 sions from the exhaust without the need for back to the in-cylinder combustion, allow-

Final presents the opportunity for equip- regeneration or any service cleaning. For ing the engine to not work as hard while

ment using a six-cylinder engine at a applications above 75 hp (56 kW), the allowing equipment users to get the same

similarly rated power to downsize to a Cummins SCR system achieves very high level of service from a four-cylinder engine

much smaller four-cylinder QSB4.5 emissions conversion efficiency with fil- as they have from six-cylinder engines.

installation, with the added benefit of ter-free, flow-through operation. The SCR Jean L. Broge

MOBILITY ENGINEERING JUNE 2015 17

1506ME.indb 17 5/11/15 5:26 PMTECHNOLOGY

Report

AEROSPACE PROPULSION

Aerojet Rocketdyne gets a boost from additive

manufactured components

Aerojet Rocketdyne recently completed Aerojet Rocketdyne

a series of hot-fire tests of additive man- recently completed

ufactured components for its AR1 boost- hot-fire testing of a

single-element

er engine at its Sacramento test facility.

main injector for the

AR1 is the first advanced hydrocarbon AR1 rocket engine

large liquid rocket engine in develop- that was completely

ment by Aerojet Rocketdyne since the built using additive

merger of Aerojet and Pratt & Whitney manufacturing.

Rocketdyne in June 2013.

The single-element main injector hot-

fire tests were conducted to evaluate

various main injector element designs

and fabrication methods. Several injec-

tors were fabricated using selective laser

melting (SLM), a form of additive manu-

facturing (AM). AM has become so ubiq-

uitous throughout the industry because

Aerojet Rocketdyne

it allows for the production of complex has conducted hot-

engine components at a fraction of the fire testing of a

cost of those produced using traditional multi-element

manufacturing techniques. preburner injector

Aerojet Rocketdyne has invested for the AR1 rocket

heavily in developing SLM capabilities engine. A similar

multi-element

for application to its rocket engines.

injector built using

Tested in excess of 2000 psi, Aerojet additive

Rocketdyne believes the AR1 single-ele- manufacturing will

ment hot-fire tests represent the highest be hot-fire tested

pressure hot-fire test of an AM part in a this spring.

rocket engine application. In the main

injector alone, AM offers the potential for Office (AHPDO) in Huntsville, AL. structure that are required with an AR1

a nine-month reduction in part lead Rapid development and certification solution, this approach is clearly the best

times, and a 70% reduction in cost. of the AR1 for current and future national path toward finding a replacement for

The AR1 is a 500,000-lb thrust-class security launch vehicles is a key focus for the RD-180,” said Linda Cova, Executive

liquid oxygen/kerosene booster engine AHPDO, particularly in terms of engine Director of Hydrocarbon Engine

currently in development as an alterna- cycles, materials, and AM. The AHPDO Programs at Aerojet Rocketdyne.

tive to the Russian-built RD-180. The office will integrate AR1 development Development of AR1 is currently

2015 National Defense Authorization Act and production activities across Aerojet being funded by Aerojet Rocketdyne

calls for the RD-180 to be replaced by an Rocketdyne’s various sites. The compa- with assistance from United Launch

American-made alternative for national ny’s Los Angeles and Sacramento facili- Alliance (ULA). Aerojet Rocketdyne and

security space launches by 2019. The AR1 ties will offer advanced large rocket ULA also continue to support the Atlas

is expected to be a catalyst for U.S. engine engineering and specialized man- and Delta launch vehicles such as the

launch providers to compete more effec- ufacturing expertise, the West Palm RS-68A, RL10, and AJ-60A.

tively in the global commercial launch Beach facility will offer additional manu- Work on the AR1 full-scale design has

marketplace. facturing and assembly work, and been progressing steadily with the team

AR1 development began in 2014 and Aerojet Rocketdyne’s Stennis facility will achieving significant milestones over the

builds on Aerojet Rocketdyne’s staged be used for AR1 engine final assembly past months, including the completion of

combustion experience gained through and could begin to test as early as 2017, a System Requirements Review, full-

technology development programs as with certification targeted for 2019. scale single-element main injector hot-

well as its recent AFRL Hydrocarbon The AR1 is designed to integrate with fire testing, subscale preburner testing,

Boost Technology Demonstration and the Atlas V launch vehicle, as well as pro- and turbopump inducer testing.

the NASA Advanced Booster vide a versatile propulsion solution for Completion of a vehicle-level system

Engineering Demonstration/Risk multiple current and future launch vehi- concept review and a main propulsion

Reduction program. All three programs cle applications. “When you consider the system Preliminary Design Review are

are part of the company’s Advanced minimal changes to the Atlas V launch planned major milestones for 2015.

Hydrocarbon Propulsion Development vehicle, launch pad, and related infra- Jean L Broge

18 JUNE 2015 MOBILITY ENGINEERING

1506ME.indb 18 5/11/15 5:26 PMTECHNOLOGY

Report

OFF-HIGHWAY ELECTRONICS

Military technologies aid the fight for improved

off-highway efficiencies

There is a never-ending need for tech- Vehicle

nologies that can improve the efficiency boom

of off-highway equipment, while en-

hancing safety for both operator and the

Laser Construction

machine. The defense sector of the in-

Beam Vehicle

dustry has an upper hand in the invest-

ment and invention of such technologies,

some of which could, and probably wood log about to hit

should, find their way into equipment the vehicle while swing

used for agriculture, construction, forest- operation

ry, and mining. Radar is one such exam-

Shown is a depiction of swing operation with the wood log position being monitored by

ple of technology that was once used using LIDAR. Currently, swing operation is done manually. If LIDAR were implemented,

just in combat applications, and was very automated swing operation could result in higher efficiencies, saving both time and fuel.

costly, but is now being widely used in

vehicles for various applications.

LASER from LADAR

Once closely guarded, many of these

technologies are now commercially avail- Construction Vehicle

able. However, as these technologies are

made to order and not being mass pro-

duced, at present their cost is higher com-

pared to other technologies being used in

Pit

off-highway equipment. But once they are

introduced in vehicles and have higher

volumes, the cost will go down. LIDAR is also a candidate for pit geometry measurement. A laser beam would

continuously scan the surface and measure the geometry of a pit being dug. The

captured data would be displayed in the vehicle real time.

SWIR and range-gated

imaging In the absence of these lights, SWIR Long-range identification may be criti-

Short-wave infrared (SWIR) works in cameras can provide excellent visibility cal in such cases. Simple SWIR cameras

wavelengths from 0.9 to 1.7 µm, which is at night due to their night radiance cannot improve visibility in these types of

not visible to the human eye. Although capabilities. environmental conditions, so adding a

not visible, light in this wavelength has Since water is opaque to SWIR, such range-gated imaging (RGI) feature aids in

the same behavior as visible light, so the cameras can also sense moisture content. imaging at long ranges, minimizing the

images taken from a SWIR camera are Objects having moisture content appear effect of adverse environmental conditions.

very similar to those taken from cameras dark in the image taken by a SWIR cam- Similar to radars, RGI uses pulsed

working in the visible wavelength range. era. The more moisture content, the laser for illumination of objects. Light

However, they are black and white. darker the image. Agricultural vehicles reflected from these objects is sensed by

In the military, SWIR is used for sur- such as harvesters can leverage this tech- a camera. Here the exposure time (or

veillance, reconnaissance, and night nology to determine moisture content in “gate”) is very short. Delaying of the

imaging. This technology can find many a harvested crop, and thus help estimate gate enables the camera to capture only

applications in off-highway equipment. the reduction in weight that can happen the light reflected from an object. Using

Off-highway equipment often has to when grains are completely dried out. this technology, one can see over a much

work or drive in low-light conditions. This may help in estimating accurately the longer range in low visibility conditions.

Work lights and drive lights provided on cost of the harvested crop in advance. RGI technology can also provide under-

vehicles may not be sufficient during In case of adverse environmental con- water visibility up to 50 to 100 m. Thus, it

dark and moonless nights. Also, these ditions such as rain, fog, smoke, dust, etc., can be used effectively in excavators to

lights often provide illumination only in visibility can be reduced to a level where monitor underwater excavation work.

close vicinity of vehicle. it is not possible to see beyond a few feet. At present, most off-highway vehicles

There is also a possibility of these lights And there would be no way for the oper- do not have anything that can see

getting damaged due to various reasons ator to know if such conditions were through clouds of dust, smoke, and smog,

like damage to an electronic control unit, restricted to a few meters or spread over and best practice in such cases is to halt

fuse or filament burn out, or smashed bulbs a broader terrain. The operator may keep the work until the operator deems work

due to flying stones or timber, further driving the vehicle in an attempt to cross conditions are safe and suitable, which

reducing the intensity of light available for a low-visibility patch, which may lead into may not always be correct. Use of RGI to

performing the job or the driving vehicle. even worse climatic conditions. improve visibility in adverse conditions

MOBILITY ENGINEERING JUNE 2015 19

1506ME.indb 19 5/11/15 5:26 PMYou can also read