Enhancement of Gas Flow Simulation of Internal Arc in Medium Voltage Switchgear

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

CIRED 2021 Conference Geneva, 20 – 23 September 2021

Paper 512

Enhancement of Gas Flow Simulation of Internal Arc in

Medium Voltage Switchgear

Mainak Sinha Roy1, Jaroslav Snajdr2, Pavel Novak2

1

Schneider Electric R&D, Bangalore, India

2

Schneider Electric R&D, Regensburg, Germany

Keywords: switchgear, internal arc, arc energy, heat flux, cotton indicator

Abstract

Internal arc in a switchgear is a rare phenomenon in its entire lifecycle. Though the mean time to failure is high, using

new materials, improved production technologies or sensors for predictive maintenance, the risk of an internal arc

persists. Unfortunately, the effects of internal arc are destructive and very harmful due to severe pressure rise and hot gas

expulsion, which can endanger an operator or damage a property. Architecture and design of medium voltage switchgear

is qualified upon the requirements of existing standards. General study across the labs indicates that a success rate of

about 70% is achieved during the initial stage of internal arc validation. Data from labs reveals that the most prominent

failure mode during internal arc testing is burning of indicators due to hot gas expulsion.

The physics of the internal arc phenomenon is studied and employed to build the model in simulation software package

using fluid dynamics numerical method. Qualitative as well as quantitative prediction is carried out, to estimate the gas

flow behaviour. Firstly, the volume of the hot gas cloud and secondly the energy incident on the indicators are

determined. Results are compared with data collected from series of internal arc tests with high-speed video and actual

measured parameters. Based on the findings, the simulation methodology is formulated which will provide input to

improve the design of switchgear.

The paper presents results of recent research activity, with the objective to increase robustness of the switchgear design

for internal arc performance. The prediction of burning of indicators remains a difficult task due to the complexity of all

involved physics, their coupling and correct representation in a simulation model. The enhanced method presented in this

paper can significantly increase the success rate during tests and ultimately safety of the switchgear and its variants.

1 Introduction boundary conditions imposed in the simulation model.

Based on the pressure values, switchgear design is

Safety of personnel around Medium voltage switchgear adapted. However, the burning of indicators and thus

during an internal arc phenomenon is one of the main personnel safety from hot gas is still difficult to predict due

concerns for users. Switchgear manufacturers design the to the complexity of the internal arc phenomenon. Since

cubicle and exhaust system to be strong enough to the major reason of failure during internal arc tests is

withhold the pressure and manage fire and gas emanating indicator burning, such prediction can significantly

during internal arc. increase the success rate during tests.

IEC 62271-200 [1] and IEEE C37.20.7 [2] specify testing Moreover, the market is demanding more tailor-made

methodology to validate the design and provide required products and it is impossible to carry out internal arc tests

robustness and safety to the switchgear. The internal arc of every single design of switchgear variant. Simulation is

validation test makes allowance for effects acting on all an excellent tool to predict the performance of such

parts of the enclosure, such as internal over- pressure, variants if the impact of hot gas expulsion on personnel

thermal effects of the arc or its roots, the effects of ejected safety can also be predicted along with pressure

hot gases. Internal Arc test is carried out by initiating short estimation. The users are also looking for incident energy

circuit phase to phase or phase to earth in the compartment around the switchgear as well as around the exhaust of

to be tested. The switchgear is placed surrounded by walls switchgear room to design the personal protective

and ceiling to simulate the room installation. Cotton equipment and also to demarcate safety zones for

indicators of approximate density of 150 g/m² and a size of personnel.

150x150 mm are placed around the switchgear to simulate

the clothing of the authorized personnel operating the 2 Challenges of Simulation Technique

switchgear.

At present pressure induced in a compartment during Cotton indicators are the primary tools for pass-fail

internal arc tests can be correctly predicted with proper criterion of internal arc tests. They are positioned in a

relative proximity of the switchgear equipment to assess

1CIRED 2021 Conference Geneva, 20 – 23 September 2021

Paper 512

the degree of heat exposure during internal arcs that could of the thermocouple bead, the equivalent calorimeter

be harmful to personnel. The flammability of similar type constant (Kt) of the thermocouple bead is calculated [4].

A cotton indicators used during internal arc tests was Stoll limit defines energy density causing second degree

studied by the working group of CIGRE A3.24 [3]. The burn on humans. The threshold incident energy values

heat flux experimentally obtained to ignite a cotton obtained experimentally by CIGRE working group is used

indicator at 1.1 s to 2 s is 90 kW/m², corresponding to a to calculate an equivalent Stoll limit (Scotton) for cotton

threshold energy ranging from 100 kJ/m² to 180 kJ/m². indicators. The equivalent Stoll limit and the calorimeter

Whereas measured heat flux to ignite a cotton indicator in constant give the Stoll limit curve in the form of a

2.2 s to 3 s is 60 kW/m², corresponding to a threshold transformed temperature-time curve. The following

energy ranging from 132 kJ/m² to 180 kJ/m². It is clear relationship is used to evaluate the Stoll limit for cotton

from the laboratory testing that there is visible scatter of indicators:

results. Unfortunately, we do not have enough data from

actual internal arc tests to corroborate the above values of E = Incident Energy = Kt · dTmax= Scotton · tmax0.2901

threshold energy level for cotton indicators. In the absence where dTmax = Delta peak temperature

of data from actual tests, it is also difficult to calibrate a and tmax = time to delta peak temperature.

simulation model and estimate the accuracy of results. An

attempt has been made to estimate the energy levels using 3.1 Data Analysis at Exhaust (T1)

thermocouples and the same approach is discussed in next The temperatures recorded by the thermocouple for each

section. of the 4 tests are plotted in Fig. 2. The maximum

temperature recorded by the thermocouple is between

3 Data from Internal arc tests 740˚C to 630˚C. In the actual test the indicators are not

placed in this location since it is not required by the

Thermocouples of K-type at specific locations were used standards and the location is inaccessible to the operator.

to indirectly measure energy incident in 4 different tests.

The arc energy for these 4 tests were varying from 40 MJ

to 47 MJ. Fig. 1 shows the arrangement of the indicators

during the test as well as the location of thermocouples.

Thermocouples were placed at three different locations to

capture the hot gas behaviour: T1 at exhaust, T2 near front

horizontal indicator and T4 near rear vertical indicator.

Fig. 2 Temperature at T1

Fig. 1 Thermocouple locations We can assume that the indicators placed at the exhaust

would have been burnt since it would be the hottest place

Temperature recorded by thermocouple is analysed at around the switchgear and would have not been able to

each of the three locations. K-type thermocouple was used withstand heat flux. From the above figure it is also

to measure temperature of the hot gas which has a range of evident that the temperature rise of the thermocouple

1300˚C. The specification of thermocouple is as follows: exceeds the Stoll limit for cotton indicators by a large

• Specific heat of thermocouple bead Cp = 523 J/(kg.K) margin.

• Radius of thermocouple bead r = 0.54 mm

• Surface area of thermocouple bead, A = 3.7x10-6 m2 3.2 Data Analysis at front horizontal and rear vertical

• Mass of the thermocouple bead, m = 5.7x10-6 kg. indicators (T2 and T4)

The temperatures recorded by the thermocouple placed

The thermocouple cannot be used to measure the gas near front horizontal indicator for 2 of the 4 tests are

temperature since its thermal time constant is 0.8 seconds. plotted in Fig. 3. The maximum temperature recorded by

Here, we will try to measure the energy incident on the the thermocouple is around 90˚C.

thermocouple with the thermocouple bead acting as a

calorimeter. Using the thermal and geometrical parameters

2CIRED 2021 Conference Geneva, 20 – 23 September 2021

Paper 512

performance, measuring accuracy, irregular flow of hot gas

in leakage areas etc.

The comparison of the Stoll limit with the measured

temperature gives a good estimation of the indicator

safety. It also confirms that the calorimeter constant can be

used to predict the incident heat flux using the temperature

rise values measured with thermocouple during tests.

4 Simulation of gas flow in switchgear

Using the thermocouple’s thermal and geometric

properties heat flux incident on the thermocouple at

location T1 is calculated. The heat flux incident on the

thermocouple is calculated using the following relation

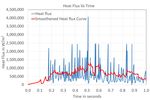

Fig. 3 Temperature at T2 and is plotted in Fig. 5:

The temperature measured at these locations does not go E = Incident Energy = K · dTmax

beyond the Stoll limit and the indicator should be safe in

this location. In the actual test the indicators are placed in

this location also and the indicators did not ignite during

both the tests.

The temperatures recorded by the thermocouple placed

near rear vertical indicator for all the 4 tests are plotted in

Fig. 4. The maximum temperature recorded by the

thermocouple ranges from 350˚C to 1050˚C. The large

variation in temperature represents the variation of the

extent of leakage of hot gas in that area.

Fig. 5 Heat Flux at T1

Heat flux curve is smoothened by moving average method.

Heat flux reaches a value of about 1250 kW/m2 at T1. The

energy incident at T1 is simulated and compared with the

values obtained during test.

The simulation was performed in a proprietary CFD

software with the help of internal arc model. The model is

based on arc radiation using user defined functions and a

real gas model. This robust model was a company solution

mainly for evaluating pressure rise within the switchgear

compartments and substations. Energy incident on the

Fig. 4 Temperature at T4 indicators was simulated by modelling the indicators and

monitoring energy levels at those locations. Simulation

The temperature measured at these locations goes beyond with laminar model approach has been attempted earlier

the Stoll limit for all tests. For test 1, test 2, the Stoll limit with moderately accurate result [5]. Simulation

is exceeded in about 0.35 second. Whereas the temperature methodology is improved using turbulent regime to

goes beyond Stoll limit for test 3 and test 4 after 0.55 accurately predict gas flow behaviour as well as the

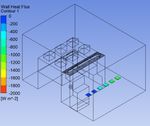

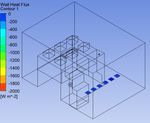

second and 0.65 second respectively. In the actual test the incident energy. Fig. 6 shows the difference in gas flow

indicators were placed in this location. The indicators were behaviour is both the laminar and turbulent regimes as

found to be safe and did not ignite only for test 4 where the well as real gas flow during test. The contour of incident

maximum temperature was recorded to be 300˚C. The energy flux on the horizontal indicators can also be

temperature of the thermocouple exceeds the Stoll limit by visualised in Fig. 6. In the laminar flow regime, the gas

about 100 C in test 4 and still the indicators safe. This is an does not propagate to the horizontal indicators and thus the

indication to the possible variation in the cotton indicator incident energy on the horizontal plane is not precisely

3CIRED 2021 Conference Geneva, 20 – 23 September 2021

Paper 512

simulated. However, the turbulent regime shows a more cubicle is considered in simulation which is not a practical

realistic gas flow and shows the gas propagation also scenario during test. The simulated incident energy levels

towards the horizontal indicators. The simulated gas flow will thus be higher than the actual values and would thus

with turbulent regime bears a more accurate resemblance represent a worst-case scenario. Moreover, the accuracy

to real time video grab from test. and uncertainties in the measurement also would

contribute to the difference.

a

Fig. 7 Simulated heat flux at T1

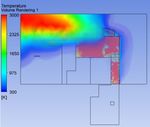

The simulation methodology was implemented to validate

the internal arc performance in an air insulated switchgear

b of 50kA, 1sec fitted with deflectors. The switchgear was to

be installed in a room with limiting dimensions in terms of

ceiling height. Thus, its performance needed to be

validated with such limiting conditions. The gas flow was

accurately simulated, and design was adapted as per the

simulation inputs. The internal arc test got validated at the

first attempt thus reaffirming the need of simulation to

predict the performance of a product beforehand to cater

faster to the market with minimum cost and effort.

Fig. 8 compares the simulated gas flow and the actual gas

flow during the test.

c

Fig. 6 (a) Simulated Gas Flow and incident heat flux in

laminar regime, (b) Simulated Gas Flow and incident heat

flux in turbulent regime, (c) Video grab from test.

Thus, simulation gas flow is matching with the real gas

flow qualitatively as evident in Fig. 6. Further, we can

evaluate the values of incident energy at location T1 to

validate the simulation accuracy.

Monitor to measure the energy flux at T1 location was

placed in the model. Fig. 7 shows the simulated as well as a

the actual heat flux values from one of the tests. Simulated

incident energy for both laminar and turbulent regime is

plotted. Simulated incident heat flux is underestimated

with laminar flow. The turbulent regime predicts the

incident heat flux more accurately and the values are much

closer to the measured values during test. Simulation for

turbulent flow is continued up to 0.6 second till the flow

and heat flux is stabilised at location T1. Though there is

some variations in the absolute values of incident energy, b

the gas flow path and the trend of the heat energy incident Fig. 8 (a) Simulated gas flow - front view for better

as well as heat flux (during the time span) is in line with visualisation, (b) Video grab from test.

actual tests. This variation in absolute values can be

contributed to the fact that no additional leakage from the

4CIRED 2021 Conference Geneva, 20 – 23 September 2021

Paper 512

5 Conclusion management based on digitisation, condition monitoring

and digital twin.

The paper demonstrated the added value of simulation for

prediction of switchgear performance during internal arc 6 References

test. Specifically, the investigation of indicator ignition

due to hot gas was of the main concern. Temperature of [1] IEC Int. Standard 62271-200: AC metal-enclosed

switchgear and control gear for rated voltages above 1

gas was measured using thermocouples for multiple tests. kV and upto and including 52 kV, 2011.

The temperature rise of thermocouples were then checked [2] IEEE C37.20.7: IEEE Guide for Testing Metal-

with the equivalent Stoll limit for cotton indicators. The Enclosed Switchgear Rated Up to 38 kV for Internal

comparison along with indicator performance during the Arcing Faults ,2007.

tests confirmed that the thermocouple parameters can be [3] Working Group A3.24, “Tools For The Simulation Of

used to predict the incident heat flux using the temperature Effects Of The Internal Arc In Transmission And

Distribution Switchgear”, Cigre Publication, January

rise values measured with thermocouple during tests. 26, 2014.

Simulation was then carried out to calibrate the model with [4] Holger Schau, Herbert Bessei,“ The influence of fuses

the measured value of incident heat flux. Simulation with on arcing fault energy and personal protective clothing

turbulence mode provided accurate gas flow as well as required,” ICEFA,2011.

incident energy values. [5] Mainak Sinha Roy,Jaroslav Snajdr,“Simulation of Hot

Gas Behavior During Internal Arc in Medium Voltage

Thus, the safety of the switchgear in terms of cotton Switchgear”,Matpost 2019.

ignition can be checked with this method by accurately

predicting incident heat flux on the indicators. Simulation

of pressure induced in compartment as well as hot gas

would give higher confidence to designers before

performing expensive tests. This would also help to ensure

the safety of switchgear variants for which internal arc

tests are sometimes not possible to perform. Users can be

provided with much more accurate data about the incident

energy level around the switchgear and around the exhaust

of switchgear room for specific site conditions. This would

increase the reliability of the switchgear in terms of safety

not only in an ideal but also in real and practical

installation conditions.

With the enhancement of computing power and meshing

methodology, the computing time is steadily reducing.

Earlier, simulation with laminar regime would take about a

week in a standard high-end CPU. Whereas, simulation

with turbulence model cannot be performed due to

complexity and higher computing time. Now a days, the

mesh count can be halved with more advanced mesh

techniques and simulation with turbulent regime can be

completed even in 3 days. The assembly time and

preparation time for a switchgear during internal arc test

can take about 20 man-days and that too without a

guarantee in successful performance of the product.

However, effort in simulating the internal arc performance

of a switchgear in terms of pressure rise and gas flow will

be around 7 days. Simulation will give a confidence of

design as well as highlight the fragilities in the design for

which corrective design actions can be taken. Going

forward, this enhanced technique of simulation would

make our products safer, more reliable, more robust with

minimum effort and time.

Simulation along with test results can deliver an effective

and acceptable characterisation of switchgear behaviour

even in such complex phenomenon of internal arc. This

goes well in hand for the forthcoming philosophy of asset

5You can also read