A Rich Heritage, a Blossoming Future The Power of Partnership

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Toray Textures CONTENTS

Reinforcing 42 A New

Corporate Philosophy 4 Safe Flying

Contributing to society through

the creation of new value with Generation 7 Auto Industry on Eve of Composites Serial Production

innovative ideas, technologies,

of Helicopters

Our Composites

10 "A natural match"

and products

12 Next Stage of TAPAS

Corporate Missions

14 Hannover Messe Success for TenCate

Market Position

For our customers:

To provide new value 17 Far, Far Away

to our customers through

high-quality products 20 D²Ragon: Aerospace Cluster in China

and superior services

23 Amber Composites Celebrates

TenCate Advanced Composites blossoms into a new era at JEC World 2019, officially becoming Toray Advanced Composites. Anniversary with New Name

For our employees:

To provide our employees 25 Tooling Reinvented

with opportunities for As we look to the future, it is important to recognize our legacy as part of the 315-year-old Dutch textiles company Koninklijke (Royal)

TenCate AmberTool® Composite Tooling Prepreg

self-development in a TenCate. TenCate revolutionized the adoption of thermoplastic composites in the aerospace industry with its Cetex® portfolio, itself in

challenging environment 28 N

ext Generation Advanced Composites for Space

its 30th year. Cetex® is responsible for numerous global firsts that revolutionized the industry and continue today with the world’s first

07 Auto Industry Advanced Rigid Array (ARA) Mk4 Panel

thermoplastic rear pressure bulkhead, manufactured by Premium AEROTEC for the Airbus A320 family of aircraft.

For our stockholders:

To provide our stockholders

on Eve of 29 Connected Aircraft

with dependable and We highlight TenCate’s legacy in this edition, sharing a range of articles published over the years in TenCate’s corporate magazine Composites 32 Small, Convenient, and Comfortable

trustworthy management txtures. These stories not only demonstrate the rich heritage TenCate brings to the Toray family as Toray Advanced Composites,

but also the necessity of partnership and support to advance technology for our customers’ success.

Serial Production 35 Ultra-Pure

Advanced Composites for Radomes

For society: Technologically Advanced Triband Satcom Radome

To establish ties and develop

mutual trust as a responsible Toray Advanced Composites continues to offer a portfolio of industry-leading resin and prepreg technologies, now with the global 36 A

ston Martin Valkyrie Door Assembly

scale to drive these technologies into new segments. The leading supplier of carbon fiber and composite materials in the world, The Power of Partnership

corporate citizen

Toray brings vertical integration and scale to Toray Advanced Composites, along with a strong commercial channel to drive these 38 Expertise in Thermoplastics

For our customers:

To provide new value to our

products into the right applications at a competitive price. 14 Hannover 41 L ightweight Stow Bin Latch Cover for

customers through high-quality

Toray Advanced Composites will bring a robust portfolio of products to our customers, leveraging our combined companies’ strength.

Messe Success Boeing 787 and 747-8I Aircraft

TenCate Cetex® Thermoplastics for Aircraft Interiors

products and superior services

We will continue to work as partners with our key resin and reinforcement suppliers to support the programs that are important to us for TenCate 42 A New Generation of Helicopters

Corporate Guiding Priniciples all. And as always, we will be transparent, honest, and committed to working as partners with our customers. After all, our goal is

Safety and Environment your success. When you succeed, we succeed. 45 The Fifth Mode of Transportation

Ethics and Fairness

Customer-focus 48 Langley Mill: the Top in Thermoset

Innovation On behalf of Toray Advanced Composites’ management and employees, I thank you all sincerely for the support you have shown

Fieldwork and Initiative 50 Thermoplastic Composites: Success and Growth

us over the years. We look forward to expanding our partnership with you in the future as Toray Advanced Composites.

Global Competitiveness 54 Thermoset Prepregs Make Space

Global Coalition Travel More Affordable

Emphasis on Human Resources

Mr. Keisuke Ishii, Chief Executive Officer 56 Underbody Panel for the Jaguar F-TYPE

Head Office Toray Advanced Composites

18255 Sutter Blvd. Global Partner for Aerospace Composites

59

Next-Generation Multipurpose Light

Morgan Hill,

Single-Engine Helicopter

CA 95037, USA

Tel. +1 408 465 8500 60 In the Center of the High-Tech Composites Industry

info@tcac-usa.com 50 Thermoplastic

64 A Royal Company

Articles reproduced from Composites:

65 Aerospace Composites Go Underground

previous editions of txtures

with the permission of

Success

68 Support without the Weight

Koninklijke Ten Cate B.V. and Growth

71 2019 Events Calendar

Photo on front cover Meet the Team

The wing tip of the Airbus ©2019. All data given is based on representative samples of the materials in question. Since the method and circumstances under which these materials are processed and tested are key to their performance,

A350 XWB (photo: Airbus and TenCate Advanced Composites has no assurance of how its customers will use the material, the corporation cannot guarantee these properties. TenCate®, (TenCate) AmberTool®, (TenCate) Cetex®, (TenCate)

CFRT®, (TenCate) MicroPly™, and all other related characters, logos, and trade names are claims and/or registered trademarks of Koninklijke Ten Cate B.V., Toray Industries Inc. and/or its affiliated companies in

S.A.S./P. Pigeyre) one or more countries. Use of trademarks, trade names, and other IP rights of Koninklijke Ten Cate B.V. or TenCate Advanced Composites without prior written approval by such is strictly prohibited.

2 Toray Textures | Spring 2019 3PROTECTING PEOPLE TENCATE COMPOSITES FOR SUSTAINABLE MOBILITY

Safe Flying

TenCate Advanced Composites supplies the aerospace industry with thermoset and

thermoplastic composite. The major end-users in the aerospace industry are Airbus

and Boeing. The proportion of composites in new generations of aircraft is increasing.

This applies to parts for the fuselage and wings as well as for the interior. In 2014,

the market group is expected to increase its revenues and result due to increasing

production for aircraft for which qualifications have been received.

TenCate revenues from the aerospace industry box) and whether they will be comfortable during

declined in 2012 and the first half of 2013 as a result the journey. This is in part determined by the cabin

of delays in deliveries for the Airbus A380 and A350 pressure and humidity and whether one is sitting

and the Boeing 787. After this period, however, comfortably. TenCate Advanced Composites USA

revenues and profitability increased: the TenCate currently supplies many composite materials to both

Advanced Composites market group recorded a 16 US and European aircraft seat manufacturers. One

percent increase in revenues in 2013. The market for of these customers is Geven, an Italian company

aerospace composites showed strong growth, and manufacturing aircraft seats and interiors. The

good progress was made in the latest generation of American company Cutting Dynamics has used

aircraft. The order book for the Boeing 787, which TenCate composite to make a lightweight, slim seat

is important to TenCate, has more than 900 aircraft frame with high crashworthiness (up to 16G).

listed in it. The order book at Airbus for the A350 is

also well filled, containing over 800 aircraft. The French company Expliseat has made an

aircraft seat weighing a mere 4 kilos, based on

Radomes a combination of titanium and TenCate composite.

Increasing opportunities for communication during This provides a saving on fuel of up to €370,000

passenger flights, especially in the United States, a year for each A320 or B737. It is the lightest

have led to a great demand for radomes. These are aircraft seat ever to have withstood the crash

made of thermoset composite material and often test. Meanwhile, a contract has been signed for

Performance Excellence Award

involve the nose of the aircraft, which houses the the delivery of these seats to a European aircraft

TenCate Advanced Composites received

radar equipment. These materials are subject to manufacturer. BE Aerospace, also a major seat Boeing Silver Performance Excellence

stringent requirements for impact tolerance. They manufacturer, uses TenCate Cetex® laminate for Awards in 2013 and 2017. This is an annual

award presented by The Boeing Company

must be made in an extremely clean environment (a the structure that joins the seat to the floor. If it

to suppliers who have put in a superior

clean room), so they do not become contaminated is the buyer of the aircraft who determines which performance.

with conductive particles, which may lead to interior will be used in the aircraft, this is known In 2013, TenCate was one of only 459 suppliers

safety problems and communication malfunctions. as buyer-furnished equipment. If the aircraft to have received this award at Silver level.

TenCate Advanced Composites produces these manufacturer sees to this, then it is known as There are in total approximately 23,000 Boeing

suppliers. This award is particularly important

materials in its facility at Morgan Hill (California). supplier-furnished equipment. because TenCate compression-molded

parts for the military V-22 Osprey helicopter

program (photo) provide a reduction in both

Aircraft seats cost and weight. TenCate also supplies similar

It is more interesting for passengers to know among parts for the F-18 program and for the Boeing

737, 747, and 787.

which TenCate materials they are traveling (see Continued on page 6

4 Toray Textures | Spring 2019 5TenCate is the exclusive supplier of carbon fibers for the production of the

monocoque of the Alfa Romeo 4C. This central passenger compartment reduces

the weight of the vehicle and gives it an extremely stiff and safe basic structure.

CONTINUED FROM PAGE 4 PROTECTING PEOPLE COMPOSITE MATERIALS ENTER THE AUTOMOTIVE INDUSTRY

New seats are one thing, but the replacement

or retrofit market is also important. Aircraft

operators like to replace old seats with new ones,

as nowadays these are lighter, smaller, and look

more attractive. Not only do they save weight, but

also space, which is then used to place one or two

additional rows of seats.

In the kitchen

Composites are also used in the galleys: the

aircraft kitchen. The galleys of the Boeing 737s

of SouthWest Airlines are made of TenCate

Auto Industry on

materials. SouthWest is the largest low-cost

carrier in the US and, measured by the number

of passengers transported, the largest aerospace

company in the world. The materials for kitchens

the Eve of Composite

and other interior applications must satisfy Helicopter tail piece made of composite.

very strict fire safety requirements. Interior

materials from TenCate also score well on their

self-extinguishing capability and requirements projects. It thus supplies directly to the OEMs. the technical and industrial partner and supplier of

Series Production

relating to fire smoke toxicity. This, moreover, After a cautious start in 2013, deliveries to materials and special processes for the Embraer

also makes them suitable for ships and trains, Airbus Helicopter (formerly Eurocopter) recovered KC-390 project. The market group is currently in

which have longer evacuation times. somewhat. In November, TenCate was selected the qualification phase for delivery to Airbus of

by the Brazilian aircraft manufacturer Embraer the protection of the cockpit door and walls in

Aerospace armor to design the ballistic protection for the Embraer passenger aircraft. In this market there have as yet

TenCate Advanced Armor is a technology-driven, A-29 Super Tucano. The design and the prototypes been only a few cases of retrofit applications.

tier 1 company in specific ballistic protection, of the ballistic protection for this military aircraft

particularly for military helicopter and aircraft program are in the final stages. TenCate is also Structural demand

TenCate Advanced Composites is well positioned

to benefit from the structural demand for weight-

saving materials in the aerospace industry. In The acquisition of Amber Composites (UK) at the beginning of 2013 has given TenCate processing of this type of advanced material.

2014, revenue and results are expected to rise, accelerated access to the market for automotive composites. These materials form one of By contrast, in the sports car market and in car

due to increasing production for aircraft for which the key points within the TenCate business development strategy. The focus is on those parts racing, apart from steel, there is almost exclusive

qualifications have been received. A key factor of the vehicle that have an effect on its safety and structure. These materials are subject to use of thermoset composites.

in this growth forecast is, as mentioned above, stringent requirements. Meanwhile, a number of interesting development projects have been

the increase in production for the Airbus A350 initiated. The demonstrators resulting from this work will in the future have to find their way Solutions for mass production

and the Boeing 787. The further increase in the into new types of vehicles. Thermoset is ideal for low-volume production.

use of thermoplastic composite material for the When it comes to large numbers, thermoplastic

aerospace industry, and in particular for Airbus, The European Commission has determined that in thermoplastic composite technology for well composite is the obvious material. In alliance with

is also highlighted by the recent expansion of the by 2020 CO2 emission standards will have to have over 30 years. This material is increasingly being BASF and Owens Corning, TenCate is developing

TAPAS consortium (see page 12). been reduced by 40%, vis-à-vis the level of 2007. used in the aerospace industry; the automotive optimal solutions in thermoplastic composite

This will force car manufacturers (OEMs) to look market is much greater and more diverse. for mass production in the automotive industry.

Are you flying to or from a business meeting or holiday destination? Then you will find yourself surrounded by www.tencatecomposites.com for weight savings. Compared with traditional Thermoplastic composite is ideal for use in series Tooling prepregs are supplied for large thermoset

composite materials from TenCate – at least, in the newer generations of Airbus and Boeing and in four types of advancedcomposites.europe@tencate.com materials, composite is 30 to 50 percent lighter and production, but it does require adaptation of

Gulfstream, for example, TenCate composite materials are used. Examples include the frames and screens for the

windows, the stow-bins, trolleys (sandwich panels), seat frames, floor panels, and ducting for the air conditioning. thus eminently suited to help achieve this weight the production chain of (structural) parts. This

saving. TenCate has occupied a leading position is because OEMs are not yet geared to the Continued on page 8

6 Toray Textures | Spring 2019 7CONTINUED FROM PAGE 7

Alfa Romeo 4C

parts; thermoplastics will mainly be processed release is expected this year and limited series ite. The company in Langley Mill (Derbyshire,UK) is supply of TenCate E700 carbon-fiber prepreg for • Thermoplastic composite is eminently

using metal molds. production will be possible about twelve months already a major supplier to the Formula 1 market. the Alfa Romeo 4C platform. This material from suited to series production, but does

later. A prototype of a composite bottom plate One of the developments in this market is that, TenCate Advanced Composites UK is used for the require adaptation of the production

Together with Kringlan Composites, TenCate is has been made jointly with Voestalpine as a result of the use of lighter turbo engines, production of the entire monocoque: the passenger chain of (structural) parts

engaged in providing solutions for the automated Polynorm. A traditional steel plate weighs 22 temperature requirements will increase. For compartment. This reduces its weight and gives • Thermoset is ideal for low-volume

manufacture of parts based on thermoplastic kilos; when produced in composite, this weighs TenCate, this increase in temperature requirements the vehicle an extremely stiff and safe basic production; for large numbers, thermoplastic

composite technology. The most significant less than 10 kilos. is not unfavorable. The expected growth of the structure. TenCate has been supplying the Adler composite is the obvious material

development at this time is a fully carbon- facility will mainly come from the automotive Group with this material for the production of • TenCate composite materials will be

reinforced composite wheel for cars in the upper Tooling – fast-growing market segment sector (Alfa Romeo 4C). The growth of tooling this car for some time. For logistical reasons, the used for the production of the passenger

segment. This wheel has a strong weight-saving TenCate Advanced Composites UK produces applications is more modest. intention is for material production to be carried On March 11 during the 2014 JEC Show, the Dutch compartment of the Alfa Romeo 4C

Minister of Economic Affairs, Henk Kamp, also visited

effect and reduces the unsprung mass of the vehicle. mainly tooling and structural prepregs (resin- out locally. For TenCate, this agreement represents

the TenCate stand, where he admired the monocoque for

Tests show that in terms of material stress, the pre-impregnated fibers) and honeycomb cores. Alfa Romeo 4C its first OEM project of this size in the automotive the Alfa Romeo 4C. On the left, the Minister and in the

demonstrator of the wheel meets extremely high As a result of the increasing use of composite TenCate and the Adler Group (Naples, Italy) have industry. Up to three thousand cars of this type middle, Frank Meurs (group director, TenCate Advanced

Composites and formerly TenCate Protective Fabrics EMEA).

safety and integrity requirements. The market material, the molds will also be made of compos- recently signed an agreement for the exclusive are expected to be manufactured annually.

8 Toray Textures | Spring 2019 9INNOVATION TENCATE AND FOKKER AEROSTRUCTURES: A NATURAL COMBINATION IN COMPOSITES

OEMs in particular. This involves accuracies to involved in the Region of Smart Factories. Together Vision for the future

tenths of a millimeter. It is specialist work, into with multinationals such as IBM and Philips, SME Aeronautical drafters at aircraft manufacturers

which a great deal of development has gone. companies, knowledge institutes, and universities, have been focusing on the aircraft of the future,

they aim to develop new techniques to substan- creating animations of planes with remarkable

“An exceptional proposition” tially improve or even double productivity in the shapes–aircraft that move like birds with a

According to Arnt Offringa, director of R&D at manufacturing industry. Existing principles like slow wingbeat. Arnt Offringa believes that the

Fokker Aerostructures, in the partnership with automation and lean manufacturing are no longer increasing scarcity of fossil fuels and global

TenCate there has been ‘‘a natural match for sufficient. Smart factories provide new opportuni- warming will ensure there will continue to be a

several decades. Together we strive to achieve ties for increasing productivity. great demand for economical and thus lightweight

the same goal: light, affordable aircraft parts means of transport.

using thermoplastic composite technology. By Smart factories constantly think for themselves

jointly distinguishing ourselves on the market and correct and improve themselves. Such a fac- For the aerospace industry, this means an ongoing

with an exceptional proposition, we acquire tory requires areas of high-caliber expertise, like need for affordable, lightweight aircraft. TenCate

orders. It’s like a marriage: you need each other advanced sensor systems and the processing of and Fokker Aerostructures are extremely well

The new Airbus A320neo is fitted with new, more economical engines, which make the aircraft heavier, so its weight must be reduced. (Photo: Airbus S.A.S.) to reach the goal you’ve set. Together you are data streams. Sensor systems allow one to fathom placed in this respect, with unique thermoplastic

stronger and you provide your customers with a out complex industrial processes. Knowledge of the composite technology from TenCate Advanced

better product.’’ He mentioned in particular as the control of large data streams is necessary to make Composites. Material, production techniques, and

strong point of TenCate its focus on thermoplastic processes self-learning. The first Smart Factory design expertise all come together here. ‘‘When

‘‘A natural match’’

composite as a material and their joint approach project has just been completed at Fokker in it comes to engines, significant development is

to the market. ‘‘This has enabled us to secure our Hoogeveen. In this project, the logistic system be- taking place: at a stroke they have become 20

current position.’’ hind part of the composites line has been optimized percent more economical, which is a revolution

using advanced techniques. The partners will in the in aircraft manufacturing.’’ As an example, he

Smart factories years ahead exchange expertise on smart factories, mentions the new Airbus A320neo (New Engine

TenCate Advanced Composites supplies thermoplastic composite material to Fokker thousands of press-formed ribs each year. All Fokker Aerostructures and TenCate are also two acquire new knowledge, and conduct pilot projects. Option) narrow body, which is fitted with these

Aerostructures in Hoogeveen. The material is processed there into parts for the aircraft and these individual parts are then welded together of the companies in East Netherlands that are new engines. ‘‘These engines do, however,

helicopters of Airbus, Boeing, Gulfstream, Dassault, AgustaWestland, and others. TenCate to form the leading edges of wings for Airbus make the aircraft heavier, so its weight must be

and Fokker Aerostructures form a natural and reliable combination in their value chain. A380 airliners and the rudders for Gulfstream reduced. Herein lies a task for both of us.’’

and Dassault business jets.

TenCate is involved in various development and Lockheed Martin. These are delivered in part • Fokker Aerostructures processes

projects and consortia for the aerospace industry, directly and in part to Tier 1 companies, which are Panels composite materials from TenCate to

including TAPAS (with Airbus) and TPRC (with the suppliers of systems to OEMs. Each year, thousands of floor panels are also make parts for aircraft and helicopters

Boeing). One of the partners in these partnership made from TenCate Cetex® for a variety of types • Both companies are co-initiators of the

alliances is Fokker Aerostructures, which special- Material processing of Gulfstream aircraft. In this process they are Region of Smart Factories, which aims

izes in the design, development, and production of The material from TenCate Advanced Composites press-formed, bonded, thermo-folded, and induc- to increase or even double productivity

lightweight parts for the aerospace industry. The undergoes a variety of different treatments in tion welded. The new Airbus A400M is fitted with in the manufacturing industry

materials that are processed are metals such as Hoogeveen. Single-layer semipreg material is ice-protection panels from Fokker Aerostructures, • New, more economical engines in

aluminum and titanium, thermoset composite, and used to laminate large parts, such as the skin based on TenCate Cetex® TC1100 PPS/glass. the aerospace industry demand further

relatively new materials, such as Glare®, a and the spars of the leading edges of wings, Fokker Aerostructures also designed the horizontal weight reduction

thermoplastic composite material from TenCate. and rudders. The supporting torsion box in the tailplane for the AgustaWestland AW169. Winand Kok (formerly manager, engineering, TenCate Advanced Composites), Arnt Offringa

The company supplies complete tailplanes and tail of a helicopter is fused in a single process Needless to say, all the processes and products (director, R&D, Fokker Aerostructures) and Michael Overd (head, Structures Design & Development,

moving wing parts for commercial and military step. Cetex®, a thermoplastic composite material have to satisfy the stringent quality requirements AgustaWestland) with the JEC Innovation Award 2013 for the first horizontal tailplane made of

thermoplastic composite for the AW169 helicopter

aircraft for customers such as Boeing, Airbus, from TenCate, is used by Fokker to make tens of set by the aerospace industry in general and the

10 Toray Textures | Spring 2019 11INNOVATION TENCATE, FOKKER, AND PARTNERS CONTINUE INNOVATION PARTNERSHIP WITH AIRBUS

Next Stage of TAPAS

On Monday January 20 2014, the CEOs of Airbus, Fokker Aerostructures, and TenCate put their signatures to the contract for the next stage

of the Thermoplastic Affordable Primary Aircraft Structure (TAPAS) program to run until the end of 2017. This innovation program, a highly

successful tool for project-based innovative partnership, has thus entered the next stage.

The TAPAS consortium consists of companies and the Technical University of Delft, and the University as part of TAPAS 2. Other aircraft components

knowledge institutes in the Dutch aerospace in- of Twente. The Dutch aerospace industry enjoys too, such as the wings and fuel tanks, are being

dustry working together with Airbus on the further a good reputation worldwide in the field of studied. A wing can be compared to the tailplane,

development of thermoplastic composite applica- lightweight materials. This is due in part to its but it is ‘‘a fairly complex part,’’ explains TenCate

tions in aircraft fuselages, wings, and tail sections. excellent knowledge infrastructure, materials, and manager of engineering, Winand Kok. It has con-

The target is to further increase the proportion of processes. In terms of size, the Netherlands has flicting requirements: ‘‘It must be light and strong,

thermoplastic composites in current aircraft as well the sixth-largest aerospace industry in Europe. conductive, the fuel has to be stored in it and it

as in new generations. The partners of TenCate must be able to lift the aircraft off the ground.’’

Advanced Composites are Airborne Composites, Tail section During a flight, lightning may strike and static

CODET, DTC, KE-Works, KVE, Technobis Fiber A demonstrator of a tail section made entirely of electricity cause sparks, which is not desirable in

Technologies, the National Aerospace Laboratory, thermoplastic composite material is being developed the vicinity of fuel tanks. While traditional wings

are made of metal, which is a good conductor, so that the aircraft becomes lighter. Yet the Senior vicepresident R&T, Axel Krein of Airbus,

composite is far less conductive. ‘‘You have to nose and fuselage must be able to withstand Loek de Vries (center), and Sjoerd Vollebregt (right), CEOs

of TenCate and Fokker Aerostructures, respectively, put

develop a specific solution for thermoplastics to hailstorms, with hailstones measuring as much

their signatures to the contract for the continuation of

overcome this, with each application making its as 8 centimeters in diameter. These are extreme

the TAPAS program. The document was signed in the

own demands. In the aerospace industry every- scenarios, but you do have to take them into presence of the French President, François Hollande, and

thing is put under the magnifying glass.’’ account. The important thing is to be able to fly the Dutch Prime Minister, Mark Rutte. (photo: René de Gilde)

safely from A to B. This can be translated into

Impact-resistance material characteristics, which are what we make

In the event of impact, a dent will be visible in our processes. It is a part of the safety that

in a metal aircraft fuselage. If the wall is made is reflected in the care that we exercise in our

of a composite (layers of materials), nothing can manufacturing processes. Our customers expect

be seen, but damage may well have occurred us always to do the same thing and deliver exactly

inside. That is why an aircraft with composites the same product.’’

is designed ‘‘thicker,’’ also due to its scale. The

walls of smaller aircraft are thinner and their im- www.tapasproject.nl

pact-resistance is greater. ‘‘Our thermoplastics are

tougher and can possibly be designed ‘thinner,’

Fokker Aerostructures, the NLR, and TenCate are three of the partners in TAPAS

12 Toray Textures | Spring 2019 13Astronaut André Kuipers shows German chancellor Angela Merkel and Dutch prime minister Mark Rutte round the TenCate stand,

where the Alfa Romeo was prominently displayed

INNOVATION TENCATE AT THE WORLD’S LARGEST TECHNOLOGY FAIR

Hannover

Messe Success

for TenCate

TenCate operates at the very heart of society and makes a genuine contribution to continuing

improvements in sustainability. With its innovative products, systems, and technological

developments, TenCate often leads the way. This is one of the main conclusions that can be

drawn from the presence of TenCate at the Hannover Messe, the world’s largest industrial trade

fair, which was held April 7–11, 2014.

The fair, which was opened by the German Moreover, the use of composite enables production

chancellor, Angela Merkel, together with Dutch volumes to be adapted fairly flexibly, as was

prime minister, Mark Rutte, was inspired by the indicated in the presentation ‘‘Global Challenges,

theme ‘‘The Fourth Industrial Revolution.’’ This year, Dutch Composites.’’

the Netherlands was the partner country. There

were 270 Dutch companies present and TenCate, Inspiring presentation

which was presenting its products here for the Robert Lenferink, director of business development

first time, attracted a great deal of attention. thermoplastic composites at TenCate Advanced

Composites, was present at the Hannover Messe

Reaching out to the German car industry and gave an inspiring presentation. ‘‘With our

For TenCate, the Hannover Messe was a great great knowledge and experience of composite

success in various respects. The company took gained in the aerospace industry, the transition

advantage of the fair in part to reach out to to the car industry is opening up an entirely new

the large German car industry, which is also market. TenCate aims to reach out from small

increasingly focusing on improving sustainability. (racing) car producers to large car manufacturers

This means lighter cars that use less energy. This with countless - thermoset or thermoplastic

is an irreversible trend, as a result of European - composite components or materials for the

regulations, which oblige even cars to reduce their large-scale production of cars.’’ To this end,

CO2 emissions. This offers a golden opportunity the company is collaborating with a number of

for composite. It is not only much lighter and more strategic partners. At the fair, TenCate prominently

sustainable, but also far stronger than steel and displayed the chassis of the Alfa Romeo 4C,

thus safer. And safety is also of great importance

on roads that are becoming ever more congested. Continued on page 16

14 Toray Textures | Spring 2019 15CONTINUED FROM PAGE 15 MOBILITY TENCATE COMPOSITES FOR AVIATION, AEROSPACE, AND AUTOMOTIVE

produced by Adler in Italy, with thermoset incorporated more and more into the interior. So companies) and the OEMs, such as companies in

composite from TenCate. Producer voestalpine it’s a case of green being combined with growth.’’ the aviation, aerospace and automobile industries.’’

Polynorm from Bunschoten (NL) is our partner for

undertrays, as is Kringlan and Sabic for wheel Increasing need for composite Industry 4.0

rims, which have already been certified. Weight ‘‘In view of the expected growth in the number This last industry also offers opportunities for

savings of no less than 50 to 70 percent have been of daily flights from 84,000 in 2011 to 170,000 in TenCate, a pioneer in the field of thermoplastic

Far, Far Away

achieved on these car components. 2030, the need for composite will only increase,’’ composite. And the problem area fits in

he continued. ‘‘Such an increase can also be seamlessly with the theme of the Hannover

Aviation industry continues strong growth attributed to other advantages of composite: they Messe in respect of the smart factories of Industry

TenCate has for many years had a prominent suffer less corrosion and material fatigue than 4.0, in which TenCate also plays a proactive

presence in the aviation industry with its traditional aluminum aircraft structures. This role. In this concept, the supply chain for value

thermoplastic composites. Thermoset composite means that a large-scale revision will need to take creation is being increasingly optimized. The

from TenCate is widely used in the space industry. place only once every 13 years, instead of every use of the internet and further digitization and

During his presentation, ‘‘Global Challenges, six, which will make a considerable difference automation or robotization will lead to flexibility in

Dutch Composites,’’ Arnt Offringa, director of R&D in costs. Moreover, it will make it possible to production and volume. The use of raw materials

of Fokker Aerostructures, indicated a number of construct larger windows and the pressure and is more efficient and there is a much improved From its production locations in Morgan Hill and Fairfield, CA, in the United States, TenCate savings needed. Astro Aerospace is a business

interesting longer-term trends. These are partly thus the moisture level in the aircraft can be higher. response to customer requirements. Philips, supplies a wide range of composite materials for communication, military, and research unit of Northrop Grumman, a North American

the result of the increasing use of composites This will all contribute to a greater degree of Fokker, and TenCate with Xennia are pioneers satellites, as well as for launch vehicles. defence, aviation, and aerospace company.

in aircraft. ‘‘Since 2000 the aviation industry comfort for the traveler,’’ claimed the R&D director with smart factories, together with partners such ‘‘TenCate Cetex® thermoplastics are integral

has grown by some 53 percent, whereas fuel of Fokker Aerostructures. as the University of Twente and the Noordelijke to the structure of our mesh reflectors,’’ states

consumption has increased by only 3 percent,’’ Ontwikkelings Maatschappij (NOM). In the words Satellites utilize high-modulus (high-stiffness) development of microsatellites, which are to Daniel Ochoa, product development manager

Arnt Offringa stated. ‘‘In addition to much more Opportunities and potential of Hans Praat, project developer of the NOM: carbon fibers combined with tailored resin be deployed in large numbers to allow internet at Northrop Grumman’s Astro Aerospace. ‘‘They

fuel-efficient engines, an important factor is the Harald Heerink, general manager of the leading ‘‘The Netherlands has a leading position in this systems for the production of structures on the access in far regions. Research satellites serve help to create the parabolic shape of the antenna.

great increase in the use of lighter composite global ThermoPlastic composites Research Center compared with Germany. With smart factories satellite, including solar arrays, booms/trusses, a variety of specialized purposes. For example, The material has been extensively tested as

materials in the leading edge, tail sections, (TPRC) in Enschede, also placed great emphasis complex processes become more customized reflectors, and bus structures. Solar arrays are they may be used to measure atmospheric part of the unit prior to flight, and is durable

and recently in the wings and fuselages of the in Hannover on the opportunities for the material and intrinsically intelligent, as well as faster used to provide power to the satellite while changes, weather, and climate change. and stiff, which is critical to the functioning

A350 and Boeing 787. Composite is also being and its potential. ‘‘Thermoplastic composite is and more meticulous.’’ it is in space; booms/trusses hold equipment of the antenna.’’

inherently suitable for use in efficient high-volume and solar arrays to the main structure of the AstroMesh®

production, such as that in the car industry,’’ he • At the Hannover Messe, TenCate was satellite; and reflectors are the communication On January 31 2015, NASA launched its Soil Launch vehicles: weight and cost reduction

said enthusiastically. ‘‘It makes very fast processing reaching out to the German car industry, disks that are used to upload and download Moisture Active Passive (SMAP) satellite. Launch vehicles (rockets) use standard- and

cycles possible. Moreover, it has greater which is increasingly focusing on greater satellite communications that enable data TenCate Advanced Composites provided Astro intermediate-modulus (moderate-stiffness)

toughness, and offers the possibility to weld sustainability transmission with mobile phones, the internet, Aerospace with TenCate Cetex® thermoplastic fibers. These fibers are impregnated with

components using a variety of technologies, in • The use of composite in aerospace means HD television, military communications, and composites for the AstroMesh® reflector on this thermoset epoxy-based resin systems (prepreg)

addition to higher chemical resistance to corrosion less corrosion and material fatigue, analytical instruments. spacecraft. The SMAP spacecraft will provide to create the rocket structure. The structures

and solvents. It is also, relatively speaking, a less revision, and makes it possible global measurements of soil moistures and indi- on launch vehicles are typically large and can

very safe material in the event of fire and also to construct larger windows and it Satellites cate whether it is frozen or thawed. The data be very heavy as a result. So the lightweight

in relation to the development of smoke and contributes to greater passenger comfort Communication satellites enable internet, will be used to understand the processes that composite materials from TenCate are used to

poisonous gas. And, last but not least, there is the • A relatively limited number of smaller television, and mobile phone communications. link Earth’s water, energy, and carbon cycles and replace metals such as aluminum and titanium

possibility of recycling and reusing the material, producers of composite means thin supply The need and the desire for mobile phones, improve weather and climate prediction models. for weight savings. Since the cost to launch

thus also making the composite sustainable.’’ chains between chemical companies and digital television, and internet connectivity The 6-meter-long AstroMesh® reflector, which a satellite is driven primarily by the weight of

Harald Heerink pointed out that there are also companies in the aviation, aerospace, are all driving the demand for communication will spin atop the spacecraft at nearly 15 the payload, reducing the weight is critical for

problem areas regarding its use. ‘‘Due to the and automobile industries satellites. Military satellites provide Earth, revolutions per minute, provides for total global cost savings. Additionally, TenCate materials

relatively limited number of smaller producers of observation, secure communication, GPS mapping every 2 to 3 days. The reflector uses are valued since they may be cured in large

composite there is a thin supply chain between location/navigation, early warning, and weather TenCate Cetex® thermoplastic composites to

Arnt Offringa: ‘‘Green combined with growth’’

the suppliers of the basic materials (chemical information. A new trend that has begun is the achieve the strength, durability, and weight Continued on page 18

16 Toray Textures | Spring 2019 17CONTINUED FROM PAGE 17

ovens under low pressure, which is a very protection group worked closely with TenCate Making a difference

valuable characteristic, as curing the parts in Advanced Composites in North America on the Customers and end-users in both the aerostruc-

large pressurised ovens (autoclaves) would be 5-year development and qualification effort tures and the space markets, like Thales, Boeing,

very expensive due to the size of the autoclave for a range of materials used in this extreme Northrop Grumman, Space Systems Loral, and

needed. One of TenCate’s newest customers application. This Lockheed Martin spacecraft SpaceX, turn to TenCate for both technical

for composite materials is SpaceX. was successfully launched as a trial at the end reasons (such as product characteristics) and for

of 2014. The TenCate materials in this space customer support reasons. First and foremost,

Orion space capsule capsule replaced the traditional titanium solution TenCate has perhaps the largest suite of materials,

In 2010, a heat-resistant composite resin was for reentry and splashdown requirements, while well-documented flight history, and an enormous

developed by TenCate and provided for the heat saving weight and cost. The composites from range of technical data on its materials for

shield (with a 5-meter diameter) and the backshell TenCate used on the heat shield design allow satellite and launch structure materials. Unique

structure of NASA’s Orion crew vehicle. very large composite structures to be fabricated data such as radiation resistance, thermocycling

Lockheed Martin Space Systems Orion thermal out-of-autoclave. and microcrack resistance, and low outgassing

TenCate Advanced Composites provided Astro Aerospace with TenCate Cetex® thermoplastic composites for the AstroMesh® reflector

are required for our customers to successfully toward more rapidly deployable architectures • With a view to weight savings, metals

apply our materials to their application. We also (designs), and will be putting hundreds of lower such as aluminum and titanium for launch

provide industry-leading response times and cost satellites into orbit. This is creating a need vehicles are replaced by the lightweight

on-site technical support for our customers, for materials with similar properties to the composite materials from TenCate

which further helps to differentiate TenCate traditional satellite materials from TenCate, • Launch vehicles are now being developed

from our competition. but that can be produced faster and at a lower that are either reusable or very low cost

cost. The space market is experiencing rapid and satellite manufacturers are shifting to

Rapid change innovation, expansion, technology adoption, more rapidly deployable architectures

The space and satellite market is an area of and change. TenCate is paying very close

extreme innovation and rapid change. Launch attention to these trends so we can maintain our info@tcac-usa.com

vehicles are now being developed that are leadership role in the market as it evolves.

either reusable or very low cost. Rather than

spending over $200 million on a single launch, • A satellite structure experiences very

satellite operators will be able to put satellites intense loads during the actual launch TenCate materials have traveled >4 billion

miles from Earth on NASA’s New Horizon

in orbit for dramatically lower cost. On top of of the satellite into orbit, and in space

The Orion space capsule from Lockheed Martin with TenCate materials was successfully launched as a trial at the end of 2014 spacecraft

lower costs, satellite manufacturers are shifting is exposed to extreme temperatures

18 Toray Textures | Spring 2019 19BUSINESS DEVELOPMENT TENCATE PARTNER IN AEROSPACE CLUSTER

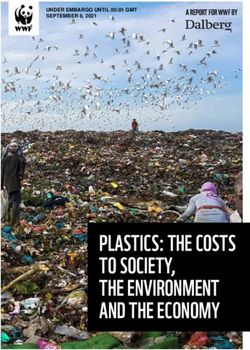

One of the aircraft types built by the Chinese aircraft manufacturer COMAC

D²RAGON: Aerospace Cluster in China

The Netherlands has comprehensive knowledge infrastructure and expertise in aerospace. This makes our country an attractive partner helicopters. The company, which has a production governments (G2G) for technological, industrial, and Chinese students at Dutch colleges and universities

for the rapidly growing Chinese aircraft industry. In April 2014, the government and a number of companies, including TenCate, signed a site in China for aircraft wiring, has had contacts academic cooperation, the development of com- that provide courses in aeronautical engineering,

covenant for cooperation in this field: D²RAGON. Within its Asia strategy, TenCate is already working jointly with players in Chinese aerospace. with aircraft manufacturer COMAC (Commercial mercial activities and involvement in the ‘‘concept which will benefit long-term cooperation.

The two programs in this twin-track approach can strengthen each other. Aircraft Corporation of China) for quite some time. definition phase’’ of the 929-wide body of COMAC.

Just as the D²RAGON partners, it sees the potential In the medium term, they intend to conclude at least Involved with D²RAGON

Partners for International Business (PIB) is a a network organized by the government (Dutch Technologies are two companies within D²RAGON for growth in the field of composites for aircraft two contracts with COMAC for development and The contacts for D²RAGON on behalf of TenCate are

public-private program for groups of Dutch Development and Research in Aeronautics supported that are already operating in the Chinese aviation designed and produced by China. design. The goal in the long term is to generate a Raoul Starmans (business development manager,

companies and knowledge institutes that have the by Government Organized Network). The contribution market. As part of its Asia strategy, TenCate has minimum of €50 million in revenues annually. TenCate for Greater China) and Harm Albers (sales

joint aim of entering a foreign market in one of the of TenCate consists of technological knowledge and concluded agreements for cooperation with major G2G and K2K manager, TenCate Advanced Composites). Raoul

top sectors. One of these sectors is High-Tech materials. players in the Asian aviation industry. Networks and D²RAGON focuses on establishing a good and stable K2K (exchange of knowledge) is also a part of the Starmans organizes the local representation of

Materials & Systems, such as composites. Part partnerships are being established and expanded. market position for the Dutch aerospace cluster in program. Chinese aircraft manufacturers can make

of PIB is D²RAGON. This includes research and Networks and partnerships Fokker Aerostructures incorporates composite China. Its short-term objectives include entering use of Dutch knowledge and expertise in the field

development in aerospace with the support of TenCate Advanced Composites and Fokker from TenCate into lightweight parts for aircraft and into an agreement between the Dutch and Chinese of aerospace. The aim is to increase the number of Continued on page 22

20 Toray Textures | Spring 2019 21CONTINUED FROM PAGE 21 BUSINESS DEVELOPMENT TENCATE ADVANCED COMPOSITES LAUNCHES IN THE UNITED KINGDOM

TenCate composite technologies for the next gener- ening the image and the reputation of Dutch

ation of Chinese commercial aircraft. Harm Albers industry. They support the valuable contacts that

was co-signatory to the D²RAGON covenant. the Dutch government has made for us in China

and from which we can benefit. The TenCate

What are the advantages of this program? Asia strategy is more ‘work on the ground,’

‘‘The cluster offers a wide range of technologies. with a strategy focused on the sale of our mater-

You enter the Chinese market together and can ials. Our products will not be used until they have

thus strengthen each other. The government been qualified. We must continue to be very alert

bears part of the costs and helps to raise the in our operations so as to enable new aerospace

awareness of companies at trade fairs and applications to be found for our materials. This Raoul Starmans, business development

seminars and by making high-level contacts requires close cooperation with partners in the manager, TenCate for Greater China

with Chinese company and government officials. supply chain.’’

Companies like Fokker already have local produc- The former Amber Composites is an important supplier

tion and their presence is an advantage for us. What opportunities are there in China for of prepreg systems and materials to the Formula 1 market.

The United Kingdom is at the heart of Formula 1 racing.

Thermoplastic composites for aviation applica- TenCate composites?

tions are relatively new for China and knowledge ‘‘China is a world power with excellent growth

of them is still very limited. Fokker can make potential in commercial aviation, therefore we

high-grade components from our composites, and are already having talks with other players,

Amber Composites Celebrates

it leads the way here in terms of thermoplastic including COMAC. There are also opportunities

technology. The combination of TenCate (material for other applications, such as satellites, but

development) and Fokker (part manufacturing) these may not legally be exported and, of course,

Anniversary with New Name

works well. COMAC is favorably disposed to an we respect that. So we shall deal only with

Harm Albers, sales manager, TenCate

open business model in which close cooperation commercial aviation and with composites for the

Advanced Composites

with suppliers plays an ever more central role.’’ automotive industry.’’

What does the PIB program mean for TenCate? How can you prevent knowledge ending up with • TenCate is a partner in D²RAGON, which On Wednesday, October 2, 2014, Amber Composites Limited, based in Langley Mill The TenCate Advanced Composites group

‘‘This year, there are G2G and K2K activities on third parties as a result of cooperation? focuses on building a good and stable (Nottingham, UK), celebrated its 25th anniversary, marking this special occasion with manufactures both thermoplastic and thermoset

the program. Together with the PIB consortium ‘‘You see that a particular need arises, for which market position for the Dutch aerospace an identity change to TenCate Advanced Composites. Sixty invited guests (customers, composite materials. The thermoset activities

we are taking part in trade fairs and promotional our materials are certified and that there is a cluster in China suppliers, associates, and other business partners) gathered together to celebrate were formally concentrated in Morgan Hill

activities, and there are airshows in China and local need for technical people who could • Thermoplastic composites for aerospace the anniversary and the change in name. (United States) and focused mainly on the

Europe, network meetings, and trade missions. take this on. China has a significant amount of applications are relatively new for China. space and aerospace sector (satellites and

These activities promote the reputation and catching up to do in the field of thermoplastics, TenCate and Fokker Aerostructures have communication). The main product lines at

image of a strong and united Dutch aerospace but they are working on this at two research detailed knowledge of the technology and the Langley Mill (UK) site are composite tooling

industry. Furthermore, TenCate would welcome institutes. These are low-grade thermoplastics application of thermoplastics prepreg (TenCate AmberTool®), structural

a combined company visit from a Chinese dele- for consumer electronics, for example. On the • D²RAGON and the TenCate Asia strategy form a component prepregs, and various honeycomb

gation to TenCate Advanced Composites, Fokker high-tech side, we have a headstart, based on a twin-track approach and reinforce each other cores. The honeycomb cores range includes

Aerostructures, and other members of twenty-year learning curve and this we of course aluminum, Nomex®, or Kevlar®. These products

the consortium.’’ want to hold on to as far as possible. Would are used in Formula 1 and high-performance

this completely block local production in China? automotive, as well as for commercial aviation,

To what extent can D²RAGON and the TenCate It seems possible to set out clear frameworks marine, and other industries.

Asia strategy strengthen each other? for this and to deal extremely cautiously with

‘‘The two strategies run parallel and strengthen acquired intellectual property and its protection. Formula 1 – highly demanding market

each other. This is a twin-track approach: the Let´s not forget that the Chinese market will Around 60 invited guests gathered together that day in Langley Mill (Nottingham) to celebrate The market for Formula 1, sports, and luxury cars

one is a collective effort by the Dutch aerospace develop anyway. It is quite conceivable that the anniversary and change in name

cluster. You can see it as a trailblazer. The other assembly will take place there.’’ Continued on page 24

is more sales-oriented. The PIB aims at strength-

22 Toray Textures | Spring 2019 23Composite

Composite Tooling

Tooling Prepreg

Prepreg

CONTINUED FROM PAGE 23

is relatively new to TenCate. It is an innovative industry and is keen to develop materials for day was an excellent opportunity to explain to

and highly demanding market noted for rapid all aspects of the vehicle. customers and other stakeholders just what

developments. A racing car is made up of more our plans with the company actually are,’’ says

than 5,000 components, and after each race Strengthening activities Frank Meurs (group director, TenCate Advanced

up to 20% of these are replaced or upgraded. Through the acquisition of Amber Composites, Composites EMEA). ‘‘Besides the new, modern

Thermoset composite materials have been used TenCate Advanced Composites can also production site, we presented TenCate as company.

in this industry for many years. New material strengthen its thermoset activities within the And the feedback we received from our guests,

innovation or a new technology can quickly European communication and satellite industry. including some Formula 1 teams, was very positive.’’

prove itself here–unlike in the aviation industry, TenCate continues to invest in the development

where new product introduction can take many and production of prepregs, as well as in the TenCate AmberTool®

years to certification approval to fly. The United necessary technical support in test equipment In September 2014, TenCate Advanced

Kingdom is at the heart of Formula 1 racing, with and manpower to support substantial growth. Composites launched a rebranded series of

no less than eight of the eleven F1 teams being For the domestic UK market, this means prepregs for composite tooling under the name

based within a 40 mile radius of the Silverstone competitive materials, supplied more quickly TenCate AmberTool®. This portfolio incorporates

race circuit. The former Amber Composites is an and efficiently. The Langley Mill facility (formerly the original heritage of the former Amber

important supplier of prepreg systems and mater- Amber Composites location) is now the center Composites’ tooling range with tooling prepregs

ials to this market. For example, the TenCate of excellence when it comes to the production of available from TenCate Advanced Composites

E745 resin system is used in high-impact struct- thermoset prepregs for Europe. Working together USA, and use is made of the 3M nanosilica

ures. From the start of 2014, this will be the with their USA colleagues, markets fortified-resin technology. New opportunities for

only material qualified and specified for use in will be developed where the strengths of its application can be found within the motor racing,

side impact structures of all Formula 1 cars. materials development can really benefit the aviation, marine, and prosthesis industries.

The Langley Mill business is dedicated to this industry and customer base. ‘‘The rebranding

• TenCate Advanced Composites is an

important supplier of prepreg systems

and materials to the Formula 1 market

• In cooperation with their USA colleagues,

markets will be developed where the

strengths of its materials development can

benefit the industry and customer base

• The TenCate AmberTool® portfolio

incorporates the former Amber Composites’

tooling range with tooling prepregs

available from TenCate Advanced

TOOL

TOOL ING

ING REINVE

REINVE NT

NT EE D

Composites USA

Frank Meurs (second from right) and Nick Tiffin (respectively group director and director of sales & marketing

www.tencatecomposites.com/tooling

D

of TenCate Advanced Composites EMEA) gave a presentation explaining the reasons for the TenCate acquisition tcacsales@tencate.com

of Amber. They also outlined their vision for the future of the company and the composite group.

24 Toray Textures | Spring 2019You can also read