TECHNICAL ISSUES FOR CANNELLONI AT HIGH POWER

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

TECHNICAL ISSUES FOR CANNELLONI AT HIGH POWER

K. Thomsen1, F. Heinrich1, M. Butzek2, J. Wolters2, F. Sordo3, A.I.S. Holm4

1

PSI, 2FZ Jülich, 3ESS Bilbao, 4Aarhus University

Abstract for use in the ESS target. As the history of PSI´s main

Quite diverse concepts for targets have been proposed spallation neutron source SINQ shows, a cannelloni target

for ESS. While there is no doubt that different approaches does not only produce neutrons very reliably at a

are possible in principle, here it is argued that a large new performance level comparable to liquid metal targets, but

neutron production facility, prepared for operation at an it also allows for stepwise and gradual improvements of

unprecedented power level, should rely as much as the neutronic yield as experience is gained over the years

possible on proven technology. The neutron spallation [1]. Recently, a second spallation neutron source for ultra

sources SINQ and UCN at PSI feature as their standard a cold neutrons, UCN, has been taken into operation at PSI,

solid state target consisting of Zircaloy tubes filled with relying on a very similar cannelloni target as in SINQ.

lead (“cannelloni”). These targets are cooled with heavy The UCN case is geared for operation with only one

water. SINQ is currently being operated for the second target for the whole lifetime of the source in the order of

decade at a power level of about 1 MW. A first quick 30 years [2]. SINQ operates in DC mode at a power level

assessment of the suitability of this target type for ESS of 1 MW, UCN takes the full power of the proton beam in

conditions gives encouraging results but a wide variety of a pulsed mode, at a duty cycle of 1 percent.

technical questions has still to be addressed in more Suggesting a step from 1 MW continuous mode to 5

detail. In particular, the limits of water cooling in an ESS MW pulsed operation, three immediate questions arise,

configuration, together with associated issues concerning i.e. can such a target be cooled, does it produce enough

transient loads and reliability shall be dealt with in this neutrons, and how long would it survive.

paper. Possible paths for optimization as well as proposals The initial preliminary assessment showed promising

for promising configurations are sketched. performance in all respects of a target of the cannelloni

type under ESS conditions [3,4].

INTRODUCTION & MOTIVATION Given the positive first evaluation and the undoubted

advantages of a water-cooled solid state target of the

The good experience accumulated at the Paul Scherrer

SINQ type with respect to licensing and safety issues,

Institute, PSI, over 14 years of successful operation of

work has started aimed at gaining a more complete

water-cooled solid state targets of the “cannelloni” type

understanding of possible cannelloni configurations and

motivates the consideration of lead-filled zircaloy tubes

their expected performance under ESS conditions.

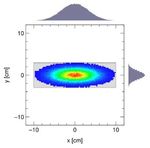

Figure 1: Evolution of the performance of cannelloni targets in PSI’s SINQ spallation neutron source. A significant

improvement of the neutronic yield over hitherto solid state targets is evidenced with the use of the MEGAPIE liquid

metal target in 2006. Switching to an optimized version “compact cannelloni” boosted the performance of the solid state

target to 85 % of the MEGAPIE yield, resulting in unprecedented neutron fluxes to SINQ users since 2009PRINCIPAL SET-UP OF WATER spallation neutron source, water cooling allows for hands-

COOLING CIRCUIT on access and consequently relatively easy maintenance

of the cooling circuit, minimizing down times and

The main advantages of water cooling are evident: therefore again contributing to the availability of the

there exists ample experience concerning this coolant installation. Although not completely trivial at a real

over a wide range of diverse conditions and thus spallation source at the MW power level, the principal

unrivalled design maturity compared to any possible lay-out of a water cooling plant comprises only 6 major

alternative. This directly translates into the reliability of components as sketched in Figure 2

the system. Second, of special importance in the case of a

Figure 2: Main components of the water cooling circuit of SINQ and UCN in the flow direction of the coolant

The good experience obtained at SINQ and UCN at PSI Whereas it is clear, that the conservative safe

and a very simple calculation confirm modest required operational regime of heat transfer from the target rod

parameter values for evacuating MWs of thermal power bundle to the coolant is lying in the convective cooling

with water. regime, it comes in very handy that water offers

In order to cool 3 MWthermal allowing for a modest substantial reserve beyond this. With subcooled boiling

temperature increase of 20 °C in the coolant, a flow of significantly enhanced heat transfer rates can be achieved

less than 40 liter per second of water is required. [5]. This guarantees that deviant beam concentrations or

other disturbances in the system can, up to a certain level,

Q = m cp ¨T safely be absorbed without endangering the cooling of the

target. Nevertheless, for a save design the limits of water

Q

…

…. transported heat [ W ] cooling have to be determined and understood as good as

m

…

…. mass flow [ kg/s ] possible for the proposed cannelloni design in order to

cp

…

…. specific heat (water = 4190 J/kg K ) prevent the target from burnout.

¨T

…

…. temperature increase in coolant [ K ]

POSSIBLE CONFIGURATIONS FOR

3 MWthermal = 35.8 kg/s · 4190 J/(kg·K) · 20 K, TARGETS OF THE CANNELLONI TYPE

i.e. ¨T = 20 K @ 36 l/s

For targets consisting in their heart of filled tubes, i.e.

“cannelloni”, many diverse configurations with their

In addition to the general benign operational

respective strength are possible. Their variation allows for

requirements associated with water cooling, also the

optimally matching the target to the prevalent beam

radiological issues relevant in a spallation neutron source

conditions and operational requirements. A stepwise

are well known and proven to be manageable. The same

optimization of the target regarding yield and reliability

holds true with respect to the selection, procurement,

of the facility can take advantage of accumulated

handling, and maintenance of the required radiation

experience gained during actual operation.

resistant components, installations, and, in particular,

A possible succession of lay-outs can be suggested,

instrumentation.

ordering targets along a dimension of design maturity,leading from well established concepts to more ambitious In the compact SINQ cannelloni target the central zone

approaches promising higher neutronic yields and is made up of zircaloy tubes filled with lead; around the

enhanced power handling capability; examples periphery, a blanket built from lead-filled aluminum rings

configurations include: minimizes water content in the target and ensures a nice

match between the beam current density distribution and

a) crossflow, along beam direction, horizontal tubes associated cooling requirements. Water flow is along the

b) „flat nose“, crossflow bottom up, horizontal tubes target axis towards the tip of the nose on the outside and

c) „flat nose“, crossflow sideways, horizontal tubes then back through the center after a 180 degree turn, see

d) „flat nose“, crossflow sideways, vertical tubes figure 3.

e) Cannelloni inserts on a platform Although this configuration is well established and

f) continuously rotating wheel supported by the best operational experience available, it

is not directly recommended for ESS as it requires

Configuration a) something like 300 cm2 cross-section, which is about

crossflow, along beam direction, horizontal tubes twice the size of the beam footprint envisioned on the

ESS target. All other configurations b) to f) discussed

This configuration with horizontal lead-filled zircaloy below can be tailored to the intended ESS geometry rather

tubes and the cooling water flowing through the target easily.

assembly along the direction of the incoming proton beam

is the starting point; both SINQ and UCN feature such Configuration b)

targets. Targets at the PSI spallation facilities have a „flat nose“, crossflow bottom up, horizontal tubes

circular cross section, but there are principal obstacles to

build this type in a narrow rectangular geometry. Tubes with lead filling have to be mounted

horizontally. This makes it possible to have a gas volume

on the top of the lead surface extending over the full

length of a cannelloni tube, allowing for unconstrained

volume changes of the lead as a consequence of different

temperatures and melting or solidification during

irradiation and especially in the case of beam trips. A

principal sketch of horizontal cannelloni, perpendicular to

the beam and cooled by water flow from bottom to top is

given in Figure 4.

Figure 3: Current generation cannelloni target as used in

SINQFigure 4: Tubes arranged perpendicular to the proton beam can be cooled by cross flow from bottom to top while

keeping the necessary water volume between the spallation zone and top- and bottom moderators at a minimum. Left:

feeding and draining lines running sideways along the target can be optimized in order to match the different cooling

requirements of different zones in the spallation zone. Cross sections in the figure are not drawn to scale. Right: coarse

CFD simulations confirm the feasibility of sufficient coolant throughput.

Configurations c) and d) similar to a liquid metal target will definitively be

„flat nose“, crossflow sideways, horizontal or vertical required; providing some water on the top and bottom of

tubes the spallation zone already inside the proper target

module could obviate the need for a separate pre-

Further reduction in the thickness of coolant between moderator.

the spallation zone and the moderators could be achieved A clear advantage of arrangements of cannelloni along

by orienting cannelloni parallel to the proton beam the beam as depicted in figure 5 or with vertical rods lies

direction. This brings the dimensions of a water-cooled in the fact that such configurations can easier be adapted

bundle target closer to the shape of e.g. a liquid metal to a homogenous distributions, necessary for an ultimate

target in the vertical direction. It is not clear that this goal of a wheel target and continuous rotation.

actually provides a benefit, as then a pre-moderatorFigure 5: Feed and drain connections are even less in the way to the moderators with horizontal cannelloni oriented

parallel to the proton beam or vertical.

For the case of vertical tubes, in essence only solid The logical step between a stationary cannelloni target

fillings are possible in order to avoid unacceptable of the SINQ-type and a continuously rotating wheel

stresses and finally failure of the tubes when fillings consists in the stepwise rotation of a platform carrying

change their volume without having a suitable gas several independent cannelloni inserts, see figure 6. This

cushion. would on the one hand allow starting up ESS with a well

established target type with high expected reliability,

Configuration e) taking advantage of the available experience, while on the

cannelloni inserts on a platform other hand it could provide the realistic test environment

for qualifying the new components required for a

Targets of the cannelloni type face their cooling limit continuously rotating wheel, i.e. bearings, drives,

around 5 MW, given the reference ESS beam footprint feedthroughs, gaskets and the like.

size and current density distribution. One way to When an insert reaches its end of life, the platform

overcome this constraint and go to higher powers has would turn and bring the next insert into the active

been proposed as moving to a continuously rotating wheel operating position with a minimum down time of the

target, effectively multiplying the time available to facility; when all inserts on a platform are consumed, the

evacuate the heat deposited in the spallation zone by the complete platform would be replaced with a new one.

proton pulses.

Figure 6: Artist’s impression of a platform carrying three independent cannelloni inserts as well as a test installation for

components required for continuous rotation.Configuration f) on a well established basis and driving the evolution to

Continuously rotating wheel higher yields and performance taking advantage of the

accumulating experience during actual operation.

A continuously rotating wheel is the natural end-point Stationary cannelloni targets provide the safe basis and

and the ultimate goal of the evolution path advocated in their mounting on a stepwise rotating platform establishes

this and previous papers, starting from the good and the required bridge for a minimum-risk approach to a

ample experience obtained over the last 14 years at PSI fully rotating wheel expectedly delivering ultimate

for cannelloni targets. In a sense, it closes a loop as a performance levels.

rotating wheel has been proposed a long time ago. The Continuing with the picture, “cannelloni” (circular

essential difference between now and then is, that what tubes with filling), could transform to “panzarotti”

once was considered as a step too big, can be broken (similar, but non-circular cross section) to arbitrarily

down into a succession of small advances, each building shaped canned tungsten blocks.

Figure 7: Principle sketch of a homogenous wheel with vertical tungsten rods cooled in cross flow.

The one essential ingredient for the here outlined Quite generally, a wide / flat beam profile relaxes

evolution path is water cooling, which is a mandatory conditions significantly for any target; reducing the

prerequisite for enough flexibility and ease of handling pointedness of the beam, i.e. flattening / smearing out the

and modification required for changes in target details intensity maximum, reduces peak loads and stresses, with

and types while leaving the overall installation and in positive effects on the lifetime and reliability of the target,

particular safety issues almost untouched. and finally on operations costs of the facility.

For the current work, the following reference beam

BEAM CONDITIONS parameters have been taken into account:

The compartmentalization of the actual spallation target

material, e.g. lead or tungsten, allows some matching 5 MW, 2.5 GeV, 2mA (average), sigmaX=5 cm,

between the current density distribution over the footprint sigmaY=1.5 cm,

of the proton beam with the material density distribution duration 1 (2) ms, repetition rate 20 Hz

inside the target. This makes an optimization of neutron corresponding to a peak current density (time

production and cooling conditions possible with all set- average) in the center of 42.44 µA/cm2

ups of the cannelloni type; the enhanced performance of

the new generation solid state targets at SINQ bears In a simple model of lead-filled cannelloni, bringing

witness to that. down the maximum current density by a factor of two

At the same time, the design and cooling requirements dramatically changes the occurring peak temperatures in

are driven by the fraction of the highest loaded tubes in the most loaded tube: 920 °C ĺ 480 (center), 500 ĺ 260

the center of the beam. One way to address non-uniform (wall, inside surface), and 190 ĺ 120 °C (outside wall

cooling demands lies in tailoring the coolant flow interface to water), respectively.

according to the needs; in parallel, adapting the beam Investigating all possibilities for ensuring more gentle

profile offers a way to mitigate the peak loads and beam conditions thus deserves strong attention and

requirements. warrants substantial effort; Figure 7 depicts the reference

beam profile, and also a feasible alternative.Figure 8: Current density distribution over the footprint of the incoming proton beam. Left: reference beam conditions;

right: one example of a “flattened” beam profile obtained by adding two octupole magnets in HEBT.

There are several ways to improve the reference beam. gaining experience and qualifying of new required

One possibility to achieve a uniform average beam components for which no information exists concerning

distribution on the target consists in “painting”, i.e. their performance and limits under the peculiar radiation

moving a rather narrow beam over the target, such that in conditions of a spallation source.

sum a flat distribution is generated. This option does not As a starting point, simulations have been performed by

appear to be advantageous in the case of a pulsed different groups, for a set-up where a liquid metal (LBE

spallation target as it will induce enhanced dynamic loads or mercury) target has been replaced by a cannelloni

caused by the temperature fluctuations occurring at any insert of identical outside dimensions and internal

point which is intermittently hit and heated by a rather composition like in SINQ [3,6,7]. This is work in

highly concentrated beam, or not at all, during successive progress, and no full agreement has been achieved yet

pulses. concerning the baseline yield of a cannelloni target with

The promising way to a flat and gentle beam profile is zircaloy tubes filled with lead and cooled by (heavy)

via proton beam optics. On this topic there is work in water. The most recent results exhibit the widest

progress; Figure 7 right shows an example of a flattened discrepancy; for somewhat different detailed parameters,

beam. Adding two octupole magnets in HEBT (High values of 58 % and 82 % performance compared to an

Energy Beam Transport between the active accelerator LBE target are obtained [6,7]. Efforts to understand and

section and the target) readily reduces the peak in the harmonize the differences are underway.

proton beam current density distribution by 35 %, and a

reduction of up to 60 % compared to a Gaussian beam

intensity distribution appears possible. With a

sophisticated multipole system even a flat profile (+/- 7

%) over 200x50 mm can probably be achieved.

NEUTRONIC PERFORMANCE

In the end, the ultimate purpose of building a neutron

spallation source lies in the reliable production of

neutrons with a useful and suitable flux level. Different

target configurations and also the beam current density

distribution have a decisive influence on the achievable

performance of a neutron spallation source [3,6,7].

The argument for starting ESS with a cannelloni type

target is not so much based on the reliable expected

neutronic performance of such a target under ESS Figure 9: One preliminary result: Cannelloni produce 82

conditions, but rather on the safe stepwise approach % of the neutrons obtained from an LBE target. This

towards optimum dense targets after some period of result has been achieved with H2O for the coolant [7].Whatever the finally established baseline performance Enhancing the brilliance of the original source term is a

of a cannelloni target under ESS conditions will be, some sure way to boost the useful neutron flux; replacing lead

things are clear from the outset. by tungsten increases density and brilliance and

Using heavy water (D2O) will enhance the neutron flux subsequently the neutronic yield. Figure 10 illustrates this

out of the target and finally the flux available to the effect.

instruments at the end of the beam lines.

Figure 10: Impact of target density. Left: replacing the lead filling in cannelloni with tungsten almost doubles the

energy deposition in the peak, leading to a much more confined spallation zone and thus brightness of the underlying

neutron source term. Right: in an example for a continuous wheel, increasing the density from 75 to 100 % tungsten still

has a significant beneficial effect on neutrons emanating the moderator.

CONCLUSIONS colleagues at PSI. The contribution of Figure 1 by K.

Geissmann (PSI) deserves specific mention, the same

It is fair to state that targets of the cannelloni type

applies to Figure 8 and H. Danared (ESS). Special thanks

feature a unique design maturity and convincing history

go to G. Heidenreich, who contributed most substantially

of successful operation. Starting ESS with a target based

to the content of this paper.

on cannelloni appears to offer a minimum risk approach,

in particular, with respect to safety issues.

Taking advantage of 14 years of SINQ operation,

REFERENCES

limited development effort is required and very high [1.] W. Wagner, B. Blau, H. Heyck, E. Lehmann, K.

reliability can be expected. Thomsen and M. Wohlmuther, Status and

Water-cooling offers relatively convenient handling development of the swiss spallation neutron

and allows for high flexibility and opens possibilities for sources SINQ & UCN, ICANS XIX, Grindelwald,

improvements as operational experience is acquired. Most March 8-12, 2010.

important, cannelloni offer the widest range of options for [2.] M. Wohlmuther and G. Heidenreich, The

improvements allowing for an evolutionary path towards spallation target of the ultra-cold neutron source

very dense, high performance wheel-based targets at UCN at PSI, NIMA 564, 51-56, 2006.

power levels exceeding 5 MW. [3.] K. Thomsen, M. Butzek, F. Gallmeier, F. Heinrich

Relatively low building-, operations- and and J. Wolters, A Case for a SINQ-type

decommissioning cost go hand in hand with the ease of Cannelloni Target at the ESS Power Level, NIMA

licensing and public acceptance. The price to pay is some 625, 5-11, 2010.

initial reduction in neutronic yield. [4.] K. Thomsen, M. Butzek, F. Gallmeier and J.

Wolters, Options for water cooling a SINQ-type

ACKNOWLEDGMENTS cannelloni target at high power, AccApp’11,

Knoxville, April 2011.

Part of the research leading to these results has received

[5.] M. Shah, A correlation of heat transker during

funding from the European Community's Seventh

subcooled boiling on a single tube with forced

Framework Programme (FP7/2007-2013) under grant

crossflow, Int. J. Heat & Fluid Flow 5, 13-20,

agreement n° 202247 "NeutronSourceESS". Extensive

1984.

and inspiring discussions with many colleagues from a

[6.] L. Zanini, this workshop, 4th HPTW, Malmö, May

large number of institutions collaborating since the ESS-

2011.

PP study are gratefully acknowledged. Valuable

[7.] F. Sordo, work in progress.

comments on an earlier draft have been made by severalYou can also read