Rheological properties of two high polymers suspended in an abrasive slurry jet

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

e-Polymers 2021; 21: 186–193

Research Article

Xinyong Wang, Dapeng Zhou, Guodong Zhu, and Chuwen Guo*

Rheological properties of two high polymers

suspended in an abrasive slurry jet

https://doi.org/10.1515/epoly-2021-0005

received June 24, 2020; accepted November 20, 2020

1 Introduction

Abstract: With high polymer added into suspension, the The abrasive slurry jet (ASJ) is a suspension consisting of

use of abrasive slurry jet (ASJ) has significant advantages abrasive particles and a high polymer solution, which is

in energy management. The quality and efficiency of ASJ a non-traditional machining tool (1). Cutting glass with

are affected distinctly by its structure and the flow field new water-soluble polymer is one of its applications and

feature, both of which depend on the rheological proper- was conducted by Anjajah (2), whose work showed that

ties of the abrasive slurry. Therefore, this paper carries

the polymer concentration and abrasive type affected

out a series of experiments to study the rheological prop-

the cutting depths mostly. Liao et al. (3) applied ASJ on

erties of abrasive slurry with polyacrylamide (PAM) and

the experimental glass polishing, in which the polished

carboxy methyl cellulose (CMC) commonly used in ASJ.

glass had a very small roughness. The abrasive water jet

The paper also explores the effect of temperature and

(AWJ) was compared with ASJ by Nouraei et al. (4,5) and

abrasive on the apparent viscosity of the abrasive slurry.

revealed the suppression on jet divergence by the added

Experimental results show that PAM and CMC solutions

behave as a pseudoplastic non-Newtonian fluid in the polymer. New technical cutting equipment of ASJ to cut

selected concentration range, whose apparent viscosity and drill glass was developed by Pang et al. (6,7), which

increases with the concentration. In addition, specific showed that the new equipment had advantages in the

non-Newtonian fluid constitutive equations of the power- performance of glass grooving and punching.

law model for PAM and CMC solution were obtained by Polyacrylamide (PAM) and carboxy methyl cellulose

nonlinear fitting calculation. The apparent viscosity (CMC) are the mostly used polymer additives in ASJ. PAM

decreases with the growth of temperature because it is an important type of water-soluble polymer with spe-

leads to the increase in spacing between molecules, cial physicochemical properties. It can be obtained by

making the attraction between molecules smaller and grafting or cross-linking a variety of modified structures

smaller. However, the abrasive has no influence on the of branched or network structure (8). CMC is a carboxy-

apparent viscosity of abrasive slurry for these molecular methylated derivative of cellulose, also known as the

bonds, and their mechanical entanglements are not cellulose gum, which has been widely used because of

destroyed by abrasive particles in the suspension. its many special properties, such as thickening, adhe-

Keywords: ASJ, rheological properties, high polymer, sion, film formation, water holding, emulsification, and

apparent viscosity, rotational viscometer suspension (9). Recent studies have shown that CMC

hydrogels have good biocompatibility and can be applied

to biomedical applications such as soft tissue enhance-

ments (10).

In the study of rheological properties of high polymer

* Corresponding author: Chuwen Guo, School of Electrical and

solutions, the effects of pH, concentration and reaction

Power Engineering, China University of Mining and Technology,

Xuzhou, 221116, China, e-mail: cwguo@cumt.edu.cn

temperature on apparent viscosity, and interfacial ten-

Xinyong Wang: School of Electrical and Power Engineering, China sion of surface-active polymer solutions are investigated

University of Mining and Technology, Xuzhou, 221116, China by Li et al. (11). The rheological properties of partially

Dapeng Zhou: China Coal Technology Engineering Group Huaibei hydrolyzed PAM have been improved by Hu et al. (12)

Blasting Technology Research Institute Limited Company, Huaibei,

through using silica nanoparticles for enhanced oil

235099, China

Guodong Zhu: Shandong Boran Enterprise Management Consulting recovery. Ujjwal et al. (13) investigated the rheological

Co., Ltd., Jinan, 250000, China properties of a random copolymer PAM-ran-PAH and

Open Access. © 2021 Xinyong Wang et al., published by De Gruyter. This work is licensed under the Creative Commons Attribution 4.0

International License.Rheological properties of two high polymers suspended in an abrasive slurry jet 187

polydactyly hydrazide (PAH) at different temperatures depends on the rheological properties of abrasive slurry

and salinity. Results showed that PAM-ran-PAH was in ASJ, which determines its structure and flow field fea-

more stable than PAH in saline and high-temperature ture and then affects its cutting quality and efficiency.

environments. Karimi et al. (14) investigated the rheolo- Therefore, this paper studies the rheological properties

gical, physical stability, and sensory properties of milk- of the suspension in ASJ. With the non-Newtonian fluid

jujube concentrate mixture at different concentrations category of the abrasive slurry explored, constitutive

of pectin and CMC. Senapati and Mishra (15) developed equations under different composition ratios are calcu-

a hydrostatic head viscometer and its novel viscosity lated by a nonlinear fitting model. Finally, this paper

equation to determine the flow characteristics of some investigates the effects of temperature and abrasive on

high polymer solutions. Haeri and Hashemabadi (16) the apparent viscosity of the abrasive slurry.

researched the rheology, surface tension, and contact angle

of falling film at three different CMC solution concentra-

tions. Ghannam (17,18) studied the rheological properties

of all-aqueous and aqueous/NaCl solution of PAM and 2.2 Experimental system

obtained that the solution exhibited the non-Newtonian

behavior with shear thinning and shear thickening areas. Figure 2 shows the testing system of the slurry apparent

Based on previous researches, ASJ shows great viscosity, which consists of a rotational viscometer, a

advantages in the field of material manufacturing. constant temperature water bath, a thermometer, and a

However, the rheological properties of suspension in laptop. The rotational viscometer is used for measuring

ASJ have not been fully studied, which will significantly the apparent viscosity of the abrasive slurry, the constant

affect the cutting quality and efficiency of ASJ. Although temperature water bath for keeping the temperature

rheological properties of certain high polymer solutions of slurry constant, the thermometer for monitoring the

have been researched, most of them are used in crude oil temperature of slurry in real-time, and the laptop for

recovery. Therefore, rheological properties of suspension recording the value of apparent viscosity measured by

with PAM and CMC commonly used in ASJ were studied the rotational viscometer through snoop ware.

in this paper, which can provide guidance to make up ASJ An NDJ-79A rotational viscometer was adopted in the

suspension in engineering works. experiments, which has a torque sensor that can measure

the torque of the rotor applied by tested abrasive slurry.

According to Eq. 1–3, the apparent viscosity can be cal-

culated and visualized on the screen of rotational visc-

2 Experiments ometer (19).

τ = M /(2πhr 2), (1)

2.1 Research object

γ̇ = 2w /[1 − (r / R)2 ] = 4πn /[1 − (r / R)2 ], (2)

Figure 1 shows the structure of ASJ at 10 MPa taken by a η = τ/ γ̇ , (3)

high speed camera. ASJ converges better than water jet where τ is shear stress, γ̇ shear rate, η apparent viscosity,

does, which is more distinct with the increase in high M torque, h length of the rotor, r radius of the rotor, R

polymer concentrations. The converging characteristic angular speed, and n spindle speed.

Figure 2: Experimental system: 1 – constant temperature water bath,

Figure 1: Structure of ASJ. 2 – rotational viscometer, 3 – thermometer.188 Xinyong Wang et al.

Table 1: Parameters of high polymers Table 2: Details of the experimental variables

Polymer Appearance MW DS Solid content Variables Details

PAM White particles 12 million — ≥89% High polymer PAM, CMC

CMC White powder 240.2 0.55 — Concentration (g/L) 18.52/25.93/33.33/40.74/48.15

Spindle speed (rpm) 100/150/200/250/300/350/400/

450/500/550/600/650/700/750

Temperature (°C) 20/25/30/35/40

Abrasive Garnet, 100 meshes, 10% volume

2.3 Experimental scheme fraction

PAM and CMC are the high polymer additives commonly

used in ASJ. The technical information of the two high

polymers is listed in Table 1. Choosing the aqueous solu- solution link each other through molecular bonds, form-

tion of PAM and CMC as the experimental object, this ing a net structure finally with mechanical entanglement

paper carried out three parts of experiments to study between molecular bonds. At a low shear rate, the net

the rheological properties of the abrasive slurry. First, structure destroyed by the rotor will recover in a short

to obtain the non-Newtonian category and constitutive period so that the apparent viscosity can be maintained

equations of abrasive slurry, a full factorial experiment at a higher level. However, at a high shear rate the

method was adopted under five kinds of high polymer damaged net structure cannot be recovered in time, so

concentrations and 14 kinds of spindle speeds. Selected that the apparent viscosity of PAM solutions measured is

concentrations were applicable to the ASJ system as very small.

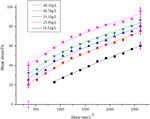

shown in Figure 2. Then, the experimental measurement In addition, Figure 3 shows that the apparent visc-

of slurry apparent viscosity was conducted under five osity of PAM solutions increases with PAM concentra-

kinds of temperatures to explore the effect of temperature tions. The intermolecular attraction of PAM solution is

on slurry apparent viscosity. very small because of the less and weak molecular bonds

Finally, the apparent viscosity of the abrasive slurry at a low PAM concentration, which caused a decrease in

with 10% volume fraction garnet (100 meshes) was mea- the apparent viscosity. However, with the increase in

sured to explore the effect of abrasive on slurry apparent PAM concentrations, hydrogen bonds between the mole-

viscosity. The details of the above experimental variables cules will increase in PAM solutions, forming a mesh

are presented in Table 2. structure gradually and increasing solution’s apparent

viscosity finally.

3 Results and discussion

3.1 Non-Newtonian fluid category of

suspension in ASJ

3.1.1 Non-Newtonian fluid category of PAM solution

Figure 3 shows the apparent viscosity of the PAM solution

at different spindle speeds and high polymer concentra-

tions. Because of the high minimum range of torque sen-

sors, the apparent viscosity of 18.52 g/L PAM solutions

cannot be measured when the spindle speed is less

than 200 rpm. The apparent viscosity of PAM solutions

declines with the increase in shear rate, which illustrates

that it is a pseudoplastic non-Newtonian fluid in the Figure 3: Apparent viscosity of PAM solutions at different shear

selected concentration range. The molecules of PAM rates and concentrations.Rheological properties of two high polymers suspended in an abrasive slurry jet 189

3.1.2 Non-Newtonian fluid category of CMC solution experimental data based on non-Newtonian fluid cate-

gory research of the abrasive slurry. With PAM and

Figure 4 shows the apparent viscosity of CMC solutions at CMC solutions being pseudoplastic non-Newtonian fluid,

different spindle speeds and high polymer concentra- the power-law model shown in Eq. 4 can be adopted in a

tions. Because of the large range of the apparent viscosity nonlinear fitting calculation:

of CMC solutions, three rotors were used to measure it at a

τ = kγ̇ n, (4)

suitable PAM concentration. Therefore, three different

shear rates correspond to one spindle speed. where k is a consistency coefficient, which represents the

As shown in Figure 4, the apparent viscosity of the average viscosity of the fluid; n is a flow index, which is a

CMC solution decreases with the increase in shear rate as measure of the deviation of fluid from Newtonian.

well as the PAM solution. Similarly, the CMC solution is a

pseudoplastic non-Newtonian fluid too. The CMC solu-

tion is the same as the PAM solution in the molecular 3.2.1 Non-Newtonian fluid constitutive equation of PAM

structure, which looks like a net with molecular bonds solution

and its mechanical entanglement. Moreover, the apparent

viscosity of a CMC solution increases with the CMC con- Figure 5 compares the rheological properties curves of

centration, which is similar to the PAM solution. The only PAM solution at different concentrations, which illus-

difference is that the CMC solution is much larger than trates the relationship between the shear stress and the

the PAM solution in apparent viscosity at the same con- shear rate. The shear stress increases sharply at the lower

centration and shear rate. Therefore, the CMC solution is range of the shear rate, whereas it increases slowly at the

much larger than the PAM solution in intermolecular higher range, leading to a similar conclusion of non-New-

attraction with stronger molecular bonds and more com- tonian fluid mentioned in Section 3.1. As shown in Table 3,

plicated mechanical entanglement. this section also obtained the specific constitutive equa-

tion of PAM solution at different concentrations through

the nonlinear fitting calculation.

In Table 3, Ek and En represent the standard deviation

3.2 Non-Newtonian fluid constitutive of consistency coefficient k and flow index n, respectively.

equation of suspension in ASJ All ratios of the standard deviation to the consistency

coefficient are about 10%, whereas ratios of the standard

To explore the rheological properties and get the non- deviation to flow index are under 5%. R2 is the fitting

Newtonian constitutive equation of the abrasive slurry confidence of the constitutive equation of PAM solution,

at different high polymer concentrations, the section whose values are more than 0.98. A high value of R2

used Origin software to carry out nonlinear fitting for shows the consistency between the experimental data

Figure 4: Apparent viscosity of CMC solution at different shear rates

and concentrations. (a) Concentrations: 25.93–48.15 g/L, (b) con-

centration: 18.52 g/L. Figure 5: Rheological properties curve of PAM solution.190 Xinyong Wang et al.

Table 3: Results of nonlinear fitting calculation for PAM solution

Concentration (g/L) Equation k Ek n En R2

18.52 τ = kγ̇ n 0.078 0.012 0.845 0.019 0.995

25.93 0.516 0.051 0.632 0.013 0.996

33.33 1.015 0.129 0.555 0.017 0.991

40.74 1.758 0.163 0.491 0.012 0.993

48.15 3.241 0.358 0.427 0.015 0.987

and fitting results, which can reveal the rheological prop- and PAM solutions, which indicates that CMC solution is

erties of PAM solutions veritably. larger than water and PAM solutions in viscosity. The

Table 3 also shows that all values of consistency coef- viscosity of a CMC solution increases with the growth of

ficient k are much larger than the viscosity of water concentration. In addition, flow index n will decrease

(0.001 Pa s), which indicates that PAM solutions are gently with the increase in CMC concentration. The CMC

larger than water in viscosity. In addition, the viscosity solution shows the rheological characteristic of shear-

of PAM solutions increases with the growth of concentra- thinning, obviously among the concentration range in

tion. Flow index n will decrease distinctly with the experiments.

increase in PAM concentrations. PAM solution is similar

to the Newtonian fluid at lower concentrations, whereas

it shows the rheological characteristic of shear-thinning 3.3 Effects of temperature on the apparent

at higher concentrations.

viscosity of suspension in ASJ

To explore the effect of temperature on slurry apparent

3.2.2 Non-Newtonian fluid constitutive equation of CMC viscosity, this section measured the apparent viscosity of

solutions PAM and CMC solution under a constant shear rate

(2616.67 s−1) and different temperatures. With five kinds

Figure 6 compares the rheological properties curves of of concentrations and temperatures listed in Table 2, the

CMC solutions at different concentrations, which illus- experimental scheme for PAM solutions does not change,

trates the relationship between shear stress and shear whereas the experimental scheme for CMC solution has

rate. The shear stress increases sharply at the lower range been changed for the limitation of the measuring range of

of shear rate, whereas it increases slowly at the higher the rotational viscometer. Lower concentrations were

range, corresponding to the result of non-Newtonian used to study the effect of temperature on the apparent

fluid in Section 3.1. As shown in Table 4, this section viscosity of CMC solutions.

also obtained the specific constitutive equation of CMC

solutions at different concentrations through the non-

linear fitting calculation.

In Table 4, Ek and En represent the standard deviation

of consistency coefficient k and flow index n, respectively.

R2 is the fitting confidence of the constitutive equation of

CMC solutions. The fitting calculation for CMC solution at

the lowest and highest concentrations is less precise, in

which ratios of the Ek exceed 15% and ratios of the En are

about 10%. However, it is accurate among the middle

concentration range. In this range, most of the ratios of

the Ek and En are less than 5% with high fitting confi-

dence, and R2 are more than 0.99. Overall, the results

of the nonlinear fitting can reveal the rheological proper-

ties of CMC solutions.

Table 4 also shows that all values of consistency

coefficient k are much larger than the viscosity of water Figure 6: Rheological properties curve of CMC solution.Rheological properties of two high polymers suspended in an abrasive slurry jet 191

Table 4: Results of nonlinear fitting calculation for CMC solutions

Concentration (g/L) Equation k Ek n En R2

18.52 τ = kγ̇ n 5.745 1.401 0.394 0.033 0.934

25.93 6.098 0.298 0.409 0.009 0.995

33.33 6.858 0.429 0.467 0.011 0.994

40.74 14.857 0.709 0.431 0.010 0.994

48.15 16.202 2.438 0.490 0.031 0.962

Figure 7 shows that the apparent viscosity of PAM 3.4 Effects of abrasive on the apparent

solutions is affected by temperature distinctly and is viscosity of suspension in ASJ

inversely proportional to temperature, especially at the

lower concentration. The reason is that the spacing To explore the effect of abrasive on the apparent viscosity

between molecules of PAM solutions increases with tem- of the abrasive slurry, 80 mesh garnet was adopted in an

perature, causing a smaller attraction between molecules. experiment, whose volume fraction was constant (10%).

The internal fraction is proportional to the attraction It has been widely used in AWJ cutting machines, and the

between molecules, which determines the apparent visc- volume fraction is suitable for material manufacturing

osity of PAM solutions. The apparent viscosity of PAM with ASJ. The concentration of high polymer is 18.52 g/L

solutions at lower concentrations is apt to be affected in the experiment that the apparent viscosity measure-

by the change in temperature. ment of PAM and CMC solutions can be in the same range

Figure 8 shows that the apparent viscosity of CMC of shear rates.

solutions is affected by temperature distinctly and has As shown in Figure 9, PAM and CMC solutions with

an inversely proportional relationship with tempera- abrasive are slightly larger than the one without abrasive

ture. The reason is that the spacing between molecules in apparent viscosity. Molecular bonds and their mechan-

of CMC solution increases with temperature, leading to ical entanglements in the solution were not destroyed by

a smaller attraction between molecules. The internal abrasive particles. The force between molecules keeps

fraction is proportional to the attraction between mole- unchanged. Thus, the apparent viscosity and rheological

cules, which determines the apparent viscosity of CMC properties of PAM and CMC solutions are still dominated

solutions. by the net molecular structure. However, abrasive

Figure 7: Apparent viscosity of PAM solution under different Figure 8: Apparent viscosity of CMC solution under different

temperatures. temperatures.192 Xinyong Wang et al.

properties of ASJ, which also can provide guidance for

the engineering application of ASJ.

Acknowledgment: This work was supported by the

Fundamental Research Funds for the Central Universities

(2017XKZD02).

References

(1) Hollinger RH, Perry WD, Swanson RK. Precision cutting

with a low pressure coherent abrasive suspension jet.

In: 5th American Waterjet Conference. Toronto; 1989.

p. 245–52.

Figure 9: Effect of abrasive on the apparent viscosity of the abrasive

(2) Anjaiah D, Chincholkar AM. Cutting of glass using low pres-

slurry.

sure abrasive water suspension jet with the addition of zyco-

print polymer. In: 19th International Conference on Water

particles raise the friction between the rotor and slurry,

Jetting; 2008. p. 105–19.

leading to a small increase in the apparent viscosity. (3) Liao Y, Wang C, Hu Y, Song YX. The slurry for glass polishing by

micro abrasive suspension jets. Adv Mater Res. 2009;69/

70:322–7.

(4) Nouraei H, Wodoslawsky A, Papini M, Spelt JK. Characteristics

4 Conclusions of abrasive slurry jet micro-machining: a comparison with

abrasive air jet micro machining. J Mater Process Technol.

In this paper, a series of experiments were carried out to 2013;213(10):1711–24.

study the rheological properties of abrasive slurry with (5) Nouraei H, Kowsari K, Spelt JK, Papini M. Surface evolution

models for abrasive slurry jet micro-machining of channels

PAM and CMC commonly used in ASJ, and the effect of

and holes in glass. Wear. 2014;309(1–2):65–73.

temperature and abrasive on the apparent viscosity of the (6) Pang KL, Nguyen T, Fan JM, Wang J. Modelling of the micro-

abrasive slurry is discussed. Specific experimental results channelling process on glasses using an abrasive slurry jet. Int

were shown as follows: J Mach Tools Manuf. 2012;53(1):118–26.

1. PAM and CMC solutions are pseudoplastic non-Newtonian (7) Pang KL, Nguyen T, Fan JM, Wang J. A study of micro-chan-

neling on glasses using an abrasive slurry jet. Mach Sci

fluids within a selected concentration range, and

Technol. 2012;16(4):547–63.

their apparent viscosity increases with concentration.

(8) Zhang D, Zhao W, Wu Y, Chen Z, Li X. Facile droplet micro-

Under the same concentration and shear rate, the fluidics preparation of larger PAM-based particles and inves-

apparent viscosity of CMC solutions is much greater tigation of their swelling gelation behavior. E Polym.

than that of the PAM solution. The increment comes 2019;19(1):579–93.

from the greater intermolecular attraction of CMC (9) Niu SY, Hao FG. Progress of sodium carboxymethylcellulose.

Anhui Agric Sci. 2006;34(15):3574–5.

solutions, the stronger molecular bonds, and the

(10) Liu B, Ma X, Zhu C, Mi Y, Fan D, Li X, et al. Study of a novel

more complex mechanical entanglement. injectable hydrogel of human-like collagen and carboxy-

2. The non-Newtonian fluid constitutive equations of methylcellulose for soft tissue augmentation. E Polym.

specific PAM and CMC solutions can be obtained through 2013;13(1):1–11.

nonlinear fitting calculations. (11) Li F, Luo Y, Hu P, Yan X. Intrinsic viscosity, rheological prop-

erty, and oil displacement of hydrophobically associating

3. The apparent viscosity decreases with the increase in

fluorinated polyacrylamide. J Appl Polym Sci.

temperature, which can be explained as that high tem-

2017;134(14):1–9.

perature increases the spacing between molecules. (12) Hu Z, Maje H, Gao H, Ehsan N, Wen D. Rheological properties of

4. Abrasive has no influence on the apparent viscosity of partially hydrolyzed polyacrylamide seeded by nanoparticles.

the abrasive slurry for that molecular bonds, and their Ind Eng Chem Res. 2017;56(12):3456–63.

mechanical entanglements could not be destroyed by (13) Ujjwal RR, Sharma T, Sangwai JS, Ojha U. Rheological

investigation of a random copolymer of polyacrylamide and

abrasive particles in the slurry.

polyacryloyl hydrazide (PAM-ran-PAH) for oil recovery appli-

cations. J Appl Polym Sci. 2017;134(13):1–14.

The results and conclusion of this paper can be used (14) Karimi N, Sani AM, Pourahmad R. Influence of carboxy methyl

to study the formulation optimization and fluid field cellulose (CMC) and pectin on rheological, physical stabilityRheological properties of two high polymers suspended in an abrasive slurry jet 193

and sensory properties of milk and concentrated jujuba mix- (17) Ghannam MT. Rheological properties of aqueous polyacryl-

ture. J Food Meas Charact. 2016;10(2):396–404. amide/NaCl solutions. J Appl Polym Sci. 1999;72(14):1905–12.

(15) Senapati PK, Mishra BK. Rheological characterization of con- (18) Lewandowska K. Comparative studies of rheological proper-

centrated jarosite waste suspensions using Couette & tube ties of polyacrylamide and partially hydrolyzed polyacrylamide

rheometry techniques. Powder Technol. 2014;263:58–65. solutions. J Appl Polym Sci. 2007;103(4):2235–41.

(16) Haeri S, Hashemabadi SH. Experimental study of gravity- (19) Instruction manual for NDJ-79A digital rotational viscometer

driven film flow of non-Newtonian fluids. Chem Eng Commun. (in Chinese) from Baidu library (https://wenku.baidu.com/

2009;196(5):519–29. view/7d83aa23ad02de80d5d84039.html).You can also read