Improving Model Geometry for CFD Analysis

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Applied Math Modeling White Paper

Improving Model Geometry for CFD

Analysis

By Liz Marshall, Applied Math Modeling Inc., Concord, NH

October, 2010

solid objects, and too much detail can make

Introduction the simulation process more cumbersome

In today’s world, computer-aided engineer- than it needs to be. This is certainly true in

ing (CAE) is an integral part of engineering data centers, where small gaps between

design and analysis. At the root of all CAE equipment are fair game for the CFD solver,

is computer-aided design (CAD), which is but may not be particularly relevant to the

used to build virtual models of objects and large-scale flow patterns in the room. Facil-

spaces. CAD models are used as input for a ity analysts must always consider whether or

number of engineering software packages, not the air flow in a narrow gap is an impor-

where stress analysis, heat transfer, or fluid tant feature of the flow in the room as a

flow is simulated. Fluid flow analysis is

done using computational fluid

dynamics (CFD), and this tech-

nology is used for applications

ranging from aircraft wings to

coal furnaces to room air

flows. Despite their close rela-

tionship, CAD models differ

from CFD models in one im-

portant way. With CAD the

focus is on solid geometry, so

more detail is generally consid-

ered better than less detail. Figure 1: An example of a

With CFD, the focus is on the mesh, used for perform-

fluid flow in the space between ing a CFD calculation of

the air flow in a room

© 2010 Applied Math Modeling Inc. 1 WP104whole. It if is not, the geometry should be cases, the results confirm that the simpler

modified to eliminate such gaps. Cleaning geometry is more cost effective for the appli-

up – or more accurately, dumbing down – the cation of CFD.

geometry in this manner can make for a

much more rapid time to CFD solution with Case 1

minimal impact on the final results.

Problem Definition

The CFD simulation process begins with the A 5000 sq.ft. L-shaped data center is in op-

construction of the model geometry. In the eration at a major medical facility in the

case of a data center, this includes the room, Northeast. It has a raised floor and ceiling

the equipment in the room, and perforated return. Three downflow CRACs with turn-

floor tiles and ceiling grills to allow for the ing vanes are positioned on the perimeter and

passage of air, as needed. Once the room an upflow CRAC is positioned in the center

geometry is specified, a computational mesh of the room. Ductwork is used to pipe the

is built. The mesh (Figure 1) is used to break supply air from the upflow CRAC to several

up the air space into thousands or millions of locations around the room.

small cells. In each of these cells, the rele-

vant variables are computed and stored. It Racks with heat loads ranging from 10 Watts

is widely believed that models with more to 8 kW comprise a total heat load of 226

cells have the potential to offer a more accu- kW with a heat density of about 45 kW/sq.ft.

rate solution, assuming that the equipment is Four power density units (PDUs) each add an

represented correctly. Cells can be wasted, average of 1 kW of heat to the room. The

however, if they are used in regions where supply plenum contains a number of pipes

the information is not relevant. When this and blockages. The rooms adjacent to the

happens, the cell count is larger than it needs data center are at a constant temperature of

to be but the accuracy in the solution is no 72°F, and the wall resistance is 2 ft2-F/(Btu/

better. Furthermore, the time to solution can Hr).

be considerably longer than it needs to be.

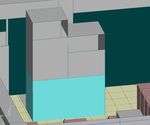

To illustrate this point, two models of me- In the original model, the racks – and 1inch

dium-sized data centers are considered using gaps between them - were properly sized, as

CoolSim software. The original models of shown in Figure 2 (top). Gaps created in this

the data centers are both accurate in the CAD fashion are assumed to be important details

sense. All of the equipment is carefully rep- when the automated mesh generator goes to

resented, but as a result, there are gaps be- work. However, their importance in the

tween adjacent equipment or there is exces- global data center flow is questionable. To

sive geometric detail. The models are then find out how important the gaps are, a second

“improved” for CFD by simplifying the ge- model is built in which the racks have the

ometry. The simulations are run and a thor- same location but are given a slightly in-

ough comparison is done to contrast the creased width to eliminate the gaps. The

original and modified geometries. In both

© 2010 Applied Math Modeling Inc. 2 WP104shows that the maxi-

mum room temperature

differs by only 1°F

while the maximum rack

inlet temperatures are

identical. The maxi-

mum flowrate through a

perforated tile is within

1% while the minimum

is within 8%. Taking a

closer look at the maxi-

mum rack inlet tempera-

tures, 35% have the

same value and only 3%

have a value that differs

by more than 5%. The

maximum difference in

the average rack inlet

temperature is 5% for all

racks in the room.

Based on these results,

simplification of the

model has the benefit of

reducing the model size

and time to solution

without introducing

negative consequences

such as large scale error

in the results.

Figure 2: In the CAD-style geometry (top), the racks are accurately

sized, but have 1 inch gaps between them; a CFD-style geometry

(bottom) eliminates the gaps between racks by increasing the

widths by 1 inch

With Gaps No Gaps

modified geometry is shown in Figure 2

Number of Cells 3.766 M 2.801M

(bottom).

Solution Time (Hours) 4.53 3.74

Results

Max Room Temperature (°F) 81 82

A CFD analysis is done using both of

the geometries and the results are com- Max Rack Inlet Temperature (°F) 77 77

pared in Table 1. The results show that Max Perf Tile Flowrate (CFM) 729 734

elimination of the gaps leads to a model

Min Perf Tile Flowrate (CFM) 472 436

with about 1 million fewer cells. The

time to solution is reduced by about 45 Table 1: A comparison of the size, solution time, and

minutes. Comparison of the results a few results for the data center modeled with and

without gaps between the equipment

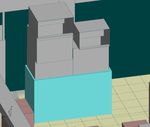

© 2010 Applied Math Modeling Inc. 3 WP104Case 2 used to guide the return air in an area where a

number of geometric constraints are present.

Problem Definition The original CFD model of the CRAC and

As a second example, consider one of the top is shown in Figure 3. While the top is an

small data centers at a large collocation facil- accurate representation of reality, its com-

ity. The 2500 sq. ft. raised floor data center plexity is perhaps more than is needed. After

has two downflow CRACs, one of which is all, the fan in the CRAC return will draw the

outfitted with a complex structure on the re- air into the unit. The role of the mounted

turn. The equipment heat load in the room is structure is simply to guide the air into the

about 100 W/sq.ft. and the complex top is

Figure 3: A complex structure mounted on the return of a downflow CRAC is used to

help guide the return air back to the unit

Figure 4: A simplified structure on the CRAC return does not have all of the features

of the original, but does include the essential shielding and open areas

© 2010 Applied Math Modeling Inc. 4 WP104openings and a much simpler structure could Looking again at the maximum rack inlet

accomplish the same goal. temperatures, half of the racks have identical

values and only 1 rack has values that differ

An alternative design is shown in Figure 4, by more than 5%. For the average rack inlet

where one such simplified structure is temperature, all of the racks in the room

shown. It has the same overall dimensions as agree to within 0 or 1% except two, where

the complex structure, but avoids the minute the agreement is within 2.5% and 5%. This

detailing. example further illustrates that less complex-

ity in a CFD model can translate into more in

Results

terms of decreased time to solution with neg-

Using the two CRAC top designs as the only

ligible loss of accuracy.

difference between the cases, two CFD simu-

lations are performed and the results com-

Summary

pared. An overview of the results is summa-

rized in Table 2. These examples demonstrate that for the pur-

pose of CFD modeling, simplified geometry

has advantages over complex, CAD-

Complex Simple

style geometries. In addition to saving

Number of Cells 1.590 M 1.168M on the number of computational cells

Solution Time (Hours) 2.32 1.87 and solution time, the effort involved

Max Room Temperature (°F) 98 96 in the setup is reduced as well. With

91 90

automatic grid generation and solution

Max Rack Inlet Temperature (°F)

procedures in place for software de-

Max Perf Tile Flowrate (CFM) 2,530 2,515

signed for data center modeling, time

Min Perf Tile Flowrate (CFM) 839 818 savings during the setup can be sig-

nificant. For the complex CRAC top,

Table 2: A comparison of the size, solution time,

and a few results for the data center modeled with a

for example, the original structure was

complex CRAC top and a simple CRAC top built using 33 baffle objects. By con-

trast, the simple model needed only 9

By changing only the structure on top of one baffles. Even if the final goal is to have a

of the CRACs in the room, about 400,000 CFD model with a large amount of geometric

cells are saved and the CPU time is reduced detail, these results show that simplified

by just under 30 minutes - or 19%. The models are an excellent first pass solution

maximum rack inlet temperature differs by and indeed, are usually just as good as mod-

1°F and the maximum temperature in the els with increased detail.

room by 2°F. The maximum and minimum

flowrates through the perforated tiles are

within 2.5%.

© 2010 Applied Math Modeling Inc. 5 WP104You can also read