Commercial Nuclear Power - Mission Critical Operational Reliability and Safety: Learning from the Transformation of - Strategic Talent Solutions

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

®

dec/jan13

the magazine for maintenance reliability professionals

Mission Critical Operational

Reliability and Safety:

Learning from the Transformation of

Commercial

Nuclear Power

uptimemagazine.comThree Mile Island

Mission Critical Operational

Reliability and Safety:

Learning from the Transformation of

Commercial Nuclear Power

Mary Jo Rogers

Over the past 30 years, despite intense regulatory oversight and they were individually.5 To that end, they

formed the Institute of Nuclear Power Opera-

public skepticism faced by the nuclear industry following the ac- tions (INPO), which was incorporated in 1979

cidents at Three Mile Island (TMI), Chernobyl, and more recently even before the President’s commission re-

leased its final report on the TMI accident at

Fukushima, Japan, nuclear plants in the United States have under- the end of that year.6 The World Association of

gone a complete transformation. Nuclear Operators (WANO) was formed after

the 1986 Chernobyl disaster.

Through INPO, U.S. industry leaders took it

They are now the most productive, the most such heavy scrutiny and regulation? And what upon themselves to address the commission’s

reliable and the safest they have ever been: can other industries learn from this transfor- recommendations and figure out how self-

mation? The lessons learned through its prac- regulation could work. Crucial to the success of

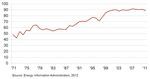

• U.S. nuclear power capacity factor has tice and research program suggest that there INPO was the cooperation of senior leadership.

gone from 48 percent in 1971 to an aver-

are four key answers to these questions: Cooperation and Information Sharing. Par-

age of 90 percent over the past decade.1

• Industry leadership, ticularly through its plant evaluation and

• Nuclear electricity production costs training programs, INPO played a key role in

dropped to 2.14 cents per kilowatt-hour • Self-regulation,

improving reliability and safety. The industry’s

in 2010.2 • Evolution of a safety culture, cooperative approach to sharing informa-

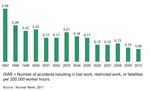

• Total industrial safety accident rate was • First-line supervisor. tion, best practices and even resources was

0.09 (industrial accidents per 200,000 a powerful factor in sustained performance

worker hours) in 2010.3 In fact, it is now Role of Industry Leadership improvements.

safer working at a nuclear power plant Forming INPO. In the aftermath of the TMI A good example of this cooperation oc-

than in a school setting.4 incident, utility CEOs recognized they were curred at River Bend Station, which is owned

How did the nuclear industry become safer, better positioned to address regulatory and and operated by Entergy. In 2006, the plant

more reliable and more profitable while under plant performance challenges together than had a number of reactivity management is-

dec/jan13 Strategic Talent Solutionssues that forced them to take power reductions and shutdowns to deal U.S. Nuclear Industry Capacity Factor

with problems that were going to impact the reactor fuel. One of their 1971-2011

reactor operators contacted Ed McVey, Exelon’s manager of reactor en-

gineering oversight, whom he had met at a meeting of the Reactivity

Control Review Committee.

Although Exelon and Entergy are competitors, Ed spent a week with

the River Bend operations department, providing feedback and sug-

gestions that they implemented very successfully over the next year.

Ed’s decision to spend a week at River Bend was fully supported all the

way up his management chain.7

Self-regulation through INPO

INPO’s overarching standard is excellence in operational reliability

and safety, and their primary means of holding the industry to this

standard are their regularly conducted in-depth assessments of all U.S.

nuclear power plants.

Each U.S. plant is evaluated once every two years against INPO’s per-

U.S. Electricity Production Costs

formance objectives and criteria. As part of this process, an assessment

1995-2010

team, including INPO personnel and experienced professionals from

other nuclear sites, spends two weeks observing how the site func-

tions and reviewing data on its operating units. The assessment team’s

final report identifies

strengths and areas

for improvement, and

INPO’s overarching plant leadership writes

standard is excellence a response indicating

what they will do to

in operational reliabil- improve their problem

areas.

ity and safety, and their Part of the impetus

primary means of to improve and fol-

low INPO’s counsel has

holding the industry to come from peer pres-

this standard are their sure. For example, ev-

ery year INPO holds a

regularly conducted conference developed U.S. Nuclear Industrial Safety Accident Rate

exclusively for CEOs, 1997-2010

in- depth assessments Chief Nuclear Officers

of all U.S. nuclear and Senior VPs of nu-

clear operating com-

power plants. panies. This includes a

closed session in which

the CEOs are presented

with a forced ranking of best to worst performers. Lower-performing

plants and the utilities that own them are thus strongly challenged to

improve.

This practice contributes to an important piece of the nuclear indus-

try’s transformation, which is the sense that industry leaders have of

being “hostages of each other.” In 1994, Joseph Rees’s book by this title

described how the industry changed after the formation of INPO due to

leaders’ belief that a disastrous incident at one plant would seriously im-

pact the entire industry.8 Safety culture does not just mean avoiding accidents and injuries

and creating a SCWE. It also includes process rigor: defining the correct,

Evolution of a Nuclear safe way of doing something and ensuring it is consistently done that

Safety Culture way. In Strategic Talent Solutions’ (STS) work with 35 different stations in

A nuclear safety culture is defined by INPO as “an organization’s the U.S. and England, it has become clear that building a stronger safety

values and behaviors—modeled by its leaders and internalized by its culture translates into getting better safety and production results in

members—that serve to make nuclear safety the overriding priority.”9 the long run. Field experience and the experience of senior leaders indi-

Last fall, the Nuclear Regulatory Commission (NRC) officially defined cate that the following are useful ways to improve safety culture:

safety culture as “the core values and behaviors resulting from a col- • Ensure that members of the leadership team have high standards

lective commitment by leaders and individuals to emphasize safety around safety and reliability, that these are reflected in their behav-

over competing goals to ensure protection of people and the environ- ior and that they are holding the organization to these standards.

ment.”10 INPO and the NRC both agree that safety culture includes hav- • Identify, track and respond to precursors or small events before

ing a safety-conscious work environment (SCWE), or an environment in they have the opportunity to contribute to significant accidents.

which people feel free to raise safety concerns without fear of retribu- • Enforce the rigorous use of human error prevention tools. Nuclear

tion. power has built these simple practices (including peer checks,

Strategic Talent Solutions dec/jan13three-way communication and proce- problems.12 INPO emphasized that supervisors

References

dure adherence) into many of its process- need to be in the field, but also need to have a

es to help ensure safety and reliability. greater oversight role, confront worker behav- 1. Nuclear Energy Institute (NEI). 2012.

• Regularly assess safety culture. Evalu- iors and be more aligned with site leadership. U.S. Nuclear Industry Capacity Fac-

In an STS research study on what makes tors (1971-2011). http://www.nei.org/

ate how safety norms and attitudes are

resourcesandstats/documentlibrary/

actually demonstrated daily in behavior, first-line supervisors most effective, the au-

reliableandaffordableenergy/graphic-

decision-making and progress on safety thors found that supervisors who felt more sandcharts/usnuclearindustrycapacity-

results. This helps identify both the gaps like members of the management team were factors/

in the safety culture and the areas in the more effective at their jobs. And the most

organization that are most at risk. powerful ways to get supervisors to show 2. NEI. 2011. U.S. Electricity Production

that alignment were to: (1) treat them as core Costs 1995–2010. http://www.nei.org/

• Build self-criticality and a learning orienta- resourcesandstats/documentlibrary/

tion. Plants and companies that are willing members of the management team, (2) give

reliableandaffordableenergy/ graphic-

to be open about performance are also them enough time with their own managers sandcharts/

in a better position to preempt problems and (3) tell them the reasons behind major de-

cisions.13 3. Nuclear News. INPO’s U.S. Reactor Fleet

because they identify them proactively. Performance Indicators for 2010 Show

They are also more open to feedback from Shift change. Over the next several years, the

Mixed Results. June 2011. pages 30–31.

others in the interest of learning and im- transition of the FLS to the management team

proving. will become increasingly critical for nuclear, as 4. U.S. Department of Labor, Bureau of

well as other industries. As an aging workforce Labor Statistics. 2010. Incidence Rates

of experienced supervisors and workers near of Nonfatal Occupational Injuries and

Illnesses by Industry and Case Types.

retirement, a new generation of supervisors

http://www.bls.gov/iif/oshwc/osh/os/

must step in to replace them. What we have ostb2813.pdf

seen work in this situation is pairing the expe-

rienced workers with the new talent in a men- 5. Rees, Joseph V. Hostages of Each Other:

toring capacity that mimics the apprentice- The Transformation of Nuclear Safety

ship model. In this way, they are more apt to Since Three Mile Island. Chicago: The

University of Chicago Press, 1994.

get engaged because they have a junior coun-

terpart looking up to them. They also may be 6. Ellis, J. O. The Role of the Institute of

more likely to feel needed in a way that isn’t Nuclear Power Operations in Self-Regu-

as physically demanding, but instead taps into lation of the Commercial Nuclear Power

their wisdom and potential desire to leave a Industry. Remarks before the National

Commission on the BP Deepwater

legacy.

Horizon Oil Spill and Offshore Drilling,

August 25, 2010.

Admiral Hyman G. Rickover Summary

The nuclear power industry has changed 7. McVey, Edward. Interviewed by Mary Jo

“You have to learn from dramatically since TMI and Chernobyl, and Rogers on January 31, 2011.

both reliability and safety have improved sig-

the mistakes of others. nificantly in a highly regulated environment.

8. Rees, Joseph V. Hostages of Each Other:

The Transformation of Nuclear Safety

You won’t live long The four ways in which other industries can Since Three Mile Island. Chicago: The

learn from this transformation are: University of Chicago Press, 1994.

enough to make them • Taking leadership of change—and thereby 9. INPO. 2004. Principles for a Strong

all yourself.” taking control of your future. Nuclear Safety Culture.

• Self-regulation—use lessons learned from 10. Federal Register (Vol. 75, No. 180),

This advice is often attributed to Admi- the formation of INPO, adapting to other September 17, 2010. Nuclear Regula-

ral Hyman G. Rickover, known as the industries. tory Commission (NRC) Revised Draft

“Father of the Nuclear Navy.” • Building a safety culture that gets results in Safety Culture Policy Statement: Re-

reliability. quest for Comments.

Professionalism and Elevation • Transforming the first-line supervisor 11. Report of the President’s Commission

on the Accident at Three Mile Island.

of the First-Line Supervisor through better engagement and alignment

Washington, D.C.: October 1979.

The fourth key to sustaining improvements with senior management.

in the nuclear industry is the transformation of 12. INPO. Guidelines for Effective Nuclear

the first-line supervisor (FLS). Many years ago, Mary Jo Rogers, Ph.D., is a Supervisor Performance. November

the FLS was a foreman or step-up lineman; a

partner at the management 2007.

consulting firm, Strategic

“union guy” who was typically not necessar- Talent Solutions (STS), where 13. Rogers, M. J. & Fearing, B. K. Strategic

ily aligned with senior management. The FLS she is the practice leader for Talent Solutions, 2010. The compre-

energy and utility leadership hensive study of nuclear supervisor

functioned essentially as an experienced pair and organizational consulting.

of hands working alongside the craftsmen and Prior to STS, Dr. Rogers was the effectiveness.

expediting work. head of management development at Exelon

Nuclear, where she was also in charge of creating

After TMI, there was a push for more ex- standard processes for supervisor and leadership

tensive training, greater professionalism and assessments for all of Exelon. She is a recognized

expert in nuclear energy leadership and orga-

a more important role for the FLS.11 And al- nizational excellence. Dr. Rogers was originally

though training subsequently improved, INPO trained and licensed as a clinical psychologist .

analyses in 2004 led to the conclusion that su- Dr. Rogers’ newly released book, Nuclear Energy

Leadership: Lessons Learned from U.S. Opera-

pervisor weaknesses were still one of the most tors - ISBN 978-1-5937024-5-8.

common causes linked to plant performance

dec/jan13 Strategic Talent SolutionsYou can also read