A cost-effi cient solution to true color terrestrial laser scanning

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

A cost-efficient solution to true color terrestrial laser scanning

Peter D. White*

School of Engineering, Durham University, Durham DH1 3LE, UK

Richard R. Jones*

Geospatial Research Ltd., Department of Earth Sciences, and e-Science Research Institute,

Durham University, Durham DH1 3LE, UK

ABSTRACT and reflect off the target object. The scanner automatically rotates con-

tinuously while the laser beam is fired repeatedly (with a frequency

This paper presents a low-cost true color terrestrial laser scan- up to 100,000 points/s, depending on the type of scanner used). In this

ning system, described in terms of the hardware and software way, a detailed three-dimensional (3D) image of the surface of the tar-

elements necessary to add color capability to existing non-color get object is captured (Figs. 1A, 1B). With conventional TLS, measured

laser scanners. A purpose-built camera mount allows a digital points in the laser scan point cloud can be assigned different shades of

camera to be positioned coincident and collinear with the beam gray according to the intensity of the reflected laser beam (Figs. 1B,

detector of the laser scanner device, such that mismatch between 1E), or can be mapped to an arbitrary color ramp according to intensity

color data and laser scan points is minimized. An analytic map- or a positional attribute such as relative elevation or distance from the

ping implemented in a Matlab toolbox registers the photographs, scan position (Fig. 1C). For some kinds of analysis (particularly purely

after rectification, with the laser scan point cloud, by solving for geometric studies such as volumetric calculations), the resulting gray

two tie-points per image. The resulting true color point clouds are scale or false color point cloud is adequate. However, while gray scale

accurate and easily interpretable. The adjustable camera mount and false color rendering can provide some help during interpretation

fits a range of cameras and, with minor adaptation, could be used of the laser scan data, they are often less useful for many kinds of more

with different laser scanner devices. A detailed error analysis will detailed analysis. For example, we find that the additional visual cues

allow comparisons to be drawn with alternative technologies, such provided by true color data (Figs. 1D, 1F) are important for the cor-

as photogrammetry and commercial true color laser scanners. This rect identification of geological features from high-resolution TLS point

low-cost, accurate, and flexible true color laser scanning technol- clouds (Clegg et al., 2005; Trinks et al., 2005; Waggott et al., 2005).

ogy has the potential to make a significant improvement to existing Added color is equally beneficial when interpreting scans taken at short

methods of spatial data acquisition. range (e.g., Kokkalas et al., 2007) and longer ranges of several hun-

dred meters (e.g., Labourdette and Jones, 2007). Here we use the term

Keywords: laser scanner, point cloud, color matching, camera calibra- “true color” to mean high-resolution (32 bit) color typically acquired

tion, lidar, terrestrial laser scanning. by a good-quality digital camera; i.e., in the opposite sense of the “false

color” outcrops shown in Figure 1C.

INTRODUCTION True color terrestrial laser scanning (TCTLS) requires undistorted digi-

tal photographs to be precisely mapped onto the laser scan point cloud

Terrestrial laser scanning (TLS) is a powerful method for the acquisi- data, thus producing a true color 3D model. A number of TCTLS devices

tion of detailed positional data, and is now routinely used as a standard are already manufactured and marketed, but generally capture low-quality

tool in civil engineering and in as-built surveying (Jacobs, 2005; Dunn, color data, and are much more expensive than conventional non-color

2005). In recent years the use of TLS has expanded widely with applica- TLS equipment. This paper presents an alternative, relatively low cost

tions in many other fields, including mining (Ahlgren and Holmlund, method for adding high-resolution color capability to standard terrestrial

2002), geomechanics (e.g., Slob and Hack, 2004), geological surveying laser scanners. In this system, the color information is captured by a digi-

(Jones et al., 2004; McCaffrey et al., 2005), erosion and landslide moni- tal camera and registered with the point cloud using an analytic mapping

toring (Haneberg, 2004; Lim et al., 2005; Rosser et al., 2005), petroleum implemented in Matlab. The key component in the system is a specially

reservoir modeling (Løseth et al., 2003; Bellian et al., 2005; Pringle et al., designed camera mount that enables the color information to be captured

2006; Jones et al., 2008), architecture (El-Hakim et al., 2005), archaeol- from precisely the same point as that from which the laser scanner cap-

ogy and heritage conservation (Barber et al., 2006), forestry (Thies et al., tures its spatial information.

2004), city modeling (Hunter et al., 2006), and many others. In this paper, the examples we show all use a common approach in

The overall principle of terrestrial laser scanners is to measure the which each point in the laser-scan point cloud is allocated a color value

return traveltime (and hence distance) for an emitted laser beam to hit from the nearest pixel in the corresponding mapped photo; i.e., the output

*White: Present address: Arup, Central Square, Forth Street, Newcastle upon Tyne, NE1 3PL, UK; peter.white@arup.com. Jones: Corresponding Author: richard@

geospatial-research.co.uk

Geosphere; June 2008; v. 4; no. 3; p. 564–575; doi: 10.1130/GES00155.1; 11 figures; 1 table.

For permission to copy, contact editing@geosociety.org

564

© 2008 Geological Society of America

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestTrue color terrestrial laser scanning

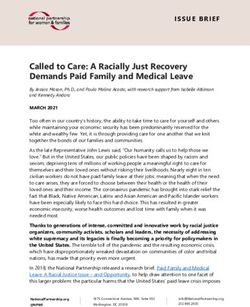

A B

8.7m

C

E

1.750m

D

F

Figure 1. Terrestrial laser scan of an abandoned sandstone quarry in Carboniferous Coal Measures, County Durham.

(A) Scanning the outcrop with a Leica HDS 3000 scanner. (B) Resultant point cloud, showing gray scale points according

to intensity of the reflected beam. (C) Point cloud given false color according to the distance of each point from the scan

position. (D) Points in the point cloud allocated true color from tightly calibrated digital photos. (E) Close-up detail of

the gray scale point cloud. (F) Close-up of the colored point cloud, showing the extra stratigraphic detail now visible.

Vegetation is also more easily recognized in the colored point cloud.

Geosphere, June 2008 565

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestWhite and Jones

as shown here is a colored point cloud, with brighter, more accurate color CAMERA MOUNT

rendition compared with most existing TCTLS devices (which typically

use a low-resolution onboard video camera to provide color data). This In order to minimize potential mismatch between the scan data and

approach can also be extended to allow the mapped images to be draped color photos, a special camera mount was designed so that the optical

onto a triangulated (meshed) surface derived from the point cloud (cf. Xu center of the camera can be positioned to align with the center of the laser

et al., 2000; Bellian et al., 2005), so that the output is a textured model scanner. The essential feature of the mount is that it ensures that the center

of the surface of the outcrop. This gives a model with even greater pixel of the entrance pupil of the camera lens remains coincident with the laser

resolution and visible detail. scanner center even when the camera is panned and tilted. A prototype

While this work was particularly motivated by the aim to demonstrate mount was designed to be used with a Measurement Devices Ltd. (MDL)

a prototype solution for a low-cost alternative to high-end commercial LaserAce 600 scanner. The mount accepts a wide range of cameras. The

TCTLS, there were a number of additional reasons behind the project: camera can easily be adjusted on the mount within a range of positions,

1. To be able to provide the best possible color-mapped point clouds although minor design modification to the dimensions of the mount was

as input for new methods for automated feature recognition (e.g., auto- needed to make it suitable for use with some other makes of scanner. The

mated removal of vegetation; extraction of fracture planes from the point mount was designed to fit the same standard tribrach fitting as the MDL

cloud, c.f. Slob et al., 2005). Existing methods typically use only geomet- scanner and maintain the camera lens pivot point at the same height above

rical analysis (e.g., edge and corner detection) and/or intensity contrasts. the tribrach as the scanner center. Thus the scanner can be removed from

Supplementing feature recognition algorithms to exploit additional color the tripod once scanning is completed, and the camera mount attached in

information has very interesting potential, but clearly relies on a precise its place, thereby ensuring that the laser scanner center and camera lens

matching of the color data and point cloud as input. pivot point are coincident.

2. To provide a platform to allow a wider range of digital cameras to be To facilitate prototype design and fabrication, a rotating tribrach adapter

used. For example, this has allowed us to test the use of lenses with longer (www.surveying.com/products/details.asp?prodID=2020-00) was used as

focal lengths to capture very detailed photographs that can then be draped the base of the camera mount. As well as fitting the scanner tribrach, the

onto meshed surfaces derived from the point cloud. rotating tribrach adapter provided a flat surface with a good sized protrud-

3. To allow for future development and testing of improved color map- ing thread in the center, and the rotation mechanism necessary for panning

ping algorithms (e.g., to develop smoother color mapping in areas of over- the camera. The rest of the mount, fabricated from aluminum, was built on

lapping images). top of the adapter. A camera attaches to the mount using the standard ¼ in

4. To be able to test the sensitivity of positioning of the camera with Whitworth (6.35 mm) thread tripod socket found on the base of most cam-

respect to the laser scanner sensor. At present, some TCTLS devices (e.g., eras. Figure 2 shows a rendered AutoCAD model of the as-built mount

Riegl LMS scanners) use cameras mounted on top of the scanner body and a photograph of the mount with an SLR camera attached.

(i.e., non-collinear with the laser scanner beam), and this introduces an The mount holds the camera in portrait format, partly because if a wide-

error during matching of the photos with the point cloud data. enough lens is used, a single photograph at each pan position will often

5. To provide calibrated color outcrop models for benchmark compari- be sufficient, and partly because it would be difficult to design and manu-

sons with other methods of building 3D outcrop models such as digital facture a mount that would hold the camera in landscape format and allow

photogrammetry (e.g., Poropat, 2001; Pringle et al., 2001, 2004). the necessary panning and tilting while keeping the position of the center

6. To have a precise, flexible system that is capable of mapping spa- of the entrance pupil constant. The design process was simplified by the

tial data and imagery captured with alternative kinds of scanner and/ fact that the majority of SLR cameras have their tripod sockets situated

or camera device: e.g., for testing prototype scanners built with differ- directly below the longitudinal lens axis (when the camera is viewed in

ent wavelengths or other laser properties, or for use with other types of landscape orientation). This meant that in the plate to which the camera is

camera such as infrared or multi-spectral equipment (see also Bellian et attached, a simple slot with its centerline passing through the horizontal

al., 2007). axis of rotation was sufficient to allow the center of the entrance pupil to

7. To develop the necessary expertise to enable independent calibration be positioned in the horizontal rotational axis. Adjustments are therefore

of camera lenses and testing of TCTLS performance. only required in two axes in order to position the pivot point of the camera

While a number of scanner manufacturers clearly have their own pro- lens in the vertical rotational axis.

prietary methods to provide TCTLS, there is relatively little information The prototype camera mount described and used in this paper is non-

available in the public domain that describes existing methods for color automated, such that the operator must manually reposition the camera

mapping of laser scan data. Balis et al. (2004) implied how mapping around its rotation axes between each overlapping consecutive shot. Work

is achieved using a Mensi GS200 scanner, which has internal onboard is under way to prototype a motorized version of the mount that will auto-

video circuitry. Abmayr et al. (2004) used a specialized line-scanning matically take the photographs needed to cover a prescribed area.

chromatic recorder to gather color information from the scanned area.

Some workers have developed methods to combine scan data with pho- CAMERA CALIBRATION AND IMAGE RECTIFICATION

tos taken with a standard digital single-lens reflex (SLR) camera from

unspecified positions (i.e., scanner and camera need not be coincident Camera calibration and image rectification are well documented in rela-

and collinear). Such methods typically minimize errors by using a large tion to applications in computer vision. Camera calibration is the process

number of manually defined tie-points for each image (tie-points are of determining the internal camera geometric and optical characteristics

points that can be located in both the rectified photographs and the (intrinsic parameters) and/or the 3D position and orientation of the camera

point cloud). Examples of this approach include Xu et al. (2000), Gram- frame relative to a certain world coordinate system (extrinsic parameters)

matikopoulos et al. (2004), and Abdelhafiz et al. (2005), although the (Tsai, 1987). It is not necessary to determine the extrinsic parameters in

details of their methods are not all fully published. Abmayr et al. (2005) the TCTLS system described in this paper, because the camera is mounted

give a comprehensive description of the use of such a method with the at the center of rotation of the laser scanner and tie-points are used to reg-

Z+F 5003 scanner. ister the images with the point cloud.

566 Geosphere, June 2008

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestTrue color terrestrial laser scanning

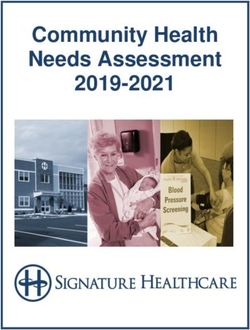

A B

Figure 2. Rendered model of the as-built camera mount and a photograph of the mount with a single-lens reflex

camera attached. Height of mount is 36 cm.

In order to register the photographs with the point cloud, the photo-

graphs must be rectified such that they appear to have been captured with xis

lA

a pinhole camera, the pinhole of which is coincident with the laser-beam P ti ca

Op

detector inside the laser scanner device. Figure 3 shows the pinhole cam-

z

era model with lens distortion, as well as how the laser scanner and image

coordinate systems relate to each other. The orientation of the scanner y

coordinate system about the vertical axis is arbitrary (for the MDL scan-

ner used in this study it is defined by the direction in which the device is

pointing when it is turned on).

According to Heikkilä and Silvén (1997), the pinhole camera model is Ta

rg

e tO

based on the principle of collinearity, where each point in the object space bje

x c

is projected by a straight line through the projection center into the image Scanner t

Pl Coordinate

plane. Since after undistortion the photographs appear to have been cap- u “Pane

inh o f System

tured with a pinhole camera, and if the camera-lens system is positioned Q' ole

”

Q

such that the pinhole is coincident with the center of rotation of the laser Pl

v Caane

scanner, then no further image rectification is required. Therefore it is nec- Im me of

essary to find the pinhole point for the camera-lens system. This point is Coage ra

Sy ord Sen

ste ina so

the center of perspective of the lens, about which the camera-lens sys- m te r

tem can be pivoted without introducing any parallax error between pho-

tographs (Kerr, 2005). According to Kerr (2005), the correct pivot point

is the center of the entrance pupil of the lens and not, contrary to popular Figure 3. Pinhole camera model with lens distortion, where P is a

belief, the front nodal point. The center of the entrance pupil is easily three-dimensional subject point, Q is its distorted image point, and

located empirically by observing the relative movement of the background Q' is its undistorted image point (Shih et al., 1995).

Geosphere, June 2008 567

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestWhite and Jones

and foreground as the camera is pivoted about different points. The point rotates about the vertical axis and is, therefore, the angle between the azi-

at which there is no relative movement between the background and fore- muth zero line in the horizontal plane and the projection of the subject

ground is the correct pivot point. point onto the same plane. This is not the same as the horizontal angle

The intrinsic parameters required to rectify the image to achieve this between the subject point and the vertical plane that passes through the

pinhole camera model are usually the effective focal length, scale factor, azimuth zero line. The inclination is simply the direct angle between the

and image center (principal point), as well as those needed to correct for horizontal plane passing through the image center and the subject point.

the systematically distorted image coordinates (Heikkilä and Silvén, 1997). The implications of the method of operation of the laser scanner can

The main type of distortion is radial distortion, in which the actual image be understood by considering the lines traced out by the laser beam on

point is shifted radially in the image plane. In addition, a decentring distor- the inside of a virtual sphere when θ or φ is kept constant, given that the

tion with both radial and tangential components occurs due to the centers of laser scanner center is at the center of the sphere. If the inclination is kept

curvature of lens surfaces not being collinear. Figure 4 illustrates the effects constant while the azimuth is varied, a line of “latitude” is traced on the

of radial and decentring distortions on a synthetic image. surface of the sphere. If, instead, the azimuth is kept constant while the

A number of methods have been documented for determining the dis- inclination is varied, a line of “longitude” is traced on the surface.

tortion parameters empirically. One example of an application for cam- The interaction of the laser scanner and the camera can be understood

era calibration and image rectification is the GML (Graphics and Media by imagining the projections of the lines of latitude and longitude onto a

Lab) C++ Camera Calibration Toolbox (v. 0.31 or later) by Vezhnevets virtual plane external to the sphere by straight lines passing through the

and Velizhev (2005, 2006). This application has been tested with the center of the sphere. If the plane is vertical, the lines of latitude above the

TCTLS solution presented in this paper, although any alternative method equator map to upward-curving lines on the plane, and those below the

that adequately removes distortion from the photographs can be used as equator map to downward-curving lines. The lines of longitude, however,

part of the system. Vezhnevets and Velizhev’s (2005, 2006) toolbox is an map to vertical lines on the plane. If the plane is now tilted upward, the

implementation in C++ of a Matlab toolbox by J.-Y. Bouguet (www.vision. projected lines of latitude now all curve upward, as long as the bottom

caltech.edu/bouguetj/calib_doc/download/TOOLBOX_calib.zip), with the of the virtual plane is above the equatorial plane. The projections of the

addition of another corner detection algorithm. Both toolboxes use an lines of longitude remain straight, but splay out toward the bottom of the

intrinsic camera model inspired by Heikkilä and Silvén (1997), and a main plane. If the plane is tilted downward, the projected lines of latitude curve

initialization phase partially inspired by Zhang (2000) and partially devel- downward and the projections of the lines of latitude splay out toward the

oped by Bouguet (both available from the Intel Open Source Computer top of the plane. This is illustrated in Figure 6.

Vision Library at www.intel.com/technology/computing/opencv). Unlike Since the scanner is an inherently spherical system using polar coor-

Bouguet’s toolbox, Vezhnevets and Velizhev’s (2005, 2006) software is dinates, and the camera sensor is a plane, the scanner-camera system

capable of rapidly undistorting large, high-resolution images. conforms to this behavior, with the virtual image plane corresponding to

In order to calibrate a camera, a set of photographs is taken of a planar the camera’s sensor. When the virtual plane in Figure 6 is vertical, this

“checkerboard” calibration target. The toolbox is able to detect the corners corresponds to the case in which the camera’s sensor is vertical, i.e., the

of the squares in the photographs of the target and use their positions to longitudinal axis of the lens is pointing horizontally. Similarly, when the

calculate the intrinsic calibration parameters. Any photographs taken with virtual plane is inclined, this corresponds to the situation in which the

the same camera and lens (at the same focal length, if it is a zoom lens) camera is tilted about a horizontal line passing through the laser-beam

can then be undistorted using the toolbox, whether or not the photographs detector (i.e., center of the scanner) and the camera lens pivot point. From

were taken before the calibration was carried out. Figure 6 it can be deduced that in the case where the lens is pointing hori-

zontally, the expression for v will be a function of both θ and φ, while u

COREGISTRATION OF COLOR IMAGES AND SCAN DATA will be a function of θ only. In the tilted case, however, both u and v are

functions of both θ and φ. This information is summarized in Table 1. A

In order to register an image with a point cloud, a mapping must be

determined that gives expressions for the image pixel coordinates u and

v (Fig. 5), in terms of the azimuth (horizontal) and inclination (vertical) u

angles, θ and φ, respectively, from the laser scanner center to the corre-

sponding point in the cloud.

It is important to note the way in which laser scanners measure the

azimuth and inclination angles. The azimuth is measured as the scanner

v

V

U

Figure 5. Coordinate system of the rec-

Original Radial Distortion Decentring Distortion tified image plane. U and V are the total

number of horizontal and vertical pixels

in the image, respectively; u and v are the

Figure 4. Effects of radial and decentring distortions on a synthetic pixel coordinates relative to the top left

image (Prescott and McLean, 1997). corner of image.

568 Geosphere, June 2008

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestTrue color terrestrial laser scanning

5. Mapping color values from the images onto the point cloud. This is

done by using Newton’s method to solve the three simultaneous nonlinear

equations as derived in the Appendix.

6. Saving an output file of point cloud data, now comprising x, y, and z

ф = constant ф = constant

θ = constant θ = constant ф = constant coordinates and RGB (red green blue) color values.

θ = constant The point cloud data can thus be suitably colored and can be imported

into appropriate visualization software, such as the open-source program

ParaView (www.paraview.org).

TESTING THE SYSTEM

To test the system a number of field tests were performed, using a vari-

ety of laser scanners and cameras. In the first tests, buildings were mainly

Plane Vertical Plane Inclined Upwards Plane Inclined Downwards

used as the chosen target objects, because they have distinct geometric

features that can readily be checked in both the scan data and photographs.

Figure 6. Projections of lines of constant azimuth and inclination Later tests used geological outcrops.

onto vertical and inclined planes. In the first field test illustrated here, part of Durham Castle was chosen

to provide a target with complicated geometry. For this test the laser scan-

ner chosen was a Riegl LMS-Z420i, which has its own in-built function

TABLE 1. FORM OF MAPPING FUNCTIONS for high-quality color matching through the use of a separate precision-

mounted digital SLR on top of the scanner. A 360° scan was acquired,

Camera horizontal Camera tilted consisting of 8 × 106 points. Two separate sets of photographs were

u = f (θ) u = f ( θ, ф ) acquired, to allow direct comparison between our method of color match-

v = f ( θ, ф) v = f (θ ,ф) ing and that provided by Riegl. The first set of 7 photographs was taken

Note: u—horizontal image pixel coordinate; with a top-mounted 6.1 mega-pixel Nikon D70 camera (giving a total of

v—vertical image pixel coordinate; θ—azimuth 42.7 × 106 pixels), following Riegl’s standard acquisition method for the

(horizontal) angle; ф—inclination (vertical) scanner. The scanner was then removed from the tripod, and a second set

angle. of 18 photos was taken using an 8 mega-pixel Canon EOS 350D together

with the camera mount and color matching method presented in this paper

(total pixels = 144 × 106). Figure 7 shows the quality of the colored point

cloud matching for part of the castle. Color matching is very precise in all

full mathematical derivation of the actual mapping functions is given in areas of the photos, including objects in the near foreground and far back-

the Appendix. ground (this is difficult to achieve when the camera is not collinear with

the scanner center, as in the top-mounted Riegl scanners). This benchmark

COREGISTRATION TOOLBOX test shows that the color matching method we present in this paper can

perform at least as well as high-end commercial solutions.

The Matlab programming environment was used to create a set of The second example shown here is from the Jurassic coastal cliff sec-

tools that can be used to carry out the registration process of a set of tions at Staithes, North Yorkshire. This site is part of a long-term project

photographs with its associated point cloud. The toolbox comprises a using laser scanning to monitor coastal erosion (Rosser et al., 2005; Lim

number of individual programs collectively controlled through a com- et al., 2005). In this test an MDL LaserAce 600 scanner and an Olympus

mon Graphical User Interface (GUI). The toolbox encompasses the fol- Camedia E-20P digital SLR camera were used. The results (Fig. 8) show

lowing functionality. that color matching has high precision, and that the addition of color to the

1. Loading and parsing of the raw ASCII laser scan point cloud file point cloud greatly increases the amount of geological detail visible in the

(comprising the x, y, and z Cartesian coordinates for each point). virtual outcrop model.

2. Conversion of the points from Cartesian coordinates to a spherical

reference frame with the center of the scanner (and camera) at the origin. ERROR ANALYSIS

The azimuth and inclination coordinates are calculated from the x, y, and

z coordinates using the following formulae: There are many stages in the data capture and image registration pro-

cesses, some of which introduce errors. Quantitative aspects of the fol-

lowing error analysis are specific to the MDL LaserAce 600 scanner and

⎛ x⎞

azimuth = arctan ⎜ ⎟ Olympus Camedia E-20P camera, but other scanner and camera combina-

⎝ y⎠ (1) tions are conceptually similar.

A significant source of error can arise because of dispersion of the scan-

and ner’s laser beam. The scanner assumes that the strongest part of the return-

⎛ z ⎞ ing beam originates from the center of the laser-beam footprint on the

inclination = arctan ⎜ 2 ⎟ . (2) target, but when the footprint overlaps areas of contrasting reflectance,

⎝ x +y ⎠

2

this concentric weighting is distorted. The effects of this error are usually

most noticeable at the edges of objects that have sky (or distant back-

3. Loading of the corrected (i.e., undistorted) images. ground beyond the range of the scanner) behind them, and is often seen as

4. Input of the tie-point coordinates. a band of sky-colored points (typically one point wide) extending around

Geosphere, June 2008 569

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestWhite and Jones

A B C

D

Figure 7. Colored point cloud of part of Durham Castle. (A) Screenshot of three-dimensional model visualized using ParaView software. (B)

Oblique view with areas of scan shadow. (C, D) Areas of detail where crenellations, buttresses, and windows reveal the quality of the color map-

ping. Vertical distance from courtyard to top of flag post is 49.4 m. Width of window lintel in (C) is 2.22 m. Height of wall in (D) is 6.05 m.

the edge of the scanned object. When a dispersed beam hits the edge of an Other sources of error relate to the discrepancy between the color of

object, part of the beam footprint is reflected and recorded by the scanner, the point in the point cloud and the color of the corresponding point in the

even though the center of the beam footprint was in the sky. The scanner subject, i.e., errors in the registration of the images with the point cloud.

therefore captures a data point beyond the edge of the object, even though In order to quantify the maximum registration error, approximate expres-

that point does not actually exist. When the resolution of the accompany- sions were derived for the angular errors at different stages in the capture

ing photo is high relative to the spacing of points in the point cloud, a thin and registration of the color information.

band of sky is mapped onto the extra trace of spurious points that flank The maximum angular registration error, αreg, is given by:

the true edge of the object. This source of error is common to all scanners

that have wide beam dispersion. It needs to be taken into consideration α reg = α pos + α rot + α rect + α tie , (3)

because the error is caused by an intrinsic property of the scanner, and is

not related to poor camera calibration or image matching. where αpos is the angular error due to positioning the center of the entrance

A second source of error can arise due to occlusion. Lim et al. (2005) pupil of the lens coincident with the beam detector of the laser scanner;

carried out an experiment using the same MDL LaserAce 600 scanner αrot is due to the deviation from vertical of the plate to which the camera

used to capture the point clouds in Figure 8. They scanned a section of attaches on the mount; αrect is the error in the rectification process using

cliff at 0.05° resolution twice in immediate succession and quantified the the GML toolbox; and αtie is due to the human judgment error in locating

discrepancies between the two scans due to occlusion errors. Occlusion the tie-points in the gray scale or false color point cloud. αpos and αrect were

errors are due to problems resulting from scanning a complex surface, quantified by making assumptions about the magnitude of tolerances and

in which some surface data are missed and, therefore, interpolated. The analytically deriving expressions for the resulting errors. αrot was deter-

errors, which are concentrated toward the edges of the scans and on pro- mined by empirically measuring the effect of an artificially applied rota-

truding ledges, occur due to the occluded data being interpolated differ- tion and αtie was based on empirical observation.

ently during successive scans. Despite these errors, Lim et al. (2005) stated When the expressions for these individual errors are substituted into the

that point cloud data acquired with the MDL LaserAce 600, over ranges above equation, the following expression is obtained for αreg, in degrees:

typically associated with scanning cliff faces, are capable of accuracies

within ±0.06 m. This error is the maximum error between the position of

⎛ 0.0025 ⎞

a subject point in space and the coordinates of the corresponding point in α reg ≈ arctan ⎜ + 0.45β + 0.017 + ( 0.5 − 0.45G ) ,

⎝ D ⎟⎠

(4)

the point cloud. The magnitude of this error is purely related to the scan-

ner; a higher quality scanner would give greater accuracy.

570 Geosphere, June 2008

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestTrue color terrestrial laser scanning

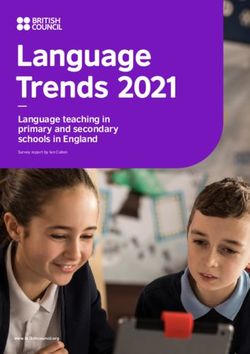

A B

C D

Figure 8. Laser scan point cloud data from a project to monitor coastal erosion at Staithes, North Yorkshire (Rosser et al.,

2005). (A) Scanning the outcrop with an MDL LaserAce 600 scanner. (B) Gray scale point cloud based on the intensity of the

reflected laser beam. (C) False color red-yellow ramp applied to intensity values (replacing the gray scale) for each point. (D)

True color point cloud significantly helps to emphasize the geological detail in the outcrop. Height of cliff is 35.5 m.

where D is the distance to the subject in meters; β is the rotation of the αreg is conservative. With G equal to unity, by far the most significant term

camera from vertical in degrees; and G is a subjective “geometricity” in the above expression is αrot, contributing 57% of the maximum regis-

coefficient. For a subject with distinct geometric features, such as a simple tration error of 0.16° when β = 0.2° and D = 5 m, and 72% of the 0.25°

building, G would take the value 1, whereas for a very irregular subject, maximum registration error when β = 0.4° and D = 70 m. To combat this

such as a cliff face, G would take a value of 0. If necessary, however, αtie error, the camera mount design could be modified so that it is stiffened, in

can be virtually eliminated by adjusting the image registration by altering order to reduce the distortion due to the weight of the camera. Better still

the three mapping parameters. To obtain the approximate maximum regis- would be the addition of a mechanism for providing a fine adjustment to

tration error in terms of a number of points, αreg should be divided by the ensure that the camera is truly vertical. This would greatly reduce the rota-

resolution of the scanner in degrees. tion error, and therefore the registration error.

Although it was necessary to make some fairly crude assumptions in The above expression was derived to give an approximate maxi-

order to derive some of the individual errors, the resulting expression for mum limit on the registration error. In practice, the errors observed are

Geosphere, June 2008 571

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestWhite and Jones

significantly less than αreg over most of the point cloud. Over those areas The level of accuracy with which the photographs can be registered with

of the point cloud colored by pixels from near edges of the photographs, the point cloud is such that the resulting true color point cloud can support

the errors approach αreg. This error analysis will allow comparisons to be very detailed analysis and data interpretation for many applications. The

drawn with associated technologies, such as photogrammetry, as well as ability to adjust the registration of the photographs with the point cloud

helping to prevent inappropriate use of the data. has considerable benefits when scanning irregular subjects such as cliff

faces, which generally have few geometrically regular features.

CONCLUSIONS Detailed error analysis enables comparisons to be drawn with related

technologies, as well as with commercially available true color terrestrial

A low-cost true color terrestrial laser scanning (TCTLS) system has laser scanners. The accuracy of the registration is comparable with that of

been developed for use in a wide variety of applications. The low cost of commercially available TCTLS devices. This novel, low-cost, accurate,

this system makes TCTLS technology more financially viable to a larger and flexible TCTLS technology has the potential to make a significant

number of people in a greater range of fields. The flexibility of the system impact on the spatial data acquisition capabilities of many companies and

also provides a useful platform for further research into TCTLS to test per- academic institutions. We hope that this paper will provide the basis for

formance of a range of digital cameras, lenses, and laser scanner devices. further research and development in the fields of low-cost TCTLS and the

True color capability can be added to existing terrestrial laser scanners analytic mapping approach, and that it has the potential to lead to the com-

using a purpose-built camera mount and coregistration software. The camera mercial implementation of a user-friendly, low-cost, true color terrestrial

mount allows the photographs to be captured from exactly the same point as laser scanning system.

the point cloud and, in doing so, reduces one source of error present in some

commercial laser scanners that use top-mounted cameras. Using a digital APPENDIX

SLR, rather than onboard video circuitry mounted inside the scanner, pro-

vides higher resolution images, and gives more faithful chromatic data. First, the mapping functions for the horizontal case will be derived. These func-

The use of an adjustable camera mount, which takes a range of cam- tions are then extended to account for the case where the camera is tilted. Finally, a

method is determined for solving the resulting functions for a pair of tie-points for

eras, allows the user flexibility over the hardware used to capture the data. each image. Figure 9 shows the relationship between the laser scanner coordinate

Further work is under way to construct an automated system prototype system and the virtual image plane with its coordinate system. The laser scanner

that applies the same principles of image and/or scan coregistration to a center and the virtual image plane are separated by a virtual distance, d, perpen-

motorized version of the camera mount. dicular to the plane. θc is the angle from the azimuth zero line to the center of the

virtual image plane, and u' and v' define an alternative image coordinate system

The calibration of the camera is simple and quick, using a stiff planar with respect to an origin at the center of the virtual image plane.

checkered calibration target and standard camera calibration algorithms. Deriving an expression for u in the horizontal case, considering triangle OAC:

There is no requirement for the camera to be calibrated prior to taking the

photographs, and each camera and lens need only be calibrated once. The

u′

undistortion process is fast and allows a batch of images to be undistorted tan ( θ − θc ) = . (5)

with one click of a mouse. d

Figure 9. Relationship between the laser scanner and the virtual image plane in the case where the lens is

pointing horizontally. See text for definition of symbols.

572 Geosphere, June 2008

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestTrue color terrestrial laser scanning

Converting between u' and u: In order to derive expressions for u and v in the case where the camera is tilted at

an angle θc to the horizontal, the coordinate system shall be rotated by θc about the

y axis. The rotation matrix required to perform the rotation by angle φc about the

U

u′ = u − . (6) y axis is:

2

⎡ cos φ c 0 sin φ c ⎤

⎢ 0

Substituting for u' in equation 5:

⎢ 1 0 ⎥⎥ . (16)

u −U ⎢⎣ − sin φ c 0 cos φ c ⎥⎦

tan ( θ − θc ) = 2 . (7)

d

Rearranging:

U

u= + d tan ( θ − θc ) . (8)

2

Deriving an expression for v in the horizontal case, considering the triangle defined

by O, A, and the point (u, v):

v′

tan φ = . (9)

l

Considering triangle OAC:

d

cos ( θ − θc ) = . (10)

l

Rearranging:

l = d sec ( θ − θc ) . (11)

Converting between v' and v:

Figure 10. Relationship between the laser scanner and virtual image

V plane in the general case where the camera is tilted. See text for

v′ = − v . (12)

2 definition of symbols.

Substituting for v' and l in equation 9:

z

V −v

tan φ = 2

. (13)

d sec ( θ − θc )

(x,y,z)

Rearranging:

y

V

v= − d sec ( θ − θc ) tan φ . (14) ф

2

θc

θ

Next, the general case in which the camera can be tilted at an angle to the horizontal x

is considered. Figure 10 shows the relationship between the laser scanner coordi-

nate system and the image plane coordinate system in the tilted case.

First, converting between Cartesian coordinates and spherical polar coordinates

as defined in Figure 11:

⎡ x ⎤ ⎡ cos ( θ − θc ) cos φ ⎤

⎢ y ⎥ = ⎢ sin θ − θ cos φ ⎥ .

⎢ ⎥ ⎢ ( c)

(15) Figure 11. Relationship between Cartesian coordinate system and

⎥

⎢⎣ z ⎥⎦ ⎢⎣ ⎥ spherical polar coordinate system on a sphere of unit radius. See

sin φ ⎦ text for definition of symbols.

Geosphere, June 2008 573

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestWhite and Jones

Therefore, premultiplying the matrix on the right side of equation 15 by the rotation

matrix above:

v=

V d ( sec ( θ − θc ) tan φ − tan φ c

−

) . (25)

2 1 + sec ( θ − θc ) tan φ tan φ c

⎡ cos ( θ′ − θc ) cos φ ′ ⎤ ⎡ cos φ c 0 sin φ c ⎤ ⎡ cos ( θ − θc ) cos φ ⎤

⎢ ⎥ ⎢ ⎢ ⎥

⎢ sin ( θ′ − θc ) cos φ ′ ⎥ = ⎢ 0 1 0 ⎥⎥ ⎢ sin ( θ − θc ) cos φ ⎥ Now a method of solution of equations 24 and 25 is described that can be imple-

mented algorithmically (e.g., in a Matlab program).

⎢ ⎥ 0 cos φ c ⎥⎦ ⎢⎣ ⎥

⎣ sin φ ′ ⎦ ⎢⎣ − sin φ c sin φ ⎦ For each image, if the u, v coordinates of two points in the image and the corre-

sponding θ, φ coordinates of the same two points in the point cloud are known, and

given the horizontal and vertical pixel dimensions of the image, then four equations

⎡ cos ( θ′ − θc ) cos φ ′ ⎤ ⎡ cos φ c cos ( θ − θ c ) cos φ + sin φ c sin φ ⎤ can be formed containing only three unknown mapping parameters, θc, φc, and d:

⎢ ⎥ ⎢ ⎥ . (17)

⎢ sin ( θ′ − θc ) cos φ ′ ⎥ = ⎢ sin ( θ − θc ) cos φ Tie-points (u1, v1, θ1, φ1) and (u2, v2, θ2, φ2):

⎥

⎢ sin φ ′ ⎥ ⎢ cos φ c sin φ − sin φ c cos ( θ − θc ) cos φ ⎥

⎣ ⎦ ⎣ ⎦

U d tan ( θ1 − θc ) sec φ c

u1 = + (26)

The equations corresponding to equations 8 and 14 for the tilted case are: 2 1 + sec ( θ1 − θc ) tan φ1 tan φ c

U

u= + d tan ( θ′ − θc )

2

(18) U d tan ( θ2 − θc ) sec φ c

u2 = + (27)

and 2 1 + sec ( θ2 − θc ) tan φ 2 tan φ c

V

− d sec ( θ′ − θc ) tan φ ′ . )

V d ( sec ( θ1 − θc ) tan φ1 − tan φ c

v= (19)

2 v1 = − (28)

2 1 + sec ( θ1 − θc ) tan φ1 tan φ c

Using equation 17 to express tan(θ'– θc) in terms of θ, φ, θc, and φc:

v2 =

V d ( sec ( θ2 − θc ) tan φ 2 − tan φ c

−

)

sin ( θ′ − θc ) cos φ ′ 1 + sec ( θ2 − θc ) tan φ 2 tan φ c

. (29)

tan ( θ′ − θc ) = 2

cos ( θ′ − θc ) cos φ ′

Only three of these equations are required in order to solve for the three mapping

parameters.

sin ( θ − θc ) cos φ If the three simultaneous nonlinear equations 26, 27, and 28 are rearranged

= . (20)

cos φ c cos ( θ − θc ) cos φ + sin φ c sin φ thus:

U d tan ( θ1 − θc ) sec φ c

Similarly, using equation 17 to express sec(θ'– θc) tan φ in terms of θ, φ, θc, and φc: f ( θc , φ c , d ) = − u1 + (30)

2 1 + sec ( θ1 − θc ) tan φ1 tan φ c

sin φ ′

sec ( θ′ − θc ) tan φ ′ =

cos ( θ′ − θc ) cos φ ′ U d tan ( θ2 − θc ) sec φ c

g ( θc , φ c , d ) = − u2 + (31)

2 1 + sec ( θ2 − θc ) tan φ 2 tan φ c

cos φ c sin φ − sin φ c cos ( θ − θc ) cos φ

=

cos φ c cos ( θ − θc ) cos φ + sin φ c sin φ

. (21)

h ( θc , φ c , d ) =

V

− v1 −

d ( sec ( θ1 − θc ) tan φ1 − tan φ c ) , (32)

2 1 + sec ( θ1 − θc ) tan φ1 tan φ c

Multiplying numerator and denominator of both the above expressions by sec φc

sec(θ – θc) sec φ: then they can be solved by using Newton’s method (http://numbers.computation

.free.fr/Constants/Algorithms/newton.html) in the following form:

tan ( θ − θc ) sec φ c

tan ( θ′ − θc ) = (22) ⎡ θc ⎤ ⎡ θc ⎤ ⎡ f ( θc , φ c , d ) ⎤

1 + sec ( θ − θc ) tan φ tan φ c

⎢ φ ⎥ = ⎢ φ ⎥ − J −1 θ , φ , d ⎢ g θ , φ , d ⎥ ,

⎢ c⎥ ⎢ c⎥ ( c c ) ⎢ ( c c )⎥ (33)

⎢⎣ d ⎥⎦ n +1 ⎢⎣ d ⎥⎦ n ⎢ h ( θc , φ c , d ) ⎥

sec ( θ − θc ) tan φ − tan φ c ⎣ ⎦n

sec ( θ′ − θc ) tan φ ′ = . (23)

1 + sec ( θ − θc ) tan φ tan φ c where J is the Jacobian matrix:

⎡ ∂f ∂f ∂f ⎤

Substituting for tan(θ´– θc) from equation 22 into equation 18, and for sec(θ′ – θc) ⎢ ⎥

tan φ′ from equation 23 into equation 19 to give expressions for u and v for the ⎢ ∂θc ∂φ c ∂d ⎥

tilted case: ⎢ ∂g ∂g ∂g ⎥

J ( θc , φ c , d ) = ⎢ ⎥

U d tan ( θ − θc ) sec φ c ⎢ ∂θc ∂φ c ∂d ⎥ . (34)

u= + (24) ⎢ ∂h ∂h ∂h ⎥

2 1 + sec ( θ − θc ) tan φ tan φ c ⎢ ⎥

⎣ ∂θc ∂φ c ∂d ⎦

574 Geosphere, June 2008

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestTrue color terrestrial laser scanning

ACKNOWLEDGMENTS Labourdette, R., and Jones, R.R., 2007, Characterization of fluvial architectural elements

using a three dimensional outcrop dataset: Escanilla braided system—South-central

Pyrenees, Spain: Geosphere, v. 3, p. 422–434, doi: 10.1130/GES00087.1.

We thank John Parker for his help with the analytical mapping, and Nick Rosser,

Lim, M., Petley, D.N., Rosser, N.J., Allison, R.J., Long, A.J., and Pybus, D., 2005, Com-

Alan Purvis, David Toll, Roger Little, Nick Holliman, and Steve Waggott (Hal- bined digital photogrammetry and time-of-flight laser scanning for monitoring cliff

crow) for their help and insight. We also thank Jerry Bellian and Klaus Gessner for evolution: Photogrammetric Record, v. 20, no. 110, p. 109–129, doi: 10.1111/j.1477-

useful reviews, as well as Tim Wawrzyniec and Randy Keller for editorial input. 9730.2005.00315.x.

Aspects of material presented in this paper are protected under UK and Interna- Løseth, T.M., Thurmond, J., Søegaard, K., Rivenæs, J.C., and Martinsen, O.J., 2003, Build-

tional Patent laws. ing reservoir model using virtual outcrops: A fully quantitative approach: American

Association of Petroleum Geologists, International Meeting, Programs with Abstracts,

Salt Lake City, Utah, May 9–14.

REFERENCES CITED

McCaffrey, K.J.W., Jones, R.R., Holdsworth, R.E., Wilson, R.W., Clegg, P., Imber, J., Hol-

liman, N., and Trinks, I., 2005, Unlocking the spatial dimension: Digital technologies

Abdelhafiz, A., Riedel, B., and Niemeier, W., 2005, Towards a 3D true coloured space by the and the future of geoscience fieldwork: Geological Society [London] Journal, v. 162,

fusion of laser scanner point cloud and digital photos, in El-Hakim, S., et al., eds., Vir- p. 927–938, doi: 10.1144/0016-764905-017.

tual reconstruction and visualization of complex architectures: International Archives of Prescott, B., and McLean, G.F., 1997, Line-based correction of radial lens distortion: Graphical

Photogrammetry, Remote Sensing, and Spatial Information Sciences, v. 36, part 5/W17, Models and Image Processing, v. 59, no. 1, p. 39–47, doi: 10.1006/gmip.1996.0407.

http://www.commission5.isprs.org/3darch05/pdf/31.pdf (August 30, 2007). Poropat, G.V., 2001, New methods for mapping the structure of rock masses, in Proceedings,

Abmayr, T., Härtl, F., Mettenleiter, M., Heinz, I., Hildebrand, A., Neumann, B., and Fröhlich, Australian Institute of Mining and Metallurgy Conference, EXPLO2001, Hunter Valley,

C., 2004, Realistic 3D reconstruction—Combining laserscan data with RGB color NSW, Australia.

information: International Archives of Photogrammetry, Remote Sensing, and Spa- Pringle, J.K., Clark, J.D., Westerman, A.R., Stanbrook, D.A., Gardiner, A.R., and Morgan,

tial Information Sciences, v. 35, part B5, http://www.isprs.org/istanbul2004/comm5/ B.E.F., 2001, Virtual outcrops: 3-D reservoir analogues, in Ailleres, L., and Rawling, T.,

papers/549.pdf (August 30, 2007). eds., Animations in geology: Journal of the Virtual Explorer, v. 3, http://virtualexplorer

Abmayr, T., Dalton, G., Hines, D., Liu, R., Härtl, F., Hirzinger, G., and Fröhlich, C., 2005, .com.au/journal/2001/04/pringle/

Standardization and visualization of 2.5D scanning data and color information by Pringle, J.K., Westerman, A.R., Clark, J.D., Drinkwater, N.J., and Gardiner, A.R., 2004, 3D

inverse mapping, in Proceedings, Conference on Optical 3D Measurement Techniques, high-resolution digital models of outcrop analogue study sites to constrain reservoir

7th, Vienna, Austria: TU Wien, p. 164–173. model uncertainty: An example from Alport Castles, Derbyshire, UK: Petroleum Geo-

Ahlgren, S., and Holmlund, J., 2002, Outcrop scans give new view: American Association of science, v. 10, p. 343–352.

Petroleum Geologists Explorer, p. 22–23. Pringle, J.K., Hodgetts, D., Howell, J.A., and Westerman, A.R., 2006, Virtual outcrop models

Balis, V., Karamitsos, S., Kotsis, I., Liapakis, C., and Simpas, N., 2004, 3D-laser scanning: Inte- of petroleum reservoir analogues—A review of the current state-of-the-art: First Break,

gration of point cloud and CCD camera video data for the production of high resolution v. 24, p. 33–42.

and precision RGB textured models: Archaeological monuments surveying application Rosser, N.J., Petley, D.N., Lim, M., Dunning, S.A., and Allison, R.J., 2005, Terrestrial

in ancient Ilida, in Proceedings, FIG Working Week, Athens, Greece, May 22–27, 2004: laser scanning for monitoring the process of hard rock coastal cliff erosion: Engi-

http://www.fig.net/pub/athens/papers/wsa2/WSA2_5_Balis_et_al.pdf (August 30, 2007). neering Geology and Hydrogeology Quarterly Journal, v. 38, p. 363–375, doi:

Barber, D.M., Dallas, R.W.A., and Mills, J.P., 2006, Laser scanning for architectural conser- 10.1144/1470-9236/05-008.

vation: Journal of Architectural Conservation, v. 12, p. 35–52. Shih, S.W., Hung, Y.P., and Lin, W.S., 1995, When should we consider lens distor-

Bellian, J.A., Kerans, C., and Jennette, D.C., 2005, Digital outcrop models: Applications of tion in camera calibration: Pattern Recognition, v. 28, no. 3, p. 447–461, doi:

terrestrial scanning lidar technology in stratigraphic modelling: Journal of Sedimentary 10.1016/0031-3203(94)00107-W.

Research, v. 75, p. 166–176, doi: 10.2110/jsr.2005.013. Slob, S., and Hack, R., 2004, 3D terrestrial laser scanning as a new field measurement and

Bellian, J.A., Beck, R., and Kerans, C., 2007, Analysis of hyperspectral and lidar data: monitoring technique, in Hack, R., et al., eds., Engineering geology for infrastructure

Remote optical mineralogy and fracture identification: Geosphere, v. 3, p. 491–500, planning in Europe: Berlin, Springer Verlag, p. 179–189.

doi: 10.1130/GES00097.1. Slob, S., van Knapen, B., Hack, R., Turner, K., and Kemeny, J., 2005, A method for auto-

Dunn, M.C., 2005, Laser scanning for everyday work: American Surveyor, January/February, mated discontinuity analysis of rock slopes with three-dimensional laser scanning:

http://www.theamericansurveyor.com/toc2-05.php (August 30, 2007). Transportation Research Record, no. 1913(2005)1, p. 187–208.

El-Hakim, S., Remondino, F., and Gonzo, L., eds., 2005, Virtual reconstruction and visu- Thies, M., Koch, B., Spiecker, H., and Weinacker, H., eds., 2004, Laser-scanners for forest and

alisation of complex architectures: International Archives of Photogrammetry, Remote landscape assessment: Proceedings of the ISPRS working group VIII/2: International

Sensing, and Spatial Information Sciences, v. 36, part 5/W17, http://www.commission5 Archives of Photogrammetry, Remote Sensing, and Spatial Information Sciences, v. 36,

.isprs.org/3darch05/ (August 30, 2007). part 8/W2, http://www.isprs.org/commission8/workshop_laser_forest/ (August 30, 2007).

Grammatikopoulos, L., Kalisperakis, I., Karras, G., Kokkinos, T., and Petsa, E., 2004, On Trinks, I., Clegg, P., McCaffrey, K.J.W., Jones, R.R., Hobbs, R., Holdsworth, R.E., Holli-

automatic orthoprojection and texture-mapping of 3D surface models: International man, N., Imber, J., Waggott, S., and Wilson, R., 2005, Mapping and analysing virtual

Archives of Photogrammetry, Remote Sensing, and Spatial Information Sciences, v. 35, outcrops: Visual Geosciences, v. 10, no. 1, p. 13–19, http://www.springerlink.com/

part B5, http://www.isprs.org/istanbul2004/comm5/papers/579.pdf (August 30, 2007). openurl.asp?genre=article&id=doi:10.1007/s10069-005-0026-9 (August 30, 2007),

Haneberg, W.C., 2004, A rational probabilistic method for spatially distributed landslide doi: 10.1007/s10069–005–0026–9.

hazard assessment: Environmental & Engineering Geoscience, v. 10, p. 27–43, doi: Tsai, R.Y., 1987, A versatile camera calibration technique for high-accuracy 3D machine

10.2113/10.1.27. vision metrology using off-the-shelf TV cameras and lenses: IEEE Journal on Robotics

Heikkilä, J., and Silvén, O., 1997, A four-step camera calibration procedure with implicit image and Automation, v. 3, no. 4, p. 323–344.

correction, in Proceedings, IEEE Computer Society Conference on Computer Vision and Pat- Vezhnevets, V., and Velizhev, A., 2005, GML C++ Camera Calibration Toolbox v. 0.31:

tern Recognition (CVPR’97), June 17–19, 1997, San Juan, Puerto Rico, p. 1106–1112. Graphics & Media Lab, Moscow State University, http://research.graphicon.ru/

Hunter, G., Cox, C., and Kremer, J., 2006, Development of a commercial laser scanning calibration/gml-c++-camera-calibration-toolbox.html.

mobile mapping system—StreetMapper, in Everaerts, J., ed., The future of remote sens- Vezhnevets, V., and Velizhev, A., 2006, GML C++ Camera Calibration Toolbox v. 0.4:

ing: International Archives of Photogrammetry, Remote Sensing, and Spatial Informa- Graphics & Media Lab, Moscow State University, http://research.graphicon.ru/

tion Sciences, v. 36, part 1/W44, http://www.pegasus4europe.com/pegasus/workshop/ calibration/gml-c++-camera-calibration-toolbox.html.

documents/contributions/Hunter_full.pdf (August 30, 2007). Waggott, S., Clegg, P., and Jones, R., 2005, Combining terrestrial laser-scanning, RTK GPS

Jacobs, G., 2005, Laser scanning today: “Another Tool in the Kit”: Professional Surveyor and 3D visualisation: Application of optical 3D measurement in geological explora-

Magazine, v. 25, no. 1, http://www.profsurv.com/archive.php?issue=96&article=1361 tion, in Proceedings, Conference on Optical 3D Measurement Techniques, 7th, Vienna,

(August 30, 2007). Austria: TU Wien.

Jones, R.R., McCaffrey, K.J.W., Wilson, R.W., and Holdsworth, R.E., 2004, Digital field Xu, X., Aiken, C., Bhattacharya, J., Corbeanu, R., Nielsen, K., McMechan, G., and Abdel-

data acquisition: Towards increased quantification of uncertainty during geological salam, M., 2000, Creating virtual 3-D outcrop: The Leading Edge, v. 19, no. 2,

mapping, in Curtis, A., and Wood, R., eds., Geological prior information: Geological p. 197–202, doi: 10.1190/1.1438576.

Society [London] Special Publication 239, p. 43–56. Zhang, Z.Y., 2000, A flexible new technique for camera calibration: IEEE Transactions

Jones, R.R., McCaffrey, K.J.W., Imber, J., Wightman, R., Smith, S.A.F., Holdsworth, R.E., on Pattern Analysis and Machine Intelligence, v. 22, no. 11, p. 1330–1334, doi:

Clegg, P., De Paola, N., Healy, D., and Wilson, R.W., 2008, Calibration and validation 10.1109/34.888718.

of reservoir models: the importance of high resolution, quantitative outcrop analogues,

in Griffith, P., et al., eds., The future of geological modelling in hydrocarbon develop-

ment. Geological Society [London] Special Publication xxx, (in press).

Kerr, D.A., 2005, The proper pivot point for panoramic photography: http://doug.kerr.home.

att.net/pumpkin/Pivot_Point.pdf (August 30, 2007).

Kokkalas, S., Jones, R.R., McCaffrey, K.J.W., and Clegg, P., 2007, Quantitative fault analysis MANUSCRIPT RECEIVED 17 SEPTEMBER 2007

at Arkitsa, central Creece, using terrestrial laser-scanning (“LiDAR”): Geological Soci- REVISED MANUSCRIPT RECEIVED 8 DECEMBER 2007

ety of Greece Bulletin, v. XXXVII. MANUSCRIPT ACCEPTED 29 JANUARY 2008

Geosphere, June 2008 575

Downloaded from https://pubs.geoscienceworld.org/gsa/geosphere/article-pdf/4/3/564/3338879/i1553-040X-4-3-564.pdf

by guestYou can also read