En-route to the A350 - "Overcoming time zones"

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

The Lufthansa Technik Group Magazine 5.2014 September/October

New aircraft

En-route to the A350

Sales reorganization

“Overcoming

time zones”

Technical Operations Management

Added value

through integration

NASA jumbo overhaul

Rejuvenating a

special lady2 | Content Lufthansa Technik Connection 5.2014

Company

En-route to the A350 • Interview with Walter Heerdt: 6

“Overcoming time zones”

Lufthansa Passage, Lufthansa Technik and Airbus put the on-board

and ground handling procedures under the microscope.

New aircraft

• Route proving tour: 8

En-route to the A350

• Lufthansa Technik Philippines: 11

Expanded A380 capabilities

8

Technology & Innovation

• Thermographic crack 12

detection (TCD):

Walking robot inspects fuselage

eServices

• manage/m®: 14

Walking robot inspects fuselage New features for m/material

A new robot automates the thermographic crack

Engine Services

detection (TCD) for the inspection of aircraft fuselages.

• Cooperation with Middle River 15

Aircraft Systems (MRAS):

GEnx thrust reverser overhaul

Aircraft Services

12

• NASA jumbo: 16

Rejuvenating a special lady

• Lufthansa Technik Philippines: 20

A320 Sharklet retrofit in Manila

• A310 aircraft conversion: 22

From VIP to ZERO-G

Component Services

Rejuvenating a special lady • A340 main landing gear: 21

Electroplating shop expands

NASA’s flying observatory SOFIA is undergoing a

capacity

major overhaul at Lufthansa Technik in Hamburg.

Total Support Services

• Technical Operations Management: 24

Added value through integration

16

Events & Exhibitions

• NBAA 2014: 26

Display with a “wow” effect

Categories

• News 3–5

• Personalities 25

24

• Products & Services 28

• Contacts 30

Lufthansa Technik Connection

is a complimentary information service for Lufthansa Technik’s

family and friends. Published every two months.

This and earlier issues can be downloaded from our website

www.lufthansa-technik.com/connection

Publisher

Lufthansa Technik AG

Tilman Tesseraux · Marketing & Sales · HAM TS/M

Weg beim Jäger 193 · 22335 Hamburg, Germany

Infoline +49-40-5070-5553 · Fax +49-40-5070-8860

Added value through integration marketing.sales@lht.dlh.de · www.lufthansa-technik.com

Editorial Production

Editorial office: Flightlines, Hamburg

Placing Technical Operations Management (TOM) in the Design: Art Works! Werbeagentur, Hamburg

hands of Lufthansa Technik is a highly beneficial solution. Photos: Lufthansa Technik AG, Lufthansa AG

Printing: Beisner Druck GmbH & Co. KGLufthansa Technik Connection 5.2014 News | 3

And the 1,500th jumbo jet goes to…

…Lufthansa! When Lufthansa’s 14th Boeing 747-8 landed in Frankfurt in June it was

not only the 76th jumbo that Lufthansa has received from Boeing in Seattle since the 1970s –

the aircraft also represents a veritable milestone in aviation history.

first European carrier to deploy the jumbo

on scheduled services. The aircraft was

host to several major world premières in

succession, including the first film shown

on board a jumbo jet. Only twenty months

after the maiden flight of the Boeing 747-130,

the fourth Lufthansa jumbo took off on

2 April 1971 as a modified model. Boeing

had equipped the 747-200 with larger

fuel tanks and a higher take-off weight of

378 tons. This meant that the aircraft had

a longer range.

Significant technological input

“A step towards the 1990s” is how Lufthansa

CEO Heinz Ruhnau described the purchase

agreement signed on 23 June 1986 for an

T

his aircraft, whose tail number is lower. The noise footprint of the Boeing initial order of six enhanced Boeing air-

D-ABYP (“Yankee Papa”), is the 747-8 is 30 per cent smaller compared craft. Lufthansa had already been involved

1,500th jumbo to be built in the with the older Boeing 747-400. in the planning of the Boeing 747-100.

world. “It’s an honour for Lufthansa that the What started as the first training flight However, as the first airline to order the

anniversary jumbo will fly in the colours of with the new Boeing 747 over the moun- “Dash 400” (Boeing 747-400), it now

the Lufthansa crane,” said Nico Buchholz, tains east of Seattle in October 1969 went played a key part in the development of the

Head of Group Fleet Management at on to become an icon of the Lufthansa new aircraft, providing many hundreds of

Deutsche Lufthansa. “For decades, Luft- fleet, and, indeed, of commercial aviation suggestions for improvements and more

hansa has been one of the aircraft manu- as a whole. On 9 March 1970, the then than 20,000 engineer hours.

facturer’s closest advisers – a pioneer when Lufthansa CEO Herbert Culmann took With this aircraft, the modern, digitalised

it comes to developing new, environmental- delivery of the first Lufthansa Boeing 747- two-man cockpit that Jürgen Weber, the

ly friendly and fuel-efficient aircraft,” added 130 in front of the factory in Everett. The man responsible for aircraft development

Buchholz at the handover in Seattle. aircraft’s production number was 12 and at Lufthansa Technik in Hamburg at the

its Lufthansa registration was D-ABYA. time and later Chairman of the Executive

World's largest 747-8 operator Lufthansa thereby became the second Board and CEO of Lufthansa, and Reinhard

international airline, after PanAm, and the Abraham, the former Chief Technical Officer

Lufthansa is expecting to receive a total of of the Lufthansa Group, had worked to

19 aircraft of this type, and will therefore be achieve became a reality.

the world’s largest operator of 747-8s As the new millennium started, the idea

among passenger airlines. The “Dash 8”, was put forth to develop an enhanced

as it is also known, has plenty to offer. By version of the Boeing 747-400. And so not

using the latest jumbo, Lufthansa is taking only was the jumbo extended by 5.6 meters,

a further step towards having a “three-liter it was also totally redeveloped, including

fleet” (per passenger and 100 kilometers). a new wing design and new engines. On

The aircraft is 15 percent more fuel-efficient 2 May 2012, Lufthansa became the first

than its predecessor model and, as a result, passenger airline in the world to receive

its CO2 emissions are around 15 percent a Boeing 747-8.4 | News Lufthansa Technik Connection 5.2014

Frankfurt

Beijing

147 young people

begin training

Hamburg Training // At the traditional

start of the German training

Line maintenance for year in August, 147 young

Singapore’s A380 people are beginning either

25 years of ETOPS

Ameco Beijing // Lufthansa traditional or dual-study training Authority approvals // On 12

Technik’s Chinese affiliate has programs with the Lufthansa June 1989 a Lufthansa Airbus

started to provide line mainte- Technik Group. All told, Luft- A300 took off from Frankfurt

nance and aircraft releasing

Training capabilities hansa Technik will be home to am Main for its inaugural flight

services for Singapore Airlines’

updated 591 trainees on their way to to Montréal and Philadelphia.

A380 aircraft which is used by Lufthansa Technical Training // professions in technical aircraft This was the first time that Luft

the carrier on Beijing-Singapore The new capability list of Luft- services or aircraft logistics. hansa had used a twinjet on a

route, seven flights per week. hansa Technical Training is One highlight of the current long-haul route and marks the

Ameco has already been pro- available online at the training training year is the success of start of such flying operations.

viding line maintenance and provider’s website. Please the company’s measures to The certification of the Airbus

aircraft releasing services for scan the QR increase the number of trainees A310-300 and A300-600R for

Singapore Airlines’ Boeing 777 code for a PDF with lower-level secondary ETOPS – Extended-Range

and Airbus A330 in Beijing download or school qualifications. And as is Twin-Engine Operational Per-

since 2011. In addition to Sin- follow this link. now traditional, several deaf formance Standards – by the

gapore Airlines, Ameco also www.ltt.aero // trainees are among those European and American avia-

provides line maintenance to “learning the ropes” as tool tion authorities had cleared the

Lufthansa’s A380 in Beijing. // mechanics. way for the highly economic

72 of the new trainees are twinjet to be used on long-haul

beginning programs in Ham- routes. On the other hand

burg, 47 in Frankfurt, 18 in ETOPS-related procedures con-

Arnstadt, 7 in Alzey and 3 in tinue to this day to be defined

Munich. They were able to by the International Civil Aviation

choose between 13 different Organization (ICAO).

professions and practice-ori- In the early days of ETOPS

ented courses of study. The flying operations at Lufthansa

percentage of women among there was a requirement that

the new trainees has risen to the aircraft should be within

15 percent. Lufthansa Technik 120 minutes’ flying time of a

will continue its efforts to seek suitable alternate airfield at all

out and inform young women times to cover potential emer-

about the variety of possibilities gencies. In the course of the 25

available in technical profes- years that have elapsed since

sions. // then there has been a series of

new, even more reliable engine

and aircraft types for which

this limit has been raised. Thus,

Airbus is aiming to have its

latest A350 XWB certified for a

diversion period in excess of

180 minutes. //Lufthansa Technik Connection 5.2014 News | 5

Frankfurt

Hamburg

Authorized training SAS launching

provider for CSeries customer for HelioJet

Lufthansa Technical Training // Original Equipment Innovation

Bombardier announced at the // Scandinavian Airlines System

Farnborough International

Beijing

Tracking goes mobile (SAS) and Lufthansa Technik

Airshow that it has appointed Logistics // The mobile version have signed a contract for the

Lufthansa Technical Training of Lufthansa Technik Logistik delivery of HelioJet, making

(LTT) as its exclusive Authorized Services (LTLS)’s web-based SAS the launching customer

Training Provider for the main- consignment tracking and trac- for the new LED cabin lighting

tenance training on the all-new

Upgrade of 4-bay ing system has been available system. HelioJet is part of a

CSeries aircraft worldwide.

hangar since the end of July. This is comprehensive cabin modifi-

As Authorized Training Provider Investment // In response to based on the L/tracking Inter- cation program for seven Air-

for maintenance training for the the growth in its aircraft over- net platform already used by a bus A330/A340 aircraft which

CSeries aircraft, Lufthansa haul workload, Ameco Beijing lot of customers. Now custom- SAS is executing over the next

Technical Training will be hand has begun to install a tail dock ers can also retrieve the status months.

ling the worldwide manufac in its current 4-bay hangar. The of their important material ship- HelioJet has been designed

turer type training courses for new dock meets the needs of ments on their mobile devices and developed in a cooperation

technical aviation personnel. new aircraft types such as the at any time. To make this possi- between the German glass and

Through its expertise and its Boeing 787 and 747-8. ble, Lufthansa Technik Logistik lighting specialist SCHOTT and

experience as a recognized The company is investing more Services has added a website Lufthansa Technik. It has the

training provider, Lufthansa than one million USD in the up- that is optimized for mobile advantages of LED technology

Technical Training will also grade, which will significantly devices such as smartphones without the color changes that

support Bombardier in the reduce turnaround time while and tablets to its web-based normally afflict ageing LEDs.

development of EASA-approved improving safety for both the tracking & tracing platform The latest version, HelioJet

courseware. aircraft and the mechanics L/tracking. SpectrumCC (Color Control),

At the same time, Flight Training who work on them. The instal- Customers can view a list of the offers a full color RGBW (red-

Alliance, a newly formed joint lation is due to be finished by latest transports and full details green-blue white) LED system.

venture between the Canadian the end of September. // of individual shipments on their Consisting of just a few ele-

manufacturer of simulation smart phones via a simplified ments, the system can be inte-

technologies CAE and Lufthansa and user-friendly interface. They grated into cabins of every

Flight Training (LFT), will support also have ready access to con- size. Heliojet is flexible enough

Bombardier’s CSeries aircraft tact details for their points of to enable the light to be con-

entry into service by providing contacts at Lufthansa Technik trolled by the airline cabin

comprehensive pilot and cabin Logistik Services, for example. crew using an integrated

crew training to CSeries aircraft Search facilities enable consign- touchscreen with Graphical

customers and operators ments to be searched by select- User Interface.

worldwide. // ed parameters. The mobile Classic LED systems undergo

version builds on the good uneven changes of color during

experience gained with the the course of their installations

operation of L/tracking. Numer- resulting in unpleasant interior

ous customers lighting conditions. //

already use the

L/tracking web-

based tracking

system. //6 | Company Lufthansa Technik Connection 5.2014

“Overcoming time zones”

Walter Heerdt, Senior Vice President Corporate Sales & Marketing, explains how Lufthansa

Technik’s new sales organization is ensuring even faster support and more proximity to its

customers. Among other measures, this will be achieved by shifting senior management into

the regions, increasing the local presence of staff and accelerating processes.

Connection: What were the most What do you expect in terms of Lufthansa Technik already has sales

important drivers in the reorganization added value for your customers? representatives in the regions. What’s

of Sales at Lufthansa Technik? First of all, we want to align all sales behind the stronger local presence,

Walter Heerdt: The Lufthansa Technik activities across the entire Lufthansa Technik especially the new senior management

MRO network has grown over time. network to the individual needs of our level?

Beyond that, market requirements have customers. One aspect is the appropriate It’s true that we already have staffed

changed. So, the reorganization naturally number of contact persons – if desired, a local offices in many different locations.

wasn’t an end in itself; it was motivated by “one face to the customer” approach. This network covers our present require-

the knowledge that changes are necessary We want to further increase responsive- ments. However, it is not static and will be

in order to achieve our targets. We know ness and speed. Strengthening our sales adjusted whenever and wherever needed.

that these depend on the customers’ trust force in the regions will reduce travel time In most cases the present processes

and satisfaction. Both result from our per- and help us to be present when needed. require coordination with the headquarters

formance, but also from our understanding The hiring of additional local employees will in Germany. With the new organization we

of the customer’s business model and our help us understand local cultures better and, will establish three areas, one in Asia/Pacific,

possible contribution to its success. if needed, overcome language barriers. located in Singapore, one for the Americas,

Still closer to the customer

Lufthansa Technik has restructured its sales organization with the goal of offering

customers services that will make them successful in a highly competitive business.

Corporate Sales // Knowing first-hand its sales organization. While the globally of customer understanding and for the

that the market and the needs of its present MRO provider has an excellent flexibility in tailoring services even more

customers have changed over the past reputation in the market, the company to individual customer and regional needs.

years, Lufthansa Technik has restructured saw the need for an even higher degree A new sales structure which actively

promotes a regionalization is to bring

the company closer to both the

markets and the customers.

Under the lead of Walter Heerdt,

Senior Vice President Corporate

Sales & Marketing, three new

main departments have been created

to achieve this goal: Corporate Sales

EUMEA (Europe, Middle East and

Africa), Corporate Sales Asia and

Corporate Sales Americas. While Gerald

Steinhoff has assumed his new position

as Vice President Corporate Sales Asia,

Wolfgang Weynell, formerly

Vice President Marketing &

Sales, is the new Vice Presi-

Corporate Sales Corporate Sales Corporate Sales dent Corporate Sales EUMEA

Americas Europe, Middle East Asia and Americas (acting). //

and AfricaLufthansa Technik Connection 5.2014 Company | 7

located in Miami, and one for Europe, the

Middle East & Africa, located in Hamburg.

Each of them is headed by a Vice

President. Each area is made up of sales

regions with offices in many locations.

With the new structure we intend to place

more responsibilities and competencies in

the regions. This delegated autonomy

allows for faster solutions and answers to

issues that come up.

Walter Heerdt, Senior Vice President Corporate Sales & Marketing

But the teams can’t succeed without the

support of the product divisions. How do

you support them? cation. As a result, the sales and product level. We are confident that these mea-

In addition to the external organization sales team can act as tandems within the sures will enable us to be even better at

I’ve just described, there is of course still regions. Together with our product experts, providing our customers the right products

an internal unit – our Sales Support Team – this combined know-how helps us to and to offer new ideas to the MRO market.

that is dedicated to backing up our sales answer questions and to react on the spot

employees in the regions with standardized without extensive travel and loss of time. But doesn’t standardization mean

processes wherever useful. This team We consider it another advantage that streamlining or even downsizing things,

takes over all the necessary internal coor- information transfer is easier and does not and thus reducing the portfolio?

dination with the different stakeholders in need to be handled across time zones, No, quite the opposite. For us it refers to

the Lufthansa Technik organization. This continents and many different organization- standardizing and organizing our internal

speeds up processes again – and also al units. The way it is designed now is sim- processes more efficiently such that our

frees up our local employees to spend ple and fast; this is what we are striving for. customers see less complexity in our direct

more time with their customers. support for them. As mentioned, this is

So, tailored products are about greater speed and availability for

The reorganization of Sales ultimately ultimately the objective? direct customer contacts.

means a change in roles, for you as well Yes, and we see two basic approaches

as for the others. for offering products. The first is customiz- Sometimes customers want to speak

The organization is designed to increase ing of products; here we set up flexible directly to the responsible management.

autonomy in the regions and to reduce links between services we already provide. How well will that work with the new

coordination. This of course requires the We turn what you might think of as a menu sales organization?

adaptation of processes – and as a conse- of services into an individual package. With the new VPs in the areas, access

quence also the roles people will play. The second approach is product devel- to management will be faster and better.

Some roles will not change at all, opment. This can either be initiated from However, the availability of our senior and

others will change, and there will even be market requirements or ideas we have top management out of Germany will not

some brand new ones. within the organization. In order to fulfill this change. The customer has either direct

part more effectively, the product develop- access or contact through the sales orga-

What’s behind the local collocation – ment process has been redesigned and nizations within the regions.

or assignment – of product sales staff? the organization has been adapted. There Customer contact is of the essence to

During the sales process, sooner or lat- is now a corporate product development us. We know that our customers value that.

er we get to the point where detailed prod- and innovation unit and there are respec- Therefore it will not change, and if it does,

uct know-how may be required. Given the tive receptacles in the individual product it will be to the better.

wide spectrum of the products we offer, we divisions. Products will in future be man-

need specialists in – or close to – the sales aged by dedicated product management For more information:

teams. We will achieve this with the collo- teams on corporate and product division www.lufthansa-technik.com/sales8 | New aircraft Lufthansa Technik Connection 5.2014

En-route to the A350

On the new long-haul Airbus A350-900’s first visit to Frankfurt, Lufthansa Passage, Lufthansa

Technik and Airbus put the on-board and ground handling procedures under the microscope.

T

he visit was part of Airbus’s official ground power, refueling, air-conditioning Lufthansa will be taking delivery of the

approval procedure for the aircraft. units and engine start assistance were all A350-900 from 2016. The new airliner

During this route-proving phase, tested for the first time. opens up a whole new dimension in aircraft

Lufthansa and Airbus are testing all the On July 26, after spending the night in engineering: 53 percent of the airframe is

relevant processes and procedures with Frankfurt’s Hangar 5, the A350 took off for made up of composite materials, which are

their system partners in order to optimize Toulouse on the next stage of its world tour. combined with titanium and advanced

the entire process chain – from arrival and Four further flights were scheduled before aluminum alloys. These state-of-the-art

handling to departure – to lasting effect. August 13. The test plane, MSN005, was materials account for over 70 percent of its

The focus is on ensuring that all workflows making these route-proving flights to a total

comply with Lufthansa standards. Towing, of 14 airports around the world.

� Please continue on page 10Lufthansa Technik Connection 5.2014 New aircraft | 9

Photos: Malaika Postberg

For more information about the

A350 scan the QR-Code.

www.lufthansa-technik.com/a35010 | New aircraft Lufthansa Technik Connection 5.2014

Photos: Dean Raineri, Malaika Postberg, Airbus

During the stop in Frankfurt, Lufthansa and Airbus were putting the entire process chain to a test – from arrival and handling to departure.

structure. The fuselage, in which lighter most fuel-efficient airliner per passenger German Airbus plants and numerous

carbon-fiber composite materials (CFRP) and 100 kilometers flown, consuming an suppliers have had an important role to

are used, makes a significant contribution average of just 2.9 liters of kerosene per play in the development and manufacture

to reducing fuel consumption. Robust sys- passenger and 100 kilometers, depending of the aircraft. The front and rear fuselage

tems based on the latest technology also on the cabin design. That’s around 25 sections are made in Hamburg, for exam-

help to reduce MRO costs. percent less than today’s aircraft. “Greater ple, while Bremen equips the wings, and

Lufthansa Technik staff from Frankfurt fuel efficiency, lower CO2 emissions and the Stade site provides the vertical stabiliz-

and Munich were on hand in Frankfurt. less noise: there’s a lot to be said for the ers. The aircraft is due to go into service

They have completed Airbus courses at A350-900, of which we will receive 25,” in the fourth quarter of 2014. So far, 742

the aircraft’s launching customer and are said Kay Kratky, a member of the Lufthansa orders have been received for the A350

highly impressed by the modern technolo- German Airlines Board – Operations and from 38 airlines.

gies used in the A350: the new flap sys- Hub Frankfurt.

tem, for instance, which allows differentia- A350-900 specifications

tion between the right and left sides. In Reduced emissions and footprint

Length 66.80 m

addition, new technologies already intro-

Wingspan 64.75 m

duced in the A380 have been further The state-of-the-art Rolls-Royce Trent

Height 17.05 m

improved. XWB engines and the aircraft’s aerody-

Max take-off weight 268.0 t

The aircraft communication network, in namic design reduce emissions to well

Range 7,750 NM

particular, has undergone significant below current statutory limits. Moreover,

Typcial seating 315

changes, and much of the maintenance the noise footprint of the new models will

Engines Rolls-Royce Trent XWB

work can be done more quickly and easily. be at least 30 percent lower than similar-

Thrust range 374 kN

The Airbus A350-900 will be the world’s sized aircraft today.

First time in Frankfurt for the Airbus

A350. Long before Lufthansa takes

delivery of its first aircraft in 2016,

Lufthansa Technik staff from Frankfurt

and Munich were on hand.Lufthansa Technik Connection 5.2014 Engine Services | 11

For the A380, the C4-check is one of

the aviation industry’s most extensive

maintenance checks to date, and

adding this capability is a significant

accomplishment for Lufthansa Technik

Philippines.

Expanded service

capability for the A380

Lufthansa Technik Philippines (LTP) reaches another milestone

in A380 expertise as Australian airline Qantas returns for C4 heavy

maintenance checks on two of its Airbus A380s.

I

t’s the first of its kind at Lufthansa Technik the aircraft. It can be raised and lowered strong impetus and dedication to further its

Philippines and the decision of Qantas as needed to provide better access to both A380 service expertise. With the C4 heavy

to send their aircraft to Manila reflects the cabin floor levels. The middle section and maintenance approvals from aviation

long-term trust and partnership between wing docking systems are also built to authorities such as the Australian Civil

the airline and MRO provider. Adding easily inspect all wing surfaces, top and Aviation Safety Authority (CASA), and the

C4-check capability for the A380 is a sig- bottom, as well as engine/pylon areas. European Aviation Safety Agency (EASA),

nificant accomplishment for any MRO. The A380 is a massive aircraft – almost LTP is confident the facility has the space

First, for the largest passenger aircraft, the double the A340’s capacity. Organizations and is ideally equipped to offer complete

C4-check is one of the aviation industry’s need to adapt to its size, so taking it apart service solutions for the largest passenger

most extensive maintenance checks to requires dedicated equipment and work- aircraft in the world.

date. Second, a very limited number of shops. For this reason, a large storage area

MRO providers worldwide are certified to was built to house all 600 seats normally Leading MRO in the region

perform this check. For Lufthansa Technik installed in three-class configurations.

Philippines, reaching its latest capability Specialized workshops for different cabin With only few MRO providers capable of

only took less than a year of planning and parts were also set up to accommodate maintaining the A380, this development

completing trainings, equipment, certifica- the parts from the plane’s two floor levels. paves the way for Lufthansa Technik Phil-

tions and investments. These requirements were fulfilled by ippines realizing its vision of becoming a

The capability expansion is right on cue, Lufthansa Technik Philippines through its leading provider of MRO services in the

as early generation A380s approach their region. To date, two leading airline opera-

sixth year mark and airline operators begin tors have sent their A380s to Manila. But

to schedule their heavy checks. This year, with the advancement of its capabilities,

Lufthansa Technik Philippines has com- Lufthansa Technik Philippines is poised to

pleted C2-checks for Air France before accommodate more customers, and meet

moving on to Qantas whose first C4-check the demand for A380 heavy maintenance

was completed recently, with the second checks in the coming years.

expected to be completed this August.

Among the improvements in the A380

hangar is a fuselage docking system that Rainer Janke

joins the existing tail docking and which Phone +63-2-855-9310

was constructed to run along both sides of rainer.janke@ltp.com.ph12 | Technology & Innovation Lufthansa Technik Connection 5.2014

vation b

no

Walking robot

In

y

Lu

k

th

ni

h

inspects fuselage

f

ans

a Te c

Lufthansa Technik has developed a robot that automates

thermographic crack detection (TCD) for the inspection

of aircraft fuselages. Once equipped with a different

sensor, the system will be capable of also examining carbon

fiber structures in the future.

I

n many industries robots are today tak- is particularly great in these applications,

ing over manual work from humans, as the visual inspections and non-destruc-

reliably and indefatigably performing tive testing procedures performed manually

extremely demanding tasks that are highly up to now not only require the highest

repetitive and call for great accuracy. level of concentration on the part of the

Lufthansa Technik has been actively pro- operators but they are also time- and cost-

moting this trend in the area of aircraft intensive.

maintenance and looking for opportunities

to automate the inspection of aircraft Cooperative effort

structures with robot-assisted systems.

The potential for productivity improvements To enable such work to be performed

more efficiently in the future, Lufthansa

Technik has teamed up with the Institute

of Aircraft Production Technology (IFPT)

at the Hamburg University of Technology

along with industrial partners edevis

GmbH and IFF GmbH to develop a robot-

assisted procedure for the inspection of Real-life test of TCD robot

fuselage structures. The Thermographic on aircraft fuselage.

Crack Detection (TCD) research project

running from September 2011 through

September 2014 is funded by the Depart-

ment for Economic Affairs, Transport and

Innovation of the Free and Hanseatic City as a walking robot and has vacuum pads

of Hamburg. on its feet so that it can also reach verti-

In the course of the TCD project a robot cal and overhanging sections of the fuse-

has been developed and fitted with the lage. Only doors, windows and mounted

thermographic inspection unit. It moves parts have to be omitted during route

past pre-programmed points on the outer planning.

skin of the aircraft fuselage and examines Thermographic crack detection entails

them for damage and especially for the use of a sensor head that consists of

cracks. The machine has been designed two exciting coils for heating metal sur-Lufthansa Technik Connection 5.2014 Technology & Innovation | 13

The IR picture on the monitor allows the

detection of even very small cracks.

faces with eddy current and an infrared (IR) records the thermal behavior of the surface.

camera for analyzing the results. The video As cracks in sheet metal have a highly

signal of the camera is recorded, allowing distinctive temperature profile during heat-

precise computer analysis of the surface ing and cooling, they are easy to spot in

later on. For the purposes of the inspec- subsequent video analysis. Even the tiniest

tion, the test area is heated briefly with the cracks that have not yet fully penetrated

coils, in the course of which the tempera- the one millimeter thick sheet are rendered

ture of the metal rises by just a few degrees. visible.

In parallel to this the infrared camera

� Please continue on page 1414 | Aircraft Services Lufthansa Technik Connection 5.2014

During one positioning operation the The combination of new detection

robot can gather data on four control procedures and mobile robot is making

areas – the edges of the chemically milled significant improvements of the efficiency

pockets of the fuselage skin plates. These of aluminum fuselage structure inspections

pockets serve to reduce the weight of the possible. Further application areas, for

fuselage skin. The IR recording of the con- example, on fuselage structures made

trol area lasts just a few seconds, so that from carbon fiber reinforced plastic (CFRP)

the entire test cycle including saving all the and glass fiber reinforced aluminum

data recorded can be carried out in less (GLARE) are to be developed and industri-

than 30 seconds. The development team alized in follow-up projects.

is currently working on improving the robot

demonstrator, the aim being to reduce its Stefan Mehler

ber 201 weight so as to improve the flexibility Phone +49-69-696-90680

cto

of the device in operation. stefan.mehler@lht.dlh.de

O

4

at

7- 9

la y

isp

On d Europe

M R O

id

M a dr

New features in m/material

Customers using the material management tool in the Technical Operations WebSuite manage/m®

will be able to enjoy valuable changes, starting this August for selected users. Airline customers

LATAM Airlines and Aeromexico were instrumental in developing the enhancements.

O

n the one hand, the design of the a customer’s material supply and returns that helped us create a tool that perfectly

module m/material has been mod- supports the customer in working more suits the needs of our customers. Every

ified in alignment with the new flexibly and independently,” adds Tobias manage/m® user can now profit from that.”

Lufthansa Technik style guide, resulting in Klippel, head of Lufthansa Technik’s materi- Nonetheless, the tool’s development is

an even more optimized general user inter- al return & balancing team. A comprehen- still in progress. Another significant feature

face for smart and easy navigation. Besides sive and customizable report in Excel format will be added to m/material in the begin-

these design improvements, the project is available, as well. ning of next year. The application c/offer

team has also integrated new functions, The development itself has been orga- will enable customers to request Lufthansa

making the material management tool an nized and managed as an agile project Technik material offers through the system,

even more valuable asset for customers. according to the Scrum framework. This which will then be created within only a

The added menu “Pool Balancing” pro- means that all developments and imple- few minutes. The customer even has the

vides customers with a centralized point of mentations are made incrementally while possibility to accept the offer directly in

contact for the entire pool cycle specific to customer feedback and close collaboration m/material. “This is another milestone in

each LRU. “The tool will allow entering with customers and users serve as a fun- MRO IT material management,” underlines

return material information and active pool damental basis. “We are especially grateful Pelda, adding: “We are already looking

balancing. It therefore gives the customer for the support by our customers LATAM forward to the next year and cannot wait

an overview of all his pool material and Airlines and Aeromexico,” says Pelda. for these functions to finally go live.”

its balance,” explains IT project manager “When we presented our first prototype of

Georg Pelda, who is responsible for the the developments, we received useful Jamila Jadran

development of m/material. “This kind of feedback that we took into account. In the Phone +49-69-696-37386

transparency and structured overview of end, it was their suggestions and reactions jamila.jadran@lht.dlh.deLufthansa Technik Connection 5.2014 Engine Services | 15

GEnx-2B reverser overhaul

Lufthansa Technik and Middle River Aircraft Systems (MRAS) have signed an MRO

agreement that allows Lufthansa Technik to be MRAS’s authorized service provider

for the thrust reverser on the GEnx-2B engines.

T

he new long-term partnership with in design and product engineering with Lufthansa Technik will provide and main-

MRAS, a wholly owned subsidiary of Lufthansa Technik’s comprehensive strengths tain an adequate pool of spares to offer

GE Aviation, will cover the 24/7 in repair development and the manage- customers exchanges and or leases while

product support, asset leasing/exchange ment and handling of their thrust reverser is

“

and maintenance service offerings to world- valuable assets.” being repaired. These

wide operators of the GEnx-2B engines that Under the agreement, serviceable spare

power the Boeing 747-8 aircraft. “We are Lufthansa Technik will Based on this partnership, we thrust reversers will

pleased to enter into a long-term partner- provide various GEnx- will be able to offer a unique be available to world-

ship with Lufthansa Technik, a global world- 2B nacelle MRO ser- and leading worldwide 747-8 wide customers on a

class MRO provider. Lufthansa Technik is vices, including but nacelle service. 24/7 support basis.

Michael Kirstein

strategically positioned to support GEnx-2B not limited to warranty Lufthansa is currently

thrust reverser customers with high-tech repairs and modifications on behalf of MRAS. the largest operator of the 747-8 aircraft

quality repairs and overhaul services,” said Initially Lufthansa Technik will set up repair with 19 total aircraft ordered. Boeing offers

Huntley Myrie, MRAS general manager of capability at its Hamburg, Germany and the 747-8 in both freighter and passenger

nacelle products. Shenzhen, China facilities. With more than aircraft configurations all powered by the

Michael Kirstein, director of Lufthansa three decades of experience within the GEnx-2B engine.

Technik’s Airframe Related Component area of advanced composites and bonded

(ARC®) business unit, said: “Based on this material repair technology, Lufthansa Technik

partnership, we will be able to offer a unique has the proven experience to support cus-

and leading worldwide 747-8 nacelle ser- tomers through the entire life cycle of the Michael Lotzin

vice. We will generate additional customer nacelle – from the entry into service up to Phone +49-40-5070-64300

value by combining MRAS’s vast experience major and complex repairs. michael.lotzin@lht.dlh.de16 | Aircraft Services Lufthansa Technik Connection 5.2014

For more information:

www.dlr.de/sofia

Rejuvenating a special lady

NASA’s flying observatory SOFIA, a modified Boeing 747SP, is undergoing a major

overhaul at Lufthansa Technik in Hamburg. The MRO provider was chosen on account

of having the widest and longest experience at maintaining this aircraft type.Lufthansa Technik Connection 5.2014 Aircraft Services | 17

Photos: Jan Brandes

SOFIA, the flying observatory dedicated to infrared

astronomy, was flown to Hamburg by a team of

NASA pilots (top). Just days later, the aircraft was

already jacked up in the dock (left).

S

OFIA (Stratospheric Observatory for major overhaul, the question arose as to As Project Manager Operations in VIP &

Infrared Astronomy) is a flying which company could take on this task. Executive Jet Maintenance at Lufthansa

observatory that was developed by Lufthansa Technik was selected, being Technik, Sven Hatje is responsible for man-

the German Aerospace Center (DLR) and ideally qualified on account of both its aging the layover in Hamburg. Together with

the US National Aeronautics and Space proven track record in the maintenance Production Planning he has also drawn up

Administration (NASA) for research in infra- and overhaul of commercial aircraft of all the detailed schedule that shows which tasks

red astronomy. A converted Boeing 747SP, sizes and its own capabilities and experi- are to be performed when. One special

the shrunk version of the jumbo jet with ence at retrofitting and fitting out private challenge about this layover is the question

higher operating ceiling and greater range, and government aircraft. Lufthansa Technik’s of how to deal with unplanned events. Hatje

serves as the platform for a reflecting tele- expertise is underscored by the fact that a gives an example: “We had an aircraft in

scope with a diameter of 2.7 meters. When, sizeable proportion of the 18-strong global the hangar that had come in for a relatively

following the conclusion of numerous test fleet of 747SP airplanes still in service are minor check with 5,000 hours. We knew

flights and the first year of the SOFIA under maintenance contracts with the

research mission, the aircraft fell due for a MRO provider.

� Please continue on page 1818 | Aircraft Services Lufthansa Technik Connection 5.2014

Photos: Jan Brandes

the aircraft and it was actually in good con- The points in the rear structure at which We will take out everything that was installed

dition. However, we found a small patch of support can be applied are only certified in the cockpit for operating the telescope.

corrosion that forced us to dismantle the for a weight of 44 tons, but in this case the The documentation that we are encountering

entire landing flap system plus all the spoil- load came to 48 tons. As Sven Hatje explains, in connection with this work is highly com-

ers on the wing upper surface and other “In order to raise the aircraft we used an plex and here we are reliant on the compe-

parts of the structure as well. This required alternative procedure that entailed using tence of the NASA inspectors.” Again, the

about 500 hours of unplanned additional five jacks instead of three. For normal air- instrumentation is quite different from nor-

effort, which in turn entailed extra work craf t this is not mal. For example,

“

over public holidays in order to be able to allowed, but for the SOFIA is the only

complete the job on time.” SOFIA jumbo it was 747SP to have all the

okay. To take the The airplane is truly unique engine indicators on

Weight and center of gravity pressure off the rear and I am sure the next a single display. This

support, we fitted two four months will be fascinating. requires the analog

In addition to the normal tasks there are a extra jacks on the rear Sven Hatje signals from the

number of special features about the SOFIA spar of the aircraft.” engines to be digi-

layover that pose a challenge even for an SOFIA’s special tized and directed to

experienced team, starting with the docking systems also present major challenges. the display via an appropriate cable har-

operation. The 747SP had to be jacked up The 747SP may be a familiar aircraft but, ness. For the overhaul this means that the

six meters off the ground in order to replace as well as modified cockpit electronics, the cable harnesses, some of which are the

the landing gear. The problem was that SOFIA-747 also has extensive additional thickness of a human arm, have to be

due to the 17-ton telescope the center of electronic systems that are not in service opened up, each individual cable labeled,

gravity on this aircraft is further back than anywhere else in this combination. Sven numbered consecutively by connector and

normal, so that the rear section of SOFIA is Hatje: “We have to then virtually take the then later reinstalled in exactly the same

too heavy for the normal jacking procedure. entire aircraft apart, including the cockpit. position. If meanwhile any repairs should

Positioning the 747 precisely prior to jacking it up.Lufthansa Technik Connection 5.2014 Aircraft Services | 19

be required, Lufthansa Technik’s cable the right side of the fuselage, run past the To ensure that the many special

workshop will be called in to assist. Sven telescope and divide again behind the tele- requirements for the layover are correctly

Hatje: “Because the cables have become scope’s second pressure bulkhead. considered, the production planners have

hard and rigid over time it is inevitable that The engine test run is anything but rou- created over 2,000 job cards, each up to

faults will be found. The cable workshop tine and, as such, is another instance of 100 pages long. The effort planned for the

and of course our electricians will then just how special the SOFIA jumbo is. The complete overhaul of this special aircraft is

come to our rescue.” distinguishing feature in this case is that the around 50,000 hours of labor. Sven Hatje:

SOFIA telescope has to be active and “I am delighted to have another unusual

Support from NASA and the DSI operational before an engine run-up can aircraft in the hangar in the form of this

be carried out. This is because, as the 747SP. And I know that the staff in the

Technicians from NASA and the German power is ramped up to take off power during maintenance team feel the same way. This

SOFIA Institute (DSI) will support the work a static test the aircraft experiences consid- airplane is truly unique and I am sure the

on the heavily modified rear fuselage sec- erable vibration. Under no circumstances next four months will be fascinating.”

tion that contains the telescope and its must this be transferred to the extremely Seeking out and accepting a major

special hatch. Here the 747SP has under- sensitive telescope. The attenuation and challenge – the SOFIA project gives

gone particularly heavy structural modifica- automatic level control for decoupling the Lufthansa Technik another opportunity to

tions compared with the factory condition. vibration of the aircraft structure from the demonstrate its prowess and flexibility,

Floor structure, windows and cargo bay telescope therefore has to be fully active. especially when it comes to performing

door disappeared during the conversion Commenting on this, Sven Hatje says: unusually demanding jobs.

and the flight control elements for the verti- “This example brings out clearly the fact that

cal stabilizer and elevator were moved. the SOFIA 747 is first and foremost a flying

The control cables that normally run in a laboratory rather than an aircraft. The tele- Sven Hatje

straight line under the cabin ceiling have scope will always be the top priority and only Phone +49-40-5070-67348

been diverted. They are concentrated on then can the aircraft be moved or worked on.” sven.hatje@lht.dlh.de

All components are removed from the aircraft including the operator stations, only the telescope (right) will remain in the fuselage.20 | Aircraft Services Lufthansa Technik Connection 5.2014

Sharklet retrofit for the A320 family

The availability of kits for retrofitting Sharklets to Airbus narrowbody aircraft – promising

substantial reductions in fuel flow – has caused numerous operators to order the improvement.

Meanwhile Lufthansa Technik Philippines (LTP) has performed the first upgrades.

E

fficiency is the name of the game. Luft-

hansa Technik Philippines has upgrad-

ed the first two Airbus A321 aircraft

from the fleet of Philippine Airlines with state-

of-the-art wingtip devices called Sharklets.

Thanks to the improved wing aerodynamics,

a Sharklet-equipped aircraft can potentially

generate fuel burn savings of up to four per-

cent, providing operators with the flexibility of

either an additional 100 nautical miles range or

increased payload capability of up to 450 kg.

The upgrades herald a major step for

operators of in-service Airbus A320 family

aircraft who can now benefit from the cost

savings and performance improvement of

installing Sharklets normally found in newer

built A320 models. Sharklets will be stan

dard on the new A320neo Family aircraft,

which are expected to enter service starting

in late 2015.

“We are honored to offer our first ever

Sharklet retrofit service for Philippine Airlines,”

said Michael Lariviere, outgoing Lufthansa

Technik Philippines Vice President for Aircraft

Maintenance. In accordance with the OEM

modification instructions and the Civil Avia-

tion Authority of the Philippines (CAAP), the

aircraft maintenance team of the Lufthansa

Technik subsidiary worked round-the-clock to

install the Sharklets on PAL’s A321s.

The retrofit project was very successful.

Immediately after the first aircraft was released

to service, the team of technicians and

mechanics commenced work on the second

aircraft, which has also meanwhile returned

to service. Meanwhile, the first international

customer has contracted Lufthansa Technik

Philippines to perform the modification.

Jetstar Japan has chosen the performance

enhancement for its Airbus A320 fleet. The

airline avoids unnecessary ground time by

combining the retrofit with a C-check. Two

A320 aircraft have been modified so far.

Pear Rubio

Phone +63-2-855-9315

pearl.rubio@ltp.com.phLufthansa Technik Connection 5.2014 Component Services | 21

Frank Küpper of the electroplating

shop puts engine shafts in a new

oven to harden them.

Electroplating shop expands capacity

The surface technology facility in Hamburg has acquired two new ovens to replace an

old one. This increases the facility’s heat treatment capacity and allows very large components

such as Airbus A340 main landing gear to be handled.

E

lectroplating, which is an electro- would lose their properties and become supplied and transported in parts and

chemical process in which coating susceptible to hydrogen embrittlement, assembled on site. The ovens will serve as

layers are formed on metal parts, causing cracks in the process. a pilot project for further ovens in Hamburg.

plays a key role in the overhaul and repair The newly installed ovens have a It is planned to procure comparable ovens

of a wide variety of aircraft components. volume of 17 cubic metres each, are for the landing gear shops and benefit from

The Lufthansa Technik electroplating shop designed for temperatures of up to 400 the experience gained at the electroplating

in Hamburg has eight electroplating bath degrees and can keep the set temperature shop.

lines with 180 treatment units for a diverse constant to within a tolerance of plus or

range of coating processes. These include minus six degrees. They thus fill the high

units for aluminium coating, waxing and requirements of Class 2 of the aerospace

degreasing equipment, a paint shop and materials specification SAE AMS 2750.

twelve heat treatment units. The latter are The total weight of the new ovens is

used regularly in the coating process: all almost eleven tons, which meant it was

chrome- or cadmium-plated parts are necessary to modify the load-bearing steel

treated in ovens in order to extract hydro- structure. And because the installation site

gen. If this was not done, the materials is on the second floor, the ovens were

The new ovens have a volume

of 17 cubic meters each.22 | Aircraft Services Lufthansa Technik Connection 5.2014

From VIP to ZERO-G

New role for a government aircraft: Lufthansa Technik is converting an Airbus

A310 to an experimental aircraft. In the future this twinjet will be used on zero

gravity research for parabolic flights.

After the final flight in service of the

Special Air Mission Wing, the aircraft

was flown to Hamburg.

A

ircraft have a long life. Airbus A310, involvement with this Airbus A310 for over intervals for the A310 with the agreement

tail sign 10+21, is an example of 14 years and knows the aircraft inside out. of the manufacturer.” His assessment:

just such an aircraft. On June 24 it “Lufthansa Technik fitted the Airbus out as “The A310 is actually an extremely reliable

was handed over to Novespace, its new a government aircraft over two decades and trouble-free aircraft, not least on

owner, exactly 25 years from the date that ago,” he says. “At that time it was flown for account of its robust CF6-80 engines.”

aircraft manufacturer Airbus originally issued civilian purposes, but under a military

the certificate of export, on June 24, 1989. license.” High loading on parabolic flights

Initially in service with the East German It was operated by Germany’s Special

government, after German reunification it Air Mission Wing in Cologne-Wahn and up It is precisely the combination of high reli-

became part of the fleet of the Special Air to now has been used in a manner pretty ability and low accumulated flying hours

Mission Wing of the Federal Ministry of much typical for a VIP aircraft. Schuller that makes the aircraft attractive to its new

Defense. Graduate engineer Horst Schuller continues: “On the basis of the low utiliza- French customer. Up to now Novespace

has had a commercial and technical tion we were able to extend the overhaul has been operating an Airbus A300B forLufthansa Technik Connection 5.2014 Aircraft Services | 23

A big thank you for

global service, says

the inscription.

parabolic flights, amongst other purposes nibalized for all the parts that could possi- unlike a normal completion with long lead

to train astronauts. However, the stress bly be lacking in the aircraft. A mock-up times, in this case a lot of work will have to

imposed on the structure in the course of about one meter long is serving as the be carried out in parallel,” explains Frank

such flights is about 30 times the load model for the finished fuselage. Nowack. Tight dovetailing and prior con-

encountered during normal operations, a sultation with the preparation and produc-

considerable fatigue loading. Conversion marathon tion departments are essential.

With just 20,000 flying hours on the Meanwhile, the customer has flown its

clock, the A310 is the ideal aircraft in For the zero gravity trials a compartment is A310 with the new registration code of

terms of coping with the requirements of to be created in the fuselage that is closed F-WNOV to France so that pilot training

the new customer. As Senior Manager by nets to the front and rear. The seat rails can begin. At Lufthansa Technik the team

Design Engineering, Frank Nowack is can accommodate equipment or racks, is busy reviewing the documentation, buy-

“

responsible for the conversion of the air- but the compartment ing parts from the

craft. He outlines the challenges associated can also be used for used parts market

with this work: “The A310 was used on the experiments emp- and building the

The A310 is actually an

military operations in the past. In order to ty. To exclude the risk mock-up. So when

extremely reliable and trouble-

be able to handle it at all, we have agreed of injury, floors, ceil- the aircraft lands in

free aircraft.

with the new customer that we will certify ings and walls are to Horst Schuller

Hamburg at the end

it under EASA regulations. But before we be fitted with a foam of September, the

can do that, we have to first restore it to a lining. In addition, Lufthansa Technik

kind of ‘zero state’, i.e. to the state in which special lighting installations are necessary team will be fully prepared – not just for the

it was delivered to Interflug.” as the windows in this section are sealed planned work but also for any surprises.

The preparations for the conversion work up. A number of normal seats will be

are in full swing. To help with restoration of installed behind the zero gravity compart- Christian Reck

the cabin structure they found an old aircraft ment for take-off and landing. “Because Phone +49-40-5070-2957

on the surplus market, which is being can- the conversion timetable is very tight, christian.reck@lht.dlh.de

In preparation for the new customer, the

Airbus A310 was given an all-white livery.24 | Total Support Services Lufthansa Technik Connection 5.2014

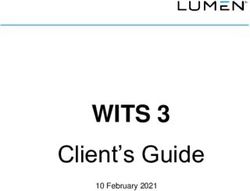

Added value through integration

When tailoring the portfolio of Lufthansa Technik services to the needs of a customer, placing Technical

Operations Management (TOM) in the hands of Lufthansa Technik is a highly beneficial option.

O

utsourcing and delegating tasks Having to coordinate a sophisticated net- parameters that go beyond MRO KPIs;

and responsibilities can be a great work of counterparts on the contractor’s instead, the customer can measure

relief – especially when you are side not only increases complexity but Lufthansa Technik by defined airline KPIs

operating in a highly complex, time-driven may cost an airline a fortune when service such as technical dispatch reliability or

and efficiency-minded business such as integration fails. even technical aircraft availability.

operating a fleet of valuable technical assets. In order to live up to the approach of

Lufthansa Technik has made the experience Focus on flight operations integration, each TOM setup includes the

that while customers profit from its wide presence of a dedicated TOM Fleet

portfolio of products and services, inte- When tailoring the portfolio of Lufthansa Manager at the customer’s site. The TOM

grating all the contracted services in an Technik services to the needs of a customer, Fleet Manager makes for smooth coordi-

efficient manner can at times be challeng- one option to handle the above-mentioned nation and execution of all contracted

ing for both customer and supplier. challenges is to place Technical Opera- services, ensuring that Lufthansa Technik

With airlines whose focus is on flight tions Management (TOM) in the hands of is available “at touching distance”.

operations and for whom the decisive Lufthansa Technik. If responsible for a cus- Thus, the TOM Fleet Manager acts as a

factor of success is time, any dead times tomer’s TechOps Management, Lufthansa constantly visible interface between the

in communication can become critical. Technik can guarantee performance customer and Lufthansa Technik.

TOS® Included: Aviation Services

Total Operational Support provided by Lufthansa Group

TTS® Optional: Technical Operations

Technical Operations Management – TOM

Total Technical Support Management – TOM

TOM enables operators to enjoy far-reaching efficiency

TMO® advantages resulting from synergies in service integration

Total Material and reduced complexity in their organizations.

Operations A Lufthansa Technik fleet manager at the customer’s home

base integrates all MRO activities contracted in a TTS®

TBS™ TES® TCS® TLS™ ALTS agreement into a comprehensive service package. Operators

Total Base Total Engine Total Total Aircraft Leas-

Maintenance Support Component Landing Gear ing & Trading can focus their management capacity and financial resources

Support Support Support Support on business development while maintaining full control over

technical issues.

Single Single Single Single Single Leas-

Aircraft Engine Component Landing Gear ing & Trading

Services Services Services Services ServicesYou can also read