TKS for Africa TKS Renault Trucks K380 P6X4 HEAVY E3 PALFINGER PK23500B PERFORMANCE

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

page: 1

TKS for Africa

TKS Renault Trucks K380 P6X4 HEAVY E3

PALFINGER PK23500B PERFORMANCE

Focus Segments: Your contact person:

LARBI MESKINE RODRIGUEZ

+43 6648343115

L.Meskine-Rodriguez@palfinger.com

PALFINGER EMEA GmbH

Lamprechtshausener Bundesstraße 8,

Bergheim 5101 | AT

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 2

CONTENT

CONTENT .................................................................................................................................. 2

1. Price overview of the TKS ......................................................................................................3

2. Scope of supply for loader crane ..........................................................................................4

2.1 Crane Price ...............................................................................................................................6

3. The benefits for you ................................................................................................................7

4. Technical data for the loader crane .......................................................................................8

5. Truck specifications ...............................................................................................................9

6. Installation .............................................................................................................................15

7. PALFINGER Tools .................................................................................................................19

8.1 Axle & Payload Calculation ..................................................................................................20

8.2 Stability Calculation TKS-Graphic & Details .......................................................................21

8.3 Lifting Capacity ......................................................................................................................23

Terms and conditions of supply and delivery...........................................................................24

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 3

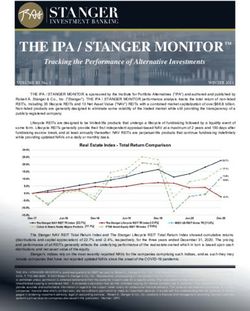

1. Price overview of the TKS

Position amount Description Price EUR

PK23500B 1 PALFINGER Loader Crane

INSTALLATION acc.

Installation 1

Description

K380 P6X4 HEAVY E3

TRUCK-RENAULT 1

acc. Description

Net TOTAL PRICE excluding VAT (EXW MCC Poland)

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 4

2. Scope of supply for loader crane

PK 23500

BASIC UNIT:

- Lifting moment 226.0kNm (23.0mt)

- Classification according to EN12999 H1/B3

- High extension speed by applying return oil utilization and oil passage through

the cylinders

- Rack and pinion slewing system

- Slewing angle 400°

- Single stabilizer control with operated check valves on the stabilizer

- Two additional valve elements for extra functions

- Controls on each side of the crane

- Box level on both control panels

- Oil tank 200L

HE - Certification Installation

declaration

TOWI – dead centre over balance

The end stops of the slew rack are located over the balance

R2X - Outriggers hydraulic, middle

Hydraulically extendable with separate stabilizer controls

Double hydraulic outrigger lock without additional mechanical lock

- Reduction of setup time

- Safety during operation

STZS3 – rigid stabilizer cylinders

LHV13 - Load hold valves

On main boom, knuckle boom and extension boom cylinders

RALSTD - Standard colour RAL3020

Painting RAL3020

STU01 - Hour counter

Crane hour counter (digital or via PALdiag)

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 5

PU002 - Preparation for constant pump

Control valve prepared for constant pump

B - 3-section hydr. extension boom

ÖLK07 - Oil cooler 10,5kW, mounted

Longer service life of the oil, seals, valves and other hydraulic

components through lower oil temperature

TL200 – 200L hydraulic oil tank loose

LH08 - Load hook

8t load hook with slide bearing and shackle

BRI-8 - Mounting parts; bolts 8 pcs.

24V - Electricity

24 volts

HDF03 - High pressure filter

High pressure filter for single circuit system - mounted

VPACK - Crating

Crane on pallet, accessories in boxes

EKAT - Spare parts catalogue

CDSPR - Language USB Stick

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 6

FR – French

EP553P-Constant Pump

Leduc axial piston fixed displacement pump; universal direction;displacement volume

65 cm³; package incl. suction and pressure hose

EZ2189-400

Stabilizer pad; measurements 400x400x50 mm

EZ2236-400

Transport boxes for square pads 400x400x50 mm

2.1 Crane Price

YOUR SPECIFICATION

Position Pcs Description

PK 23500 1 PK 23500

HE 1 Certification

LAAU 1 Country code

TOWI 1 Dead centre over balance

R2X 1 Outriggers hydraulic, medium

STZS3 1 Rigid stabilizer legs

STU01 1 Hour counter

LHV13 1 Load hold valves

B 1 3-section hydr. extension boom

OSK 1 Hydr. overload protection

PU002 1 Preparation for constant pump

NOTAUS 1 Emergency shutdown

RALSTD 1 Standard colour RAL3020

ÖLK07 1 Oil cooler 10,5kW, mounted

TL200 1 200L oil tank-loose

LH08 1 Load hook

BRI-8 1 Mounting parts; bolts 8 pcs.

24V 1 Electricity

HDF03 1 High pressure filter

VPACK 1 Crating: crane on pallet, accessories in cases

KRANK 1 Crane preservation

EKAT 1 Spare parts catalogue

CDSPR 1 Language USB Stick

EP553P 1 Leduc axial piston fixed displacement pump; universal

displacement volume 65 cm³;

EZ2189-400 2 Stabilizer pad; measurements 400x400x50 mm

EZ2236-400 2 Transport Boxes for square pads 400x400x50 mm

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 7

3. The benefits for you

Coating technology

A combination of KTL coating (Cathodic dip painting) and powder coating or two-

component top coat guarantees the highest quality standards for the surfaces of

PALFINGER loader cranes.

High-Speed Extension

The High-Speed Extension that comes as standard on PALFINGER cranes

increases the boom system extension speed by up to 30 percent. The associated

technical term ‘return oil utilization’ denotes a regenerative hydraulic circuit for the

cylinders of the extension boom system.

.

Low-maintenance extension system

With sliding elements made of synthetic material and the high-quality KTL coating,

this boom system significantly simplifies service performed by the operator. This

saves time and money-and protects the environment.

Overload Protection System

Safety feature with three hydraulic adjustable valves, which are needed for a

safe working environment. If.the value of 107% of the maximal load is reached, the

overload protection system responds and only the retraction in the outer boom is

available. This helps to guarantee a safe operation of the crane and to prevent damages

in the parts.

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 8

4. Technical data for the loader crane

PK23500B

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 9

5. Truck specifications

Truck:

- K 380 P6X4 HEAVY.34 E3 - GVW 34T / GTW 37.5 T

- Wheelbase: 4600mm

- Engine-type: DXi11

- Performance: 240 kW Euro3

- Suspension front: 3-leaf reinforced front leaf springs & stabiliser bar

- Suspension rear: 11-leaf elliptic suspension, stabiliser bar & rear shock absorbers

- Maximum weight front axle: 9.000 kg

- Maximum weight rear axle: 26.800 kg

- Payload: 18.902 kg

- tire dimension: 13 R22.5. Profile B. M840 EVO / L355 EVO. Steel disc wheels

- year of production: 2021

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 10

WEIGHTS

Wheelbase mm 4.600

Maximum Weight (registered) Total (GVW) Kg 34000

Payload (C) Kg 24321

Kerb Weight total Kg 9679

Front axles (Liftable axle down) Kg 5118

Chassis cab kerb weight

Rear axles (Liftable axle down) Kg 4561

Front axle 1 Kg 9000

rear axle 1 Kg 13400

Maximum Weight (registered)

rear axle 2 Kg 13400

Rear axle(s) Kg 26800

total (CoC: 16.1.) Kg 34800

Maximum Weight (technical) front axles (CoC: 16.3.) Kg 8000

rear axles (CoC: 16.3.) Kg 26800

This table includes the weights of the RENAULT TRUCKS options: full urea tank, oil, screen wash fluid and coolant at 100%, fuel fill level 90%

and driver present (75 kg)

To maintain the driving comfort (lightness of steering, braking) of vehicles in all load and driving conditions once the vehicle is bodied, the

following minimum axle load(s) must be respected: A value corresponding to 26% of the weight of the unladen bodied vehicle kerb weight (with

driver, without passenger)

LENGTHS

Wheelbase mm 4.600

Min. (Wmin / BEP L105) mm 9.688

Body length

Front Overhang (H / BEP L016) mm 1488

Cab entry (B / BEP L102) mm 832

Wheelbase (F / BEP L011) mm 4600

Technical wheelbase (F' / BEP L015) mm 5285

Axle Spacing Axle 2-3 (BEP L012.2) mm 1370

Rear overhang Chassis mm 2136

Overall Chassis Length (A / BEP L032+L016) mm 9033

Min. (Ymin / BEP L104) mm 504

Centre of Gravity of load

Max. (Ymax / BEP L103) mm 626

HEIGHTS

Wheelbase mm 4.600

Cab height (unladen) (O) mm 3385

Max. exterior height unladen (BEP H001) mm 3825

Side member height (BEP H032) mm 300

Front (U1 / BEP H015) mm 383

Ground clearance, laden

Rear (U3 / BEP H016) mm 338

Unladen (H1 / BEP H035) mm 1190

Frame top height at front axle

Laden (H1 / BEP H036) mm 1118

Unladen (H2 / BEP H037) mm 1193

Frame top height at drive axle

Laden (H2 / BEP H038) mm 1126

Unladen (HN) mm 1195

Frame top height at the rear of the frame

Laden (HN) mm 1131

WIDTHS

Wheelbase mm 4.600

Max. cab width (BEP W002) mm 2492

Front (BEP W035) mm 1080

Frame width

Rear (BEP W036) mm 852

Rear axle 1 (V3 / BEP W003.1) mm 2544

Width at rear wheels

Rear axle 2 (V5 / BEP W003.3) mm 2544

Front (V1 / BEP W013.1) mm 2028

Track Rear 1 (V2 / BEP W013.2) mm 1874

Rear 2 (V4 / BEP W013.2) mm 1874

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 11

DXi11 ENGINE

Maximum power output: 240 kW at 1900 rpm.

Maximum torque: 1650 Nm from 1000 to 1400 rpm

6-cylinder in-line diesel engine - High-pressure fuel-injection

(1700 bar) by pump injectors - 24 valves - overhead camshaft,

rear-mounted timing

Bore 123 mm - stroke 152 mm - Capacity 10.8 L

Turbocharger

Electronically controlled fan

Direction of rotation (seen from G/B end): anti-clockwise

Sheet metal oil sump

EEC EURO III exhaust emissions level

ENGINE EQUIPMENT FRONT AXLE

Cast iron engine flywheel casing. Front hub joints with grease nipples

Fast idling control whilst moving (muddy site) Front load capacity (technical max.): 8 t

Power mode inhibited after passing the 'hard spot' of the

accelerator pedal

Without engine Power Take Off. REAR AXLES

Without speed limiter. PMR 3361 drive axle with double reduction

Single-plate clutch, diameter 430 mm

Integral differential lock

Rear loading capacity (technical max.): 32 t

GEARBOX Rear load equally distributed

Drive axle ratio: 3.76

Optidriver AT 2612F gearbox (14.94 - 1) with automatic Engine speed at 90 km/h: 1645 rpm

clutch. Aluminium housing.

Max. torque 2550 Nm, 12 forwards gears and 3 reverse

gears. WHEELS AND TYRES

Steering wheel-mounted operating mode selection Dimension 13 R22.5

(automatic/manual) via gear shift selector. Profile B. M840 EVO / L355 EVO

Reinforcement of the Optidriver gearbox for heavy duty use Steel disc wheels

(XTREM) Spare wheel and tyre supplied loose.

Heavy duty gearbox oil cooler, oil/water external heat

exchanger

BRAKING

RETARDER

OPTIBRAKE (power rating 300 kW at 2300 rpm): Service brake:

combination of the exhaust brake and valve compression Twin-cylinder air compressor 900 l/min, 636 cm³

braking, coupled to service brake Braking system with two independent circuits

Drum brakes

Dust protection on rear brake

POWER TAKE-OFFS Electronic management of air production by EACU (Electronic

Power take-off S81 Air Control Unit):

Output: splined hollow shaft (DIN 5462) Dryer cartridge optimised by preventive maintenance.

Direction of rotation: opposite to engine Silencer on pneumatic circuit

Torque: 1000 Nm Two line trailer braking system (ISO connections).

Ratios: 1:0.80 Trailer brake device on rear crossmember

Position: 18h High-position rear brake cylinders

STEERING

Power steering, variable-flow hydraulic pump

Steering ratio 20:1 - Steering wheel diameter 460 mm

Driving on the right

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 12

EBS: Cab interior:

Anti-lock braking system (ABS) Quality roof console, 1 storage compartment with key lock, 1

Drag torque control (Torque control during downshifting). storage space with net and 4 ISO modules

Brake harmonisation of tractor and trailer. Interior sun blind on windscreen

Retarder and service brake linking Without tachograph

Differential engagement management (if equipped) at speeds Air-suspended driver's seat with fitted seat beltpage: 13

BUMPER - STEPS AND LIGHTING

3-part steel bumper with headlight grilles

Retractable windscreen access steps in radiator grille and

under bumper

Access to driving position by 4 steps. 1st step flexible and of

composite material.

Step lighting

Electrical headlamp levelling control.

Lighting to EEC standards.

Provision for lighting rail on front end

Black fog lamp trims

Two rotating orange lights

SUSPENSION

Front suspension

3-leaf reinforced front leaf springs

Stabiliser bar

Rear suspension:

11- leaf elliptic suspension

Stabiliser bar

ELECTRONIC EQUIPMENT: Rear shock absorbers

English and French language display

Additional language (Spanish) FUEL TANK

Prise OBD en cabine pour extraction de données et

Main steel tank.

diagnostic du véhicule

Main fuel tank: 315 litres capacity D560 profile mounted on

4G TGW telematics unit (telematic gateway) including an

right

antenna and enabling subscription to Optifleet services (Map,

Heavy duty sedimenter and prefilter (R90).Bleed control on

Check, Drive)

dashboard.

ELECTRICAL EQUIPMENT

AdBlue

Battery capacity: 185 Ah

Batteries with level check without AdBlue tank

Manual battery isolation

Electrical circuit enters standby

Alternator : 120 amp capacity.

STANDARD EQUIPMENT

Rear signalling lighting. Tool kit.

Windscreen washer bottle capacity: 8.8L

CHASSIS

Chassis protective paintwork, mineral grey colour

technical code: 03650

Chassis reinforcement from rear of engine to rear end of

chassis

Standard rear overhang, pre-drilled for bodybuilder

Reinforced removable front towing cap

Without rear under-run bar .

Transmission crossmember Medium

Trailer cross member for G150 hook (100 x 160 mm

attachment)

Twin cartridge air filtration for dusty environments

Exhaust and vertical silencers

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 14

BODYWORK

Space available for crane installation

Flexible bodywork attachment with springs

Front body mounting brackets.

Bodybuilder access through bulkhead

Orange LED side marker lights with reflector

Interface for bodybuilder connections and BBM module (Body

Builder Module)

Electrical provision for crane

SPECIAL OPTIONS

REAR OVERHANG 2300 MM LAST REAR AXLE

CRANE BRAQUET 40T

FUEL TANK MOVE BACK 400 MM

AIR PRODUCTION UNIT INSIDE CHASSIS

GEARBOX RATIOS

1 2 3 4 5 6 7 8 9 10 11 12

14.94 11.73 9.04 7.09 5.54 4.35 3.44 2.70 2.08 1.63 1.27 1.00

The manufacturer reserves the right to modify the specifications above without prior notice.

Non contractual document.

For further assistance please contact Product Applications at Renault Trucks UK Limited,Wedgnock Lane , Warwick , CV34 5YA Telephone+44

(0)1926 475333.

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 15

6. Installation

Mounted in our Mounting Competence Center (MCC)

Providing engineering, mounting software Pacwin

All process handled in one hand (engineering to

handover)

Custom engineered sub-frame and mounting solution

Higher payload due to intelligent lightweight design of

crane and installation

Warranty for the complete unit handled by PALFINGER

Maximal performance of the PALFINGER products

Full range of mounting accessories

Factory installed Crane, compliant with truck- and crane manufacturers installation guideline

Complete chain of documentation and record-keeping for vehicle, crane, equipment and

installation

Local service network with direct supporting structure from the crane manufacturer

Reliable and well-established safety systems to protect the operator and equipment

Raw installation PK-crane 18-30mt, LKW-base, front:

Crane installation:

- Positioning and installation of the crane onto the provided

truck, in accordance with the crane and vehicle manufacturer's

installation guidelines

Subframe and side plates:

- Delivery and installation of a PALFINGER subframe

- Delivery and installation of individual side plates

- Priming and painting of all steel components according

PALFINGER standard, max. 1 colour

- Top-coat painting in RAL standard colour

Hydraulics:

- Installation of a provided hydraulic pump (PTO must be

available on the truck for the installation of a hydraulic pump)

- Delivery and installation of the hydraulic piping between

provided hydraulic tank, oil cooler, crane and pump

- Filling with PALFINGER hydraulic oil PREMIUM 32

Electrics:

- Installation of the electrical connection between crane and

vehicle with customized cable harness

- Parameter setting of the vehicle for crane operation

Functional check:

- Adjustment of the pump

- Palcheck crane

- Functional check for crane and final inspection of the vehicle

PALFINGER top mounted platform - Eco

customized Installation of platform with side and tail boards acc. to following specification:

- platform floor made of steel checker plate

- Inner dimension 6.500mm x 2.480mm

- Height of front board 1.500 mm

- Height of side and tail boards 600 mm

- Boards made of steel profiles 33mm

- all steel parts sandblasted, primed and painted

- Side boards divided in three parts, with 2 middle-pillars foldable and detachable

- rear wall foldable and detachable

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 16

- middle and rear pillars detachable

- all walls with rubber stop when opened

- Lashing point only in the side frame of the platform (app. all 280mm)

- step up in side wall at the left rear side

- Installation of a provided stabilizer plate holder

Two pairs of JOST-container locking mechanisms for ISO-container

- mounted on extensions lateral on the subframe.

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 17

7. PALFINGER Tools

Whether hydraulically or mechanically, PALFINGER offers a comprehensive range of

additional equipment to make the loader crane a flexible and versatile tool for several

applications. To ensure the working success, we only offer PALFINGER proven applications.

Another plus is, that you get everything from one hand. The top seller for multi-use crane

are:

Pole manipulator

Poly grab

Earth auger

Workman basket

Pallet folk

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 18

8.1 Axle & Payload Calculation

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 19

8.2 Stability Calculation TKS-Graphic & Details

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 20

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 21

8.3 Lifting Capacity

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 22

Terms and conditions of supply and delivery

Payment conditions

Full payment upfront

Delivery conditions and pricing

FCA. All prices are strictly net plus statutory VAT.

Price validity

Overall quotation is subject to alteration.

Delivery date

By arrangement.

Condition of the vehicle

As is.

Delivery conditions

In accordance with the current valid General Terms and Conditions of Business and Delivery, which

can be found at http://www.palfinger.com/de/aut/Pages/agb.

We will also be happy to send these to you upon request.

Installation pricing

-Typing and description errors as well as technical examination and feasibility reserved. Depending

on the final vehicle design, details of this offer may still change.

-If not explicitly stated in the offer, without any changes, relocations, adjustment or customer brand

work on the vehicle. (steering, track, brakes, etc.).

-RAL standard colours do not include RAL 9006 and any metallic colours.

-Crane accessories such as stabilizer plates with brackets, additional stabilizers, pumps, hydraulic

tanks, PA parts etc. are provided by the customer.

-The truck will be provided and collected in MCC-plant by the customer at no charge for PALFINGER.

The truck must arrive at the factory 3 weeks before the start of assembly, the crane 1 week before. In

the event of late provision, we will redefine the delivery date. Please note: The truck can be transferred

between the assembly plants by axle as part of the PALFINGER mounting process. PALFINGER will

bear all transfer costs including insurance. PALFINGER explicitly points out that there is no entitlement

to compensation for kilometer-dependent truck wear and tear by the customer/dealer!

-After the "design freeze" date has passed, no further changes are possible. The date will be

announced in the course of scheduling and in the MCC-dealer sheet.

Subject to technical changes. Graphical representations may differ.

Please take time to examine our quotation in detail.

Offer No.. 032020_Africa_PK Date: 05.01.2021

PALFINGER.COMpage: 25 Offer No.. 032020_Africa_PK Date: 26.03.2020 PALFINGER.COM

You can also read