TECASINT Compendium Stock shapes Direct forming - Ensinger

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Content

4 TECASINT in application

5 Product families

7 Direct forming process

Direktformung 10 Mechanical properties

14 Thermal/Electrical properties

15 Tribological properties

16 Resistance to environmental influences

17 Flammability, weather resistance Parts and shapes made of TECASINT have excellent long-term thermal stability. The broad tem-

18 Chemical resistance perature application spectrum of these materials ranges from –270 °C to +300 °C. Even when heated

19 Purity briefly to 350 °C, TECASINT materials will not melt or soften. Strength, dimensional stability and

20 FAQs creep strength remain high under mechanical stress even during long-term usage.

21 Machining guidelines, bonding

23 Standard shapes dimensions

The trend towards space and weight saving in TECASINT from Ensinger is a range of non-

modern engineering applications results in melting high-temperature polyimides which

increased thermal and wear resistance expecta- are characterized by the following properties:

tions in the materials used. The characteristic ˌˌHigh strength over a wide temperature

profile of polyimides addresses these stringent range from –270 °C to +300 °C

demands with outstanding success: ˌˌLong-term thermal stability up to 300 °C

ˌˌHDT /A up to 470 °C

ˌˌExcellent electrical insulation properties

ˌˌHigh compressive and creep strength

ˌˌHigh radiation resistance

ˌˌHigh purity, low outgassing in vacuum

in accordance with ESA regulation

ECSS-Q-70-02

ˌˌMinimal thermal expansion

ˌˌMinimal thermal conductivity

ˌˌExcellent friction and wear properties –

even without lubrication

ˌˌGood chemical resistance to acids,

fats and solvents

ˌˌGood cryogenic properties

ˌˌInherently flame resistant (UL 94 V0)

TECASINT high-temperature polyimides Processing methods

are used in demanding applications which Precision components made of TECASINT are

are beyond the capability of other ma-

produced in small production runs using ma-

terials. Key benefits include extreme

temperature resistance, good mechanical chining processes in accordance with customer

load capacity, weight saving, good sliding drawings. For larger volumes, components can

and wear properties and good thermal and

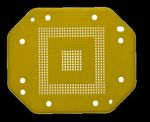

electrical insulation. This test socket made be cost-effectively pressed and sintered using

of TECASINT 4011 is used in the semi- the direct forming process.

conductor industry and combines low

thermal expansion with high dimensional

stability and temperature resistance. TECASINT is available as:

ˌˌStock shapes

(rods, plates, short tubes, discs)

ˌˌMachined parts

ˌˌSerial parts using the

direct forming process

2 3H H H H H H H H

C C C C C C C C CH 3 O H H

n

1

n

2

n

3 O O O

H H H H C C O C O C O C

n l

O C O C C

N CH 3 n

H H

ABS PC PEKEKK POM-C

TECASINT – high-temperature polyimides Product families stock shapes

for special applications

H H H H

Glass industry Aerospace industry TECASINT 1000 TECASINTO 5000

N CH 2 C C C S O C O

The use of polyimides can enhance productivity

x

O

n

Low outgassing rates, high purity and good

H H

n

ˌˌVery high modulus ˌˌCost-effective

O

materials

n

H

n

in the manufacture of glass bottles for the bev- mechanical properties are key requirements ˌˌHigh rigidity and hardness ˌˌExtremely good dimensional stability

erage, pharmaceutical and cosmeticsPA6 industry. in the manufacture of satellites. Excellent tri- PE ˌˌPrevious designation: SINTIMID PES

and load capacity up to 300 °C POM-H

Their excellent temperature resistance and low bological properties, a long service life and low

thermal conductivity lend these high-perfor- wear are essential criteria for the production TECASINT 2000 TECASINT 8000

mance plastics key benefits, particularly for hot of bearing bushes used in modern aircraft ˌˌVery high modulus ˌˌMatrix of PTFE reinforced with PI powder

glass handling, compared to components made engines. TECASINT is the ideal material to ˌˌHigh rigidity ˌˌReduced creep under load

of graphite. They also help extend the service address all these needs. ˌˌHigh hardness ˌˌExcellent sliding and friction properties

life of components and reduce the reject rates. Compared to TECASINT 1000, significantly ˌˌIdeally suited for soft sliding partners

H H

In addition, these materials are economical

H Hto

Oreduced moisture absorption. Higher tough- (stainless

O Osteel, Haluminium,

H brass, bronze)

N CH 2 N C CH 2 C C C O C C O C C

process, making them an ever more popular x y

O

n

O O Cness and improved machining capability.

n

ˌˌBest chemical resistance and easy

n

H CH 3

n

O H H

alternative for the production of take-out tongs Ideally suited for direct forming components. machining properties

and bottle grippers. PA66 PEEK PET PP

TECASINT 4000

Compared to the other TECASINT materials,

TECASINT 4000 is characterized by the fol-

lowing properties:

O O O O O ˌˌMinimalCH 3

water absorption O O O O O

C Automotive

C N R N industry

C C C ˌˌHighest heat ageing resistance

CH 2 C C C C C CH 3

O C O

N Due to H

theHTECASINT

property

N Rprofile, these

n

N

ˌˌLow friction

CH 3

and wear N

n

-R N N

n

-R N N

m

O

n

C CH 2 C C C

C

materials are frequently superior to other C

ˌˌOptimum chemical resistance C

O O O O O O O CH 3

plastics and metals. They can be used to imple- ˌˌHDT /A up to 470 °C

PAI ment applications involving the most extreme PEI ˌˌDifferent types available with high Structural

PI formula PI PPO > PPE?

conditions, and are used for applications in elongation at break and toughness

the automotive industry requiring mechanical or with high flexural modulus

Electrical /electronics stability under high continuous temperatures

and semiconductor industry or high pV values in lubricated and unlubri- Clip

TECASINT 2011 (PI):

Alongside its excellent electrical insulation, cated environments. Use of the direct forming High purity.

H H

TECASINT also offers a very low ion content, method allows the economical manufacture Very good machinability.

C C

n

making it ideal for use in the semiconductor

O O of

H serial

H H parts

H complying with the narrowest of CH 2 H

O

industry and in cleanroom environments, for

C C O tolerances. n

C C C C O

O C CH S

H H H H n H 3C CH 3 n

example in test sockets or in chip and wafer

manufacture. Mechanical engineering, vacuum technology

PBT PEK PMP PPS

and cryotechnology

The fields of application are widely varied: in

Sensor housing

mechanical engineering applications, the ex- TECASINT 5011:

cellent sliding properties of graphite or graph- Thermal resistance up to 300 °C.

Very good electrical insulation.

ite/PTFE-modified TECASINT types are the

preferred choice. In vacuum technology and

cryogenic applications, unreinforced or MoS2

modified types are used for sliding applications.

4 5Modifications

Unfilled + 15 % graphite / + 10 % PTFE

ˌˌMaximum strength and elongation ˌˌExtremely low static friction and low

ˌˌHighest modulus coefficient of friction due to PTFE

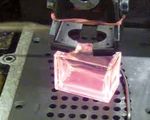

ˌˌMinimal thermal and electrical conductivity modification Direct forming process

ˌˌHigh purity ˌˌGood properties also in dry running

ˌˌLow outgassing in vacuum in accordance conditions due to self lubrication

with ESA regulation ECSS-Q-70-20 ˌˌFor applications involving low friction Low-cost manufacturing method Conditions for direct forming

and wear characteristics at medium for high volume precision parts

+ 15 % graphite temperatures and loads (< 200 °C)

ˌˌEnhanced wear resistance Fast-running vertical automatic presses (me-

Min. part thickness ~ 1 mm

and thermal ageing + 15 % MoS2 chanical or hydraulic) compress the powder

ˌˌSelf lubricating, for lubricated ˌˌBest friction and wear properties in in the die. The part geometry must permit the Max. part thickness 30 mm

and unlubricated applications vacuum part to be ejected from the press die. Blanks are

Max. outside diameter 145 mm

ˌˌFrequently used in space applications, in then sintered for a number of hours at high

+ 40 % graphite vacuum or in inert gases (techn. dry) temperature. This causes a degree of shrinkage, Min. inside diameter ~ 2 mm

ˌˌReduced thermal expansion ˌˌLow outgassing in vacuum in accordance which is accounted for in the original design of

Surface quality ~ 1 μm (Ra)

ˌˌMaximum creep strength with ESA regulation ECSS-Q-70-20 the die.

and resistance to thermal ageing Flattening at the chamfers 0.15 – 0.3 mm

ˌˌImproved self-lubrication + 30 % glass fibres The following types are available

Reference value

ˌˌReduced strength ˌˌReduced thermal expansion for direct forming:

ˌˌHigh thermal-mechanical load properties

ˌˌExcellent electrical insulation TECASINT 2000 DF Applications:

ˌˌTECASINT 2012 (unfilled) Valve seats, sliding rails, chain guides, piston

SD ˌˌTECASINT 2022 (wear resistant grade) rings, guides, wear rings, axial sealing rings,

ˌˌStatic dissipative / antistatic, permanently ˌˌTECASINT 2032 (highly filled grade, shaft end seals, bearing discs, bearing bushes,

migration free low friction) collar bushes, sliding bearings, hot glass grippers

ˌˌSurface resistance 10 6-8 Ω oder 10 10-12 Ω ˌˌTECASINT 2062 (15 % graphite, 10 % PTFE)

ˌˌFor explosion-proof equipment and in

semi-conductor technology (test sockets) TECASINT 6000 DF

Overview of modifications ˌˌTECASINT 6012 (unfilled)

ˌˌTECASINT 6022 (wear resistant grade)

Description Nomenclature Availability TECASINT ˌˌTECASINT 6032 (highly filled grade,

Stock shape 1000 2000 4000 4100 5000 Modifications 8000 low friction)

Pure x011 1011 2011 4011 4111 5111 80 P / 20 PI 8001

ˌˌTECASINT 6062 (15 % graphite, 10 % PTFE)

15 % graphite x021 1021 2021 4021 4121 – 85 P / 15 PI 8061

40 % graphite x031 1031 2031 – – –

15 % graphite / x061 1061 2061 – – –

10 % PTFE Filling Pressing Demoulding

15 % MoS2 x391 – 2391 – – –

30 % GF x051 – – – – 5051

SD static x501 – – – – 5501

dissipative x511 – – – – 5511

Feeder shoe Top die

Customized products available on request.

Overview of nomenclature TECASINT Cavity Bottom die

TECASINT xxxx

For more informationen

1st digit • PI basic material / product family regarding direct forming

2nd + 3rd digit • Formulation code / modification please have a look on our Powder is filled into the cavity, Pressing between the Pressed part out

website: tecasint.com parallel ejection of pressed part. top and bottom die. eject the cavity.

• Production process

4th digit

(1 = stock shape, 2 = direct forming)

6 7Tolerance guideline Seal rings

for direct formed parts

Diameter Height Seal rings made of TECASINT are suitable for continuous application temperature

ranges of –270 °C to +300 °C. Compared to seal rings made of metal, they offer

0 – 14 mm ± 0.030 mm 0 – 5 mm ± 0.10 mm

greater yield, and their higher degree of elasticity makes them more resistant to

15 – 30 mm ± 0.050 mm 5 – 15 mm ± 0.20 mm permanent deformation.

31 – 60 mm ± 0.075 mm 15 – 40 mm ± 0.25 mm

Reference value

W

H

W = Wall thickness

ID = Inside diameter

ID OD = Outside diameter

H = Component height

OD

Butt joint Scarf joint Stepped joint

ˌˌDirect formable ˌˌDirect formable with ˌˌDirect formable with

Diameter Concentricity Roundness Parallelity Flatness ˌˌGap closes when heated and subsequent finish machining subsequent finish machining

response to pressure without ˌˌJoint customarily with 20 degree ˌˌStepped joint seal created by

0 – 25.4 mm 0.04 0.050 0.040 0.050

permanent deformation ˌˌGap clearance effect far lower media pressure at any application

25.4 – 50.8 mm 0.05 0.125 0.075 0.125 ˌˌLow-cost solution rings with than with butt joint temperature

very low constant leakage rates ˌˌSeal effect less dependent ˌˌBehaves on principle in the same

> 50.8 mm 0.05 0.125 0.075 0.125

ˌˌMinimum oil pressure required on minimum oil pressure way as a butt joint connection

All values in [mm] Reference value for even contact pressure on the with slightly reduced clearance

groove flanks ˌˌRings with very low constant

Shape and position tolerances can be manu- ˌˌBevelled edges up to an angle of 30 ˌˌMaximum wall thickness for leakage rates

factured off-tool. Depending on the part geo- degrees starting from the horizontal level straight butt joint sealing rings: ˌˌSeal less dependent on

metry and component size, deviations to the are possible, but need to be integrated 0.5 x (min. shaft diameter – groove minimum oil pressure

listed tolerances are possible. Consequently, into the female die base diameter) – 0.05 mm

tolerances have to be considered individually ˌˌLarger phase angles require flattening

for each component. Undercuts and transverse by 0.15 mm to 0.3 mm around the die

holes, which cannot be manufactured off-tool, periphery

and also narrow tolerances can be realized by a ˌˌFlattening (appr. 0.15 mm – 0.3 mm)

subsequent machining operation. is required at the base of all 45 – 60 degree

phases

General design guidelines ˌˌWhen pressing on one level, grooves can

ˌˌNo undercuts possible still be demoulded up to a depth of max.

ˌˌCollar bushes require a radius between 30 % of the part height, but should have

the flange and hub a demoulding incline of 1 degree on both

ˌˌA minimum wall thickness of 1 mm is sides

recommended ˌˌHoles should be at least 2 mm in diameter

ˌˌThe wall thickness is a function of the

part height. This depends on the material

and should not exceed the value of 1:10

8 9Mechanical properties

The determination of mechanical properties by tensile testing provides information about Dynamic Mechanical Analysis (DMA)

stress-strain behaviour and the resulting modulus. As components made of TECASINT are only DMA measurement is defined as the mechani- dependent basis. The storage modulus E' con-

seldom used at room temperature, material behaviour at elevated service temperatures is required cal response behaviour (storage modulus E' stitutes the proportion of rigidity which allows

for successful component design. Even at high temperatures where conventional thermoplastic and loss factor tan ∂) of a material exposed to the energy of a mechanical load to be stored by

materials would fail or disintegrate, TECASINT polyimides are characterized by very high strength minimal oscillating load. Measured values are the material as a result of elastic deformation

and modulus levels. recorded on a time, temperature and frequency- and then given off again.

Tensile Test TECASINT types at 23 °C / 73 °F Tensile Test TECASINT types at 260 °C / 500 °F Storage modulus E’ as function of temperature

EN ISO 527 EN ISO 527 DMA, 3-point bending test, 1 Hz, 2 K/min

140 70 8,000

120 60

6,000

100 50

80 40

4,000

> Storage Modulus E' [MPa]

60 30

40 20

> Stress [MPa]

> Stress [MPa]

2,000

20 10

0 0 0

0 1 2 3 4 5 6 0 2 4 6 8 10 12 14 16 -200 -100 0 100 200 300 400 500

> Strain [%] > Strain [%] -328 -148 32 212 392 572 752 932

TECASINT 1011 TECASINT 1011 > Temperature [°C] / [°F]

TECASINT 2011 TECASINT 2011

TECASINT 1011 4011

TECASINT TECASINT 2011 TECASINT 1011 4011

TECASINT TECASINT 2011 Tecapeek TECASINT 1011 TECASINT 2011

TECASINT 4011 4111

TECASINT TECASINT 4111 TECASINT 4011 4111

TECASINT TECASINT 4111 TECASINTTECASINT

4011 1011 TECASINT 4111

TECASINT 2011

TECASINT 4011

TECASINT 4111

TECAPEEK

Tensile Modulus [MPa]

EN ISO 527

0 1,000 2,000 3,000 4,000 5,000 6,000 7,000

Tecasint 1011

Tecasint 2011

Tecasint 4011

Tecasint 4111

E-Modulus 23 °C / 73 °F [MPa]

E-Modulus 260 °C / 500 °F [MPa]

10 11Creep strength

Creep strength is the term given to the defor- and demonstrates very low creep tendency

mation increase depending on time and tem- under load. The diagrams below demonstrate

perature under a constant load. TECASINT is the creep modulus and creep strain depend-

a non-melting material which does not soften ing on time and temperature under a load of

even under the influence of high temperatures 17 MPa.

Creep Strain TECASINT at 23 °C / 73 °F Creep Strain TECASINT at 250 °C / 482 °F

17 MPa, ISO 899-1 17 MPa, ISO 899-1

1 10

1

> log creep strain [%]

> log creep strain [%]

0.1 0.1

0.1 10 1,000 0.1 10 1,000

> log time [h] > log time [h]

TECASINT 2011 TECASINT 2011

TECASINT 4011 TECASINT 4011

TECASINT 2011

TECASINT 4111

TECASINT 4011 TECASINT 4111 TECASINT 2011 4111

TECASINT TECASINT 4011 TECASINT 4111

Creep Strain TECASINT at 150 °C / 302 °F Creep modulus EC TECASINT at 150 °C / 302 °F

17 MPa, ISO 899-1 17 MPa, ISO 899-1

1 10,000

> log Creep Modulus EC [MPa]

> log creep strain [%]

0.1 1,000

0.1 10 1,000 0.1 10 1,000

> log time [h] > log time [h]

TECASINT 2011 TECASINT 2011

TECASINT 4011 TECASINT 4011

TECASINT 20114111

TECASINT TECASINT 4011 TECASINT 4111 TECASINT 2011 4111

TECASINT TECASINT 4011 TECASINT 4111

12 13Thermal properties Tribological properties

Due to their chemical structure and infusibility, polyimides are far superior to thermoplastics TECASINT polyimides benefit from high abrasion resistance and are ideally suited for ap-

for use in high temperature applications. By ascertaining their thermal oxidation stability, a guide- plications involving minimum lubrication or dry running. For tribological requirements, types

line can be seen for service life and ageing resistance under thermal load. containing graphite or graphite/PTFE modifications are used, while in vacuum applications,

molybdenum disulphide (MoS2 ) is used.

Thermal Oxidation Stability at 300 °C / 572 °F Heat Distortion Temperature The tribological characteristics depend heavily the coefficient of friction and wear always have

4.8 bar for 300 hours HDT / A 1.80 MPa on the ambient conditions. Factors such as to be considered in the light of the test system

sliding speed, load and form of movement used. This makes it almost impossible to pro-

0 0.2 0.4 0.6 0.8 1.0 1.2 0 100 200 300 400 500

(linear, oscillating, rotating) exert a major in- vide precise values for each application, so that

Tecasint 2021 Tecaflon PVDF fluence. Because of these complex correlations, testing under practical conditions is essential.

PI competitors Tecapei

Tecasint 4021 tecason s

Tecasint 4121 Tecatron Shaft-Bushing-Test after 72 hours Ball-Prism-Test, Steel 100Cr6

> Weight loss [%] tecapeek pV = 10.000 (Rpm: 1278 / 30 psi) Unlubricated, F = 30 N, n = 60 1/min

Tecator pai

Here, TECASINT 4000 materials Tecasint 2011 0 0.10 0.20 0.30 0 0.04 0.08 0.12 0.16 0.20

demonstrate their excellent properties

with minimal weight loss at 300 °C Tecasint 4011

TecaPEEK PVX Tecasint 1021

and with additional pressure of 4.8 bar. Tecasint 4111

Tecasint 1021 Tecasint 1061

> Temperature [°C]

Tecasint 2021 Tecasint 1611

Ageing resistance in air at 340 °C / 644 °F

Tecasint 4121 Tecasint 2021

Long-term tests performed at 340°C in air tes- With its residual flexural strength of 70 % after

PI competitors Tecasint 2061

tify to the excellent properties of TECASINT 3,100 hours, TECASINT 4111 sets the bench-

> Wear [mm] Tecasint 4121

4000. After 2,000 hours, TECASINT 4011 still mark for extreme high-temperature applica-

PI competitors

attains 50 % of its original flexural strength. tions.

> Wear [mm]

Ageing curve, max. flexural strength at 340 °C / 644 °F oven storage

200

150

> Flexural strength (σ max) [MPa]

100

50

0

0 400 800 1,200 1,600 2,000 2,400 2,800 3,200

> Oven storage in hours [h]

TECASINT 1011

TECASINT 1011 2011

TECASINT TECASINT 2011 TECASINT 4011 TECASINT 4111

TECASINT 4011

TECASINT 4111

Electrical properties

Due to their excellent electrical insulating electrical properties. With rising moisture

properties, high strength and very good radia- content, the dielectric loss factor and the

tion and thermal resistance, components made dielectric constant both increase. The surface

of TECASINT are ideally suited for electrical and volume resistance are only minimally

applications under difficult conditions. Even influenced by increasing moisture content.

at high temperatures, they do not lose their

14 15Behaviour under environmental influences Flammability and weather resistance

TECASINT components are often exposed to wide-ranging different environmental influences Flammability Weather resistance

which may result in property changes in the polymer. The combination of different environmental Oxygen index LOI in accordance Polyimides are highly radiation resistant. To

influences results in unpredictable reciprocal effects. It is only by testing under practical conditions with EN ISO 4589-2 assess weather resistance, Xenotest weather-

that this type of influence can be simulated. The “Limiting Oxygen Index” (LOI) indicates ing in compliance with EN 4892 was selected.

the minimum oxygen concentration which This simulates not only radiation with artificial

must prevail in an oxygen/nitrogen mix when sunlight but also regular rain cycles to test the

Water absorption ISO 62 at 23 °C / 73 °F [%] a material burns. TECASINT will only burn influence of rain, humidity and temperature

EN ISO 62 (in water) with an oxygen content of around 50 % and is in natural weathering. The TECASINT 4000

consequently not burning in normal air with an types emerged particularly well from these tests,

Tecasint 0 0.2 0.4 0.6 0.8 1.0 oxygen content of only 21 %. demonstrating over 70 % of their flexural

1011

strength even after 5000 hours.

1021

1031

Oxygen index LOI

2011

EN ISO 4589-2 Flexural strength after weathering

2021 LOI Xenotest, DIN EN ISO 4892-2

2061 Tecasint 2011 51

200

2391 Tecasint 4011 49

4011

Tecasint 4111 52 160

4021

4111

120

4121

> Flexural strength (σ max) [MPa]

80

> Water absorption 24 h (23 °C / 73 °F) [%]

40

Drying 0

0 500 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 5,000 5,500

Like many other plastics, TECASINT also When producing components with very low > Weathering time in hours [h]

TECASINT 1011

demonstrates hygroscopic behaviour. This tolerances, however, it can make sense to dry TECASINT 2011

TECASINT 2011 TECASINT 4011 TECASINT 4111

means that the plastic is able to absorb water, TECASINT prior to machining, in order to re- TECASINT 3011

TECASINT 4011

generally in the form of air humidity. This move any residual moisture and ensure that TECASINT 4111

absorption of moisture is reversible, i.e. the the parts are conditioned to a uniform starting

absorbed water can be fully removed again status. The dried finished parts then have to be

by drying. packaged in an airtight sealable PE bag.

When manufacturing high-precision compo- Drying process

nents, we therefore recommend drying the ˌˌStore the component for

parts prior to machining in order to eliminate at least 48 hours at 150 °C

the disturbing influence of water. Even compo- ˌˌThen heat to 240 °C within 8 hours

nents with an application temperature of over and leave to dry for at least 24 hours

200 °C should be dried in order to prevent the at this temperature

formation of bubbles in the material as a result ˌˌSwitch off the oven and leave

of vapour pressure. to cool slowly

Annealing Hydrolysis

Due to the sintering process, semi-finished and Polyimides are sensitive to hydrolysis at

machined parts made of TECASINT are almost temperatures > 100 °C and are consequently

stress free and have low warping tendencies, not suitable for use in hot water, steam or for

meaning that they do not require annealing. repeated steam sterilization processes.

16 17Chemical resistance Purity

TECASINT products offer a high level of chemical resistance are temperature, concen- In ultra-clean production environments such

resistance to many chemical substances, in- tration of agents, exposure time and me- as in the semi-conductor and solar industry,

cluding organic and inorganic solvents, fuels, chanical load. In the table below, resistance foreign ions can result in contamination and

oils and synthetic lubricants. TECASINT to different substances is listed. This overview higher reject rates.

products are susceptible in combination with is provided as an aid to orientation. For specific

water and water vapour above 100 °C. Due to applications, customers are advised to perform Ionic purity Ionic purity

their hydrolysis susceptibility, marked cracks their own verification tests. The TECASINT materials can be classed in the

TECASINT TECASINT TECASINT

can occur here. Important criteria for testing “high purity” category. [mg/kg] • 2011 4011 4111

Aluminum (Al) 1FAQs Machining guidelines

What benefits does TECASINT offer when How do slide bearings made of TECASINT General

producing bushings and slide bearings? compare to other plastic bearings? TECASINT products can be machined wet feed rates for the individual machining pro-

TECASINT offers an unusual characteristic Applications possible at pressure levels, sur- or dry on all machine tools suitable for metal cesses. Deformation as a result of excessively

profile permitting applications for compo- face speeds and temperature ranges where machining. The use of cutting tools made of high clamping pressure, in particular when

nents exposed to extreme levels of stress which technical thermoplastics are unable to func- carbide with a cutting angle for aluminium machining thin-walled parts, must be avoided.

cannot be achieved using other materials such tion. Higher impact, compression and creep machining has proven the most successful for Preferably, clamping sleeves, clamping man-

as ceramics, metal or conventional plastics. strength. Very high abrasion resistance. Very machining these materials. To avoid machin- drels or vacuum clamping fixtures should be

Bushings and slide rings made of TECASINT good cutting properties and lower tolerances ing errors, it is important to recognize and used. The use of four-jaw chucks is recom-

remain tough, abrasion and creep resistant are possible. replace worn out cutting tools in good time, mended. A higher number of jaws results in

over a continuous application temperature of and to follow the recommended cutting and improved distribution of the clamping force.

– 270 °C to 300 °C, and often exceed the perfor- Sintered parts compared to extruded

mance of other bearing materials. semi-finished products:

How do TECASINT sliding bearings behave in Pressing Turning Dimensional stability

comparison to needle and roller bearings? ˌˌSemi-finished part geometries For all machining steps, the use of carbide For machined parts with extremely close

Due to their good tribological characteristics, close to finished measurement tools, of the type customary for machining tolerances, the material should preferably be

no external lubrication is required. Applica- ˌˌExtreme economy due to material savings aluminium, offers the best solution. The tip machined dry due to its hygroscopic behaviour.

tions are possible in temperature ranges at ˌˌLow tendency to warp due to almost of the cutting tool should have a radius of However, in this case, attention should be paid

which lubricants are ineffective. Good func- isotropic characteristics between 0.2 and 0.4 mm. As a result of wet to ensuring good heat dissipation during the

tionality in dirty environments. Noise, weight ˌˌConsequently also easier to machine machining, the cutting pressure at the work- machining operation. PI and PAI parts with

and cost reduction. ˌˌDiscontinuous production process piece increases, which can give rise to increased large diameters tend to spring back slightly

ˌˌHigh semi-finished product costs burr formation. The service life of the cutting immediately after piercing due to the high

How do the wear properties compare with tools is substantially extended by wet machin- cutting pressure. Consequently it is advisable

bronze, brass and sintered metal? Extrusion ing. If all the essential machining instructions to always produce these in the lower tolerance

Extended life of other components due to ˌˌContinuous production process are taken into account during turning, high band. Semi-finished products for the manu-

marked reduction in wear compared to metal- ˌˌLower semi-finished product costs quality products with a good surface finish facture of extremely precise parts must be

to-metal mating. Reliable functionality in ˌˌHigh tension levels due to can be achieved during the machining of annealed prior to machining. An additional

applications where unlubricated metals fail orientations during production PAI / PI products (Ra ≥ 1.6). intermediate annealing process is generally not

as a result of combined pressure, heat and ˌˌMore difficult to machine Cutting speed for face, longitudinal, cylindrical required during machining. In order to prevent

surface speed. Impact and creep resistant. turning / grooving and parting off dimensional changes to the finished parts due

No problems due to lubricant loss where tex- V = 100 – 130 m / min. to their hygroscopic behaviour, it is advisable

tile or paper dust are produced. f = 0.05 – 0.25 mm / rev. to seal high-quality components in vacuum

barrier film if they are expected to remain in

storage for an extended period.

Do you have any other questions?

Please do not hesitate to contact our technical service:

Markus Edelbauer: m.edelbauer@de.ensinger-online.com

or Ben Sin (Asia): s.ben@ensinger.com.sg

20 21Milling Drilling Standard shapes dimensions

Milling is performed exclusively using the Carbide drill bits are recommended for ma-

downcut milling. For all machining steps, the chining PAI and PI materials. The exception

use of carbide tools with the same cutting ge- to this is boreholes less than 1.5 mm dia. These TECASINT semi-finished products are available Cutting service

ometry as that customarily used for alumini- should be produced exclusively using HSS as plates, rods and short tubes: ˌˌThis is a cost-effective alternative as there

um is the best solution. Individual grinding drill bits which should be ground to a pointed ˌˌRods from Ø 6 mm to max. Ø 100 mm, is no need to buy complete plates or rods

of tools can result in improved results with angle of 120 degree. To counteract the effects max. length 1,000 mm (low capital tie-up)

certain work steps. Dry and wet machining of heat generation, adequate chip removal and ˌˌPlates from 5 mm ˌˌA convenient option permitting

is possible. As a result of wet machining, the wet machining are recommended for all to max. 100 mm thickness need-driven order placement

cutting pressure at the workpiece increases, drilling processes. ˌˌMaximum plate formats ˌˌFast availability. Generally

which can give rise to increased burr forma- HM drill: up to 300 x 1,000 mm within 2 – 3 days

tion. The service life of the cutting tools is V = 100 m / min. (max. dimensions depend on type)

substantially extended by wet machining. f = 0.02 – 0.1 mm / rev.

Excessive single-sided application of heat into HSS drill: Extensive stocked range

the material should be avoided. Alternating V = 15 – 40 m / min ˌˌFast and flexible: All product types

two-sided machining is recommended as the f = 0.02 – 0.1 mm / rev. and dimensions shown on the stock list

preferable method. are available immediately

A comprehensive

Face milling: overview is provided at

ˌˌLarge plate formats for high cutting

V = 90 – 100 m / min. tecasint.com efficiency

f = 0.04 – 0.08 mm / tooth

Preferred dimensions can be found online at:

www.goo.gl/upydXH

Key facts at a glance

For detailed instructions on machining, we are pleased to provide our

technical information sheet “Machining guidelines for TECASINT”.

Machined parts

TECASINT 1000 – 4000 (PI):

Very high thermal stability.

High strength also at high temperatures.

Bonding TECASINT

TECASINT components can also be bonded to roughened in advance either mechanically or by

each other or to other plastics, metals and elas- blasting. Oils, greases and dirt must be removed

tomers. In order to ensure a good glue joint, using solvents. Suitable glues include adhesion

the components must be matched precisely glues based on epoxy resin, polyurethane, rub-

to each other. The contact surfaces should be ber or cyanacrylate.

22 23Contact Headquarter

Ensinger Sintimid GmbH Ensinger GmbH

Ensingerplatz 1 Rudolf-Diesel-Straße 8

4863 Seewalchen 71154 Nufringen

Austria Germany

Phone +43 7662 88788 0 Phone +49 7032 819 0

tecasint@ensingerplastics.com info@ensingerplastics.com

tecasint.com ensingerplastics.com

B-TS-Komp-EN-V1-04/20

TECASINT is the Ensinger portfolio of non-melting

high-temperature polyimides. Sintered TECASINT parts and

shapes are used in numerous demanding industries.

ensingerplastics.comYou can also read