HYDRONEWS - page 10 MEGATRENDS - No.30 - ANDRITZ GROUP

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

MAGAZINE OF ANDRITZ HYDRO 02-2017 ENGLISH

SANTO ANTÔNIO

An Amazonian Example

of Sustainable Hydropower

(page 22)

HYDRONEWS No.30

MEGATRENDS

page 10

Scenarios of the Future2 Editorial

HYDRONEWS No. 30

© iStock.com/YiuCheung

Dear

Business Friends,

Global demographic, technological and activities of ANDRITZ HYDRO world-

economic megatrends – such as urbani- wide. A special highlight is the com-

zation, climate change, and the rising pletion of the hydropower plant Santo

demand for electricity – will bring about Antônio in the Amazon region of Brazil,

major social and political changes which has the world’s most power-

over the coming decades to 2050. At ful bulb turbines installed to date. The

ANDRITZ HYDRO we consider this successful commissioning of this pro-

“Scenario 2050” a motivating vision – ject, which went ahead on schedule, yet

finding tomorrow’s solutions today. again underscores ANDRITZ HYDRO’s

high level of technical competence

So far, the enormous potential of hydro- when it comes to low-head hydraulic

power has not been fully exploited. In power plants. Other examples include

fact, it can still make a significant con- the new contracts for electro-mechan-

tribution to the redesign of global energy ical equipment and hydraulic steelwork

supply on the road to sustainability. engineering for the Gouvães pumped

At the moment the general conditions storage power plant in Portugal, as well

in the hydropower market are very chal- as for Nam Theun I in Lao PDR, Yusufeli

lenging indeed. With investment level- in Turkey, and the John Day refurbish-

ling off, the market appears to be rather ment project in the USA.

stagnating. However, in Europe and

North America especially, further invest- Each of these projects can be linked

ments in the aging pool of facilities and to at least one of the key megatrends IMPRINT

in the expansion of pumped storage mentioned above. In view of this, we Publisher: ANDRITZ HYDRO GmbH,

A-1120 Vienna, Eibesbrunnergasse 20, Austria

hydropower are needed urgently to en- are looking ahead to the coming devel- Phone: +43 50805 0,

sure future network stability. In South opments in the hydropower market with E-Mail: hydronews@andritz.com

Responsible for the content: Alexander Schwab

America, Asia, and Africa, projects to optimism. Editorial Board: Clemens Mann, Bernhard

harness vast hydro resources are under Mühlbachler, Jens Päutz, Hans Wolfhard

Project Manager: Judith Heimhilcher

development. Editorial Assistance: Marie-Antoinette Sailer

Copyright: ANDRITZ HYDRO GmbH 2017,

All rights reserved.

This latest edition of Hydro News pro- With kind regards and our sincere thanks Graphic design: A3 Werbeservice

Circulation: 17,500

vides an overview of the various recent for your continued trust Printed in: English

This issue includes links to videos on external

websites whose content we can’t influence.

The opinions expressed in the videos are person-

al views of the speaker, which must not match

with the positions of ANDRITZ HYDRO GmbH.

The initiator of the video is responsible for the

W. Semper H. Heber accuracy of the content.NEW

INTERVIEW

TOP STORY

Santo Antônio

Megatrends An Amazonian Example of

Scenarios of the Future Sustainable Hydropower

10 22

Content

02 EDITORIAL SITE REPORT

04 LATEST NEWS 20 Pembelik, Turkey

21 Reisseck II, Austria

NEW PROJECTS 26 La Grande 3 & 4, Canada

06 Tedzani III, Malawi 27 Generator Rehabilitation Program,

07 Song Lo 6, Vietnam Tasmania

08 John Day Lock and Dam, USA

09 Wettingen, Switzerland TECHNOLOGY

14 Yusufeli, Turkey 28 Concrete Volute Pumps

15 Huinco and Matucana, Peru

16 Nam Theun I, Lao PDR 30 HIGHLIGHTS

17 Gouvães, Portugal

18 Búrfell Extension, Iceland 36 EVENTS

19 Manic-5, Canada

iPad App Android App Online magazineLatest Vietnam

Nam Na 1

ANDRITZ HYDRO has received an order from Hung Hai

News

Group of companies for the supply, supervision, and commis-

sioning of the electro-mechanical equipment for the Nam Na 1

hydropower plant in Vietnam.

The hydropower plant is located on the Nam Na River, in the

Lai Chau Province. With an installed capacity of 30 MW it will

supply an annual average of 134 GWh of renewable energy to

Fiji the national grid. The hydropower plant is scheduled to be put

Wailoa into commercial operation in 2018.

ANDRITZ HYDRO has received a further order for the replace-

ment of three spherical valves at the Wailoa hydropower plant

in Fiji, supplying up to 80 MW to the 150 MW grid on the main

Fijian island of Viti Levu. The order was placed by the Fijian

Electricity Authority.

A previously ordered main inlet valve also manufactured by

ANDRITZ HYDRO was already installed with a station outage

of only four days in 2016.

Costa Rica

Rio Macho

In December 2016, with the Final Acceptance Certificate

(FAC) for unit five, Instituto Costarricense de Electricidad (ICE)

completed the good collaboration with ANDRITZ HYDRO Germany

during the Rio Macho project in Costa Rica. Langenprozelten

After this last step, all five units of the Rio Macho hydro- Since August 2016, the world’s most powerful single-phase

power plant are rehabilitated and successfully put into com- hydropower motor generator is in operation at the pumped

mercial operation. storage power plant Langenprozelten in Germany. Dismantling

and reassembling of the second machine will start in the sec-

ond quarter of 2017 and should be completed until end of

2017.

With an output of 2 × 94 MVA, Langenprozelten is Deutsche

Bahn’s primary peak-load power plant, providing sufficient

electrical energy to sustain 50 InterCity trains travelling at

200 km/h.

An article with detailed information about the refurbishment

of the first machine was published in Hydro News 29.5 Latest News

HYDRONEWS No. 30

DR Congo

Mwadingusha

ANDRITZ HYDRO has been awarded in a consortium a con-

tract for the refurbishment of the existing Mwadingusha hydro-

power plant in the Katanga Province, DR Congo. The hydro-

power plant is equipped with six Francis units with a capacity

of 11.8 MW each.

The scope of supply for ANDRITZ HYDRO comprises re-

placement of four turbine units, generators, governors, inlet

valves, exciters, voltage regulations, and draft tube stop logs

including dismantling, erection, and commissioning.

Angola

Laúca

After two years of work, the rotor of unit #1 at the Laúca hydro-

power plant in Angola has been successfully installed.

This large project on the Kwanza River consists of two

machine halls, for which ANDRITZ HYDRO is supplying elec-

tromechanical equipment for six 340 MW Francis turbines in-

cluding generators, transformers, control and protection sys-

tems as well as auxiliary equipment.

Rwanda

Rusumo Falls

In November 2016, ANDRITZ HYDRO signed a contract

for design, supply, installation, and commissioning of electro-

mechanical equipment for the Rusumo Falls Hydroelectric

Project with Rusumo Power Company Ltd. The new power

station will be located at the border between Rwanda and

Tanzania. The project is a joint development of three east

© Rune Freyer

African nations Burundi, Rwanda and Tanzania.

ANDRITZ HYDRO’s scope of supply comprises the deliv-

ery of three 27,5 MW vertical Kaplan turbines and its auxilia-

ries, generators, EPS, powerhouse cranes, draft tube gates

and stop logs as well as the control and protection system of

Uganda the whole power plant. Completion of the project is planned

Nkusi for the end of 2019.

In November 2016, ANDRITZ HYDRO received a contract for

the complete electro-mechanical equipment for the new

9.6 MW Nkusi hydropower plant in Uganda.

The customer requested a complete “from water-to-wire”

package to ensure a high quality delivery with minimal in-

terphases and simplified logistics. The scope of supply for

ANDRITZ HYDRO consists of engineering, two identical hor-

izontal Francis turbines, generators, and all equipment and

installation up to the 33 kV switchgear. Transportation up

to Nkusi site, supervision of installation, and commissioning

complete the contractual scope of supply. The HPP Nkusi

project should be completed mid-2018.6 New Project

HYDRONEWS No. 30

Tedzani III

by Walter Schwarz

walter.schwarz@andritz.com

Shire River

Malawi – The Electricity Supply Cor All installation works will be done by Machine hall before rehabilitation

pora

tion of Malawi Ltd (ESCOM) and local ESCOM staff under supervision of

ANDRITZ HYDRO signed a contract for ANDRITZ HYDRO. Specialist training in System (GCMS), which is interfacing

rehabilitation, modernization and upgra Malawi as well as in Austria also forms with all ESCOM hydropower plants has

ding of the Tedzani III hydropower sta- part of the contract. A project team from been awarded to ANDRITZ HYDRO.

tion in March 2016. ANDRITZ HYDRO Austria is commit - As such it underlines the technological

ted to complete the project within less know-how and confirms the high pro-

HPP Tedzani III is located in southern than 20 months, so the Tedzani III fessionalism of ANDRITZ HYDRO em

Malawi, about 100 km northwest of the hydropower plant will be put back into ployees.

city of Blantrye – Malawi’s center of fi- operation by the end of 2017.

nance and commerce and the second

largest city in the country. The majority Following the projects HPP Nukla A, TECHNICAL DATA

of the country’s hydropower stations are HPP Tedzani I and II and HPP Wovwe,

Output 2 × 25.6 MW

located on the Shire River; such as HPPs the order for HPP Tedzani III is the

Head 44.80 m

Nkula A and Nukla B, HPPs Tedzani I, II fourth contract for ANDRITZ HYDRO

Speed 187.50 rpm

and III, and HPP Kapichira. Impressively, in Malawi. Recently, a further contract

Runner diameter 2,950 mm

more than 90% of Malawi’s power gen- for a Generation Control and Monitoring

eration comes from hydropower.

ESCOM will execute the Tedzani III

project together with ANDRITZ HYDRO

as the original equipment manufacturer

© iStock.com/christophe_cerisier

(OEM). The existing units were first commis-

sioned in 1995–1996. ANDRITZ HYDRO

will be responsible for design, manufac-

turing, supply, installation, and commis-

sioning of a completely new control and

SCADA system, new excitation, protec-

tion and synchronization systems, as

well as specifically defined repair and re-

placement works on turbines and gen-

erators.7 New Project

HYDRONEWS No. 30

Song Lo 6

by Xu Wenye

xu.wenye@andritz.com

Nearby HPP Song Lo 6 site

Vietnam – In 2016, ANDRITZ HYDRO sion and support during commissioning.

received a contract for the deliv- ANDRITZ HYDRO has to meet a narrow

ery of electro-mechanical equipment time schedule for design and delivery;

for the Song Lo 6 hydropower plant 19 months for unit #1, 20 months for

from Xuan Thien Ha Giang Company unit #2 and 21 months for unit #3 were

Limited – a civil works company enlarg- agreed upon.

ing its field of activities into hydropower

and developing several projects in Viet On the occasion of the groundbreak-

nam. Following the order for HPP Hang ing ceremony of HPP Song Lo 6, which

Dong A in 2012, this is the second pro took place in September 2015, the in- TECHNICAL DATA

ject awarded to ANDRITZ HYDRO by vestor made a charitable donation to

Output 3 × 20 MW

this customer. the Son Ca Kindergarten in the Vi Xuyen

Voltage 10.5 kV

District, Ha Giang Province and the Vinh

Head 10.5 m

HPP Song Lo 6 is located on the Lo Hao and Yen Thuan communes.

Speed 107.14 rpm

River in the two Vietnamese provinces of

Runner diameter 5,500 mm

Ha Giang and Tuyen Quang. The hydro- After start of commercial operation in Av. annual production 242 GWh

power plant is designed with an installed 2018, HPP Song Lo 6 will significantly

capacity of 60 MW. Once completed contribute to the security of national ener-

and synchronized with the national grid, gy supplies, ensure water resources for

the facility is expected to produce about agricultural production and boost socio-

242 GWh of electrical energy per year. economic development in the southern

provinces.

For the newly built run-of-river plant

ANDRITZ HYDRO will deliver three

20 MW turbines with oil-free hubs and

accessory equipment. Further parts of

the contract are the installation supervi-8 New Project

HYDRONEWS No. 30

John Day

Lock and Dam

by Jack Heaton

jack.heaton@andritz.com

© iStock.com/nesneJkraM

View of the dam

USA – In June 2016, the US Army erators were originally provided by turbine replacement and unit rehabili-

Corps of Engineers, Portland District, ANDRITZ HYDRO’s predecessor com- tation project for the same customer.

awarded a contract to ANDRITZ HYDRO panies. Should the fifth unit option be exer-

for the upgrade of the Kaplan turbine cised, the entire project is expected to

hubs of the John Day Lock and Dam hy- After a half century of operation, some be completed by 2021.

dropower station, in the northwest of of the turbines have passed or are near-

the United States of America. ing the end of their design lives, espe- TECHNICAL DATA

cially the hub internals. This contract in-

Output 16 × 135 MW

With a total installed capacity of cludes work on four units and a fifth unit

Voltage 13.8 kV

2,160 MW, HPP John Day Lock and as an option. ANDRITZ HYDRO will dis-

Head 30 m

Dam is the fifth largest hydropower facil- assemble the entire turbine-generator

Speed 90 rpm

ity in the United States. It is fed by Lake unit, repair the Kaplan runner on-site, Runner Diameter 7,925 mm

Umatilla, a reservoir running 123 km up replace as-needed wearing compo- Av. annual production 8,418 GWh

to the foot of HPP McNary Dam. nents, install new runner hub internals,

refurbish as-required mechanical com-

Primary construction works of the ponents off-site, reassemble the unit,

run-of-river power plant began in 1958 and perform testing and commissioning

and were completed in 1971, at the after the installation. Following the re-

time making it the newest dam on the pair, all the runners under the contract

lower Columbia River with the highest will function as double-regulated Kaplan

lift (34 m) among all locks in the United runners.

States. The powerhouse is equipped

with a total of 16 units, each with an out- Prior to this award, ANDRITZ HYDRO

put of 135 MW. All turbines and gen- successfully completed the Hills Creek9 New Project

HYDRONEWS No. 30

Wettingen

by Christoph Bütikofer

christoph.buetikofer@andritz.com

Switzerland – A contract for the re-

furbishment and revision of the electro-

mechanical equipment at the Wettingen

hydropower plant in the Swiss canton

of Aargau was awarded to ANDRITZ

HYDRO in June 2016.

© ewz

Built in the years 1930–1933, HPP

Wettingen utilizes the waters of the river

Limmat between the upstream power Birdview of the powerhouse and dam area

plant of Dietikon and the downstream

facility of Baden-Aue. tion of new oil mist extractors, and the

revision, modification and replacement

Under the terms of the contract awar of various pumps, bearings and instru-

ded by Elektrizitätswerk Zürich (ewz), the ments. Due to the narrow dimensions

public energy utility of the City of Zurich, of the installation, the new exciter had

ANDRITZ HYDRO’s scope of supply in- to be specially manufactured and opti-

cludes the revision and refurbishment of mized for use with the generator.

essential components of the three units.

In addition, ANDRITZ HYDRO will con- Having a single-source supplier for

duct hydraulic model tests for the de- the entire electro-mechanical e quipment

sign of the new turbine blades, which has a lot of advantages. The ability to

are expected to raise the annual output leverage synergies in terms of order pro-

of the facility by 4%. cessing, installation, revision, and com-

missioning means less coordination ef- Powerhouse

Working in close collaboration with fort and lower costs for the customer.

ewz to identify relevant operating con- TECHNICAL DATA

ditions as accurately as possible, the The handover of the model test results

Output 3 × 8.5 MW / 3 × 10 MVA

turbines were examined for their op- is scheduled for December 2016. On-

Voltage 6.4 kV

timization potential and specific solu- site refurbishment work will start with

Head 21.5 – 23 m

tions developed. ewz decided in fa- the first unit in September 2017 and

Speed 214.3 rpm

vour of a solution that reduces operating is scheduled to be completed by April

Runner diameter 2,835 mm

costs while maximizing the availabil- 2018. The other units will be refurbished Av. annual production 135 GWh

ity of the units and ensuring their safe successively at one year intervals, which

operation. Based on an initial analysis means the last unit is scheduled to be

of the turbine shafts’ remaining useful handed over to the customer for com-

life, it was decided to replace them as mercial operation in April 2020.

well and to optimize the shaft coupling

and gasket construction at the same This project not only reinforces a

time. Essentially, the rehabilitation of the long-standing business partnership with

generators comprises control, dry-ice ewz, but also strengthens ANDRITZ

cleaning, and revision of the stators and HYDRO’s position as a single-source

rotors as well as the revision of the poles supplier for service and refurbishment

at the workshop in Kriens, the installa- projects in Switzerland.10 Top Story

HYDRONEWS No. 30

A Scenario of the Future

by Alexander Schwab

alexander.schwab@andritz.com

by Alexander Schwab and Peter Stettner

alexander.schwab@andritz.com peter.stettner@andritz.com

We are living in a changing world, a rapidly

changing world. Even though these changes are

marked over years or even decades, they are long-

term and fundamental. They are shaping the future

of all nations, countries, social structures, and of

every individual. And they are happening today.

MEGATRENDS

SCENARIOS

OF THE FUTURE

© Pictures from iStock.com11 Top Story

HYDRONEWS No. 30

POPULATION

7.5 billionAS OF TODAY

10 billion AS OF 2050

The biggest changes are encompassed in so-called mega- it will no longer make economic sense to harness fossil fu-

trends. The most important of these megatrends are urbaniza- els. Regardless of this, existing fossil reserves will still be used

tion, shifts in economic power, demographic change, climate extensively causing additional increases in greenhouse gas

change, resource stress, and technology development. It is emissions, resulting in global warming. The goal reached at

in this context that people are discussing a “Scenario 2050”. the climate summit in Paris at the end of 2015 to limit global

warming to less than 2°C will only be achieved with extreme

Forecasts that the global population will be about 10 bil- efforts. Integrated solutions that optimally combine renewable

lion people in 2050 mean that energy demands will have at energies are already in demand today and will be even more

least doubled by then when compared with today. This situa- so in the future.

tion poses a challenge for politics, economics, and research.

It’s a challenge that requires serious consideration today. Demographic and social developments

Regional differences in demographic development could not

With global megatrends shaping our present, answers to be more dramatic. In the future, the majority of the world's

the questions of the future are needed today. Upon examina- population will be over 65 years old, especially in the indus-

tion of changes in demographics, economics, and energy pol- trialized nations. On the other hand, the population of Africa

icy, it quickly becomes clear that we are heading toward a will probably have doubled by 2050, while the population of

challenging future. Europe will shrink. By this time, individual countries in Africa

could have more inhabitants than the USA has today.

Urbanization

In 2050, half of the world’s population will live in major ur- Overall, the world’s population increases

ban centers and there will likely be at least 40 cities with more

by about 150 people every minute.

than 10 million inhabitants. Megacities such as New York, São

Paulo, Cairo, and Beijing will have to make billions of dollars of

infrastructure investment within the next 10 years. Urban tech-

nologies to keep growing cities viable are racing ahead. An ex-

ample is the emergence of “smart cities” in which inhabitants

can interact intelligently and efficiently with their urban envi-

ronment. But despite increasing energy efficiency, the energy

demands of such megacities will be enormously high.

Currently cities cover just 0.5% of the

earth’s surface. However, they consume

some 75% of global resources.

Climate change and resource scarcity

Population increases, urbanization, and increasing en-

ergy demand will ensure that conventional energy sources

will reach their limits in the near future. With respect to cur-

rent consumption data, it appears that in just a few decades12 Top Story

HYDRONEWS No. 30

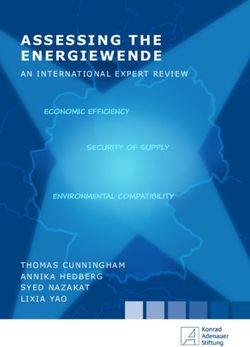

Purchasing Power Parity of the G20 nations in 2050

61 000

(values in US$bn) 61,000

8)

42 000

41 000

11)

10)

19)

13)

18)

14)

17) 7)

15)

16)

12)

6)

9) 20)

4)

5)

3) 2) 1)

actual 2014 predicted forecast 2050

* G20 nations according to GDP at PPP (Purchasing Power Parity) ranking: 1) China, 2) India, 3) USA, 4) Indonesia, 5) Brazil, 6) Mexico,

7) Japan, 8) Russia, 9) Nigeria, 10) Germany, 11) United Kingdom, 12) Saudi Arabia, 13) France, 14) Turkey, 15) Pakistan, 16) Egypt,

17) South Korea, 18) Italy, 19) Canada and 20) Philippines.

Based on the study “The World in 2050” by PWC, dated February 2015

Shift in global economic power Today’s frontier markets will become

The way individual national economies are classified will

future emerging markets. Today’s

become less relevant in the future. Increasing incomes and

closing wage gaps will lead to a growing global middle class. emerging markets will become future

Markets grow unpredictably, however. For example, China and core markets.

Mexico have grown exceptionally over the last years, whereas

countries in Europe have seen their economies stagnate. To Technological breakthrough

reflect these changes we have to adjust our view of the global Technology development is an underestimated force today,

economy. Some markets will become more important due to but will gain more and more importance as a major compo-

the value chain and become core markets for global busi- nent in the re-shaping of the future economy. The time it takes

nesses. Developed countries will benefit from a more diverse from invention to breakthrough to mass application is getting

business culture, skilled talent will be spread multinationally, shorter and shorter. For example, it took 76 years for the tele-

education and health care will become more important indi- phone to reach half the population, the smart phone took only

cators. about a decade.

Digitalization has had a profound impact not only on society,

but also on the economy. Today the value created by tech-

nology, especially internet-based technology, is extraordinary.

The importance of e-commerce, interconnectivity and digital

brands is crucial for industry. Social media, mobile applica-

tions and cloud services to meet the customers’ needs are

already vital parts of future strategy to succeed in the digital

age.

The role of hydropower in the future

In a time when producing fossil resources is becoming less

economical and energy demands continue to climb, a com-

promise between the needs of the present and responsibil-

ity to future generations has to be found. Hydropower is the

most proven and best-developed form of renewable electric-

ity generation. Increasing awareness of global climate change13 Top Story

HYDRONEWS No. 30

and sustainable electricity generation, social responsibility on Hydropower is sustainable, renewable, and flexible, has

the part of politics, as well as an increasingly critical attitude many benefits and great potential. It is the answer to many of

toward CO2 emissions from fossil fuels, will cause demand for the questions posed for the future. Constant research and de-

hydropower to increase in the coming years. velopment will ensure that hydropower remains the most im-

portant renewable energy resource, as it is today.

Currently, approximately 16% of the world's electrical en-

ergy comes from hydropower. In the future, the assumption is The traditional approach to the operation of hydropower

that the enormous and increasing demand for electricity will facilities has to be reconsidered though. New demands are

be fulfilled by those energy concepts that best combine the fast response times, frequent load changes, and extended op-

various resources available. Hydropower is trend-setting here, erational ranges. Anticipated future requirements include calls

for it does not end with power generation. Instead, it offers a for frequency regulation by run-of-river power plants, mini

wide spectrum of applications, including energy storage for pumped storage for balancing small wind farms, ocean energy

grid stability and peak load coverage. applications combined with off-shore wind farms, small hydro

to balance the impact of clouds passing over a solar plant, as

well as upgrading all existing power plants to new standards

technically and network codes, and linking them with the state-of-the-art

feasible 16,000 automation systems of the digital world.

hydropower TWh

potential For ANDRITZ HYDRO, the changing future is a big motiva-

tion to find tomorrow’s solutions today. The immense potential

of hydropower has by no means been fully exploited – it can

25% (4,000 TWh) still make a significant contribution to the redesigned and sus-

exploited as per today tainable future energy supply system.

“From water-to-wire” 2050

14 New Project

HYDRONEWS No. 30

© Nejdet Duzen/Shutterstock.com

Çoruh River, near Deriner Dam

Yusufeli a rated discharge of 107 m3/s. The dam

is of double-curvature type and with a

height of 270 m from its foundation it will

by Özkan Yilmaz be Turkey’s highest and the third highest

oezkan.yilmaz@andritz.com dam of this kind worldwide.

Turkey – ANDRITZ HYDRO received a ANDRITZ HYDRO’s contractual scope

second order within 12 months for the of supply comprises design, supply, in-

Yusufeli hydropower project in Turkey stallation, and commissioning of three

in September 2016. The actual order generating units, each with a rated out-

for three generating units and relat- put of 186 MW, main power transform- turbine auxiliary systems as well as main

ed equipment follows the recent con- ers, 380 kV switchyard equipment (AIS inlet valves will be supplied by ANDRITZ

tract for supplying the intake structure, and GIS), and all relevant control, meas HYDRO China.

as well as the penstock and gates (see uring, and protection equipment.

Hydro News 29). The start of commercial operation

With the focus on providing premium is scheduled for the third quarter of

The impoundment facility is located on quality under challenging circumstances, 2019. This contract strengthens again

the Çoruh River in northeastern Turkey, handing over of the units is planned within ANDRITZ HYDRO’s leading position in

upstream of HPP Borçka, HPP Muratli, 33 months after commencement of the the Turkish hydropower market.

and HPP Deriner. As with these plants, works. ANDRITZ HYDRO takes ad-

HPP Yusufeli is also owned by General vantage of its international structure, TECHNICAL DATA

Directorate of State Hydraulic Works so several ANDRITZ HYDRO compa- Output 3 × 186 MW

(DSI), a company which has already nies in close co-operation are contribut- 3 × 203 MVA

been working with ANDRITZ HYDRO on ing with supplies to the plant. ANDRITZ Head 191 m

these projects, as well as HPP Ermenek HYDRO Turkey will provide major equip- Speed 214 rpm

and HPP Ilısu, which is currently under ment for the electrical power system and Runner diameter 3,500 mm

construction. installation services. ANDRITZ HYDRO Av. annual production 1,888 GWh

Austria will supply the turbine runners

The new Yusufeli hydropower plant and governors. The generator and au-

will have a total installed capacity of tomation system will be provided from

558 MW with a rated head of 191 m and ANDRITZ HYDRO India, whereas the15 New Project

HYDRONEWS No. 30

Huinco &

Matucana

by Peter Gnos

peter.gnos@andritz.com

and Andreas Kronsteiner

andreas.kronsteiner@andritz.com

Peru – In June 2016, ENEL Gene -

ración Perú S.A.A. and ANDRITZ

HYDRO signed a con tract for reha-

bilitation works at the two Peru vian

hydro power plants Huinco and Ma - Powerhouse of HPP Matucana

tucana. With a capacity of 1,283.8 MW

(739.4 MW thereof produced by hydro- HPP Matucana is located in the high- vision, electrical tests and commission-

power) Edegel S.A.A. is the largest pri- lands of Lima and is fed by the Rímac ing. At present, the engineering process

vate electric generation company in Peru. River and the Yuracmayo dam. The run- is finished and approved by the client

of-river power plant began its power and the manufacturing of components

Huinco and Matucana hydropower generation in 1972. It has an installed in the ANDRITZ HYDRO workshop in

plants are located in the province of capacity of 137 MW and counts two Araraquara, Brazil, has already started.

Huarochirí, about 70 km east of Lima. double horizontal Pelton turbines. The All works on-site will be carried out be-

After continuously operation of more intake is connected to the plant via a tween 2017 and 2019.

than 40 years, the rehabilitation of two 20 km long tunnel. The reservoir tank at

generators at HPP Huinco and one gen- Matucana is made up of two 500 m long

erator at HPP Matucana is necessary. underground chambers, with a capac-

ity of 30,000 m3 each. Thanks to these

The Huinco storage power plant is the chambers, the plant’s nominal capacity

result of an electric expansion plan in- could last up to three hours, even during

tended to adequately meet the future dry periods.

electricity demand in the 1920s, using

the waters of the Rímac and Santa Both projects will be carried out by

Eulalia Rivers. After damming up the ANDRITZ HYDRO Peru and Austria.

lakes on the Santa Eulalia River, diver The scope of delivery comprises new

ting the waters of the Rímac River complete stator windings for two units

to the Santa Eulalia River, and build- at HPP Huinco a new stator for HPP

ing the Callahuanca, Moyopampa, and Matucana, as well as installation, super- Machine hall of HPP Huinco

Huampaní hydropower plants, a trans-

Andean tunnel was built in the early TECHNICAL DATA

1960s to provide sufficient water for Huinco

HPP Huinco. HPP Huinco has an in- Output 265 MW

stalled capacity of almost 265 MW. The Voltage 12.5 kV

first of the four horizontal Pelton turbines Head 1,245 m

was commissioned in 1964. Currently, it Speed 514 rpm

has the highest head used to produce Stator diameter 3,300 mm

hydroelectric energy in Peru (1,293 m).

HPP Huinco was built in a cavern, due Matucana

to the river course of the Santa Eulalia, Output 137 MW

which runs near HPP Huinco through a Voltage 12.5 kV

narrow gorge and enforced the construc- Speed 450 rpm

Stator diameter 3,400 mm

tion of an underground powerhouse.16 New Project

HYDRONEWS No. 30

Nam Theun I

by Oliver Gielesberger

oliver.gielesberger@andritz.com

Region close to HPP Nam Theun I

Lao PDR – In August 2016, ANDRITZ its confluence with the Mekong River. It operation is scheduled for the end of

HYDRO received an order from Phone is the last plant in the Nam Theun-Nam 2020.

sack Group (PSG) to supply electro-me- Kading Hydropower Cascade. The in-

chanical equipment for the Nam Theun 1 flow reaching the Nam Theun I reservoir Following HPP Huay Ho, HPP Nam

hydropower project in Lao PDR. is affected by the existing upstream hy- Theun II, HPP Theun Hinboun and HPP

dropower plants including HPP Theun Nam Lik, this is a further private hydro-

Lao PDR is a landlocked and moun- Hinboun, HPP Theun Hinboun Expan power plant in Vietnam to be equipped

tainous country with borders to Myan sion, and HPP Nam Theun II. ANDRITZ with the state-of-the-art equipment of

mar, China, Vietnam, Cambodia, and HYDRO completes its supply of electro- ANDRITZ HYDRO.

Thailand. The Mekong River acts as a mechanical equipment in this cascade

major part of the Laotian border and by supplying the last plant on the river. TECHNICAL DATA

also represents a large part of the coun-

Output 2 × 265 MW / 1 × 132.5 MW

try’s enormous hydropower potential. By The hydropower plant houses three

Head 140 m

developing these resources the Laotian units with a total output of about

Speed 2 × 187.5 rpm / 1 × 250 rpm

government intends to transform the 662 MW. The scope of supply for

Runner diameter 2 × 4,450 mm

country into “the Battery of Southeast ANDRITZ HYDRO comprises design,

1 × 3,250 mm

Asia”. manufacturing and supply of the com-

plete electro-mechanical equipment, in-

HPP Nam Theun I aims to contribute cluding three vertical Francis turbines,

to the Lao PDR’s development by creat- model test, generators, governors, and

ing revenues from the export of electric- automation system. The scope also in-

ity, as well as covering future increases cludes the main transformer, medium-

in domestic demand. and low-voltage switchgears, power and

control cables, fire protection system,

The Nam Theun I hydropower stor- 500 kV GIS, the main inlet valve, me-

age scheme is located on the Nam chanical auxiliaries, installation super-

Kading River, about 33 km upstream of vision, and commissioning. Commercial17 New Project

HYDRONEWS No. 30

Gouvães smaller size, this scheme will ideally

complement volatile electricity genera-

tion from wind power, which has been

and reliability will be met in an optimum

way.

by Franco Michele Bennati growing significantly in recent years. This is the third large contract between

francomichele.bennati@andritz.com

Additionally, the project will have a very Iberdrola Generación and ANDRITZ

positive impact on the employment situ- HYDRO on the Iberian Peninsula, after

Portugal – ANDRITZ HYDRO has ation in the region. having received the contracts for equip-

been contracted by the Spanish ener- ment deliveries for the San Pedro II hy-

gy utility Iberdrola Generación S.A.U. The scope of supply for ANDRITZ dropower plant in 2011 and for modern-

to supply the electro-mechanical equip- HYDRO comprises design, manufactur- ization of the Aldeadávila hydropower

ment and the penstock for the new ing, delivery, and installation supervision plant in 2014.

pumped storage power plant Gouvães for the reversible pump turbines, motor

in Portugal. generators, and electrical power sys-

tems. Also part of the contract are de- TECHNICAL DATA

With four 220 MW pump turbines sign, manufacturing, supply, and com-

Output 880 MW

PSPP Gouvães will be the heart of the plete installation of a penstock including

Head 660 m

Alto Támega hydropower scheme, con- three bifurcators with a total weight of

Speed 600 rpm

sisting of three hydropower plants. The about 12,000 tons, an average diame-

Runner diameter 3,500 mm

scheme will be built on the Támega ter of about 5,400 mm and a length of

River in northern Portugal, close to the 2.5 km.

seaport of Porto. Together with HPP

Alto Támega and HPP Daivoes, the With a net head of about 660 m, to

Gouvães pumped storage power plant provide a safe basis for the design of

will produce in total 1,468 GWh of elec- the technically outstanding high head

trical energy. PSPP Gouvães will cover pump turbines extensive research and

the need for peak-load energy and pro- model testing activities have been per-

vide fast-responding regulating power. formed in ANDRITZ HYDRO’s test lab-

Together with the baseload generation oratory. Thus, the high requirements of

from the other two power stations of Iberdrola Generación regarding feasibility

Penstock area18 New Project

HYDRONEWS No. 30

© iStock.com/philotera

Búrfell mountain

Búrfell will be installed in a separate under-

ground powerhouse. This new unit will

With an overall project duration of

26 months from commencement, the

Extension increase the total capacity of the com-

bined Búrfell hydropower stations by

300 GWh per year.

delivery and completion dates of this

project are tight. Hence, the project

management requires high performance

by Michael Stadler engineering to place purchasing orders

michael.stadler@andritz.com

ANDRITZ HYDRO’s scope of sup- in due time, as well as a clear focus on

ply comprises the delivery and installa- the interface management, and close

Iceland – Icelandic utility Landsvirkjun tion of the turbine and its auxiliaries, the monitoring of sub-suppliers.

has a warded a contract to ANDRITZ generator, the electrical power system,

HYDRO for the supply of electro-mecha MV and LV systems, a fire extinguish- The Búrfell Extension hydropower

nical equipment and control systems for ing system, the powerhouse cranes, the station is expected to start operation

the Búrfell Extension hydropower station auxiliary systems, as well as the con- in 2018.

in Iceland. trol and protection system of the whole

power plant. TECHNICAL DATA

Located about 130 km east of Rey

Búrfell

kjavík, the existing Búrfell hydropower In June 2016, the first important mile-

Output 6 × 45 MW

plant has been operating continu ously stone – the model acceptance test – was Voltage 13.8 kV

since 1969. It is equipped with six Fran performed together with the customer in Head 115 m

cis units with a total output of 270 MW, the ANDRITZ HYDRO hydraulic labo- Speed 300 rpm

providing 2,300 GWh of electrical en- ratory in Canada. Existing components Runner diameter 2,460 mm

ergy annually to the national grid. Until from various developed projects were Av. Annual production 2,300 GWh

the inauguration of HPP Kárahnjúkar used to build a Búrfell Extension model.

in 2007, it was the largest hydropower During the witness tests the combina- Búrfell Extension

plant in the country. tion of those components could be suc- Output 1 × 100 MW

cessfully verified. The use of existing hy- Voltage 13.80 kV

The new HPP Búrfell Extension pro draulic components made it possible to Head 119 m

ject is located about 2 km from HPP start the inquiry process of components Speed 230.70 rpm

Runner diameter 3,190 mm

Búrfell at the foot of the Sámsstaðaklif with a long delivery lead time directly af-

Av. Annual production 300 GWh

depression. A 100 MW Francis turbine ter the project commencement.19 New Project

HYDRONEWS No. 30

View of the dam

Manic-5 ings will be supplied to replace the old

bronze bushings. The project, including

all engineering activities, is being man-

Following commissioning of the last

two units completion of the contract is

scheduled for October 2019.

by Francoys Gauthier aged by ANDRITZ HYDRO Canada.

francoys.gauthier@andritz.com

TECHNICAL DATA

Works on the first two units at site will

Output 1,528 MW

Canada – In June 2016, ANDRITZ start in March 2017. A very challenging Head 142 m

HYDRO received a contract from Hydro- aspect of the project is that the valves Valve nominal pressure 15.2 bars

Québec for the rehabilitation of turbine cannot be removed from site or brought Valve nominal diameter 3,658 mm

spherical inlet valves at the Manic-5 to a workshop for refurbishment works.

hydropower plant in the administrative The site set-up does not allow it as there

region of Côte-Nord in Québec. is not enough access space outside the

valve gallery and the overhead crane

HPP Manic-5 is situated on the Mani does not have the necessary lifting ca-

couagan River at the Daniel-Johnson pacity. For the same reason, the valves

Dam. With a height of 214 m, a length cannot be completely dismantled. Much

of 1,314 m, and 2.200,000 m3 of con- of the refurbishment work, including in-

crete, Daniel-Johnson Dam is the high- spections, grinding, welding, machin-

est multiple-arch-and-buttress dam in ing, and painting, has to be done on-site

the world. directly in the valve gallery.

ANDRITZ HYDRO is very familiar with Existing valves

the project, since the company was the

Original Equipment Manufacturer (OEM)

of the valves back in the 1970s. The

current contractual scope comprises

engineering, supply, dismantling, refur-

bishment, and reassembly of the valves

of six out of eight units at a rhythm of

two per year. The scope of work also in-

cludes new electrical and hydraulic con-

trol panels, instrumentation, piping and

platforms, as well as refurbishment of

servomotors and levers. An anti-auto-

oscillation hydraulic control system will

also be provided preventing oscillation

phenomena. In order to eliminate the old

greasing system, self-lubricating bear-20 Site Report

HYDRONEWS No. 30

Pembelik

by Burak Celikel

burak.celikel@andritz.com

Turkey – In the summer of 2016, the

Pembelik hydropower plant on the Eu-

phrates River in Turkey was fina lized

and started commercial operation. The

order for the project was awarded to

ANDRITZ HYDRO in 2011 by Darenhes

Enerji Üretim A.Ş. – together with a con-

tract for HPP Tatar, which started com-

mercial operation in 2014 (see Hydro

News 25).

The Pembelik hydropower plant is lo-

cated on the Peri Stream River, a ma-

jor branch of the Euphrates which runs View of the hydropower station area

between the provinces of Tunceli, Bingöl

and Elazığ and within the borders of

the Karakoçan district in Turkey. HPP

Tatar is situated downstream of HPP

Pembelik. Both projects were won fol-

lowing an international bidding process,

with ANDRITZ HYDRO succeeding

through both its technological know-

how and the best offer, as well its exten-

sive expericence in the Turkish market.

The agreed time schedule was chal-

lenging from the beginning, but HPP

Pembelik was completed and handed

over to the customer for commercial

operation two months earlier than the

contractual handover date. Machine hall

ANDRITZ HYDRO’s contractual scope the special components of the turbine – HPP Pembelik has two units with a to-

comprised design, engineering, manu like the head cover, bottom ring, and tal capacity of 131.6 MW and will deliver

facturing, transport, and installation stay ring – and of the generator – like 372 GWh of electrical energy per year to

of turbines, generators, and electrical the rotor spider, lower and upper brack- the national grid.

equipment as well as supply of an au- ets – as well as installion service were

tomation and protection system. In ad- provided by ANDRITZ HYDRO Turkey.

dition a 161 kV switchyard, two feeder

stations, and equipment training on-site

were also part of the deal. TECHNICAL DATA

Output 2 × 65.8 MW

Executed by ANDRITZ HYDRO lo-

2 × 74.2 MVA

cations in Austria and Turkey, the de-

Voltage 13.8 kV

sign and supply of turbine and generator

Head 69.8 m

core equipment, the protection, auto-

Speed 166.7 rpm

mation and excitation system were pro-

Runner diameter 3,620 mm

vided by ANDRITZ HYDRO Austria. The

Av. Annual production 372 GWh

delivery of the 161 kV switchyard and21 Site Report

HYDRONEWS No. 30

VIDEO

Transportation of the rotor

Reisseck II

(control, excitation, and protection), hy- increased by 50 % (as calculated with

draulic protection, gates and valves, linear material properties).

ANDRITZ HYDRO also installed two

by Walter Scheidl

identical generator units in the cavern. With this project ANDRITZ HYDRO

walter.scheidl@andritz.com

once again strengthened its relationship

and Rupert Kirchengast The ideal hydraulic unit is a 215 MW with the customer and adds an important

rupert.kirchengast@andritz.com single-stage reversible pump turbine Austrian project to its references.

with vertical shaft, a nominal speed of

Austria – Commercial operation of the 750 rpm and a dynamic runaway speed TECHNICAL DATA

new pumped storage power plant Reiss- of 1,142 rpm. During the project plan-

Output 2 × 215 MW / 2 × 240 MVA

eck II in Austria started in October 2016. ning process, potential European gen-

Head 595 m

erator manufacturers were asked to

Speed 750 rpm

Owner VERBUND has awarded a con- examine the basic feasibility of an ap-

Rotor diameter 3,202 mm

tract to ANDRITZ HYDRO for the de- propriate motor generator, which was Annual production 970 GWh

livery of electro-mechanical equipment, confirmed, even though units with an

the control system and protective infra- output of 30 MVA per pole had not been

structure in 2013 (see Hydro News 24). realized in Europe at that time. Rotor for unit #1

As part of the Malta-Reisseck Power To achieve a robust unit with a long

Plant Group – the largest group of hy- service life, many different load cases

dropower plants in Austria – PSPP Reis needed to be mastered and their defi-

seck II consists of an underground pow- nitions represented the basis for the

erhouse. It is owned by VERBUND and design. VERBUND requested rotor

is situated in the province of Carinthia overspeed testing of at least 1,200 rpm.

in the Austrian Alps. The newly built Highly stressed areas tend to plastify

pumped storage power plant extends during overspeed testing and compres-

this group by using the existing reservoir sive residual stresses remain, which re-

Grosser Mühldorfer See. duces tensile stresses during operation.

In contrast to many common designs

In addition to design, installation and of units without overspeed testing, this

commissioning of automation systems allowed the value for peak stress to be22 Interview HYDRONEWS No. 30 INTERVIEW Santo Antônio An Amazonian Example of Sustainable Hydropower Brazil – Recently completed, the 3,568 MW Santo Antônio hydropower plant is one of the five largest hydroelectric stations in Brazil and supplies energy to some 44 mil- lion people from its 50 units. Antônio de Pádua Bemfica Guimarães is technical director of Santo Antônio Energia (SAE), a company responsible for implemen tation of Santo Antônio, he talked to Hydro News about the project. World’s largest bulb turbine being installed at Santo Antônio

23 Interview

HYDRONEWS No. 30

“ An evaluation made by the International

Hydropower Association (IHA), considered

”

Santo Antônio the most sustainable project

evaluated by them in the world.

– Antônio de Pádua Bemfica Guimarães

What makes the bulb turbines at HPP Santo Antônio

special?

HPP Santo Antônio uses the largest bulb turbines in the world.

The previous record-holder uses machines rated at 68 MW, our

turbines have 71.6 MW. In terms of size, at 7,500 mm diame-

ter they are second only to the 8,410 mm units installed at HPP

Murray Lock, in the USA.

The decision to use bulb turbines was driven by the flow char-

acteristics of the Madeira River and the necessity to minimize

the environmental impact of a large project, significantly reduc-

ing the area of the reservoir. Precisely because it is a run-of-river

power plant, the bulb turbine proved the best solution to com-

bine lowest impacts with highest use of the hydroelectric poten-

tial of the river.

What were your main considerations in selecting the key

contractors for Santo Antônio?

Due to the project complexity, a lot of equipment involved,

and the size of the turbine set for the Santo Antônio hydropower

plant, the supply chain was concentrated in the most experi-

enced and largest power generation equipment manufacturers.

In addition, the Santo Antônio project implementation is under

an EPC (Engineering Procurement and Construction) contract

structure.

ANDRITZ HYDRO is part of the Santo Antônio Constructor

Consortium (CCSA). Its scope of supply included 14 bulb tur-

bines, 13 generators, 28 excitation systems, 26 generator

switch

gear systems, and three power transformers rated at

13.8 kV–500 kV.

The companies that make up the CCSA had, in addition to

their expertise, an important role in the development of local

companies and service providers. This partnership is leaving

an important legacy because they prepared local companies to

meet the demands of other projects.24 Interview

HYDRONEWS No. 30

Installation works Bulb nose

What unexpected challenges have arisen during the con- Given its location on the Amazon, how does Santo Antônio

struction and installation of Santo Antônio? address environmental sustainability concerns?

Many adverse situations have arisen during the implementa- The Amazon is a sensitive area, with strict environmental pres-

tion phase of the Santo Antônio hydroelectric plant. Two of them ervation standards. Therefore, it is essential to adopt practices

deserve to be highlighted: that minimize to the maximum the effects that large infrastruc-

ture projects, such as hydroelectric dams, can cause in a region

The high concentration of sediments carried by the Madeira like the Amazon. One way to ensure this is to allocate financial

River, which reaches 500 million tons/year; and, the large resources and apply techniques and appropriate technologies

amount of floating elements during the flood season, which add to mitigate these effects, compensating for the impacts caused.

up to about 30,000 logs, antlers and other objects a day.

The Basic Environmental Project (PBA) is a document that de-

Construction, erection, and commissioning activities took scribes the set of actions and measures to be implemented be-

place simultaneously with operating activities so while genera- fore, during and after the works of our hydroelectric installation.

tion units were being installed many problems were identified in Despite the name, it does not cover only environmental initia-

the units that were in commercial operation. This required a con- tives. The recovery and strengthening of the history and culture

tinuous reassessment of the project and often further studies. of Porto Velho, as well as the enhancement and development

of the local population, are vectors of sustainability that are also

part of our company project. In total, 28 programs have been

conducted and add great results.

Machine hall

Regarding social and environmental concerns in the country,

the Santo Antônio hydropower plant is a good example for im-

plementation of sustainable power generation models. Strictly

respecting the rules established by the Brazilian environmental

agencies, the project was designed to respect the natural char-

acteristics of Amazonia, at the same time taking the maximum

advantage of the Madeira’s hydraulic potential.

An evaluation made by the IHA – International Hydropower

Association, considered Santo Antônio the most sustainable

project evaluated by them in the world, achieving the highest

number of top marks in more than 20 topics related to environ-

mental issues and stakeholders influenced by the project.25 Interview

HYDRONEWS No. 30

Powerhouse and dam area

How do you see future hydropower development in the

Amazon region of Brazil unfolding?

The Amazon is the last frontier of the country's hydropower

generation development, with about 70% of its potential yet

to be explored. Given this, it is natural that there is a strate-

gic interest in making the region an important hub of clean and

renewable power generation, attracting large projects. Today, ABOUT

using the Santo Antônio hydropower plant as an example, you

realize that you can explore all this power responsibly, incorpo-

rating the new project mechanisms that significantly reduce the

environmental impact and ensure the use of the Amazon’s po-

tential. The implementation of Santo Antônio is an important

benchmark for other projects planned for the region, especially

in breaking the old paradigm. It is possible to generate energy

from the Amazon with sustainability.

Joining knowledge and the sum of the technical experience

of the team of Santo Antônio Energia, ANDRITZ HYDRO and

other manufacturers, we are certainly making history in the Antônio de Pádua Bemfica Guimar ães

implementation of large infrastructure projects, and helping to is technical director of the Santo

avoid imperfections in future projects. Antônio Energia (SAE) Company, re

sponsible for implementation of the

Interview by David Appleyard Santo Antônio hydropower project on

Freelance journalist focused on energy and technology (UK) the Madeira River in Porto Velho, the

capital of the northwestern Brazilian

SANTO ANTÔNIO IN SHORT

state of Rondônia.

Part of the Madeira River Complex

3,568 MW installed capacity

A civil engineer, since graduat

50 units in operation since November 2016

ing in 1980 he has held senior roles

71.6 MW, world's largest bulb turbines

in Enerpeixe and Furnas Centrais

7,500 mm runner diameter, among the largest worldwide Elétrica. Today, Antônio de Pádua is

responsible for the EPC Contract Ma

2.5 km dam length – The amount of steel and concrete used correspond nage ment and construction inspec

to 40 Maracanã Stadiums and 18 Eiffel Towers. tions on this giant project.26 Site Report

HYDRONEWS No. 30

© Photo Hydro-Québec

Dam area HPP La Grande-3 HIPASE-E as installed at La Grande-3

La Grande to produce 2,199 A at 306 V and com-

prises a redundant thyristor bridge with

HIPASE-T platform. The first unit was

successfully commissioned end of

3&4

forced cooling, the static excitation sys- 2016. Closing of the complete project

tem will be the biggest ever delivered by and commissioning is scheduled for

ANDRITZ HYDRO. The exciter cubicle 2019.

by David Tawfik contains power circuits, the automatic

david.tawfik@andritz.com voltage regulator and the complete se- Both contracts strengthen ANDRITZ

quencer, which is necessary to control HYDRO’s position in the Canadian market.

Canada – 2015 Hydro-Québec has the individual components. The system

awarded two contracts to ANDRITZ also comprises the newly developed TECHNICAL DATA

HYDRO for modernization works at the HIPASE-E platform. La Grande-3

James Bay Project in Canada. Initiated Output 12 × 200 MW

by Hydro-Québec and the Québec gov- Hydro-Québec is stringent regarding Voltage 13.8 kV

ernment in the 1970s, and located be- quality in many segments, like drawings, Frequency 60 Hz

tween James Bay and Labrador on selection of the material, test procedures Head 79.2 m

the La Grande River in Northwestern and homologation process. Given the Speed 112.5 rpm

Québec Canada, it is one of the largest size of each unit, minimum ventilation is Av. annual production 12,484 GWh

hydroelectric systems in the world with required to properly cool the exciter and La Grande-4

a total capacity of more than 16,000 some modifications had to be made. Output 9 × 308 MW

MW. Eight hydropower stations gener- The first system has already been de- Voltage 13.8 kV

ate an average of 83 TWh a year, allow- livered, the remaining 11 excitation sys- Frequency 60 Hz

ing pollution-free production of a sig- tems will be delivered over a period of Head 116.7 m

nificant portion of Québec’s electricity. five years up to 2020. Speed 128.6 rpm

After more than 30 years’ of operation Previously, another contract for the Av. annual production 13,670 GWh

the need to exchange parts of the sec- modernization of the 2,772 MW La

ondary systems has arisen. Gran de-4 hydropower station was

awarded to ANDRITZ HYDRO in No

In December 2015, ANDRITZ HYDRO vember 2015. The scope of supply com-

received a contract for design, manu- prises design, supply, and delivery of

facturing, supply and delivery of 12 sta- nine digital HIPASE-T turbine governors,

tic excitation systems with transformers including the process of homologa-

for HPP La Grande-3. Each unit has an tion for the hardware and software for

output of 200 MW. Of the delivered ex- the new product. This order is the first

citation systems each has the capacity turbine governor project for the new27 Site Report

HYDRONEWS No. 30

Generator

Rehabilitation

Program

by Peter Jaunecker

peter.jaunecker@andritz.com

Tasmania – Just over one year ago

in October 2015, Hydro Tasmania and

ANDRITZ HYDRO signed a frame Contract signing

agreement for a generator rehabilitation

program – a contract lasting for sev- how as well as positive experiences from TECHNICAL DATA

en years. ANDRITZ HYDRO agreed to previous co-operations, such as the sta-

supply seven stators, five stator wind- tor rehabilitation at the Cethana and Output 12 × 11–66 MVA

Speed 136.4–600 rpm

ings and four pole sets for 12 genera- Fisher hydropower plants (see Hydro

Voltage 6.6–16 kV

tors in eight different hydropower plants News 25). The Alternator Upgrade Pro

with rated outputs of 11–66 MVA. gram forms part of Hydro Tasmania’s

overall upgrade program, and ANDRITZ

In 2015, Hydro Tasmania produced HYDRO is pleased to support Hydro

more than 8,000 GWh of electrical en- Tasmania with a rehabilitation program

ergy – mainly through its 30 hydropower for Kaplan turbines, governors and con-

stations. Founded more than 100 years trol systems.

ago, today Hydro Tasmania is Australia’s

largest renewable energy producer and The contract started with the Separ

the main energy supplier in Tasmania. able Portion No.1 (SP1), an order for

the design of 12 generator units. After

A key criteria for Hydro Tasmania to finalization of the design works for the

choose ANDRITZ HYDRO as supplier generator at HPP Repulse (see Hydro

was the company’s technological know- News 27), Hydro Tasmania issued SP2,

an order for the supply of a new stator Machine hall HPP Catagunya

winding for the same generator in March

2016. ANDRITZ HYDRO is manufactur-

ing the stators and poles of the genera-

tor units for HPPs Catagunya 1 and 2,

which will be delivered out of India in

2018. Furthermore, a design and lifetime

study of the remaining generator com-

ponents will be carried out. It will form

the basis for a decision on whether any

other generator components need refur-

bishment and if the expected lifetime of

50 years can be achieved without any

further major refurbishment works.

Co-ordination between two generator

manufacturing sites, while preserving

highest quality standards and optimiz-

ing on-site works with local partners,

proves the vast experience of ANDRITZ

HYDRO in project execution.You can also read