Connections - SAFETY T H E FOCUS

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

E D I TO R I A L CONTENTS

Contents

AMERICAS 10 A Strategic Partner Says Thanks!

11 Mission Possible

12 Flawless execution

15 Keeping a Safety Diary

How Are APAC 16 A Bright Idea: Use of Solar Energy in Singapore

12

You?

18 The Reverse HSSE Trap

21 A Mission for Safety

TANK TERMINAL

EMEA 22 First Auction for Storage Capacity

of Refined Products

24 Ensuring Safety from Above

In general, this question is often more of an “ice- it comes as no real surprise that safety is our

28 Pulling Together for a Laboratory Project

breaker,” a polite way of starting a conversation. spotlight topic in this issue. For one, there are

The type of answer depends, among other things, articles about the various initiatives and measures GLOBAL 09 Zooming in | Taking Ownership

on the level of relationship that exists between the we implement to ensure the safety and well-being 29 Implementation of Standardized Risk

people. For example: Would you answer a stranger of our employees, customers, and contractors. But Management Process

32

honestly and tell them what is on your mind? Or is we also report on steps that affect the health of

30 Life Saving Rules as a Common Language

there even time for anything other than a short our company. So that we can continue to answer

“Fine, thanks!”? any potential questions about how we are doing 32 Focus on Life Saving Rules

with an honest “Fine, thanks”! 34 Integrated AO&S Audits

GLOBAL SAFETY DAY

However, since last year and the outbreak of the

36 SMART indicators help with performance

COVID-19 virus, the question of how people are Happy reading and stay healthy! measurement

has taken on a whole new dimension. The pandemic

has had a dramatic impact on the global 38 Oiltanking’s Global Web Portal

community: on people’s lives and health, on their Matti Lievonen

livelihoods, on their togetherness and on the CEO | Oiltanking GmbH SUSTAINABILITY 26 Start of Sustainability Strategy

economy. Oiltanking and its employees are also

affected. PEOPLE 04 We Can, We Care ... Health, Safety, Security

& Environment

& PLACES

04

Oiltanking always puts the safety and wellbeing of

its employees, families and business partners first.

07 We Can, We Care ... About Health and Safety

However, the pandemic has made workplace 40 Cultural Experiences | On the Safe Side

protection even more urgent and far-reaching. So 54 In a nutshell

HSSE

LEISURE & 20 Number | 0

ENTERTAINMENT 39 Lexicon | Safety Incident Pyramids

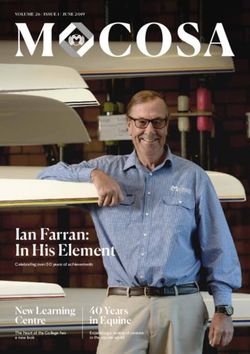

42 Goo-Goos Cover: Biometric

authentication methods

45 I do's

such as fingerprints, facial

Publishing Credits connections Vol. 33/1/2021 Published by Oiltanking GmbH, Corporate Center, Koreastrasse 7, 48 Interesting Artwork, No Doubt recognition, and iris scans

20457 Hamburg, Germany, www.oiltanking.com, Telephone +49-40-37099-7485, Fax +49-40-37099-7499

Email connections@oiltanking.com Coordinator Gabi Wuestenberg, Manager Communications Editor Renate Eijkholt

50 100 Percent Certainty?! are forward-looking safety

technologies.

Design raz design, Hamburg Print Beisner Druck GmbH & Co. KG, Buchholz Published Two times a year 55 Reader's Corner

Copy Deadline vol. 33/2 week 35, 2021 56 Last but not least | Fingerprints

ID-No. 21101448

2 CONNECTIONS CONNECTIONS 3PEOPLE & PLACES PEOPLE & PLACES

“

WE CAN, WE CARE … While Oiltanking has

Health, Safety, Security already established a good

HSSE environment, there is

& Environment (HSSE) some room for improvement,

especially given our aim to

reach target zero.

Oiltanking owns and operates 64 terminals with a total storage

capacity of 20 million cbm in 24 countries on five continents – in

Europe, North America, Latin America, the Middle East, Africa, India

Dirk Stöppler

and the Asia-Pacific region. The handling of large volumes of valuable Vice President HSSE

and potentially hazardous liquids calls for responsible and safe

operations at all of its facilities around the world. In early 2020 the

Health, Safety, Security and Environmental (HSSE) function was

integrated into Assets, Operations & Safety (AO&S). The change

allowed for even better coordination of the Oiltanking HSSE policy

and guarantees smooth implementation of newly defined and udated In our company’s HSSE since. He has more than 20 years the responsibilities to the

processes and standards. Policy, we underline our of HSSE leadership experience Operating Units and HSSE

commitment to preventing all and fully understands the function offers the advantage of

“

accidents, injuries and operational side of the business very clear and shortened

occupational illness, and to from his own experience coming communication channels and

protecting the environment. We from the chemical industry. His greater flexibility, and

I believe that a commitment to therefore continually optimize department divides HSSE guarantees more ownership.

all our activities with a view to responsibilities into People

safety must run deeper than simply technical, organizational and Safety and Process Safety. Dirk

‘being a top priority’. Priorities can behavior-based safety, and is supported by Serena Lee, What is on the

promote a proactive safety Process Safety Manager, and to-do-list?

change depending on business culture. Oliver Albarran, Safety Engineer.

conditions, while safety is a value At the regional level Cecilia “While Oiltanking has already

Historically, the corporate HSSE Descalzo (Americas) and Keith established a good HSSE

that shapes all decision-making at department served as central Low (APAC) act as HSSE Vice environment, there is some

interface for all internal and Presidents. With this set-up, the room for improvement,

every level, long-term.

external HSSE topics. Since HSSE department will be more especially given our aim to

2020, HSSE has been integrated independent from Marquard & reach target zero, “ says Dirk

into the Assets, Operations & Bahls and focus more on HSSE Stöppler. The introduction, at

Yvan Tavernier Safety (AO&S) global function governance and improvement. the beginning of 2020, of the 8

Senior Vice President AO&S at Oiltanking, led by Yvan A steering committee is Safety Principles developed by

Tavernier, Senior Vice President. currently working on the future the Oiltanking Management

Dirk Stöppler, Vice President HSSE organization and the Team as well as the 6 Life-

HSSE, joined Oiltanking in question of how all services Saving Rules (also see page 30)

September 2020 and has required at Oiltanking facilities rolled out in mid-2020, and the

continually developed his people worldwide can be provided in core theme “Life Saving Rules”

& process safety skills ever the most efficient way. Directing for Global Safety Day in October

4 CONNECTIONS CONNECTIONS 5PEOPLE & PLACES PEOPLE & PLACES

© Helmut Hofer

E

WE CAN, W CARE …

Health and safety are

important values at our

company. We continually

optimize all our activities

with a view to technical,

organizational and behavioral

PLEDGE Safeguarding health, safety, security and environmental protection is a priority for us safety, and promoting a proactive

safety culture. 2020 took caring for

the wellbeing and safety of our

2020 have already contributed to a safer (MOC), and Contractor Management to increase colleagues, customers, and contractors to

performance in 2020, with fewer accidents and an the reliability of our safety barriers in our daily another dimension with the outbreak of COVID-19.

STRICT PROCEDURES

overall improvement in matters of HSSE. business. Following the successful roll-out and In response to COVID-19,

implementation of our 6 Life-Saving Rules at all Oiltanking introduced strict

How is Oiltanking handling the situation and what

Our most urgent concern is to reduce the frequency Oiltanking terminals, best practice sharing sessions hygiene protocols and a close measures have been taken to ensure a healthy and safe

and the impact on people of accidents and improve were recently conducted, and further concepts and monitoring of employees’ health

at all its worldwide locations working environment at the terminals?

our HSSE performance with more of a focus on refresher workshops on this topic are currently

leadership and behavior-based safety (BBS), not being developed.

just for our own employees but also for our

contractors and other third parties. To this end, To underpin the Oiltanking strategy, we are also At the beginning of 2020, no one could have imagined positions where this was possible. A wide range of additional

part of the focus KPIs will be re-defined in 2021 expanding the Functional Competencies (FunC) that an invisible virus would change the world. Since then, security measures have been applied to minimize the risk

(also see page 36), and the integration of a detailed program. This involves a total of 12 electronic the global COVID-19 pandemic has affected every aspect of of spreading the virus. These steps include restricting

HSSE dashboard will provide crucial support. All courses tailored to our needs, which cover HSSE- our daily life. Each one of us has faced challenges, both access to our sites, temperature controls, enhanced

KPIs can be retrieved worldwide and are updated relevant topics in a depth previously unknown in personally and professionally. Many of us have family hygiene measures for tanker and truck handling, preventive

daily in the HSSE & Sustainability Dashboard. e-learning, and have been assigned to defined members who contracted COVID-19. More than 300 of our quarantine, and regular site disinfection. The teams were

target groups in modular packages. New hires employees and contractors had tested positive by January

The development and roll-out of a Risk Management within these target groups will be assigned to these 2021, and sadly we lost one Oiltanking colleague to the

strategy that includes competence-related courses as well. We are aware that electronic virus.

elements (e.g. Process Safety Trainings for key and training is only one of many steps, yet this has

general users, practical exercises) as well as allowed us to move forward in the current global The outbreak of COVID-19 confronted all of us with

terminal-specific improvement actions in the field situation to build our awareness regarding the unprecedented health and safety questions. In order to

of process safety is currently underway. Terminal “Target Zero” vision. By the way, we mentioned guarantee a swift and coordinated implementation of

Improvement Plans have been updated accordingly target groups – every Oiltanker is welcome to join procedures, Oiltanking immediately activated the

based on the outcome of a group-wide status FunC! Contact your local HR Manager for assistance emergency teams on local, regional, as well as global

analysis on the maturity level of risk management if needed. level. At very short notice, the teams reviewed the

and process safety across all regions. necessary measures to reduce the risk of contamination at

all our locations, and rolled-out a specific COVID-19

Other initiatives will focus on improving critical protocol. For example, work schedules have been re-

processes, such as Permit to Work (PtW), Lock-out organized and colleagues were encouraged to work from

& Tag-out & Try-out (LTT), Management of Change home, which they managed to do in nearly 100 percent of

6 CONNECTIONS CONNECTIONS 7PEOPLE & PLACES ZOOMING IN

Taking Ownership

DEFINITELY NOT BUSINESS AS

USUAL Until the situation has

stabilized, attending conferences

or events is on hold, as are business

trips, or receiving visitors at the

global offices or tank terminals Last year, Oiltanking introduced 8 Safety

Principles that reflect the company’s

beliefs and how it enhances its safety

culture and performance. Taking full

ownership of safety performance

hard at work all last year and will reinforces our commitment to safety as a

continue in 2021. value that shapes all decision-making at

While public information channels

every level of our business. We asked

overwhelmingly reported about the Yvan Tavernier, Senior Vice President

corona situation, Oiltanking and its

Assets, Operations & Safety, for his

holding company Marquard & Bahls unwell or tested positive for very effectively minimize the risk of

kept their employees informed on a COVID-19. In some cases, we also contamination. thoughts on this.

regular basis about the status of the provided local medical assistance.

pandemic crisis and the measures To ensure the safety of our teams, We all quickly adapted to new ways

of the need to embrace the notion

taken by the company, via internal we took a cautious and conservative of working and reinvented our connections: “Taking What kind of commitment

that all injuries are preventable, and

communication channels. Matti approach to approving anyone who collaboration. Even though travel Ownership” – what does that schedule, cost, or operations

are we talking about?

Lievonen, CEO Oiltanking, addressed had been quarantined for return to restrictions and lockdowns limited this mean for Oiltanking? We need to continue to create an

should not take precedence over an

employees in video messages to work – even if that meant an our options for meeting face to face, Yvan Tavernier: Taking ownership environment that encourages all our

injury-free workplace. Nothing is

provide updates and encouragement. extended stay at home. we were able to keep our terminals begins with doing a self-assessment employees and contractors to work

more important than going back home

operational. Despite a few COVID-19 of how strongly our own behavior together on safety – because they

safe and healthy.

In cooperation with the HR The sharing of experience among related delays in our construction reflects a commitment to the safety of want to, not because they have to.

community, Oiltanking monitored Oiltanking teams was and still is projects, our customer services have our people and our assets, which we The idea is be proactive in assessing

the condition of anyone who was helpful not only in determining not been impacted. This was only should view as the most important

Does this mean you the risk in all our work activities,

optimal safety measures but possible with the tremendous effort element of our management think safety performance looking out for each other and

also in increasing the level of and engagement everyone put into empowering colleagues to intervene

responsibilities. is the key to success?

mutual support. Oiltanking’s supporting the business. on behalf of others when faced with

I am convinced that excellence in

leaders took every possible potential risk situations. Last but not

safety performance leads to excellence

measure to guarantee the We hope that in the course of 2021, What does “Taking least, we have to seek opportunities

in operations and business

safety and the health of our global vaccination programs will Ownership” mean to you performance. Companies that have a

to continuously improve our approach

employees. Together, we quickly start to bring this pandemic to the prevention of injuries. This is

in your function as Senior strong safety culture and high

managed to mitigate the impact crisis under control and relieve the an ongoing journey, and an imperative

Vice President Assets, standards not only operate more

on our people. Also the great pressure it places on people and for our business success. I am

safely, but also more professionally

collaboration and solidarity business. During this time it is more Operations & Safety? and more profitably. The fundamentals

confident that our organization can

between the different important than ever to ensure we Personally, towards the beginning of succeed in this journey. We have set a

for achieving the best possible safety

stakeholders of our organization take care of ourselves and those my career, I faced a severe incident solid foundation, but there is more

performance are the same as those

(Oiltanking/Marquard & Bahls) around us. during a commissioning of a work to be done, and the recent

required for managing a successful

and departments helped us to production plant. One of my colleagues incidents remind us to stay vigilant.

business. The road to safety excellence

was severely injured, and an

must be built on great safety leadership

investigation of the incident found

and an integrated, comprehensive

that we had underestimated the risk

EVERY REASON TO BE PROUD management system - which requires

of an activity, and one of the

A big thank-you to all for the a personal commitment at all levels in Here you can find

contributing factors was that we were

solidarity, dedication, resilience the organization to work according to our HSSE policy

and care you demonstrated under time pressure to restart

the rules. www.oiltanking.com/013223

during these difficult times operations. This incident reminds me

8 CONNECTIONS CONNECTIONS 9AMERICAS AMERICAS

CERTIFICATE OF RECOGNITION M I S S I O N

Possib e

The STAMP award will be proudly

displayed at Oiltanking North

America’s terminals as a reminder

of a job well done!

Working in partnership, Oiltanking North

America identified and executed a project

Oiltanking Ebytem ended the year 2020 with a flawless scorecard, achieving

involving both the Texas City and Galveston

County terminals. Once executed, the the Target Zero goal set by our Management Team. How did they do it?

project provided storage and inbound/

outbound capability for this new

specification of IPA product safely, under Oiltanking Ebytem has adopted a model of continuous training process also makes it possible to take advantage

budget, and faster than Dow had hoped – improvement by comprehensively adhering to an ISO of audit findings from one sector and apply them in other

within less than five weeks from concept to certification process: Every relevant aspect of critical areas sectors that may be faced with similar issues. Every auditor

start-up, all while both parties followed such as Safety, Occupational Heath, Security, Environment, is also trained in “soft” skills, which are important for

stringent COVID-19 distancing protocols! Quality, Operations, Maintenance and Administration building empathy between auditors and auditees, and

As a result, Dow was able to very swiftly matters is covered in an Integrated Management System facilitate personal interactions.

make a meaningful contribution to the fight (IMS).

against the COVID-19 pandemic. Another key to the company’s success in achieving Target

The IMS is certified for Quality (ISO 9001), Environment Zero is the continuous improvement system, which detects

Every quarter, Dow’s Corporate Quality (ISO 14001) and Occupational Health and Safety (ISO minor deviations and identifies their underlying causes.

organization awards a STAMP (*Sustainable 45001), and calls for the participation of every employee, This provides a safety environment where corrective

*Traceable *Actionable *Manageable supervisor, manager and contractor. The system is assessed actions are promptly implemented, which helps prevent

A Strategic Partner *Preventable) Certificate of Recognition for one

event. Oiltanking North America became the

recipient of the Q3/2020 award for its actions

quarterly using a specific matrix and with the involvement

of the company’s Regional Managers and Country VP. The

matrix covers legal aspects and requirements to ensure

the occurrence or recurrence of undesirable events. The

year 2020 strongly tested the system. Most paper-based

exchanges have now been converted to digital, taking

Says Thanks! taken to enable this significant new business that

impacted the world’s effort to fight the COVID-19

License to Operate; HSSE corporate and regional targets;

internal audit training, planning and completion. It is

advantage, among other things, of the certified digital

signature adopted earlier. This practice was subsequently

pandemic. Bea Grimme, Dow’s Product Quality meticulously followed up and updated to monitor critical extended to the company’s main contractors, eliminating

Director, sent the award with the following aspects of operation and management. most of its paper-based exchanges.

Oiltanking North America was recognized

message:

by its strategic customer Dow following a One key element to reach Target Zero is the training of The system is further consolidated and strengthened by

project to store and throughput a new “communities

We’re very proud to have supported our

and medical professions in a

employees as internal auditors, allowing them to better conveying the policies and objectives to the company’s

understand the system and feed into it efficiently. The main contractors: most of them have since been evaluated

feedstock for incremental production of time when Isopropanol was in short supply and qualified and the audit findings were

and we couldn’t have done this without a

hand sanitizer. followed up and concluded. The goal for

true team effort. contractors in 2021 is to lead-manage the

development of an HSSE system for those

As COVID-19 cases started escalating in the U.S. in late

Thank you to our partners at Oiltanking for that do not yet have a formal one in place.

March 2020, Dow approached Oiltanking North America

the support and collaboration to pull this

with an urgent request. Due to overwhelming demand, Dow

off. This project was an amazing

had been challenged to produce a new version of Anhydrous

accomplishment.

”

Isopropanol (IPA 99.5 percent) at their U.S. plants on a

very fast track to supply critical incremental feedstock for The award was for the third quarter of 2020, but INTEGRATED MANAGEMENT SYSTEM

The team is strongly committed to

hand sanitizer production. While Dow’s Galveston County was presented to the Oiltanking Texas City/

carrying out the second certification

Plant had the capability to produce the IPA through a Oiltanking Galveston leadership just prior to the process, knowing that they are on

reconfiguration of one of their production units, it lacked winter holidays, providing a welcome year-end the right path and that operational

picture: archive

the ability to store and throughput the product. pat on the back for a job well done. excellence is the ultimate goal

10 CONNECTIONS CONNECTIONS 11AMERICAS AMERICAS

OILTANKING ON THE MAP The Tuxpán terminal with a total storage capacity of KICK-OFF On March 3, 2020 the first ship

approximately 127,000 cbm (222,000 cbm by the end of 2021) gives Oiltanking a “Atrotos” was received at the Tuxpán terminal

Clear vision

significant footprint in Mexico for reloading 16,000 cbm of jet fuel

200 expectations to ensure

a flawless operation were

summarized in its 18 elements:

Element 1: Leadership, commitment,

responsibility and staff involvement

Element 2: Identification and compliance with

legislation and industry standards

Element 3: Selection of personnel, training,

evaluation of competences and

health assurance

Element 4: Communication with stakeholders

Element 5: Risk Analysis and identification

Element 6: Documents, records and knowledge

management

Flawless execution

Element 7: Operating manuals and procedures

expected operational excellence and integrity in our

Element 8: Process and operational status

operations,” explains Guagliardo.

monitoring and handover/interfaces

Running Engineering, Procurement and Construction Management (EPCM) services The terminal’s SIGO System was developed based on Element 9: Standards, practices and project

the recommendations of the Energy Institute and all of management

for the Tuxpán terminal in Mexico, as well as starting up the terminal’s operation, Oiltanking's operating safety procedures. “200 of our

Element 10: Change management

posed some particular challenges for Oiltanking. Thanks to their teamwork, expectations for flawless operations were summarized

in 18 elements - thanks to the teamwork and knowledge Element 11: Commissioning and startup of

dedication and safety consciousness, our colleagues managed a flawless

exchange between colleagues like Captain Javier facilities

commissioning in March 2020. A review. Feijoo, Terminal Manager Puerto Rosales, Argentina,

Element 12: Emergency Preparedness

an operations group from Puerto Bahia terminal,

“Loading more than 35,000 barrels of fuels a day is our colleagues were faced with the challenge to bring Colombia, formed by supervisor Jaime Espinosa, and Element 13: Inspection and maintenance

quite common for Oiltanking, but doing so safely in a forward the commencement of operations due to the our highly trained operators: Deiner Blanco, Jorge

Element 14: Management of critical devices

swamp requires a combination of a gigantic engineering decision of the owner of the terminal. Oiltanking's clear Arrieta, Juan Herrera and Sergio Herrera,” highlights

effort, talent, dedication, and industry best practices," says mission was to make the new timeframe possible without Guagliardo. Element 15: Work Control, work permits and

Sergio Guagliardo, Head of Operations at the Oiltanking any failures and accidents. In order to fulfill Oiltanking's high-risk works management

Tuxpán terminal in Mexico. There were many challenges commitment to its HSSE values, several measures were “Developing our very demanding and extensive

Element 16: Contractors and suppliers selection

the colleagues in Mexico experienced in connection with taken and appropriate systems implemented. training program with several disciplines was quite

and management

the EPCM services and the long-term Operations & challenging, but it ensured that our team was capable,

Maintenance (O&M) contract Oiltanking is responsible for. “First of all we applied the best practices designed for highly committed, and rigorously trained. Establishing Element 17: Incidents reporting and

safety assurance, for our people’s health, and to protect a knowledge-sharing metric ensured that the staff investigation

The first challenge was the construction itself. The terminal the environment. The development and implementation of knew and understood what the company considered

Element 18: Operations Integrity, evaluations

is located in the state of Veracruz and had to be built over Oiltanking Mexico’s Operating Integrity Management paramount.”

and improvements

a swamp, using pylons more than 40 meters long under its System (SIGO*) was a fundamental tool for our success in

fuel storage tanks and other heavy structures. In addition, risk and HSSE management, as well as for achieving the * SIGO - Sistema Integrado de Gestión Operaciones

12 CONNECTIONS CONNECTIONS 13AMERICAS AMERICAS

TUXPÁN SECTOR

LOADING RACK

The terminal lies

along the Tuxpán KEEPING A

SAFETY

River approximately

12 km from the

river’s mouth on the

Gulf of Mexico

DIARY

In an effort to increase and continuously improve

the performance and safety of its terminal farm,

Oiltanking Colombia has successfully incorporated

various initiatives in the past. Keeping a daily

safety log is the most recent of these measures.

The existing

hazard and Sociedad Portuaria de Puerto consumption, total productive resolved an interesting safety situation

operability study Bahia (SPPB) is located near maintenance (TPM), and lean during their daily work, for later

(HAZOP) and the Cartagena in the Colombian Caribbean. manufacturing concepts. analysis and deployment of lessons

Risk Assessment The terminal, which has eight tanks learned.

gave colleagues for handling crude oil, heavy fuel oil As part of our annual safety planning,

all necessary information to establish several “The global pandemic made our endeavor even more and naphthas with a total storage in early 2020 we resolved to record However, the most beneficial effect

preventive and mitigating measures in high-risk challenging. In March 2020, México experienced a capacity of 424,160 cbm, was images of our daily operations every was an increase in colleagues’

scenarios, reducing such risks to medium or low. skyrocketing of COVID-19 cases. This unique commissioned in 2015 and has been month for every operating shift (the commitment and awareness as they

These mitigating measures allowed the Oiltanking situation not only forced us to rethink our procedures operated and maintained by Oiltanking terminal runs 24/7). The operators prepared and conducted the program

Mexico Management Team to greenlight the but also to be more inventive and demanding in since the beginning. In recent years, not only collected controversial themselves. The management has

commencement of operations. Planning the tasks in everything related to hygiene and personal care. A we have stabilized and normalized our scenes, but also prepared footage to decided to establish this program as a

a very detailed manner proved a valuable tool for fundamental element in achieving a smooth operation against the backdrop of be presented at a quarterly safety regular task within our annual

being able to receive the first ship on March 3, 2020, commencement of operations was the collective many challenges arising from the workshop. Shift leaders and management plan, based on the

and to dispatch the first batch of trucks on March 14, experience of long hours of supervision during this terminal's frequent portfolio changes. supervisors conducted these conviction that safety must involve all

2020, in a facility that was still under construction. start-up”, remembers Guagliardo. “Today we can We have been implementing workshops in small teams to ensure employees as part of our challenge to

safely say that the tools implemented not improvement initiatives related not everybody’s participation. Most of the reach the generative rung on the

only enabled us to achieve a flawless only to safety, but also to productivity photos come from conducting safety “safety culture ladder.”

startup of operations, but also to close and reliability: e.g. digitization of walks, but others were filed directly

the year 2020 without reportable internal processes, energy by operators who encountered and

incidents. This motivates all of us to

additionally commit to continue with

flawless operation. NOTEWORTHY Oiltanking is responsible for the operation and

maintenance of the liquids terminal at Sociedad Portuaria Puerto

Bahía, Colombia’s most state-of-the-art multipurpose terminal

READINESS The success of the

past is a great motivator for the

picture: archive

colleagues to continue with

flawless operation

14 CONNECTIONS CONNECTIONS 15APAC APAC

kilograms of carbon dioxide emissions a year, total amount of electricity produced from the

which is equivalent to planting over 3,600 solar photovoltaic system is 353.2 megawatt-

trees. peak with 186.8 megawatt-peak from the

Use of

private sector. By contributing 600 kilowatt-

A BRIGHT IDEA: The solar panels are located at the office peak, Oiltanking accounts for 0.3 percent of

buildings, contractor facilities, and two the amount produced by the private sector.

Solar Energy

substations within the three Oiltanking

terminals on Jurong Island – Oiltanking Besides integrating solar panels, Oiltanking is

Singapore, Oiltanking Singapore Chemical constantly monitoring new developments in

Storage, and Oiltanking Helios Singapore. technology for renewable energy usage. With

in Singapore

the comprehensive, effective Oiltanking

While solar panels are becoming more widely Sustainaibility Strategy 2025, Oiltanking will

adopted particularly in residential areas and take further steps to reduce water

by the public sector, Oiltanking is among the consumption, energy usage, waste generation

first entities to use this renewable energy on and carbon footprint as part of the "Green

its roof on Jurong Island, the hub of the city Spots" initiative (see also page 54).

state’s chemical and energy industry. The

CONTRIBUTION TO

SUSTAINABILITY More than

SUNNY SIDE UP 1,500 solar panels have been

Located almost on the placed at the Oiltanking

equator, the Singapore facility. The amount of

terminal is practically Oiltanking in Singapore took another step towards renewable electricity they

predestined to use produce is expected to reduce

solar energy integrating the principle of sustainability in its operations the amount of fossil-powered

electricity used by 2.5 percent

by installing more than 1,500 solar panels at its premises.

As one of the first among the companies located on Jurong

Island to use this energy source, Oiltanking sets a clear

example for sustainability.

In early 2019, Oiltanking Asia Pacific energy partner’s central control room to

formed a team comprised of employees ensure that a robust monitoring system

from Maintenance, Commercial, is in place.

Procurement, Engineering, and

Operations to study the feasibility of After nine months of discussion and

installing solar panels at our storage evaluation, Oiltanking entered into a

assets in Singapore. While environmental renewable energy partnership with

sustainability is the key driver, the team Sembcorp Solar and identified all

also evaluated other important factors possible installation sites for our assets

such as power supply reliability, safety on Jurong Island. Since then, over 1,500

measures, rooftop space availability, solar panels have been installed. They

efficiency, loss, technological upgrades, have been operational since January picture: archive

financial impact, and reputation of the 2021 and will have a combined capacity

EFFICIENCY CHECK Our colleagues were allowed to follow PIONEER Oiltanking is among the first

renewable energy partner. The team of approximately 600 kilowatt-peak. the live data transfer of the operational performance of companies on Jurong Island to install

also visited our potential renewable This will prevent more than 300,000 Sembcorp's solar panels in its control room solar panels on its premises

16 CONNECTIONS CONNECTIONS 17APAC APAC

The

everse sober elephant would not dare run into these nails).

However, even if intruders managed to get past the

gate, they would only see a wall! The actual gate to the

taken by the invaders, it could never be pointed at the

main fort.

HSSE Trap

fort was at the end of a narrow alley inside. This would Confined spaces and unsafe

confuse hundreds of charging soldiers to change heights (again!)

direction in a narrow space while giving the armed A maze of caves carved into solid basalt rock is the

snipers inside the fort precious seconds to launch a ultimate defense. The unventilated caves are so dark

lethal attack of boiling oil and hurled boulders. that it was impossible to notice a sword until it was too

late. The only source of sunlight that would attract

Unsafe heights attackers came from increasingly steep chutes carved

Modern-day Health, Safety, The second deterrent was a deep moat of rock-cut in stone, dropping vertically into the moat.

Security & Environment (HSSE) canals, which effectively turn the fort into an island.

Their opaque green waters were infested with But how was the fort eventually conquered? Well,

processes and activities make crocodiles, and the only way to cross over the moat HSSE had nothing to do with it. It was by treachery!

places safer. India’s medieval and was a drawbridge, which could be collapsed, sending The rations of the fort were replaced with bags of salt.

those over the bridge to a watery grave. This forced the defending king to surrender the fort,

ancient forts reversed this marking its only involuntary change of stewardship in

concept to keep enemies out. Locked equipment history!

A cannon beyond the moat would fire at the attackers

Let’s take a tour of Daulatabad

across the waters. The cannon’s pivoting base was

Fort in India’s Deccan plateau, CAMEL CUSHIONS locked in such a way that even if the cannon were BRIDGE OVER TROUBLED WATER

Camels often had to

which challenged enemies by stand parallel to an

This fixed bridge replaced a canvas

drawbridge that would collapse to drop

making sure no safety norms armed door equipped enemies into the green waters below

with spikes and nails

were met in its construction. while the elephant

was forced to ram

the camel in order

to break the door.

Modern-day Daulatabad is a favorite tourist

Because camels were

destination – seven centuries ago, this sleepy not as expensive as

town was India’s capital! Daulatabad Fort is one elephants, their loss

of India’s most impenetrable fortresses and has was given less weight

never been taken in a fair battle thanks to its

architecture. Its perimeter wall – five kilometers

long and three meters thick – was only the first

of its obvious defenses. The hidden defenses

and traps inside challenge known HSSE rules,

making the fort virtually impregnable.

© all pictures, Yogesh Damle

Confined spaces

The idea: to trap the enemy and catch them

unawares. The front end of the trap in this

scheme is an imposing 12 meter tall wooden

gate, studded with iron nails. These gates had to

be broken open by intoxicated elephants (a

THE SAFETY ANGLE With mobility A LEAP IN THE DARK Thousands of bats

limited to 180 degrees, the cannon could and dozens of armed snipers awaited

never be aimed at the mother fortress the enemy in this dark stone cave

18 CONNECTIONS CONNECTIONS 19734094545239523082

403479234802340823

L E I S U R E & E N T E R TA I N M E N T APAC

840238042480524805

A M I S S I O N F O R

SAFETY

248602486024680246 Safety is a journey to the future to ensure Zero Harm at all our locations, building on

NUMBER

802468024473462345

0

the lessons of the past. At Indian Oiltanking, this thought is combined with a sense

of leadership across ranks, as colleagues are assigned ownership and accountability

of safety within designated areas of their terminals. While there is no magic spell for

784025072358249502

safety, the new approach is producing noteworthy results.

0

2020 was an especially humbling year for Indian The contribution of the steering team and their support is

Oiltanking. At Paradip, we mourned the loss of a colleague leading to a very effective safety improvement program.

935802357023758245

to a fall from height, and it was our utmost priority to

determine how this could have been avoided. In the wake The activity very quickly began to show results. The Paradip

of this collective grief we were driven to ensure such a loss terminal has recorded no major incidents, and proactive

doesn’t occur on our watch ever again. indicators like Work Permit Audits, reporting of unsafe acts

823507235087230750

and conditions, safety walks, safety trainings etc. have

The first step to delivering on this claim was a root cause improved significantly with contributions from all team

invent new tools and analysis (RCA), conducted jointly with investigating teams members including third-party contractors.

strategies for safety. On our from Oiltanking Singapore and Hamburg. Our safety

582375235976956892

“Target zero” is an journey towards this goal, we mission, named ‘Project Raksha’ (Raksha – Protection in The exercise is showing immense promise in accelerating

incident philosophy that aims have defined 8 safety Occupational Health & Safety Hindi) made a bold start to improve safety management improvements in HSSE culture, so that the blueprint of

for an incident- and injury- principles: have the highest priority in all systems and behaviors by establishing it as an on-ground Project Raksha is now to be adopted by the Navghar and

free work environment. our activities. We identify and stakeholder-driven project within the terminal teams. Goa terminals, with the remaining locations planning to be

Though this may sound like a • Health and safety of analyze potential risks and on board by March.

734094545239523082

rightful and desirable goal, people and the take measures to avoid, To improve line ownership in safety and engage all

the concept is polarizing. environment is valued prevent, control and limit stakeholders, the sprawling terminal was divided into 17 We’re committed to having a safe day, every day, and that

Opponents might argue that above all else them. We are in the process zones, and a safety champion identified for each zone. is how we will have a safe year!

is merely a Public Relations • All incidents can be of establishing a proactive Each zone thus had a dedicated team of

403479234802340823

gimmick and that it might prevented and generative safety culture, management, staff and contract workers to

specify the target but misses • Management at all levels and work to continuously improve safety within its perimeter. Since

the point. Being afraid of not is accountable for safety improve all our activities with August, the teams have taken 1,495 safety BEFORE AND AFTER An unsafe

reaching the goal and fearing and leads by example regard to technical, walks to identify unsafe conditions and actions work situation was identified and

safety measures were taken

• We plan and train for

840238042480524805

negative consequences organizational and behavioral to rectify them. 2,363 work permits were

employees might tend to not safety safety. By living the Oiltanking reviewed to ensure every task had been

report issues and incidents. • Everyone looks out for values (respect, planned out even before the tools were picked.

However, we at Oiltanking each other, no matter who accountability, integrity and 1,426 training sessions adding up to 2,741

wholeheartedly advocate and they work for responsibility), we walk our man-hours across 14 topics were conducted;

248602486024680246

embrace “Target zero – No • Everyone has the talk, and make sure our 2,811 unsafe conditions and actions were

injuries, no incidents.” Our authority to STOP any behavior backs up our claim: rectified; 1,080 improvements in housekeeping were

policy of speaking up unsafe work carried out. Every week, the 17 teams across the terminals

encourages our employees to • Safe behavior is Everyone who works with would update Indian Oiltanking's (IOT) leadership on the

802468024473462345

report at-risk-behaviour and recognized, acknowledged us has the right to return improvements they had achieved. The most significant of

unsafe acts and conditions. and reinforced home safely, every day! these improvements were condensed into a monthly

Therefore “Target zero” is a • Zero tolerance for safety update, submitted to a steering committee comprised of

motivator to explore and even breaches members from IOT & Oiltanking in Singapore and Hamburg.

20 CONNECTIONS CONNECTIONS 21EMEA EMEA

First Auction seconds to the clock! This allowed

the counterparty to submit a new

for Storage – higher – bid until ultimately one

party stopped submitting. Through

Capacity the bidding process we won a new

customer, something we had not

of Refined

expected," recalls Sjoerd Boer,

Vice President Commercial

OILTANKING COPENHAGEN

Oiltanking EMEA.

Products By auctioning its storage capacity,

Oiltanking achieved an important

milestone in its digitalization and

innovation roadmap. “We will

continue to explore innovative

ways to even better serve our

valued customers around the

world,” comments Boer.

EXTENDED SERVICE The partnership between Matrix Global and

Oiltanking also includes auction services for the Oiltanking MOGS

facility at Saldanha Bay, South Africa

How it works

THE MATRIX AUCTION

PLATFORM A tool that was

developed to optimize

For the first time, Oiltanking Copenhagen used a the value of the facility’s • The auction provides a transparent, seconds, and such extensions will continue

competitive platform for individual until no further bids are made during the

competitive bidding process to sell volume of its storage assets through

the creation of proprietary companies who bid on available tank storage last 30 seconds of the Auction.

storage capacity for refined products. The electronic short-term physical bilateral capacity in real-time and within a preset

auction was successfully executed in partnership with

agreements and financial

derivatives products

time frame of 10 minutes. The item being • An auction participant may make a valid bid

auctioned is exclusive use of a defined at any time during an auction.

Matrix Global on December 10, 2020. number of storage tanks for a defined time

period. • Each auction participant will be able to see,

For Oiltanking Copenhagen, December 10, 2020 ushered in a new era of at all times, their most recent valid bid and

managing their storage capacity. For the first time ever, the company used a • Customers have to complete the Matrix and the highest bid from all of the auction

competitive bidding process to sell a term contract for individual refined products Oiltanking documentation and are notified in participants.

capacity. In partnership with Matrix Global and using their electronic platform, advance of any upcoming auctions.

Oiltanking Copenhagen held an online auction for jet fuel and ultra-low sulfur • The auction participant offering the highest

diesel storage. After ten minutes, the auction was successfully concluded with • Unless otherwise provided in an Auction price for the offered services at the end of

the sale of a storage capacity volume of 77,150 cbm per month for 2021. “It was Notice, an auction will remain open for ten the Auction will have purchased the right to

fascinating to follow two oil majors bidding against each other in real-time. The minutes, provided that if any bid is made use such services during the offered period

action occurred mostly in the last leg, because every new bid added another 30 during the last 30 seconds of an auction, the in accordance with the terms of the Services

auction will be extended by another 30 Agreement.

22 CONNECTIONS CONNECTIONS 23EMEA EMEA

Ensuring

Safety FROM

After obtaining all the necessary permissions

Specifications & functions

from the authorities, Oiltanking Copenhagen recently

put a new autonomous drone into operation to Skeyetech Specifications

ABOVE supplement the operator’s safety and security

patrolling. “Skeyetech” is an innovative, highly

automated drone-in-box solution that provides round-

• Response time: The drone is ready for

take-off in 30 sec and can fly at speeds

of up to 50 km/h

the-clock service and security and carries out regular • Flight time: 25 min, before automatic

security patrols on the terminal as well as operation- recharging at its base station

specific flights – such as:

• Range: 2 km

• Flight height: 40 meters

• Pipeline inspection during imports

• Cameras: HD 20x optical zoom/640x480

and exports

thermal imaging camera

• Pipeline inspection during pumping

to Copenhagen Airport • Charging time: 1,5 times the flight time

• Temperature control of specific pumps

(Onboard thermal camera) Video Management Features

• Launch surveillance flights

The autonomous drone solution offers 360-degree (preconfigured flights)

surveillance with no blind spots, more accurate • Follow drone’s position on site

insights, and higher reactivity. To perform its security cartography

and operation missions, the drone is equipped with • Guide the drone to a point of interest

two cameras, one HD 1080p 20x optical zoom lens, (Click & Go navigation)

and a thermal imaging camera. It livestreams both the

• Pause a mission to manually control the

optical camera feed and thermal feed directly to the

cameras

terminal's control room via our CCTV software

• Switch between camera modes

(Milestone XProtect VMS).

• Activate playback mode

The Skeyetech drone is very easy to use as it is fully • Check real-time weather conditions and

autonomous: It takes off automatically in case of an telemetry of the drone

alert, or on demand with a single click by the operators. • Trigger missions based on alarms from

The drone is programmed to fly along very specific I/O modules, PSC systems, and the like

flightpaths that define the route, altitude, where to stop

and zoom in, and which cameras to use and

where. The operators can intervene in the

flight at any time to zoom in on specific objects

along the flight path. They can also send it to

a new location by simply clicking on the map of

the Oiltanking Copenhagen site (except for

AERIAL VIEW

A picture (fisheye predefined no-fly zones). Prior to using the

effect) taken by the The Oiltanking terminal in Copenhagen is the first drone on site, the operators underwent

autonomous drone one in the network to have introduced a new, training in the Skeyetech system and clocked

from a height of some flight time with a regular drone.

40 meters additional way to secure and operate its terminal:

remote monitoring by an autonomous drone.

JUST A CLICK AWAY

Operators can intervene

and redirect the drone’s

flight mode at any time

24 CONNECTIONS CONNECTIONS 25S U S TA I N A B I L I T Y S U S TA I N A B I L I T Y

START OF

Sustainability

OFFSETTING UNAVOIDABLE

1

EMISSIONS Last year Oiltanking

started to offset more than 5,000 t

of unavoidable air travel emissions

The most important aspect in 2021 for our local communities, e.g. by Optimize the core

by planting over 13,000 trees in a will be to cascade the strategy to the increasing employee volunteering.

Strategy

community-based reforestation organization, so that every terminal • Build a sound sustainability

initiative in Nicaragua. knows our overall aspiration, So what happens next? Now that the organization on holding,

ambitions, and key initiatives. One broad framework has been created, regional and local level incl.

important key initiative will be to the individual measures need to be target setting and KPI

integrate Environmental, Social and worked out in smaller working tracking

Governance (ESG) aspects in future groups, each dedicated to a • Finalize and implement the

business decisions, for example. In particular strategic ambition. Once Sustainability Strategy

Oiltanking was the first operating unit the area of environmental protection, the Management Team Meeting has • Minimize the environmental

the strategy will provide a clear given its final agreement, the footprint in core business

within Marquard & Bahls to define its roadmap that supports the energy strategy will be communicated to all with dedicated projects to

sustainability strategy in 2020. Eight transition and decarbonization of our regions and terminals so that they reduce energy and water

footprint. A key initiative will be the can start bringing the strategy to life consumption, waste

colleagues with different professional global roll-out of “Green Spots”. And by moving forward with local generation and avoid

backgrounds and from various regions last but not least, Oiltanking aims to initiatives and action plans. product releases

live up to the motto “We Can, We

were instrumental in this. What’s next

Care” and make a positive difference

2

on the agenda?

Get fit for the future

• Transform the company

After Marquard & Bahls revised its long-term towards new

sustainability strategy in 2019, the definition energies

and operationalization of the strategy in the • Increase the focus on

operating units (OU) is now being accelerated. gases and chemicals

Oiltanking was the first OU to start this process • Screening of future

in 2020. In September, the Oiltanking investments regarding

Management Team agreed on an approach for Guillermo Snehashish Kelvin Ling, Jerlyn Tan, ESG criteria

developing an Oiltanking Sustainability Blanco, Chatterjee, APAC APAC

Americas APAC

Strategy. Eight experts with different

3

professional backgrounds and from various

© TreeNation

regions joined forces to advance the Go the extra mile

development of the strategy. A lot has happened

since. vision, mission, aspiration, strategic directions,

key initiatives, enablers and workstreams will be • Invest in sustainable

In five interactive workshops, Team Sustainability finalized in discussion with the Management ‘lighthouse projects’

from Hamburg shared information on the current Team. These will go hand in hand with the • Offsetting of unavoidable

sustainability performance of Oiltanking and its Oiltanking Business Strategy 2025. Further emissions by carbon credits

competitors. The group did a SWOT (strengths, steps will be to work on a concrete action plan Richard Dikkers, Liz Mayhew, Sarah Anna as a last step

weaknesses, opportunities, and threats) with the terminals, to specify how to fulfil our EMEA Global Dannenfeldt,

Marquard & Bahls

Weritz,

Marquard & Bahls

• Show commitment towards

analysis, and discussed targets, measures and overall ambitions, and to define the local communities through

budget planning in an iterative process. In the communications approach. TASK FORCE Eight colleagues from around the world gave input voluntary corporate

first quarter of 2021, the overall sustainability from their field of work to advance the sustainability strategy citizenship

26 CONNECTIONS CONNECTIONS 27EMEA GLOBAL

Pulling Together

JOINT VENTURE

The joint test center

underlines the high level of

successful partnership and

Implementation of Standardized

for a Laboratory Project social responsibility among

the signing parties, who are

from both the public and

Risk Management Process

the private sector

At the beginning of January In 2020, Oiltanking set itself the task of redefining its Assets &

2021, six of the SOHAR Port Operations (A&O) Risk Management process. The result, a standardized

and Freezone’s tenants, framework to manage risks, will be implemented in 2021 along with

among them Oiltanking appropriate trainings for all Oiltanking terminals.

Terminals, entered into an

agreement with the Ministry As part of our ongoing continuous improvement process we will learn more about our operations and keep abreast

and the Oiltanking Strategy 2025 of putting sustainable with new technologies and industry practices. The collected

of Health of Oman to equip

enablers in place, we defined the Oiltanking Assets and data can be used to optimize and further improve not only

a molecular Polymerase Operations (A&O) Risk Management process in 2020. This our A&O risk management process but also our asset integrity

Chain Reaction (PCR) helped to clarify Oiltanking’s intent and expectations as management strategies and minimum operational excellence

well as internal requirements and criteria. and engineering requirements, to remain a safe and

laboratory for the North Al competitive company compared to our industry peers.

Batinah Region. The test center will play a vital role in accelerating diagnostic The process entails the systematic application of procedures Depending on needs, more associated relevant documents

and practices to the activities of communicating, consulting, and guidance to support the overall risk management process

processes, e.g. COVID-19 testing. establishing the context of, and identifying, analyzing, will be progressively developed over the course of 2021 and

evaluating, treating, monitoring and reviewing risk. A 2022. The ultimate objective is to drive improvements in our

The public and private sectors in Sohar have joined The new laboratory will start operations in the first quarter standardized framework to manage our A&O risks for both safety culture and performance with a more preventive

forces in an effort to improve healthcare services in Oman of 2021 with a team of 12 highly qualified medical staff. existing operations and new projects, will allow us to approach, to achieve and maintain Target Zero.

while simultaneously preventing and controlling sources of Over and above being the natural landing point in terms of appropriately and consistently prioritize resources

COVID-19 infections. The idea for this community project geographical location, it will also serve as an alternative to (personnel and capital) to tackle the range of risks we

was first floated in September 2020, and in January 2021 the current Muscat-based Ministry of Health’s Central Public encounter inherently due to the nature of our business. It

KNOWLEDGE IMPROVEMENT Colleagues (picture

the Ministry of Health signed an agreement with the Sohar Health Laboratories in case of emergencies, like the current also fosters the understanding and ownership of risks along taken during the webinar) participate in a virtual

Industrial Port Company (SIPC) and the contributing coronavirus situation. Equipped with the latest the entire project/asset lifecycle, while meeting to learn more about risk management

tenants at SOHAR Port and Freezone, among them polymerization apparatuses, it will contribute decisively to focusing on loss prevention.

Oiltanking Terminals, to equip a regional molecular accelerating the diagnostic processes, which will presumably

Polymerase Chain Reaction (PCR) laboratory in Sohar that significantly reduce the average time for conducting All terminals had actively engaged in a

would cover the needs of the Northern part of the Sultanate. COVID-19 tests. In addition, the devices can provide gap analysis exercise in 2020 to

analysis capabilities for other ailments, including influenza understand their current status. These

and hemorrhagic fevers, in the future. results were analyzed and used as

input to plan for the variety of

For Oiltanking Oman, this project demonstrates our necessary training for specific target

commitment to be part of the local community by roles/groups within the whole global

contributing to meaningful and impactful projects. This one organization and to refine the

has the potential to provide quick access to testing services implementation approach for the risk

as early as possible in view of curbing the spread of viral management needs and activities for

diseases. each region/cluster/terminal in a more

fit-for-purpose manner.

A GOOD MOVE Oiltanking Terminals is

As we proceed with the trainings in the

one of the six tenants of SOHAR Port and

Freezone who support the development of first quarter of 2021 and subsequent

a regional laboratory for COVID-19 tests implementation in 2021 and beyond,

28 CONNECTIONS CONNECTIONS 29You can also read