Postharvest Machinery - Hot Water Treatment Tank - Methods of Test - AMTEC

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

PHILIPPINE NATIONAL STANDARD PNS/BAFS PABES____:2019 ICS 65.060.99 Postharvest Machinery – Hot Water Treatment Tank – Methods of Test BUREAU OF AGRICULTURE AND FISHERIES STANDARDS BPI Compound Visayas Avenue, Diliman, Quezon City 1101 Philippines Trunkline: (632) 928-8741 to 64 loc. 3301-3319 E-mail: info.dabafs@gmail.com Website: www.bafs.da.gov.ph

Contents Foreword....................................................................................................................... iii 1 Scope .................................................................................................................... 1 2 Normative references ............................................................................................ 1 3 Terms and definitions ............................................................................................ 1 4 General Conditions for Test .................................................................................... 2 5 Test Preparation ..................................................................................................... 3 6 Pre-Test Observation ............................................................................................. 4 7 Performance Test ................................................................................................... 4 8 Laboratory Analysis ................................................................................................ 5 9 Presentation of Results........................................................................................... 5 10 Formula .................................................................................................................. 6 11 Test Report............................................................................................................. 6 Annex A ........................................................................................................................ 7 Annex B ........................................................................................................................ 8 Annex C ...................................................................................................................... 11 Annex D ...................................................................................................................... 15 Annex E ...................................................................................................................... 18 Annex F ...................................................................................................................... 21 Annex G ...................................................................................................................... 23 Bibliography ................................................................................................................ 28

PHILIPPINE NATIONAL STANDARD PNS/BAFS PABES ____:2019 Foreword The formulation of this national standard was initiated by University of the Philippines Los Baños – Agricultural Machinery Testing and Evaluation Center (UPLB – AMTEC) through the project “Testing and Evaluation of Machinery Generated from PCAARRD- funded Projects” funded by the Philippine Council for Agriculture, Aquatic and Natural Resources Research and Development – Department of Science and Technology (PCAARRD – DOST). This is in collaboration with the Bureau of Agriculture and Fisheries Standards (BAFS). This covers the development of PNS for Hot Water Treatment Tank. This Standard has been technically prepared in accordance with International Organization for Standardization/International Electrotechnical Commission (ISO/IEC) Directives Part 2, 8th Edition - Principles and rules for the structure and drafting of ISO and IEC documents. The word “shall” is used to indicate mandatory requirements to conform to the standard. The word “should” is used to indicate that among several possibilities one is recommended as particularly suitable without mentioning or excluding others. iii

PHILIPPINE NATIONAL STANDARD PNS/BAFS PABES ___:2019 Postharvest Machinery – Hot Water Treatment Tank – Methods of Test 1 Scope This standard specifies the methods of test and inspection for hot water treatment (HWT) tank. Specifically, it shall be used to: 1.1 verify the mechanism, dimensions, materials, accessories of the HWT tank and the list of specifications submitted by the manufacturer; 1.2 determine the performance of the machine; 1.3 evaluate the ease of handling and safety features; 1.4 analyze the treated commodities through laboratory analysis; and 1.5 report the results of the tests. 2 Normative References The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 874 – 1980, Fresh Fruits and Vegetables – Sampling PAES 103:2000, Agricultural Machinery – Method of Sampling PNS/BAFPS 13:2004, Fresh Fruits – Mangoes – Specification PNS/BAFS PABES ---:2019, Postharvest Machinery – Hot Water Treatment Tank – Specifications 3 Terms and Definitions For the purpose of this standard, the definitions given in PNS/BAFS/PABES ---:2019 and the following shall apply. 3.1 batch type capacity weight of commodities to be treated per unit total time of operation, expressed in kilogram per hour (kg/h) 3.2 continuous type capacity weight of treated commodities collected at the outlet per unit time, expressed in kilogram per hour (kg/h)

PNS/BAFS PABES ____:2019 3.3 heat injury any damage that occurs to commodities due to excessive temperature or prolonged duration of exposure to heat, and is evident externally or internally which is visible immediately or after a period of storage 3.4 mechanical damage any damage that occurs to commodities due to compression, impact, vibration, abrasion and others which are brought about by the action of machinery or improper physical handling during harvesting and postharvest operations 3.5 overall height distance between the horizontal supporting surface and the horizontal plane touching the uppermost part of the HWT tank 3.6 overall length distance between the vertical planes at the right angles to the median plane of the HWT tank and touching its front and rear extremities 3.7 overall width distance between the vertical planes parallel to the median plane of the HWT tank, each plane touching the outermost point of the machine on its respective side 3.8 running-in period preliminary operation of the machine to make various adjustments prior to the conduct of the test until the operation is stable 3.9 test applicant manufacturer, inventor, direct importer, or any legitimate distributor, dealer, or end- user of the machine 3.10 thermal efficiency ratio of heat absorbed by water during heating to a specified temperature to the heat released by the heat source for the same period 4 General Conditions for Test 4.1 Selection of HWT tank to be tested HWT tank submitted for testing shall be sampled in accordance to PAES 103:2000 or any other suitable method of selection. 2

PNS/BAFS PABES ____:2019 4.2 Role of the test applicant The test applicant shall submit specifications and other relevant information about the HWT tank. They shall abide with the terms and conditions set forth by the official testing agency. 4.3 Role of the representative of the test applicant An officially designated representative of the test applicant shall operate, demonstrate, adjust, repair as the case maybe and decide on matters related to the operation of the machine. 4.4 Test site conditions The HWT tank shall be tested and installed for normal operation. The site should have ample provisions for material handling, temporary storage, workspace and suitable for normal working condition. Adequate ventilation and lighting, and good drainage system shall be provided in the area. 4.6 Suspension/Termination of test If during the test run, the machine stops due to breakdown or malfunction so as to affect the machine’s performance, the test may be suspended. If the machine will not be able to continue operation, the test shall be terminated. 5 Test Preparation 5.1 Preparation of the HWT tank for testing The representative of the test applicant and testing agency shall check the HWT tank so as to ensure that the machine has been assembled and installed in accordance with the instruction of the manufacturer. The official testing agency will test the aquaculture feeder according to the specifications of the manufacturer. 5.2 Test instruments and other materials The suggested list of minimum field and laboratory test equipment and materials needed to carry out the HWT tank test is shown in Annex A. These instruments shall be calibrated regularly. Before and after each test, these instruments shall be physically checked for operation and shall be cleaned, respectively. A checklist of instruments and materials to be used before departure to and from the testing area shall be prepared. 5.3 Test materials The test material to be used should be commonly or locally grown, newly harvested, mature green Carabao mango fruits of fairly uniform size. The amount of test material to be supplied shall be sufficient for the required test trials, running-in, and laboratory tests. Prepare the sample in such a way that test sample to be used for the running-in 3

PNS/BAFS PABES ____:2019 and in each test trial have identical characteristics in terms of size, maturity, and variety. However, if the test materials are not conforming to the recommended quantity and characteristics, the test engineer shall not pursue the test. 5.4 Running-in and preliminary adjustments The HWT tank shall have undergone a running-in period before starting the test. During the running-in period, the various adjustments of the machine shall be made according to the recommendation of the manufacturer. 6 Pre-test observation 6.1 Verification of specifications The specifications claimed by the manufacturer and the physical details given in Annex B shall be verified by the testing agency. A stable and level surface shall be used as reference plane for verification of dimensional machine specifications when fully assembled and ready for use. 6.2 Test samples Representative test samples shall be collected by the testing agency from the test material for analysis. Test material shall be treated within 24 hours after harvest. Sampling procedure is shown in Annex C. 7 Performance Test 7.1 Operation of the HWT tank The HWT tank shall be operated for sufficient duration with load at the test site by the official representative of the test applicant using the manufacturer’s recommended setting. The testing agency shall make all measurements, which form part of the test and take the prescribed samples. After the test run, the area shall be cleaned and then prepared for the next test trial. This procedure shall be repeated for the succeeding test trials. No other adjustments shall be permitted during the test. 7.2 Test trials 7.2.1 For batch type HWT tank, a minimum of three (3) batches of mango fruits shall be treated for batch type HWT tank following the prescribed dipping duration as shown in Annex A of PNS/BAFS/PAES ---: 2019. 7.2.2 For continuous type HWT tank, a minimum of three (3) trials with minimum duration of fifteen (15) minutes of continuous dipping following the prescribed dipping duration for mango fruits as shown in Annex A of PNS/BAFS/PAES ---: 2019. 4

PNS/BAFS PABES ____:2019 7.3 Sampling Samples shall be collected during each test trial. Sampling procedure is shown in Annex C. 7.4 Data collection 7.4.1 Duration of test The duration of each test trial shall commence from the heating of water from ambient temperature to set point temperature and shall end after the last batch of mango fruits is unloaded from the dipping chamber. Each test trial shall include water heating, dipping and water reheating. 7.4.2 Heating test The heating test shall be carried out to determine the water heating time, water heating rate, theoretical heat supply rate during water heating, thermal efficiency, water temperature standard deviation and hot water and set point temperature difference. The HWT shall be run at the manufacturer’s recommended setting. Water shall be heated to 54 °C, the set point temperature. 7.4.3 HWT test The HWT test shall be carried out to determine the actual dipping duration, capacity, theoretical heat supply rate during dipping, and noise level. Mango fruits shall be loaded to the HWT tank after water heating for disease control treatment. The treatment schedule shall be 54 °C for 10 min as prescribed in Annex A of PNS/BAFS/PABES__: 2019 for ‘Carabao’ mango. 7.4.5 Data recording and observations Record sheet for all data and information during the test is given in Annex D. Observations to be taken during the performance test shall be recorded in this sheet. 8 Laboratory Analysis Laboratory analysis shall be made to determine the average size of the mango fruits and the standard deviation of their weights before HWT. After HWT, the commodities shall be inspected for any incidence of heat and mechanical damages. The procedures for the different analyses are given in Annex E, while data sheets to be used are given in Annex F. 9 Presentation of Results Machine specifications and the results of the test shall be presented in tabular form in which data shall be taken from Annexes B and D. A schematic diagram of the power transmission system shall also be included. Observations made on the machine while in operation shall be supported with photographs. 5

PNS/BAFS PABES ____:2019 10 Formula The formula to be used during calculations and testing are given in Annex G. 11 Test Report The test report shall include the following information in the order given. 11.1 Name of Testing Agency 11.2 Test Report Number 11.3 Title 11.4 Summary of Results 11.5 Purpose and Scope of Test 11.6 Methods of Test 11.7 Conditions of the Machine 11.8 Description of the Machine 11.9 Results and Discussions 11.10 Observations (include pictures) 11.11 Names and Signatures of Test Engineers 6

PNS/BAFS PABES ____:2019 Annex A (informative) Minimum List of Field and Laboratory Test Equipment and Materials A.1 Equipment Quantity A.1.1 Performance Test A.1.1.1 Thermocouple A.1.1.2 Data logger (8-channel) Resolution: 0.5 °C Accuracy: ±1.0 °C A.1.1.3 PC laptop 1 A.1.1.4 Tachometer (contact type or photo electric type) 1 A.1.1.5 Timers 1 Maximum resolution: 0.1 sec A.1.1.6 Measuring tape (at least 5m) 1 A.1.1.7 Sound level meter 1 Range: 30 to 130 dB(A) A.1.1.8 Weighing scale 1 Minimum capacity: 100 kg Maximum scale divisions: 0.2 kg A.1.1.9 Graduated cylinder 1 Capacity: 500 mL A.1.1.10 Clamp-on type power meter 1 A.1.1.11 Digital camera 1 A.1.1.12 Pail/Bucket 1 Capacity: 20 L A.1.2 Laboratory Test 1 A.1.2.1 Weighing scale Minimum capacity: 50 kg 1 Maximum scale divisions: 0.2 kg A.1.2.2 Plastic crate Capacity: 20 kg A.1.2.3 Digital camera 1 A.2 Materials A.2.1 Sample bags A.2.2 Labeling tags which include: A.2.2.1 Date of test A.2.2.2 Machine on test A.2.2.3 Sample source A.2.2.4 Variety A.2.2.5 Trial number 7

PNS/BAFS PABES ____:2019 Annex B (informative) Specifications of Hot Water Treatment Tank Name of Applicant : ______________________________________________ Address : ______________________________________________ Tel. No. : ______________________________________________ Name of Manufacturer : ________________________________________ Address : ________________________________________ Tel. No. : ________________________________________ GENERAL INFORMATION Make : _____________________ Type : __________________ Serial No. : _____________________ Brand/Model : __________________ Date of Manufacture : _____________________________________________ Testing Agency : ________________ Test Engineer : ____________ Location of Test : ________________ Date of Test : __________________ Items to be inspected* Manufacturer’s Verification by the No. Items Specification Testing Agency B.1 Main Structure B.1.1 Overall dimensions (mm) B.1.1.1 Length B.1.1.2 Width B.1.1.3 Height B.1.2 Material B.1.3 Insulation B.2 Rated capacity (kg/batch or kg/h) B.3 Dipping Chamber B.3.1 Dimensions (mm) B.3.1.1 Length B.3.1.2 Width B.3.1.3 Height B.3.2 Material B.3.3 Flotation barrier B.3.3.1 Type B.3.3.2 Dimensions (mm) B.3.3.3 Material B.4 Water Pump B.4.1 Brand B.4.2 Model B.4.3 Size (mm) B.4.4 Type 8

PNS/BAFS PABES ____:2019 Manufacturer’s Verification by the No. Items Specification Testing Agency B.4.5 Rated maximum discharge capacity (L/s) B.4.6 Rated maximum head (m) B.4.7 Rated motor power (kW) B.4.8 Rated motor speed (rpm) B.4.9 Suction side B.4.9.1 Type B.4.9.2 Nominal diameter (mm) B.4.9.3 Material B.4.9.4 Other feature(s) B.4.10 Discharge side B.4.10.1 Type B.4.10.2 Nominal diameter (mm) B.4.10.3 Material B.4.10.4 Other feature(s) B.5 Heating system B.5.1 Type B.5.2 Brand B.5.3 Rated output power (kW) B.5.4 Fuel consumption (kg/h) (if applicable) B.5.5 Other feature(s) B.6 Material Handling B.6.1 Batch system’s cradle (if applicable) B.6.1.1 Dimensions (mm) B.6.1.1.1 Length B.6.1.1.2 Width B.6.1.1.3 Height B.6.1.2 Material B.6.2 Lifting system B.6.2.1 Type B.6.2.2 Brand B.6.2.3 Type of driving mechanism B.6.2.4 Drive motor (if applicable) B.6.2.4.1 Brand B.6.2.4.2 Type B.6.2.4.3 Rated power (kW) B.6.2.4.4 Rated speed (rpm) B.6.2.4.5 Electric service required (single phase or 3-phase) B.6.2.4.6 Frequency (Hz) 9

PNS/BAFS PABES ____:2019 No. Items Manufacturer’s Verification by the Specification Testing Agency B.6.2.4.7 Voltage (V) B.6.2.5 Other feature(s) B.6.2 Continuous system’s conveyor B.6.2.1 Brand B.6.2.2 Type B.6.2.3 Number B.6.2.4 Rated capacity (kg/h) B.6.2.5 Drive motor B.6.2.5.1 Brand B.6.2.5.2 Type B.6.2.5.3 Rated power (kW) B.6.2.5.4 Rated speed (rpm) B.6.2.5.5 Electrical service requirement B.6.2.5.6 Voltage (V) B.6.2.5.7 Frequency (Hz) B.6.2.6 Control(s) B.6.2.7 Material B.6.2.8 Other Feature(s) B.7 Instruments and Controls B.7.1 Water temperature sensor B.7.1.1 Type(s) B.7.1.2 Location(s) B.7.2 Fruit temperature sensor B.7.2.1 Type(s) B.7.2.2 Location(s) B.7.3 Other features B.7.4 Type of temperature recorder B.8 Safety feature(s) B.8.1 Product safety B.8.2 Machine safety B.8.3 Operation and maintenance safety *if applicable B.9 Illustration of HWT tank set-up 10

PNS/BAFS PABES ____:2019 Annex C (normative) Sampling Procedures and Measurement C.1 Sampling from Test Material The conditions of the mango fruits to be used in each test including quality, maturity, and uniformity shall be taken using “representative samples”. This is done by randomly obtaining the required mass or number of samples according to the total mass of test material as given below. Data on the commodity such as variety, source, and date of harvest shall be recorded. TOTAL MASS OF TEST REQUIRED MASS OF REQUIRED NUMBER MATERIAL, kg SAMPLE*, kg OF SAMPLE, piece Up to 200 10 40 201 to 500 20 80 501 to 1,000 30 120 *Source: ISO 874-1980 (E) C.2 Handling of Samples All samples to be taken to the laboratory shall be placed in appropriate containers and properly labeled. Care should be taken so as to prevent alterations of the conditions of the test samples. C.3 Heating Test C.3.1 Water heating time C.3.1.1 The dipping chamber shall be filled with water at ambient temperature to the proper level according to the tank’s water capacity or as specified by the manufacturer. C.3.1.2 The set point temperature (Tsp) shall be set to 54 °C. C.3.1.3 Heating time shall start immediately at the activation of the heat source and shall end once the water temperature registered by the test equipment (e.g data logger, digital thermometer) reaches the set point temperature. The time shall be recorded as the water heating time (tp). C.3.2 Water heating rate C.3.2.1 The dipping chamber shall be divided into at least six portions. Temperature shall be taken at center of each section using a calibrated thermocouple probe. A digital thermometer or data logger shall be used for measuring temperature. 11

PNS/BAFS PABES ____:2019 C.3.2.2 Water temperature data during heating shall be taken at each section of the dipping chamber. Measurements shall be automatically sampled at five-minute intervals. C.3.2.3 Temperature readings shall be plotted against time. The heating slope (ΔT/Δtp) of the said plot shall be determined. C.3.2.4 The heating rate (Qw) shall be computed using the mass of water bath (m w) and the heating slope (ΔT/Δtp). C.3.3 Theoretical heat supply rate C.3.3.1 Theoretical heat supply rate to heat the water shall be determined. C.3.3.2 In the case of LPG-heated HWT tank, the initial weight of the LPG tank (Mig) shall be recorded prior to the start of water heating, and its final weight (M fg) once the setpoint temperature is reached to determine the fuel consumption rate. C.3.3.3 For electric-heated HWT tank, a power meter shall be used to measure voltage, current, and the total electric power requirement during the water heating process. There shall be three (3) sets of data with a minimum of five (5) observations per set taken with and without load. C.3.3.4 To get the amount of fuel consumed by HWT tank heated by liquid fuel, the fuel tank shall be filled to full capacity before the test. After the test, fill the fuel tank with measured fuel to the same level before the test. When filling up the fuel tank, careful attention shall be paid to keep it horizontal and do not leave empty space inside. There shall be three (3) sets of data with a minimum of five (5) observations per set taken with and without load. C.3.4 Thermal efficiency Thermal efficiency (ηt) shall be determined by obtaining the ratio of the heating rate of water (Qw) and the theoretical heat supply rate. C.3.5 Water temperature standard deviation C.3.5.1 After heating to and stabilizing at set point temperature, water temperature shall be measured and recorded using at least six thermocouple wires, each positioned at every section of the dipping chamber previously divided. C.3.5.2 Mean water temperature (T ̅w ) shall be determined to compute the temperature standard deviation of water (Sw). The hot water and set point temperature difference (ew) shall also be calculated. C.4 Hot Water Treatment Test Mango fruits shall be loaded to the HWT tank after water heating for disease control treatment. The treatment schedule shall be 54 °C for 10 min. 12

PNS/BAFS PABES ____:2019 C.4.1 Batch type capacity C.4.1.1 Input weight (Wi) of material to be treated shall be determined and recorded before each trial. C.4.1.2 With water bath at the set point temperature, dipping duration (th) shall be verified for each trial using a timer. Loading time (tl) of mango fruits into the dipping chamber shall be recored. The dipping duration shall start when the cradle or set of crates is fully immersed into the dipping chamber and shall end after 10 min. Unloading time (tu) of mango fruits from the dipping chamber shall also be recorded. C.4.1.3 The duration (tr) to reheat the water bath to the set point temperature shall be recorded for each trial, should there be a temperature drop after the treatment of the first batch or set of material. C.4.1.4 The total operating time (T) shall be calculated by adding the loading time (tl), dipping duration (th), reheating duration (tr) and unloading time (tu). Capacity (Ct) of batch type HWT tank shall be calculated using the formula in Annex G. C.4.2 Continuous type capacity C.4.2.1 Output weight (W o) of material treated shall be determined during each test trial. C.4.2.2 With water bath at the set point temperature, the dipping duration shall start when the first crate or first set of material is fully immersed into the dipping chamber. C.4.2.3 The total weight of the treated fruits collected from the outlet conveyor (W o) for fifteen (15) minutes of continuous dipping duration shall be recorded. C.4.2.4 Capacity (Ct) of continuous type HWT tank shall be calculated using the formula in Annex G. C.4.3 Theoretical heat supply rate C.4.3.1 Theoretical heat supply rate to maintain the water bath temperature at the set point temperature shall be determined. C.4.3.2 In the case of LPG-heated HWT, the initial weight of the LPG tank (Mig) shall be recorded prior to dipping of the material. The final weight of the LPG tank (Mfg) shall be measured if the water temperature is equal to the set point temperature upon removal of the commodity treated, or after reheating the water to the set point temperature. C.4.3.3 For electric-heated HWT tank, a power meter shall be used to measure voltage, current, and the total electric power requirement during the HWT process. There shall be three (3) sets of data with a minimum of five (5) observations per set taken with and without load. 13

PNS/BAFS PABES ____:2019 C.4.3.4 To get the amount of fuel consumed by HWT tank heated by liquid fuel, the fuel tank shall be filled to full capacity before the test. After the test, fill the fuel tank with measured fuel to the same level before the test. When filling up the fuel tank, careful attention shall be paid to keep it horizontal and do not leave empty space inside. There shall be three (3) sets of data with a minimum of five (5) observations per set taken with and without load. C.4.3.5 Water temperature shall be measured and recorded using at least six thermocouple wires, each positioned at different location of the dipping chamber at the start of dipping, at 5 minutes, and before the end of dipping. C.4.4 Noise level C.4.4.1 The sound emitted by the machine while dipping fruits with the different components operating at the recommended settings and with the heating system on, shall be measured using a sound level meter at the location of the operator/s. The noise level, expressed in decibel [dB (A)], shall be measured 50 mm away from the ear level of the operator/s. C.4.4.2 For each data to be taken, there shall be a minimum of five (5) observations. Before taking data, it should be ensured that the feed rate, speed, and other functional characteristics have stabilized. The time of recording shall be properly spaced during the whole duration of the test trial. 14

PNS/BAFS PABES ____:2019 Annex D (informative) Performance Test Data Sheet Test Trial No. : ___________________ Date : __________________ Test Engineers : ___________________ Location : __________________ Assistants : ___________________ Machine : __________________ Test Applicant : ___________________ Manufacturer : __________________ Trial Trial Trial No. Items Ave 1 2 3 D.1 Conditions of Mango Fruits to Be Treated D.1.1 Variety D.1.2 Source D.1.3 Date of harvest D.2 Heating Test D.2.1 Heating time (h) D.2.2 Initial water temperature (°C) D.2.3 Set point temperature (°C) D.2.4 Total mass of water (kg) D.2.5 Heating slope (°C/s) D.2.6 Water heating rate (kW) D.2.7 LPG D.2.7.1 Initial weight of LPG tank (kg) D.2.7.2 Final weight of LPG tank (kg) D.2.7.3 Heat available in the fuel (kW) D.2.8 Electric D.2.8.1 Power (kW) D.2.8.2 Current (A) D.2.8.3 Voltage (V) D.2.9 Liquid fuel D.2.9.1 Fuel consumed (L) D.2.9.2 Heat available in the fuel (kW) D.2.10 Thermal efficiency (%) D.2.11 Mean water temperature D.2.12 Temperature standard deviation of hot water (°C) D.2.13 Temperature absolute difference of hot water (°C) D.3 HWT Test D.3.1 Batch type D.3.1.2 Input weight of fruits (kg) D.3.1.3 Dipping duration (min) D.3.1.4 Reheating duration (min) 15

PNS/BAFS PABES ____:2019 No. Items Trial Trial Trial Ave 1 2 3 D.3.1.5 Total operating time (h) D.3.1.6 Capacity (kg/batch) D.3.2 Continuous type D.3.2.1 Output weight of treated fruits (kg) D.3.2.2 Output time (min) D.3.2.3 Capacity (kg/h) D.3.3 LPG D.3.3.1 Initial weight of LPG tank (kg) D.3.3.2 Final weight of LPG tank (kg) D.3.3.3 Fuel consumption (kg/h) D.3.4 Electric D.3.4.1 Power (kW) D.3.4.2 Current (A) D.3.4.3 Voltage (V) D.3.5 Liquid Fuel D.3.5.1 Fuel consumed (L) D.3.5.2 Fuel consumption (L/h) D.3.6 Noise level [dB(A)] D.4 Observations: D.4.1 Ease of loading ___________________________________________________________________ _____________________________________________________________________________________________________ _____________________________________________________________________________________________________ D.4.2 Ease of cleaning parts ___________________________________________________________________ _____________________________________________________________________________________________________ _____________________________________________________________________________________________________ D.4.3 Ease of adjustments ___________________________________________________________________ _____________________________________________________________________________________________________ _____________________________________________________________________________________________________ D.4.4 Ease of collecting output ___________________________________________________________________ _____________________________________________________________________________________________________ _____________________________________________________________________________________________________ D.4.5 Safety ___________________________________________________________________ _____________________________________________________________________________________________________ _____________________________________________________________________________________________________ 16

PNS/BAFS PABES ____:2019 D.4.6 Labor requirements ___________________________________________________________________ _____________________________________________________________________________________________________ _____________________________________________________________________________________________________ D.4.7 Failure or abnormalities that may be observed on the corn mill or its component parts during and after the milling operation. ___________________________________________________________________ _____________________________________________________________________________________________________ _____________________________________________________________________________________________________ D.4.8 Others ___________________________________________________________________ _____________________________________________________________________________________________________ _____________________________________________________________________________________________________ 17

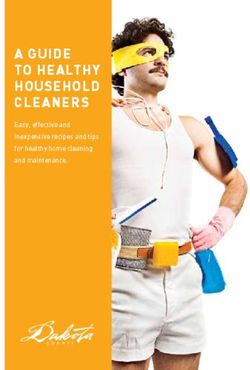

PNS/BAFS PABES ____:2019 Annex E (normative) Laboratory Analysis E.1 Maturity Test E.1.1 Submerge the test sample for the float test in 1 % salt solution (100 g salt/10 L of water). Float test can be done in a pail in increments. E.1.2 Count and compute the percentage of the fruits that sank in the salt solution. Sinking of at least 75 % of the fruits is an indication that the fruits are already matured. E.2 Average Weight of the Mango Fruits E.2.1 From the obtained samples for float test, weigh each fruit using a digital weighing balance. Record each resulting mass. E.2.2 Calculate the average mass of the mango fruits. Determine the average size of the mango fruits based on the standard size of mango below. SIZE WEIGHT, g/piece Extra large (XL) ≥ 350 Large (L) 300-349 Medium (M) 250-299 Small (S) 200-249 Super small (SS) 160-199 Source: PNS/BAFPS 13:2004 E.3 Mechanical Damage Incidence E.3.1 For each test trial, randomly select thirty (30) pieces of ‘Carabao’ mango fruits of good quality and condition from the input test material. Mark each fruit using a waterproof permanent marker. E.3.2 Immediately after HWT, collect all thirty (30) previously marked mango fruits from the treated output. Visually inspect each fruit for any external, mechanical damages (cracks and cuts) as shown below, and count the damaged ones. The number of damaged fruits shall be recorded. E.3.3 Allow the previously marked mango fruits to ripen to full yellow stage to inspect the occurrence of any mechanical damage (abrasion and compression). The number of damaged fruits shall be recorded. 18

PNS/BAFS PABES ____:2019 Abrasion Compression Crack Cut Figure 1 – Mechanical and handling damages on mango fruits Source: PNS/BAFPS 13:2004 E.3.3 Mechanical damage incidence shall be computed using the formula in Annex G. 19

PNS/BAFS PABES ____:2019 E.4 Heat Injury Incidence E.4.1 After HWT, previously marked mango fruits shall be checked for the occurrence of any of the symptoms of heat injury as given below. OCCURENCE SYMPTOMS OF HEAT INJURY Surface of the fruit Skin scalding or browning Desiccation Internal part of the fruit White, starchy, tough lesions near the seed Cavitation or air pockets E.4.2 Immediately after HWT, visually inspect each fruit for any external damage and count the injured ones. After 4 to 5-day storage, same set of fruits shall be inspected for the occurrence of internal damages. The number of damaged fruits shall be recorded. E.4.3 Heat injury incidence immediately after HWT and after 4 to 5-day storage shall be computed using the formula in Annex G. 20

PNS/BAFS PABES ____:2019 Annex F (informative) Laboratory Analysis Data Sheet Machine Tested : __________________ Date Tested : ____________ Analyzed by : __________________ Date Analyzed : ____________ F.1 Maturity of ‘Carabao’ Mango Fruits Item Value Total number of fruits Total number of fruits that sank Percent of fruits that sank (%) Maturity test result F.2 Average Size of Mango Fruits Sample Mass Sample Mass Sample Mass Sample Mass no. (g) no. (g) no. (g) no. (g) 1 31 61 91 2 32 62 92 3 33 63 93 4 34 64 94 5 35 65 95 6 36 66 96 7 37 67 97 8 38 68 98 9 39 69 99 10 40 70 100 11 41 71 101 12 42 72 102 13 43 73 103 14 44 74 104 15 45 75 105 16 46 76 106 17 47 77 107 18 48 78 108 19 49 79 109 20 50 80 110 21 51 81 111 22 52 82 112 23 53 83 113 24 54 84 114 25 55 85 115 26 56 86 116 27 57 87 117 21

PNS/BAFS PABES ____:2019 28 58 88 118 29 59 89 119 30 60 90 120 Mean, mm SD, mm AS Legend: SD – Standard deviation; AS – Average size F.3 Mechanical Damage Incidence Test trial I Test trial III Test trial III No. of Damage No. of Damage No. of Damage Time damaged incidence damaged incidence damaged incidence fruits (%) fruits (%) fruits (%) Before HWT After HWT F.4 Heat Injury Incidence Heat injury incidence Time No. of damaged fruits (%) Immediately after HWT After 3 days 22

PNS/BAFS PABES ____:2019 Annex G (normative) Formulas Used During Calculations and Testing G.1 Water Heating Rate ∆ = · · ∆ where: Qw is the water heating rate (kW) mw is the total mass of water (kg) Cp is the specific heat of water (kJ/kg·K) ΔT/Δtp is the heating slope (°C/s) G.2 Theoretical Heat Supply Rate of the Fuel G.2.1 LPG − = ℎ · where: Qg is the theoretical heat supply rate (kW) HVh is the higher heating value of LPG equal to 50,294 kJ/kg (ASHRAE, 1997) Mig is the initial weight of LPG cylinder (kg) Mfg is the final weight of LPG cylinder (kg) tp is the total heating time (s) G.2.2 Liquid fuel = ℎ · · where: Ql is the theoretical heat supply rate (kW) HVh is the higher heating value of liquid fuel (kJ/kg) Fv is the volume of fuel consumed (L) tp is the total heating time (s) ρf is the density of fuel (kg/L) 23

PNS/BAFS PABES ____:2019 G.3 Thermal Efficiency G.3.1 LPG-heated HWT tank η = · 100 where: ηt is the thermal efficiency (%) Qw is the water heating rate (kW) Qg is the theoretical heat supply rate (kW) G.3.2 Electric HWT tank η = · 100 where: ηt is the thermal efficiency (%) Qw is the water heating rate (kW) Qe is the electric power consumption (kW) G.3.3 HWT tank heated by liquid fuel η = · 100 where: ηt is the thermal efficiency (%) Qw is the water heating rate (kW) Ql is the theoretical heat supply rate (kW) G.4 Capacity G.4.1 Batch type C = where: Ct is the capacity (kg/h) Wi is the input weight of fruits (kg) T = tr + th is the total operating time during HWT (h) 24

PNS/BAFS PABES ____:2019 G.4.2 Continuous type C = where: Ct is the capacity (kg/h) Wo is the weight of treated fruits collected at the outlet conveyor (kg) To is the output time (h) G.5 Fuel Consumption G.5.1 LPG − = where: Fc is the fuel consumption (kg/h) Mig is the initial weight of LPG cylinder (kg) Mfg is the final weight of LPG cylinder (kg) To is the total operating time during HWT (h) G.5.2 Liquid fuel = where: Fc is the fuel consumption (L/h) Fv is the volume of fuel consumed (L) To is the total operating time during HWT (h) G.6 Water Temperature Standard Deviation ∑ ̅ = ∑( − ̅ )2 = √ −1 25

PNS/BAFS PABES ____:2019 where: ̅w T is the mean water temperature (°C) Tj is the individual water temperature reading (°C) n is the total number of HWT temperature readings sampled Sw is the temperature standard deviation of water (°C) G.7 Hot Water and Set Point Temperature Difference = | ̅ − | where: ̅w T is the mean water temperature (°C) Tsp is the set point temperature (°C) G.8 Average Size of the Fruits G.8.1 Average weight ∑ ̅ = where: w ̅f is the average fruit weight (g) wj is the individual fruit weight (g) n is the total number of samples G.8.2 Standard deviation ̅ )2 ∑( − = √ −1 where: w ̅f is the mean water temperature (°C) wj is the individual water temperature reading (°C) n is the total number of HWT temperature readings sampled Sf is the temperature standard deviation of water (°C) G.9 Mechanical Damage Incidence (MDI) = × 100 26

PNS/BAFS PABES ____:2019 G.10 Heat Injury Incidence (HII) = × 100 27

PNS/BAFS PABES ____:2019 Bibliography Alvindia, D.G., & Acda, M.A. (2014). Revisiting the efficicacy of hot water treatment in managing anthracnose and stem-end rot diseases of mango cv. ‘Carabao’. Crop Protection 67:96-101. doi: 10.1016/j.cropro.2014.9.016. Animal and Plant Health Inspection Service – United States Department of Agriculture. (2002). Treatment Manual. Retrieved July 30, 2017 from https://www.aphis.usda.gov/import_export/plants/manuals/ports/downloads/tr eatment.pdf. American Society of Heating, Refrigeration and Airconditioning Engineers [ASHRAE]. 1997. Combustions and fuels . In: Parsons, R.A. (Ed/s).Fundamentals Handbook (SI), (pp. 17.1-17.6).Atlanta, Georgia: ASHRAE. Directorate of Plant Protection, Quarantine & Storage. (2005). Guidelines for certification of hot water immersion treatment facilities for mango fruits. Retrieved July 30, 2017 from http://plantquarantineindia.nic.in/pqispub/pdffiles/NSPM15%20Guidelines%2 0for%20Certification%20of%20HWT.pdf. Usall, J., Ippolito, A., Sisquella, M., & Neri, F. (2016). Physical treatments to control postharvest diseases of fresh fruits and vegetables. Postharvest Biology and Technology 122:30-40. doi: 10.1016/j.postharvbio.2016.05.002. Yaptenco, K.F., de Ramos, J.D., & Amatorio, E.Q. (2015). Development of a batch- type hot water tank for postharvest disease control for ‘carabao’ mango and other crops. Philippine Journal of Agricultural and Biosystems Engineering, 11, 22-35. 28

Agricultural Machinery Testing and Evaluation Center Testing and Evaluation of Machinery Generated from PCAARRD-funded Projects Project Leader Darwin C. Aranguren Engineer IV Project Staff Romulo E. Eusebio Engineer III Technical Staff Ray D. Alipio Science Research Specialist I Support Staff Gerald S. Trinidad Laboratory Technician I Micah A. Almalvez Science Aide Fortunato L. Parducho Laboratory Aide I

Technical Working Group (TWG) for the Development of Philippine Agricultural Engineering Standards (PAES) for Various Agricultural Machinery from PCAARRD-funded Projects Chairperson Dr. Aurelio A. Delos Reyes Jr. Agricultural Machinery Testing and Evaluation Center Members 1 John Gregory V. Aquino 3 Francia M. Macalintal Bureau of Agriculture and Philippine Council for Agriculture Fisheries Standards and Fisheries 2 Romeo P. Santiago 4 Crestituto C. Mangaoang Philippine Council for Agriculture, Philippine Society of Agricultural Aquatic, and Natural Resources and Biosystems Engineers Research and Development Secretariat Ray D. Alipio Agricultural Machinery Testing and Evaluation Center

BUREAU OF AGRICULTURE AND FISHERIES STANDARDS Compound Visayas Avenue, Diliman, Quezon City 1101 Philippines T/ (632) 928-8741 to 64 loc. 3301-3319 E-mail: info.dabafs@gmail.com Website: www.bafs.da.gov.ph

You can also read