Operator awareness FATIGUE MANAGEMENT & COLLISION AVOIDANCE - Hexagon Mining

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

FATIGUE MANAGEMENT & COLLISION AVOIDANCE

Operator awareness

Safety focussed on collision avoidance and

fatigue management remains a top priority

in the mining industry, and the technologies

available are now achieving impressive

results, reports Paul Moore

he integration of the most promising fleets,” said Ola Rollen, Hexagon’s President Newcrest Mining’s Lihir gold operation in

T technologies into the mining industry’s

key suppliers is a natural progression.

This has been seen in fatigue management

and CEO. “Our combined expertise will enable

us to better meet the increasing demand for

‘zero harm’ safety goals while providing a

Papua New Guinea recently went live with a full

installation of GE Mining’s collision avoidance

system (CAS)

solutions with Caterpillar and Seeing Machines, natural bridge to fully autonomous systems.

and with GE Mining and Optalert. Last year this This is key as more and more of our customers follows: “It’s 6:00 am on a Wednesday. A crew of

trend continued when Hexagon AB, a global express interest in moving beyond automation miners is starting a shift of seven, 12- hour work

leader in digital solutions, announced the into the world of autonomous technologies – a days for a major oil sands mining project in

acquisition of Guardvant, a global player in trend we are uniquely positioned to embrace.” Canada. In two hours this group of fathers,

operator safety solutions for the mining Headquartered in Tucson, Arizona, US, mothers, spouses and friends will experience the

industry. Guardvant is now operating within Hexagon’s highest level of fatigue risk during their work week.

Guardvant’s flagship solution, OpGuard, is Mining division. That’s not a hunch. It’s a quantifiable fact proven

used to detect and respond to driver fatigue and through the power to ‘see’ and measure fatigue risk

distraction – the most common underlying Caterpillar’s impressive DSS results across this operation.”

cause of accidents. To further mitigate operator- in oil sands “It isn’t a matter of if one of our operators will

related accident risks, Guardvant’s fatigue A recent case study from Caterpillar from the oil fall asleep at the wheel of a 400 ton (363 t) haul

monitoring capabilities are complemented by sands shows the power of fatigue management truck, it’s a matter of when,” said the Mine

collision avoidance and proximity detection technology. The company sets the scene as Operations Manager. “We won’t eliminate that

solutions, which provide drivers with 360-

degree situational awareness. The combination

of safety-enhancing technologies keeps drivers

safe, equipment protected, and productivity

rising.

“The benefits of Guardvant’s safety-

enhancing solutions are applicable to any

industrial worksite, as well as improving

transportation safety in industries such as

trucking & hauling and aviation. Its market

expansion plans are now supported both by

new product additions and the ability to

leverage Hexagon’s wider market footprint.”

“Guardvant’s highly dedicated and

experienced team is a natural fit for Hexagon.

We share the vision that driver-assisted

solutions are an integral part of safe, efficient,

productive operations – whether in mining,

construction, agriculture or any industry facing

the inherent challenges and risks of operating A Caterpillar fatigue monitoring analyst overseeing data coming in from mines worldwide

40 International Mining | JANUARY 2019FATIGUE MANAGEMENT & COLLISION AVOIDANCE

risk, but we’re doing everything in our power to

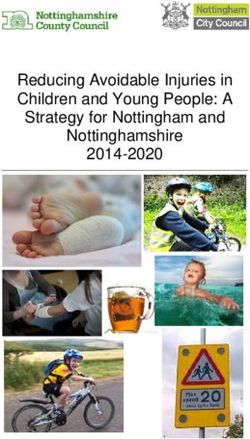

Data from a 90-day fatigue risk assessment

protect our people against it.” So on this day

the crew is starting its shift with a discussion Statistic Phase 1 Phase 2 Phase 3

about fatigue. Routine educational sessions are Total Mobile Hours 2,966 1,981 2,005

part of the company’s robust Fatigue Risk Total Fatigue Events 63 31 9

Management System. Operators are empowered Average Fatigue Events 0.020 0.020 0.004

with information to personally manage their (per mobile hour)

sleep health, but they’re also provided peace of Distance travelled while 1,611 922 369

mind that technology will protect them if the fatigued (metres)

formidable force of fatigue bears down.

That technology is the Cat® Driver Safety the monitoring centre and reviewed by a safety protocol involves direct human contact with the

System (DSS), an in-cab fatigue and distraction advisor. If the analysis confirms a microsleep operator, possibly a break from driving, but

monitoring and mitigation device. A camera that occurred, the safety advisor contacts a dispatch never punishment. “When the DSS alerted me, I

utilises non-intrusive facial mapping technology officer on site to communicate the incident. didn’t believe I had really fallen asleep – until I

watches for physical signs of weariness. If the What happens next is dictated by a Fatigue saw the video,” said one operator. “Often we

operator nods off for a couple seconds – Intervention Plan designed with guidance from a don’t realise how fatigued we are, and likely

experiences what is called a ‘microsleep’ – the Caterpillar fatigue management expert. The don’t even know we’re falling asleep.”

system activates a rumble in the seat and

audible in-cab alarm.

In its initial pilot test of the technology, the

DSS was installed in just five of the company’s

haul trucks and a 90-day, three-phase approach

to quantifying fatigue risk and mitigating

incidents ensued. To see and measure the scope

of the problem, for the first 30 days the in-cab

cameras recorded microsleep events, but the

alert systems didn’t activate to alert drivers. In

one month 63 fatigue events were recorded.

Operators travelled 1.6 km while sleeping.

A three-phase Fatigue Risk Assessment

uncovered its scope of risk (Phase 1), started

mitigating incidents (Phase 2) and initiated

comprehensive fatigue risk management (Phase 3).

“Seeing those numbers made the threat and

ability to reduce it so obvious that our senior

leadership committed immediately to using the

technology across our fleet,” said the mine’s

Technical Services Manager. “When I saw

operators falling asleep at the wheel, I couldn’t A leading global supplier of unique system solutions

in good conscience turn away from this for the mining industry from energy distribution to

system.” The alarms in those first five trucks automation, communication and transportation

were activated and fatigue events diminished by

86% in the next 60 days.

“Of all the safety hazards on a mining site,

fatigue is a unifier – because no one can escape

it. At some point, every human gets so sleepy

that decision making, reaction time and overall

cognitive power is compromised. For miners, the

potential for reaching that ultra-weary state is

heightened because 24/7 operations require

people to work when the human body is wired

to be sleeping.

Similar in concept to a safety harness, the DSS

serves as personal protective equipment – ready

to catch operators if they fall. The system also

includes living, breathing protection in the way of

safety advisors who work in a 24/7 Fatigue

Monitoring Centre. When a DSS unit activates www.varismine.com | 1-877-658-2747

because the operator’s eyes have closed for 1.5

seconds and the truck is moving at least 10 km/h,

a short video clip of the event is captured, sent to

JANUARY 2019 | International Mining 41FATIGUE MANAGEMENT & COLLISION AVOIDANCE

Analytics from the Driver Safety System systems to specialised headbands worn by

(DSS) have revealed previously hidden operators. The headbands monitored the

trends that are shaping the organisation’s fatigue levels of 20-25 open pit operators

incident prevention strategy. For example, per shift by taking Electroencephalography

data from this site shows the first day of a (EEG) readings. The device, which fit into a

seven-day shift is the most likely time for standard hard hat or cap, is similar to an

an operator to succumb to fatigue. Echocardiogram but it monitors electricity

Longitudinal reporting shows precisely emitted from the forehead rather than the

which hours of the day and night are high- heart. The EEG results appeared on a

risk for each crew, and which hours monitor mounted inside the cab of the

operators are most alert. open pit haul trucks every 2-3 minutes.

The company tracks every data point Drivers experiencing high levels of fatigue

possible and continually refines its would be notified by alerts from the

management system. It’s become a system. If a driver received three high-

passion, because many here bear fatigue alerts without taking a break the

Barrick’s Cortez mine recently completed two

emotional scars from a time before fatigue was important pilot projects to help its people system would flag this for a supervisor who

taken so seriously. “Three years ago we had a combat fatigue in the workplace could then intervene and assess a driver’s fitness

fatality, we lost someone we loved, and we for duty.

believe it was due to distraction,” one crew Barrick Cortez addresses fatigue The projects helped employees self-manage

member shared. Distraction is a common Barrick’s Cortez mine recently completed two their fatigue and determine when they may

symptom of fatigue because operators often important pilot projects to help its people experience a fatigue “wall.” Seeing the results

move around to avoid nodding off, so the DSS combat fatigue in the workplace. The month-long and acknowledging how their fatigue progressed

watches for both distraction and fatigue. pilots involved haul truck drivers who worked on throughout their shifts helped employees

“If we had the DSS at that time, there’s a day and night shifts. Among the key findings identify the most opportune time to counter

strong possibility our co-worker would still be were that day shift workers hit their highest level fatigue by drinking a glass of water or taking a

with us today. This initiative is very personal,” of fatigue on the last day of their work week. quick walk. “Many participants have

the crew member added. That loss catalysed a Night shift workers, however, experienced high acknowledged an increased awareness when it

culture change in this organisation, which like levels of fatigue as early as their second work comes to their personal fatigue management,”

many in the industry once perceived fatigue as a day through to the last day of their work week. Tueller says. “This awareness will help minimise

sign of weakness, something shameful. The way “Fatigue is a term used to describe a wide fatigue-related incidents.”

management has responded to each DSS alert variety of conditions,” says Justin Tueller, Cortez is evaluating data from the projects and

has shaped a new attitude about fatigue and Industrial Hygiene Specialist at Cortez. “We determining whether to proceed to a site-wide

forged trust between leaders and operators. “No summarise it as the feeling of being tired or implementation. This would see the SmartCap

one has ever been, nor will ever be, punished for weary because of insufficient sleep, lengthy system expanded to more equipment such as

having a fatigue event,” said the Technical periods of mental or physical work, or prolonged loaders and graders, and the use of the

Services Manager. “The technology will only episodes of stress or anxiety.” Predictive Safety testing tool in other divisions

protect people if they trust the purpose, and you Cortez identified fatigue as a key risk to such as Cortez Underground. The tool may also

have to earn trust – you can’t buy it.” worker safety and the pilot projects are a be adopted at the Goldstrike mine.

Within two years after the first DSS units were proactive way to address the issue. A person

installed, more than 2,000 fatigue events were struggling with fatigue will show slower reaction SmartCap taking next steps

recorded on this site. That doesn’t surprise time, make more errors, and experience On the back of a major update in late 2016,

management, nor discourage them. In fact, DSS decreased cognitive ability. The type of shift, SmartCap says it has seen significant growth in

alerts have prevented about 500 km of fatigued number of breaks, consecutive shifts, and hours the mining sector. Daniel Bongers, Chief

driving in that time. “Imagine, two, three years worked per shift influence the risk level in the Technology Officer at the company told IM: “A

ago we were driving hundreds of kilometres a workplace. large copper operation in Mongolia has

year while asleep,” said the Coordinator of Mine One of the pilot projects was called the expanded its use of SmartCap to protect

Operations. “Predictive Safety” pilot. It involved short two- operators in the open-cut HME, long-haul

An effective Fatigue Risk Management System minute tests on tablets conducted before and concentrate transportation and its bus fleet for

delivers benefits beyond its primary objective to after shifts at the Cortez open pit. Each shift, 20- workforce transport. They have achieved

protect operators. Reduced berm contact and 25 participants filled out a sleep questionnaire significant reductions in incidents across the

prolonged tyre health are typical outcomes of and took an ‘alert monitoring’ test which board, with a total elimination of fatigue

increased operator alertness. Over two years this calculated reaction time based on how quickly incidents for SmartCap users. Similar results

company reduced equipment maintenance participants completed the questionnaire. The have been achieved by an iron ore operation in

spending by $500,000, savings management results were entered into an algorithm that South Africa, who have successfully transitioned

attributes to increased operator alertness. The produced each employee’s fatigue level. There to the new SmartCap product suite after years of

organisation is growing, and with each acquisition were three levels: guarded (low fatigue), incident-free operations using the earlier

or expansion comes new assets. Every one of the significant, or high. generation. Utilisation has increased as a result

haul trucks is upgraded with a DSS, an expense The second project was called the “Smartcap” of the improved comfort, and the greater usage

management doesn’t hesitate to make. The power pilot utilising the namesake technology from and engagement with the technology has led to

to see, mitigate and manage fatigue risk is saving Australia’s SmartCap Technologies. Using near-immediate increase in the effectiveness of

this company much more than money. Bluetooth technology, it connected haul truck responses to early warning alerts.”

42 International Mining | JANUARY 2019FATIGUE MANAGEMENT & COLLISION AVOIDANCE

However, Bongers added that perhaps the most GE’s CAS goes live at Newcrest Lihir order and the first deadline. Fortunately, GE had

notable trend of late has been led by a multi-site Newcrest Mining’s Lihir gold operation in Papua deployed its solution on other customer sites

deployment in Chile that have taken the next step New Guinea recently went live with a full around the world and could adapt quickly.”

in data-driven improvements by providing installation of GE Mining’s collision avoidance On the bigger picture, GE says it has a clear

individual assistance to workers identified by a system (CAS). This follows the CAS being fitted roadmap to evolve to the Level 9 Intervention

high SmartCap alarm rate. “Their formal processes to equipment in the Telfer open-pit mine Controls — an industry goal, and an international

have helped uncover underlying health issues and (Western Australia) and the gradual installation standard tabled by the Earth Moving Equipment

impacting lifestyle choices, and the follow-on of units at Lihir. Since installation over a year ago Safety Round Table (EMESRT), of which Newcrest

treatment or education is having a positive impact at Telfer, vehicle-to-vehicle collisions have is a member.

on their risk profile and rate of fatigue reduced by 33%, Newcrest said in its recently- “Managing vehicle interaction risk (which may

interventions, and providing value to both their published sustainability report. include L9 intervention controls) is now also a

customers and employees.” Proximity detection technology has been key initiative with the global body ICMM , who

progressively rolled out across the company are targeting 2025. The system being installed at

Antofagasta’s Critical Control following incidents at its operations involving Lihir is currently rated Level 7 Situational

Management collisions or near misses between vehicles and Awareness, and already incorporates some Level

All International Council on Mining & Minerals other vehicles, vehicles and pedestrians, and 8 Advisory Controls capabilities. In order to

(ICMM) members implement the 10 principles vehicles and infrastructure. address the significant challenges in achieving a

that underpin its Sustainable Development Supported by Newcrest’s Executive Level 9 CAS system, GE has developed

Framework. Principle 5 requires companies to Committee, a working group comprising proprietary software logic that is able to interpret

continually improve health and safety performance representatives from Newcrest’s Group Safety, and anticipate the complex scenarios presented

with the ultimate goal of zero harm. The Health and Technology & Innovation, Group Supply, and key during normal mining operations. This enables

Safety strategy of Antofagasta Minerals is focused stakeholders from each of its sites, developed a the GE CAS system to operate seamlessly with

on Critical Control Management. The Mining Group strategy to deploy the technology and identified the operator and confidently act as the last

has identified 22 fatality risks, all of them with solutions suitable for use in surface and barrier, should the operator not take the

defined Critical Controls and verifiable on site by underground mining, supplied by GE Mining and appropriate action. GE is committed to delivering

workers. One of the main risks to Antofagasta Newtrax Mineprox, respectively. a world-class Level 9 CAS system to the global

Minerals is Equipment Loss Control, which is a Newcrest started implementing GE Mining’s mining community, in their efforts to continue to

factor present in 20% of the high potential CAS at Lihir back in October 2017. Around 1,500 support the mining companies in their efforts to

incidents recorded in the company. Therefore, the employees were to be protected in addition to up reduce the risk exposure of operators.”

Mining Group is permanently evaluating the to 250 vehicles.

performance of the control and seeking for In addition to the GE Mining contract, Telfer Anglo deploys Komvision at

improvements and optimisations. and Gosowong (Indonesia) underground Mogalakwena

Fatigue is a major cause of accidents associated operations have awarded tenders to Newtrax to Anglo American Platinum recently brought two

with operating heavy equipment and has been deploy Mineprox on the mobile mining fleets. KomVision-equipped Komatsu 930E mining

seen to be present in fatal accidents that have Contractor mobilisation at Telfer commenced in trucks into production at the Mogalakwena

occurred at Antofagasta Minerals. For this reason September 2018. And there could be more Complex. The Komatsu KomVision technology is

the company decided to implement a critical contract awards on the way. Newcrest said: a significant step towards improving safety at the

control that allows the effective management of “Given the anticipated automation and mine as it gives the truck operator a 360-degree

fatigue in operators. A study that considered the teleremote system programme of works at Cadia bird’s eye view and significantly reduces the risks

most used technologies on the market with (New South Wales), the business has adjusted associated with a man-machine interface.

respect to fatigue and drowsiness control was the criteria for its proximity detection solution The new system has an additional eight radars

carried out. The result showed that the solution and is expected to award a contract soon.” – over and above the current standard of front

most align to Antofagasta Minerals Standards are GE Mining told IM: “Our initial success at and rear radars – and six cameras that provide

technologies with real-time feedback, helping Newcrest’s Telfer mine, with the relatively smaller zero-metre visibility of the truck’s footprint.

operators manage their alertness and alerting a deployment of 140 vehicles, led to the expanded Mogalakwena Mine General Manager, Richard

control room for continuous monitoring. technology rollout at Lihir of 250 vehicles. As Cox said: “This technology sets a new

The fatigue alert system consists of a device mentioned, since installation over a year ago at benchmark. It improves our ability to integrate

installed in heavy equipment and a sensor that Telfer, vehicle-to-vehicle collisions have reduced into future collision avoidance systems. In line

operators must wear in helmets, caps or by 33%. We are also currently installing GE CAS with our strategy of FutureSmart Mining™, it will

headbands. If a fatigue episode is detected, an at the Newcrest Cadia mine site, a third mine, generate close-to-real-time health and

alert is emitted to the operator and the control based on the success at Telfer and Lihir.” performance data that will support us in

room, generating different actions according to the Previous to the progress with Newcrest, optimising our operations.”

alert intensity. The system was defined as a critical Pilanesberg Platinum Mines (PPM) was in the Anglo American Platinum’s safety strategy is

control, implying a mandatory use of the sensor by process of evaluating CAS solutions when the based on four pillars – systems; people and

operators, a continuous system operation and Department of Mineral Resources for South behaviour; engineering solutions; and wellness

verifications by supervisors and executives. Africa’s North West province, where the mine is in the workplace. The Komatsu trucks are

The fatigue alert system as a critical control is located, set a deadline of April 31, 2016 for area included in the significant investments in

being implemented in Centinela with a focus on mines to outfit 25% of the fleet with CAS engineering controls that the company has made

operators of heavy equipment, mainly haul solutions. “With the clock ticking, PPM selected to manage risks.

trucks. Subsequently, the critical control will be GE’s CAS to meet the mandate. The timeline was Chris Griffith, CEO of Anglo American Platinum,

standardised in all Antofagasta Minerals assets. aggressive, with just three months between the said: “Investing in this technology is a major step

JANUARY 2019 | International Mining 43FATIGUE MANAGEMENT & COLLISION AVOIDANCE

in increasing safety levels at our mines. We access the right data

remain committed to our objective of eliminating at the right time,

fatalities with a zero-harm mindset. We put gaining unprecedented

safety first and believe that every employee has insight into a wide

the right to return home unharmed every day. variety of safety

And we recognise that although we have made scenarios and

significant progress in improving safety over the performance trends.

years, there is still much to do. This technology Based on situational

will eliminate a number of risks and we look safety data, users can

forward to benefitting from the improved safety identify and analyse

and operational features of these trucks.” the root causes of

“The case for innovation in mining remains failing operational

highly compelling. To deliver the step-changes controls.

required to create a truly modern, safe and Seeing safety data

productive industry on a sustainable basis that at a granular level

society demands and that our customers expect, empowers users of MineEnterprise CAS Analytics Hexagon’s Mining division recently introduced

HxGN MineEnterprise CAS Analytics, a web-

the industry must continue to evolve. Therefore, to drill down to locate vehicles operating under based reporting and analytics platform that

Anglo American continues to invest time working risk and vehicle types exhibiting higher-than- adds a powerful layer of safety to its portfolio

through how innovation can help the industry average numbers of incident events. The tool’s

address its major challenges. Through alarm analysis module used together with safety incidents and their effect on productivity,

FutureSmart Mining, the company has situational analysis can help to reveal hazardous contributed to Hexagon Mining‘s release of a

successfully drawn on the expertise of diverse locations and operational flaws: dangerously consolidated system. “It makes sense for safety

stakeholders, including employees, partners in close interactions at dump sites and low visibility and operations data to be in a single repository.

academia and civil society, peers in the mining at poorly designed intersections, for instance. Now customers can quickly make sense of that

and parallel industries.” MineEnterprise CAS Analytics‘ optimised data for greater insight into how operator

The company continues to focus on driving a mobile interface delivers real-time safety behaviour, environmental conditions, and road

more sustainable approach to mining through information on tablets or cell phones to conditions affect mine safety and productivity.

cutting-edge mining software and other supervisors in the field. This helps strengthen the “It’s one more way we are helping customers

technology-led innovations. Production Manager integrity of daily, weekly and monthly performance to run safer, more productive mines using

Judd Barlow said: “We are proud to partner with indicators for safety process improvement. digitally integrated technology. The latest version

Komatsu as this technology allows us to maximise “Accessing relevant data in real time is the key of our FMS system informs controllers of the

capacity and safely deliver on our promises.” to operational safety success,” said Safety location of all vehicles equipped with our CAS,

Cox added: “What excites me most is that Product Manager, Marcos Bayuelo. “HxGN and of alerts if, for instance, visibility is poor.

these two vehicles offer a fully integrated system MineEnterprise CAS Analytics provides all the Controllers can warn operators to pay more

that will deliver on our safety requirements, dashboards necessary for monitoring and attention, or enforce a lower speed limit to

while reducing maintenance and downtime.” The minimising accidents while also offering the improve safety.”

new trucks will be the first earthmoving vehicles tools to build and manage customised CAS is used in more than 25,000 mine vehicles

at Mogalakwena to fully integrate a range of dashboards. The technology needed to create in over 55 mines worldwide. Besides CAS anti-

business improvement initiatives, including: reports for short-interval control, daily and collision alerts, the latest version also alerts for

n Collision avoidance ready technology monthly safety management tasks, fleet rollovers, potential obstacles, and over-speeding.

n A tyre monitoring system management, personal protection, fatigue CAS symbols are integrated into the Jigsaw

n A safety standard fuel saving card and monitoring and vehicle intervention – it’s all at platform so that users of both systems require

extended fuel tank your fingertips!” minimal training during the transition.

n An optimised payload system for payload Mine vehicle operators face numerous “Additionally, vehicles equipped with just CAS

monitoring distractions. Busy pit traffic, blind spots, poor are visible in our FMS – one controller, one FMS-

n An Ansul foam fire protection system which visibility because of bad weather, fatigue and the CAS system. For instance, now a contract light

combines dry powder with foam monotony of a 12-hour shift can all conspire to vehicle equipped with CAS is visible in the FMS.

n A lightweight bowl divert a driver from their task. The last thing an The controller’s life becomes much easier when

operator needs on top of all that is a cabin tasked with monitoring so many types of vehicles.”

Hexagon adds to layers of safety with cluttered with display panels.

CAS Analytics In keeping with its commitment to help mines Netstar responds to industry need in

Hexagon’s Mining division recently introduced with a digitally integrated strategy, Hexagon South Africa

HxGN MineEnterprise CAS (collision avoidance Mining has now also embedded collision Ensuring safe working conditions for the mining

system) Analytics, a web-based reporting and avoidance technology into its fleet management sector is a challenge, particularly when it comes

analytics platform that adds a powerful layer of system: one solution that allows heavy and light to complying with regulatory standards such as

safety to its portfolio. MineEnterprise CAS vehicles to be seen and heard, no matter their the Department of Mineral Resources’ collision

Analytics monitors and controls critical risk location in a mine. avoidance system requirements for mine

events by connecting a multitude of data sources The integration means an improved user vehicles.

via live dashboards, visualising all aspects of the experience, greater oversight for dispatchers, Pierre Bruwer, Group MD of Altron subsidiary

CAS. and quicker communication of vital safety and Netstar, explains how the company has stepped

All mine stakeholders will now be able to operations data. Client demand for data about up to the plate and developed a unique and fully

46 International Mining | JANUARY 2019FATIGUE MANAGEMENT & COLLISION AVOIDANCE

compliant solution that helps mitigate some of have created a fleet

the potential for accidents for mine fleets. solution that makes

“Our system for surface vehicles in mining mining – a core part of

operations was developed by us and is a first for South Africa’s economy

South Africa. We are proud to be able to offer – safer,” adds Bruwer.

such a solution to the mining industry and be The real-time solution,

part of finding solutions to ensure safe however, is also

conditions for people working on the mine site.” relevant to other

Netstar’s fleet solution for mines, recently sectors, such as

unveiled at Electra Mining Africa 2018, the warehousing,

largest convention of its kind for the industry, it distribution,

says benefits mines across South Africa and the manufacturing and

globe, and speaks to Altron’s vision of creating logistics. “No matter

innovative technology solutions that aid in what vehicle you use,

creating safe, compliant and secure working our solution will be fit

environments for all. for your purpose,”

The solution was developed following the Bruwer concludes. At Polyus Olimpiada gold mine in Russia, the

Department of Mineral Resources’ 2015 whole fleet is equipped with Orlaco cameras,

radar and monitors including the Cat 785C truck

legislation amendment of the Chapter 8 Act, Orlaco RadarEye tech at Olimpiada fleet as well as IZ-Kartex rope shovels

which made it mandatory for all vehicles on Orlaco, the global supplier of camera-monitor

mines to be fitted with collision avoidance vision solutions for mines has come up with a

proximity systems. This law was enacted to solution where its RadarEye camera technology Orlaco’s RadarEye camera systems are

improve safety on mines, especially when can integrate with any monitor in the machine: deployed widely in the global mining industry,

vehicles as tall as 30 m are in operation, such as “If workplace safety is an important issue for such as at the Polyus Olimpiada gold mine in

in open-cast operations, as well as aiding in the you, your fleet will no doubt be equipped with Russia, where the whole fleet is equipped with

reduction of injuries associated with pedestrian camera monitor systems. You can now make your cameras, radar and monitors including the Cat

mining accidents. machines even safer by integrating RadarEye on 785C truck fleet as well as IZ-Kartex rope

Bruwer adds that the system provides drivers your monitor. This active detection system is now shovels, whose operators can now view the

with a 360-degree view, via an in-vehicle display, available for all existing Orlaco monitors and engine, cables, dipper and counterweight, all on

of the proximity of other vehicles as well as third-party monitors. their monitors. This gives them the control they

pedestrians and is particularly effective in dusty “RadarEye prevents collisions by actively need to remain flexible in all conditions and keep

conditions and at night, when visibility is warning you about objects and people around the constant flow of dump trucks driving up and

significantly reduced. the machine. You therefore know what is down the mine filled up.

“The system works by alerting drivers audibly happening in the vicinity of your vehicle and can The fleetwide installation followed a

and visually ahead of potential issues, which not work even more safely, comfortably and successful pilot in 2016, after which all

only reduces accidents, but also improves efficiently.” excavators, loaders, dump trucks, bulldozers,

operational efficiencies. Furthermore, the system RadarEye provides additional safety for the pipe layers, motor graders and other mining

provides real-time data and connects through a greatest risk areas around vehicles, from trucks vehicles were equipped with the Orlaco system,

variety of options, including cell networks, Wi-Fi, to mining machinery. For example, in the case of totaling 1,500 cameras and 320 monitors. This

Bluetooth and radio,” as additional fail safes. loaders, which constantly drive back and forth, was done by VIST Group, Orlaco’s Preferred

As the Department of Mineral Resources’ there is a high risk of collisions around the Partner in Russia.

requirements ramp up, so will the system be machine due to the limited view from the cab. Orlaco states: “Since installing the systems,

upgraded to ensure compliance. By June 2019 “With RadarEye, you can ensure that people or safety in the mine has increased. There have

the solution will have the added functionality to objects that are too close to the vehicle are been fewer impacts, collisions and cases of

be able to take over control of a vehicle and slow detected in time. A clear audible signal will warn damage, and loaders have not been involved in

it down if the operator does not acknowledge the the operator, and the hazard area will be any incidents at all. This has helped reduce

presence of a vehicle, person or object, referred highlighted via an overlay on the monitor.” downtime for vehicles and therefore increase

to as a level 8 intervention, and by June 2020, Thanks to an SRD interface, RadarEye can be efficiency. Drivers say that they no longer have to

the solution will be able to automatically come to integrated with third-party monitors that have a twist to look behind them while reversing,

a stop without human intervention, a level 9 PAL/NTSC video input. This means that RadarEye resulting in fewer physical complaints. There has

intervention. can now be used independently of the SRD also been a drop in stress at work thanks to

In addition, when coupled with Netstar’s other monitor, and standard camera systems can easily improved vision. This is part of the reason why

fleet functionality, the solution enables be expanded with active radar detection. “Using PJSC Polyus is going to equip its vehicles in a

companies to optimise their fleets as it monitors the box, you can integrate radar alerts directly second Siberian mine with Orlaco’s vision

driver behaviour, which aids in cutting down on into the view on the existing monitor via visual solutions for heavy duty vehicles. Loaders may

excessive fuel usage, alerts managers as to when overlays. Audible signals can also be used. Via also receive an additional camera to gain a view

maintenance services are required, and provides the SRD interface box, you can now also connect of the area beneath the bucket toward the front

valuable data that will aid in the event of an the DVR One Channel recorder to RadarEye to of the machine. With this, the Russian gold

insurance claim. record camera images. The system can be further producer is once again demonstrating that it

“By incorporating telematics and collision expanded using master/slave cables and a takes mine safety and the working comfort of its

avoidance software into our current toolkit, we switcher to add multiple sensors and cameras.” employees very seriously.” IM

JANUARY 2019 | International Mining 47You can also read