TECO: A deep dive into optimization data yields unexpected savings

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

TECO: A deep dive into optimization data

yields unexpected savings

Layered efficiencies drive down costs while maintaining reliability

By Michael P. Manoucheri and Ben Erpelding

TECO

Thermal Energy Corporation’s district energy system serves 51 buildings on the campus of Texas Medical Center.

three-phrase initiative to explore customer demand for chilled water con- ing the chiller plant’s electrical demand.

A and implement cost savings across

the largest district cooling sys-

tem in North America has paid off

handsomely – and quickly – bringing sig-

nificant system improvements even in

tinues to rise.

TECO, named IDEA's System of the

Year in 2019, provides chilled water

and steam to Texas Medical Center in

Houston, which – as the world's largest

In the first seven months of optimization

– from June to December 2020 – TECO

lowered peak demand by 2 MW, saving

nearly 10.5 million kWh, and reduced the

plant’s energy consumption by 6%. Now,

the midst of the COVID-19 pandemic. medical campus – requires reliable, TECO can avoid spot-purchasing power

Efficiency gains have been seen in con- economical heating and cooling and from the sometimes unreliable public grid

denser management, chiller operations has growing needs. and more easily keep up with customer

and thermal energy storage. Peak chilled water demand has demand. By reducing peak demand, TECO

The project’s genesis can be traced increased by 9,000 tons over the past four also bought time to develop a new mas-

to IDEA’s annual conference in June 2019, years and is expected to grow by an addi- ter plan, including how and when to add

when representatives from tional 9,000 tons over the next power production capacity.

Thermal Energy Corporation three years. TECO has found

(TECO) and Optimum Energy MAINTAINING that the most cost-effective PHASE 1: CONDENSER-SIDE

struck up a conversation about RELIABILITY, way to manage district growth OPTIMIZATION

the pitfalls of drawing electric- EVEN AS DEMAND while maintaining its histori- TECO has two interconnected plants

ity from the grid in the swelter- RISES, THROUGH cal reliability of 100%, with no housing 27 chillers, nine boilers and one

ing heat of a Texas summer. INNOVATIVE unplanned outages since 1992, TES tank, managed by a Toshiba distrib-

The TECO team wondered EFFICIENCY is to layer on new efficiency uted control system. System capacity is

if the company could decrease MEASURES. measures. 120,000 tons, with a peak load of 78,600

electrical consumption from Partnering with Opti- tons and 345 million ton-hours per year

its main site before June 2020, mum Energy, TECO’s engineer- of annual load. The system’s latest chilled

the start of the next peak demand sea- ing team developed a three-phase plan. water expansion, called the East Chiller

son. Customer chilled water demand was First, for the condenser water system to Building, consists of four 8,000-ton vari-

growing rapidly enough to soon exceed conserve more energy and reduce costs; able-speed York Titan chillers; four

on-site generation resources. second, to have the chiller staging pro- variable-speed, primary-only chilled

TECO needed a solution that would cedures better handle changing loads; water pumps (24,000 gallons per min-

maintain reliability, keep costs down and and third, to take advantage of real-time ute, or gpm, 1,000 horsepower (hp), 138

conserve resources. That initial conversa- electricity pricing for the thermal energy feet head; four fixed speed condenser

tion, in 2019, turned into a multiphase, storage (TES) tank dispatch. water pumps (16,300 gpm, 600 hp, 112

plant-wide optimization journey that Two years down the road, TECO has feet head) and six variable-speed cooling

now saves TECO $550,000 and 16.1 mil- improved control over the energy balance tower fans (16,300 gpm, 101-86 degrees

lion kWh of energy annually – even as of its CHP system and its TES tank, reduc- F, 80 F WB, 250 hp).

© 2022 International District Energy Association. ALL RIGHTS RESERVED. District Energy | Spring/Summer 2022 25The East Chiller Building condenser

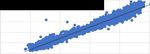

FIGURE 1. 2019 trends for variable speed chiller #4 efficiency (kW/ton) vs. lift (deg F). water system was considered a low-risk,

ECH B CH4- kW/Ton versus Lift

high-reward starting point. Improvements

1.00

1.00

focused on reducing chiller lift, which is

0.90

0.90 defined as the leaving condenser water

0.80

0.80 temperature minus the leaving chilled

0.70

0.70

• water supply temperature. (High chiller

0.60

0.60

lift reflects hot, humid ambient condi-

y = 0.0106x + 0.0242

0.50

::. 0.50 tions that are typical in the summer, when

kW/ton

>

>

� R2 = 0.9769

0.40

0.40 demand for low-temperature chilled

0.30

0.30 water is high. Conversely, in winter, lift is

0.20

0.20 lower.) For example, a chiller with a sup-

0.10

0.10 ply temperature of 40 F and a leaving

0.00

0.00

condenser water temperature of 95 F

10.0 20.0 30.0 40.0 50.0 60.0 7C would have a design lift of 55 F.

10.0 20.0 30.0 40.0 50.0 60.0 70.0

Chiller Lift (deg F)

Chiller lift Figure 1 shows one of the 8,000-ton

chiller’s trended data for efficiency

Source: TECO

(kW/ton) versus chiller lift. If TECO’s

chiller were operating at 6,500 tons, a

2 degree F reduction in lift would save

FIGURE 2. ECHB Cooling Tower Performance; leaving condenser water temperature vs. outdoor wet 137.8 kW of energy.

bulb temperature at different delta Ts. Conditions were ripe for optimiza-

SPX Cooling Technologies

TRACS Version 6-MAY-09

tion: The four 8,000-ton chillers in the

90 Model F4109-4.0-10B

Number of Cells

Motor Output

10

250 Hp

East Chiller Building were designed for a

Motor RPM 1800

85 Fan

Fan RPM

32 ft HP7 9

112

2 gpm/ton condenser water system. The

(Full Speed)

Design Conditions:

remaining 23 chillers in the two plants

Cold water (F)

Flow Rate 163000 gpm

80 Mass Flow

Hot Water

22509.5 lb/s

101 °F

were designed for a 3 gpm/ton system.

Cold Water 86 °F

Inlet Wet-Bulb

L/G

4 18 F range

80 °F

1.263

Automated balancing valves maintained

75

Curve Conditions:

Fan

3 Pitch

15 F range Constant

design flow through the condenser bun-

Flow Rate 163000 gpm

70

( 100% Design Flow )

2 12 F range

dle on each East Chiller Building running

10 cell, Fans Full

4 205.000017

1 9 F range

chiller. In general, the cooling tower fans

65 3

were often operating at 100%.

Design point

2

q 18 °F Range The Optimum Energy and TECO team

60 1 p 15 °F Range

o

n

12 °F Range

9 °F Range developed a consistent, real-time, digi-

45 50 55 60 65 70 75 80 85 X Design Point

45 50 55 60 65 (°F)

Wet Bulb 70 75 80 85 tal standard operating procedure that

Wet bulb (F) Time: 08:37:03 Date: 12-03-2009 Drawn By: BCS included automation, operator prompts

Source: TECO

and screens, and energy conservation

measures. The plan included increasing

FIGURE 3. 2019 trends for constant speed chiller #9 efficiency (kW/ton) vs. lift (deg F) and two setpoints so that all condenser water bal-

different loading bins. ancing valves were near 100%.

A deliberate commissioning pro-

0.70 cess ensured that condenser water pump

motors did not over-amp as they rode

0.65

down their pump curve, that there was

0.60

no excessive pump/motor vibration, that

header pressures stayed high enough for

kW/ton

6,500 - 7,500 tons

0.55

5,000 - 6,000 tons

other auxiliary equipment served by the

condenser water system, and that the

0.50

flow stayed below the maximum allow-

0.45 able for each chiller. The new operat-

ing procedure includes running as many

0.40 cooling towers as possible while staying

above minimum flow requirements and

10 15 20 25 30 35 40 45 50 55

Lift (F)

implementing power-based relational

control of the cooling tower fan variable

Source: TECO frequency devices (VFDs).

26 District Energy | Spring/Summer 2022 © 2022 International District Energy Association. ALL RIGHTS RESERVED.Because of the interdependencies Finally, the engineering team PHASE 2: CHILLER-STAGE OPTIMIZATION

of the energy conservation measures improved tower fan speed control. While As the engineering team moved to

(ECMs) above, the energy savings are conventional cooling tower control involves the second phase of optimization, it real-

compounded. When the condenser delivering a specific condenser water tem- ized that TECO’s shift operators were

valves are opened to 100%, the 16,300 perature to the chillers, holistic optimiza- using different ways of staging and run-

gpm pumps produce 19,500 gpm with tion achieves the best overall total plant ning the chillers – adding or shedding

no amp or vibration issues. The extra efficiency when calculated relationships chillers by looking at the chiller amps,

3,200 gpm in flow results in a 16% between fan energy and chiller energy are chiller vanes and district chilled water

reduction in chiller lift and a smaller con- maintained. The TECO systems employ a end-of-line differential pressure (DP).

denser water delta T (differential). The patented speed control method for tower High amps, vanes near 100% or a low

smaller delta T improved the cooling fans that is based on chiller power (kW). DP could trigger the operator to initi-

tower’s performance. Figure 2 shows the This first phase, from programming to ate a chiller add; low amps, vanes near

cooling tower leaving condenser water commissioning, was completed in March 20% or a high DP could trigger the opera-

temperature versus outdoor wet bulb 2020. In just the first year of improved tor to initiate a chiller shed. They main-

(WB) temperature at 100% flow and operations, TECO saved 6,656,000 kWh. tained end-of-line differential pressure

100% fan speed.

At 70 degrees F WB, for exam- In just the

ple, the cooling tower approach with first year of

a 15-degree F range is 8.7 F, while the improved

approach with a 12 F range is 7.5 F. The efficiencies, the

company saved

cooling tower approach also improves 6,656,000 kWh.

as flow is reduced. Running more towers TECO can now

creates a larger surface area, and at 80% avoid spot-

flow, the approach at 70 F WB with a purchasing

power and

12-degree F range is 4.5 F. The improve- more easily

ment in lift in this example is 8.7 – 4.5 keep up with

= 4.2 F. Using the result from Figure 1 customer

yields a 0.0445 kW/ton improvement in demand.

efficiency. TECO

About TECO

Houston-based Thermal Energy

Corporation’s 48 MW combined heat

and power-based district energy system

provides chilled water and steam to 51

buildings totaling 24.3 million square feet

at Texas Medical Center. The chilled water

system consists of 27 chillers and an 8.8

million-gallon thermal energy storage

tank. The equipment is controlled by a

Toshiba distributed control system.

Cooling capacity is 120,000 tons at 40 F.

Annual chilled water production is 345.1 TECO

million ton-hours.

Benefits of optimization • Cost savings Texas Medical Center

• Improved plant efficiency - Annual operations: $550,000 • 10 million patient encounters annually

- 7% annually - Simple payback: 1.9 years • 180,000+ surgeries annually

• Energy savings • Lower CO2 emissions totaling • 9,200 patient beds

- Electrical: 16.1 million kWh/year 13,685,000 lbs/year • $2 billion of annual life science

- Demand reduction: 2,112 kW • Enhanced maintenance prioritization research

© 2022 International District Energy Association. ALL RIGHTS RESERVED. District Energy | Spring/Summer 2022 27by increasing or decreasing the chillers’ foot, 8.8 million-gallon TES tank, the tall- TECO’s utility. It then calculates the com-

evaporator flow set points. est thermal energy storage tank in the parative cost of discharging the tank and

TECO employed several ECMs to world when it was installed. It has a using the stored water during the day. This

standardize procedures. First, the team capacity of 76,000 ton-hours, a maximum gives TECO the real price of the stored

began automating the chiller add/shed flow of 16,500 gpm and a maximum out- energy as it comes in every five minutes.

decision criteria – screen graphics in the put of approximately 8,250 tons (at a Done correctly, it is much like successful

Toshiba distributed control system inter- 12-degree F chilled water delta T). stock trading: buy low, sell high.

face now tell the operators the next chiller The TES tank allows TECO to serve If the real-time cost of electricity

to stage on or off, and the optimum flow its customers with absolute reliabil- is greater than the trigger cost and the

setpoints on chilled water and ity, even in the case of chiller time is within the appropriate window of

condenser water. TECO runs plant equipment failure, using operation, operators will receive a mes-

the older constant-speed chill- A NEW ALGORITHM stored energy when it’s less sage to discharge the tank at a specified

ers as close to full amps and OFFSETS expensive and reducing elec- flow rate.

full vanes as possible. These INCORRECT trical demand during peak

machines are served by 900 WEATHER chilled water usage. TECO CONTINUOUS IMPROVEMENT, ALWAYS

hp constant-speed condenser FORECASTS AND was surprised to discover As TECO has discovered, the result of

water pumps and 500 hp and KEEPS UP WITH that charging the tank every chiller plant optimization is not necessar-

600 hp constant-speed chilled ELECTRICITY night was much more expen- ily a one-time gain.

water pumps. Figure 3 trends RATE CHANGES. sive than expected – and the Lasting value often comes from

the 7,000-ton constant speed data showed that significant implementing standard operating proce-

York chiller efficiency (kW/ton) cost savings could be gained dures, maintaining consistent operations

versus lift (degrees F) at different load- by using real-time pricing information to across all shifts and accruing multiple

ing bins (6,500- to 7,500-ton bins and automatically charge and discharge the continuous savings, such as the daily trim-

5,000- to 6,000-ton bins). Also, TECO now tank at optimal times. ming of TECO’s electrical bill through pre-

allows the East Chiller Building to modu- TECO had been following the gen- dictive TES dispatch.

late chilled water flow to make up the dif- erally accepted practice of charging the Progress may start with a big bang –

ference and maintain the end-of-line DP tank at night when electricity prices are a revamped chiller plant that immediately

at 7 psi. The district chillers are staged by lower and discharging it during the day. In drops cooling costs – but continual data-

looking at the tons, amps and VFD speed Texas, real-time pricing can change every driven efficiencies can save hundreds of

of the East Chiller Building chillers. five minutes. The operations team was thousands of dollars annually as well.

Along with the ECMs, TECO inte- relying on weather forecasts, electricity

grated the Optimum Energy Plant Diag- market price predictions and manual cal-

nostics tool into its work to help maintain culations to estimate the most advanta- Michael P. Manoucheri,

business continuity. TECO engineers have geous times for charging and discharging. P.E., is TECO’s president and

traditionally collected monitoring data; Those methods couldn’t offset incorrect CEO. He holds a Master of

adding data rationalization and diagnos- forecasts or keep up with rapid changes – Science in mechanical engi-

tics allows the team to mine those assets but a clever algorithm could. neering from UT Austin and

and prioritize opportunities to increase Optimum Energy engineers rea- a Bachelor of Science in

reliability and efficiency and to track key soned that the tank could be even more mechanical engineering from Colorado

performance indicators and monitor each cost effective with an automated algo- State University.

piece of equipment in the plant. rithm, which would allow the Toshiba dis- mmanoucheri@tecothermalenergy.com

Even with Covid-19 restrictions in tributed control system to automate the

place, the second phase was completed TES charge/discharge decision criteria.

by June 2020 – in time to maintain oper- Optimization would also include graphics Ben Erpelding, P.E., chief

ational reliability and avoid the high screens in the Toshiba human-machine technology officer at

demand charges of a Texas summer. interface that could tell operators when, Optimum Energy, has over

TECO saved 9,491,000 kWh of how and why to use the tank. Called eco- 20 years of experience in

energy in the first year of chiller stage nomic dispatch, the solution uses histori- energy efficiency, chiller

optimization. After completing the first cal data and actual electric market pric- plant optimization, and

two phases, electrical demand was ing to calculate the true costs of charging combined heat and power. He received his

reduced by 2,112 kW. the tank at night with power from TECO’s Master of Science and a Bachelor of Sci-

local grid and using the stored chilled ence in mechanical engineering from San

PHASE 3: TES SYSTEM OPTIMIZATION water during the day. Diego State University and is a registered

A deep dive into data collected over The algorithm takes into account the professional mechanical engineer in the

the first year of operations revealed a kilowatts needed to charge the TES tank state of California.

source of additional savings: TECO’s 150- and the real-time electrical rate from ben.erpelding@optimumenergyco.com

28 District Energy | Spring/Summer 2022 © 2022 International District Energy Association. ALL RIGHTS RESERVED.You can also read