Model of Nano-Metal Electroplating Process in Trapezoid Profile Groove - MDPI

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Article

Model of Nano-Metal Electroplating Process in

Trapezoid Profile Groove

Oksana Yu. Egorova 1, *, Victor G. Kosushkin 2, * and Leo V. Kozhitov 2, *

1 Kaluga Branch of Bauman Moscow State Technical University, Bazhenov St., 248001 Kaluga, Russia

2 Moscow Institute of Steel and Alloys, Leninsky Prospect 2, 196036, Russia

* Correspondence: oksana.egorova95@yandex.ru (O.Y.E.); kosushkin@gmail.com (V.G.K.);

kozitov@rambler.ru (L.V.K.)

Received: 26 December 2018; Accepted: 19 February 2019; Published: 21 February 2019

Abstract: The principle of the electrodeposition method is to immerse the coated products in a water

electrolyte solution, the main components of which are salts or other soluble compounds—metal

coatings. The software COMSOL Multiphysics was allowed to perform a simulation of the processes

of electrodeposition of the metals copper and silver in the groove of the trapezoidal profile.

Keywords: electrodeposition process; group 1 metals; modeling; COMSOL Multiphysics

1. Introduction

The process of electrodeposition of metals is important in micro- and nano-electronics, as it is

used in the production of multilayer printed circuit boards (MPC). MPCs consist of many layers, most

of which are complex electrical circuits. The formation of interlayer compounds is an important

technological task and, as a rule, is carried out with the help of through metallized holes [1].

The manufacture of transition holes with diameters of less than 300 microns with the help of various

metallized pastes is complicated by the difficulties of free penetration of the paste into the hole and the

air out of it. The simplicity, availability, and technological capabilities of the electrodeposition process

make it possible to use it for local electrochemical deposition, especially with an unchanged decrease

in topological dimensions. Electrodeposition is a complex process occurring at the interface of type 1

and 2 conductors and depends on various factors such as temperature, mixing rate, and electrolyte

composition, as well as ion solvation processes, adsorption at the phase boundary, the state of the

double electric layer, the phenomena of electrode polarization, diffusion, and convection flows near the

deposition surface. However, the process of local metallization is affected by a complex surface relief.

In some cases, mathematical modeling methods can replace a full-scale experiment, saving

material and time costs. In this article, we consider the possibility of mathematical modeling of

electrochemical deposition of copper and silver under local metallization in a hollow trapezoidal

profile groove using the basic package of COMSOL Multiphysics.

2. The Process of Electrodeposition

The principle of the electrodeposition method is to immerse the coated products in an aqueous

electrolyte solution. The main components are salts or other soluble compounds called metal plating.

The coated products are in contact with the negative pole of the direct current source, i.e., the cathode.

A plate made of a deposited metal or an inert electrically conductive material, such as graphite, is used

as the anode. It is in contact with the positive pole of the direct current source and dissolves when the

flow of electric current, compensating for the decrease of ions, is discharged on the coated products [2].

The reduction of cations on the cathode leads to the release of a metal layer on the negative surface of

the cathode. As a result, a metal film with a fine-crystalline, coarse-crystalline, shiny, or matte surface

Condens. Matter 2019, 4, 26; doi:10.3390/condmat4010026 www.mdpi.com/journal/condensedmatterCondens. Matter 2018, 3, x FOR PEER REVIEW 2 of 5

Condens. Matter 2019, 4, 26 2 of 5

the coated products [2]. The reduction of cations on the cathode leads to the release of a metal layer

on the negative surface of the cathode. As a result, a metal film with a fine-crystalline,

structure can be formed

coarse-crystalline, shiny, on the cathode.

or matte surfaceThe deposition

structure can beofformed

metal atoms

on thebegins

cathode.at the

Thecrystallization

deposition of

centers,

metal the number

atoms begins atofthe

which is determined

crystallization by the

centers, theamount

numberofofovervoltage at the cathode.

which is determined by theDefects

amountin

theovervoltage

of structure of the substrate

at the influence

cathode. theinnucleation

Defects process,

the structure and substrate

of the then they influence

move along thenucleation

the surface to

the fractures,

process, and forming

then they a film.

move Thus, thethe

along filmsurface

develops

to into

the islands thatforming

fractures, grow in aallfilm.

directions

Thus, until they

the film

merge [3].

develops into islands that grow in all directions until they merge [3].

3. Modeling

3. Modeling thethe Process

Process of of Electroplating

Electroplating Metals Metals of

of the

the 1st

1stGroup

Groupin inaaTrapezoid

TrapezoidProfile

ProfileGroove

Groove

Using the Software COMSOL

Using the Software COMSOL MultiphysicsMultiphysics

The deposition

The deposition of

of metals

metals in in the

the trapezoid

trapezoid profile

profile groove

groove is

is an

an example

example ofof the

the modeling

modeling of of the

the

electrodeposition process in the COMSOL Multiphysics program. The standard

electrodeposition process in the COMSOL Multiphysics program. The standard model Copper model Copper Deposit

in a Trench

Deposit in awas taken

Trench was as taken

a basisas[4].

a basis [4].

In this paper, we used aa trapezoidal

In this paper, we used trapezoidal profile

profile groove

groove toto show

show how

how the

the electrodeposition

electrodeposition process

process

proceeds depending on the change in form and

proceeds depending on the change in form and composition. composition.

The geometry

The geometryof of the

the model

modelisisshown

shownin inFigure.

Figure 1.

1. The

The upper

upper horizontal

horizontal boundary

boundaryisis the

the anode,

anode,

and the trapezoidal cathode is located at the

and the trapezoidal cathode is located at the bottom. bottom.

Figure 1.

Figure The geometry

1. The geometry of

of the

the model.

model.

The vertical

The vertical walls

walls on

on the

the main

main electrode

electrode are

are considered

considered isolated:

isolated:

Ni ××n ==00 (1)

(1)

The flow for each of the ions in the electrolyte is determined by the Nernst–Planck equation:

The flow for each of the ions in the electrolyte is determined by the Nernst–Planck equation:

=− ∇ − ∇ (2)

Ni = − Di ∇ci − zi ui Fci ∇ ϕi (2)

where is the ion flow (mol/m2∙s), is the ion concentration in the electrolyte (mol/m3), is

the charge of the ion particles, 2 is themobility of charged particles (m 3/s∙J∙mol),

where Ni is the ion flow (mol/m ·s), ci is the ion concentration in the electrolyte (mol/m ), zi is is 3

theFaraday

constant

the charge(As/mol) is the

of the ion potential

particles, ui inisthe charged particles (m3 /s·J·mol), F is theFaraday

electrolyteof(V).

themobility

constant

This (As/mol) is the potential

equation allows in the electrolyte

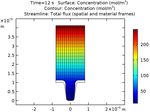

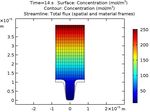

us to calculate (V). of copper ion concentrations, isopotential

the distribution

lines,This equation

current densityallows

lines, us

andtodisplacements

calculate the distribution

of the cathodeof copper ion surfaces

and anode concentrations,

after 12,isopotential

14, 16, and

lines,

20 s of current density

operation, whichlines, and displacements

are shown in Figure 2. of the cathode and anode surfaces after 12, 14, 16,

and 20 s of operation, which are shown in Figure 2.Condens.

Condens.Matter 2018,4,3,26

Matter2019, x FOR PEER REVIEW 33 of

of 55

Figure2.2. Concentrations

Figure Concentrations ofof copper

copper ions (mol/m33), isopotential

ions(mol/m isopotential lines,

lines, current

current density

density lines,

lines, and

and

electrode

electrodedisplacement

displacementininthe

thecell

cellafter

after12,

12,14,

14,16,

16,and

and20

20s sofofwork.

work.

Lines

Linesofoflayer

layerthickness

thicknessshow

showthe thedevelopment

development ofof

non-uniform

non-uniform deposition

deposition of aofcopper

a copperlayer duedue

layer to

the non-uniform distribution of current density from the bottom to the upper edge

to the non-uniform distribution of current density from the bottom to the upper edge of the groove.of the groove. This

effect

This is directly

effect related related

is directly to the decrease in the concentration

to the decrease of copper of

in the concentration ions in the ions

copper depthinofthe

thedepth

cavity.of

From this, it can be concluded that with an increase in the duration of the process, the groove hole

the cavity.

on theFrom

upper edge

this, begins

it can to taper, and

be concluded its with

that overgrowth is possible

an increase in the due to theofnon-uniform

duration the process, deposition

the groove

thickness.

hole on the Therefore, for copper

upper edge beginsdeposition, the optimal

to taper, and process duration

its overgrowth is possibleis 14

dues. to the non-uniform

An analogical

deposition thickness.modeling

Therefore,was performed

for copper for thethe

deposition, silver deposition

optimal on the surface

process duration is 14 s. of the

trapezoidal profile.

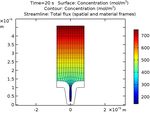

An analogical modeling was performed for the silver deposition on the surface of the

Figure 3profile.

trapezoidal shows the distribution of the concentration of silver ions, isopotential lines, current

densityFigure 3 and

lines, shows thethe

displacement

distribution ofof the

the cathode and anode

concentration surface

of silver ions,after 12, 14, 16,

isopotential and

lines, 20 s

current

of operation.

density lines, and the displacement of the cathode and anode surface after 12, 14, 16, and 20 s

of operation.Condens.

Condens.Matter 2018,4,3,26x FOR PEER REVIEW

Matter2019, 4 of

of5 5

(a) (b)

(c) (d)

Figure 3. Concentrations of silver ions (mol/m3 ), isopotential lines, current density lines, and electrode

Figure 3. Concentrations

displacement in the cell afterof

12,silver

14, 16,ions (mol/m

and 20

3), isopotential lines, current density lines, and

s of operation.

electrode displacement in the cell after 12, 14, 16, and 20 s of operation.

It can be concluded that with an increase in the duration of the process, the cavity hole begins to

narrow It can be concluded

gradually due to that with an increase

the non-uniform in the duration

thickness of the process,

of the deposited the differs

layer, but cavity hole begins to

significantly

narrow gradually due to the non-uniform thickness of the deposited layer,

compared to the results for copper. The process of narrowing is slower, which may be associated with but differs significantly

acompared

lower initial to concentration

the results forofcopper.

silver. InThe

thisprocess

case, theofoptimal

narrowing is slower,

duration of the which may be associated

silver deposition process

with

is 20 s.a lower initial concentration of silver. In this case, the optimal duration of the silver deposition

process

Thus, is the

20 s.modeling of copper and silver deposition processes allows us to obtain preliminary

data onThus, the modeling

the formation of topology

of the copper and silver deposition

of contacts at the localprocesses allowson

metallization usthe

to obtain

surfacepreliminary

of printed

circuit boards and other electronics products, without resorting to full-scale experiments. of printed

data on the formation of the topology of contacts at the local metallization on the surface

circuit boards and other electronics products, without resorting to full-scale experiments.

4. Conclusion

4. Conclusion

The software COMSOL Multiphysics allowed us to perform the modeling of the processes of

copper Theandsoftware

silver electrodeposition

COMSOL Multiphysics in the trapezoidal

allowed us profile groove.the modeling of the processes of

to perform

Theand

copper results

silverobtained for the thicknesses

electrodeposition of the deposited

in the trapezoidal profilelayers of copper and silver can optimize

groove.

the deposition

The results regimes.

obtainedForforexample, it is advisable

the thicknesses of thetodeposited

carry outlayers

metal ofdeposition

copper and in a silver

periodic

can

mode,

optimizechanging the polarity

the deposition of the electrode

regimes. For example,to theitopposite. This should

is advisable to carryensure the alignment

out metal deposition of the

in a

concentration

periodic mode, of metal ions in

changing thethepolarity

depth ofofthe thegroove, and thus

electrode to thereduce the thickness

opposite. This shouldvariation of the

ensure the

layers on theofvertical

alignment walls.

the concentration of metal ions in the depth of the groove, and thus reduce the

thickness variation of the layers on the vertical walls.Condens. Matter 2019, 4, 26 5 of 5

Author Contributions: V.G.K. and L.V.K. provided the necessary theoretical materials, O.Y.E. performed

experiments and analyzed data.

Funding: This research received no external funding.

Conflicts of Interest: The authors declare no conflict of interest.

References

1. Tyulkova, A.A. Electrolytes for the electroplating of 3D micro-transitions. In Proceedings of the All-Russian

Scientific and Technical Conference, Moscow, Russia, 7–10 April 2015; Available online: http://studvesna.

ru/?go=articles&id=1270 (accessed on 28 September 2018).

2. Dzidziguri, E.; Ryzhonkov, D.I.; Levina, V.V. Nanomaterials Tutorial Nanomaterialy Uchebnoe Posobie; BINOM

Knowledge Laboratory: Moscow, Russia, 2010.

3. Belenky, M.A.; Ivanov, A.F. Electrodeposition of Metallic Coatings; Metallurgy: Moscow, Russia, 1985; p. 288.

4. The COMSOL® Software Product Suite. Available online: https://www.comsol.com/products (accessed on

17 September 2018).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access

article distributed under the terms and conditions of the Creative Commons Attribution

(CC BY) license (http://creativecommons.org/licenses/by/4.0/).You can also read